Ref.: RX182/006

Version 01/2017 - English

This document must not be reproduced nor information therein disclosed without our authorization

Page 1/ 28

Summary: English version

1INTRODUCTION 2

1.1 WARNINGS 2

1.2 GEARBOX IDENTIFICATION 2

1.3 LONG TERM STORAGE 2

2TECHNICAL DATA 3

2.1 GEARBOX 3

2.2 OUTPUT PINION 3

2.3 MOUNTING POSITION NOMENCLATURE 3

3LUBRICATION 4

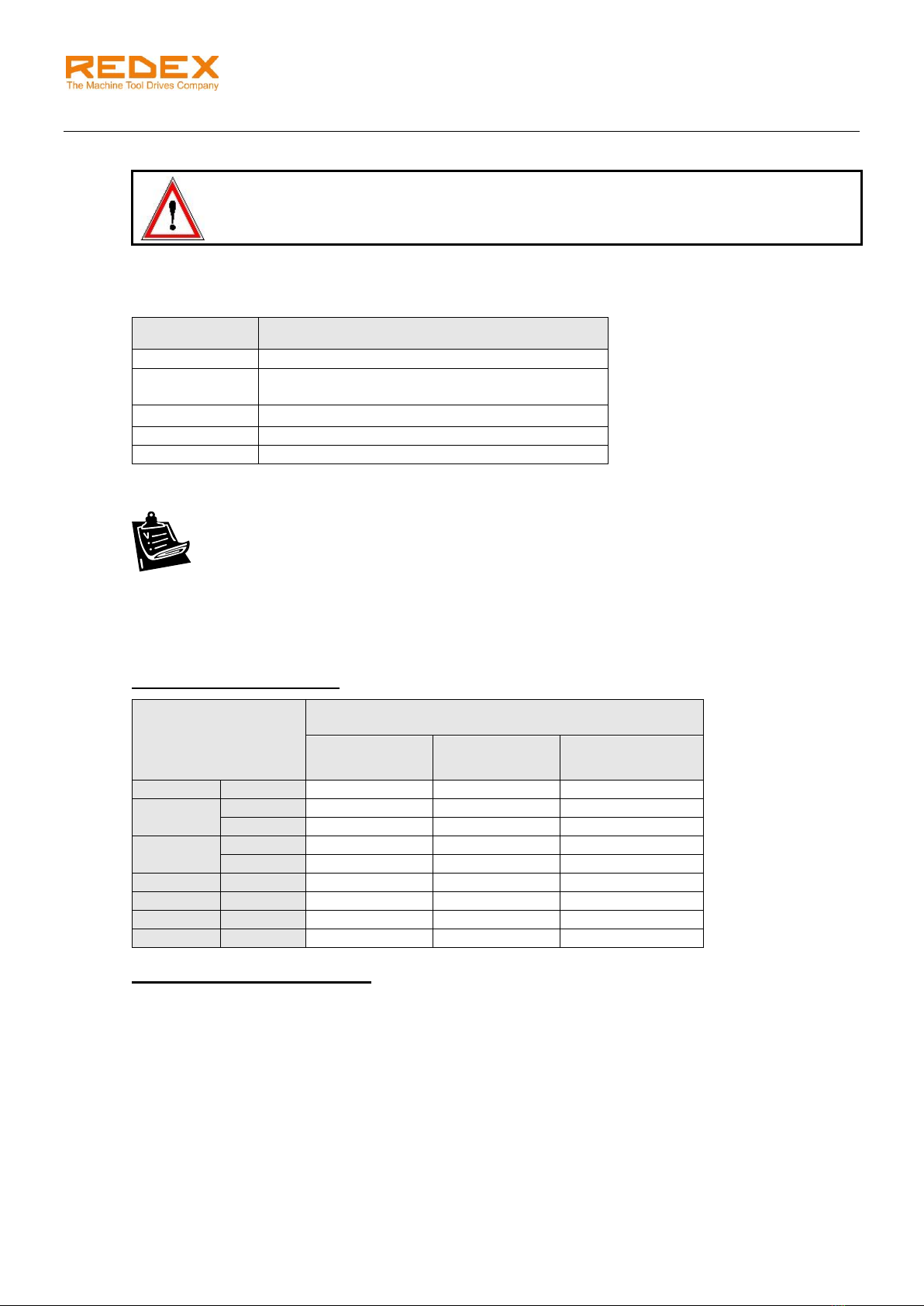

3.1 RECOMMENDED LUBRICANTS 4

3.2 OIL FILLING 4

3.3 OIL DRAINING 5

4MOTOR INSTALLATION 8

4.1 MF-TYPE MOTOR FLANGE MOUNTING (FOR RIGHT ANGLE CONFIGURATIONS SRP.R AND CYLINDRICAL SHAFTS) 8

4.2 MF-TYPE MOTOR FLANGE MOUNTING (FOR RIGHT ANGLE CONFIGURATIONS SRP.R AND TAPER SHAFTS) 10

4.3 IF-TYPE MOTOR FLANGE MOUNTING (FOR IN-LINE CONFIGURATIONS SRP.M) 11

5OUTPUT PINION (OP) MOUNTING 14

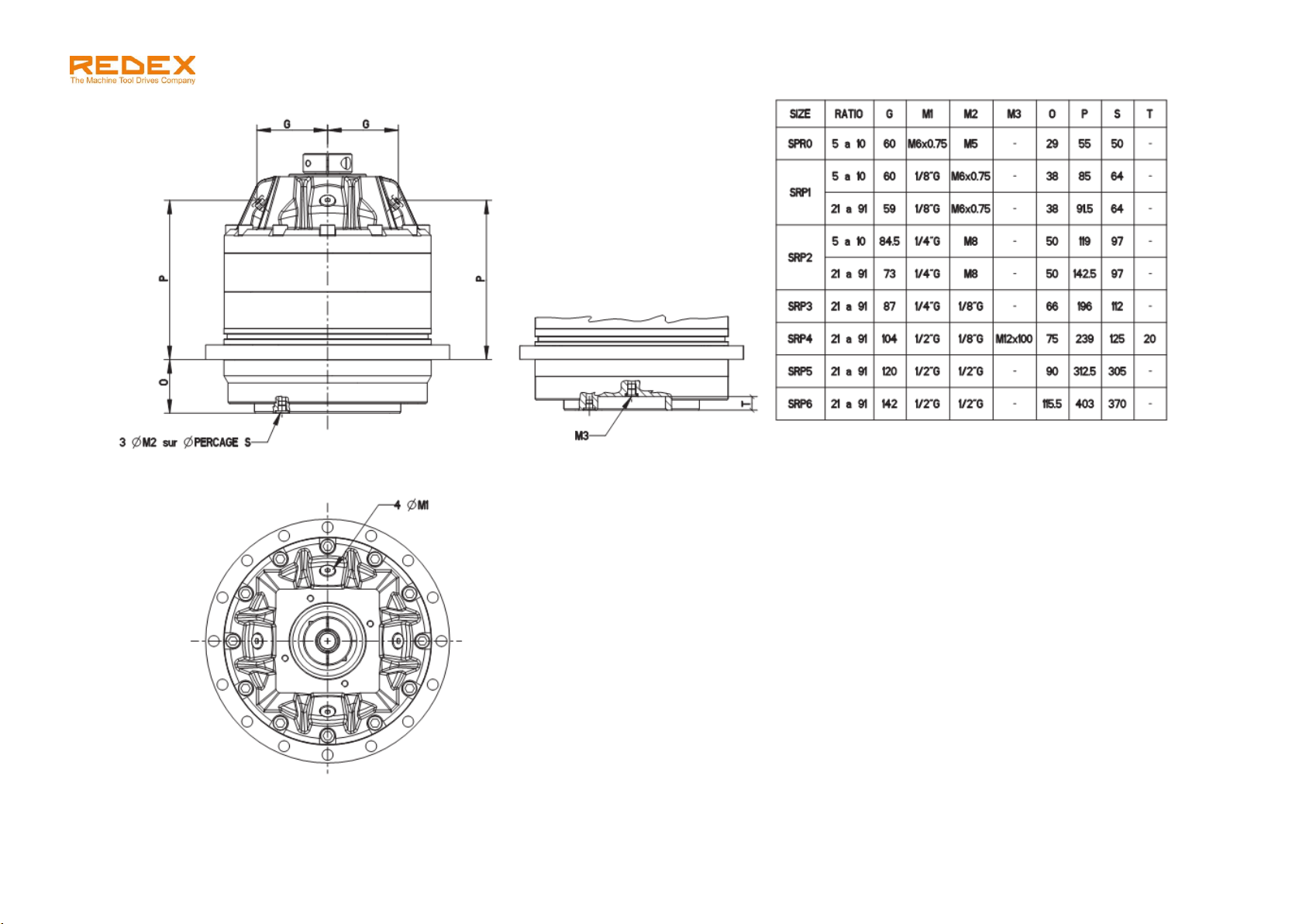

6MOUNTING OF THE SRP ON THE MACHINE FRAME 15

6.1 GEARBOX FIXING FLANGE DETAILS 15

6.2 OUTPUT FLANGE CONNECTION 16

7MOUNTING OF THE SRP WITH OUTPUT PINION ON THE MACHINE 17

7.1 RACK MOUNTING TOLERANCE 17

7.2 SRP PARALLELISM AND PERPENDICULARITY TOLERANCES 18

7.3 SRP MOUNTING HEIGHT SETTING 19

7.4 PROPER TOOTH MESHING VALIDATION 20

7.5 TOOTH CONTACT PATTERN CHECK 21

8SRP WITH MECHANICAL PRELOAD 22

8.1 DESCRIPTION 22

8.2 SHAFT ALIGNMENT 23

8.3 GANTRY MACHINE CONFIGURATION 24

8.4 PRELOAD SETTING –LINEAR DRIVE 25

8.5 PRELOAD SETTING –ROTARY DRIVE 27

9RACK & PINION LUBRICATION: OPTIONAL LUBE PINION (PGRP) AND LUBE PINION SUPPORT (SURP)

28

9.1 DESCRIPTION OF THE PGRP &SURP OPTION 28

9.2 RECOMMENDED LUBRICANTS 28

9.3 OIL FLOW RATES 28