3

Contents

Safety . . . . . . . . . . . . . . . 4

1 Getting Started . . . . . . 5

Room Temperature

and Humidity . . . . . . . . . . . . . . . . 5

Thunder Storms and

Power Surges . . . . . . . . . . . . . . . 5

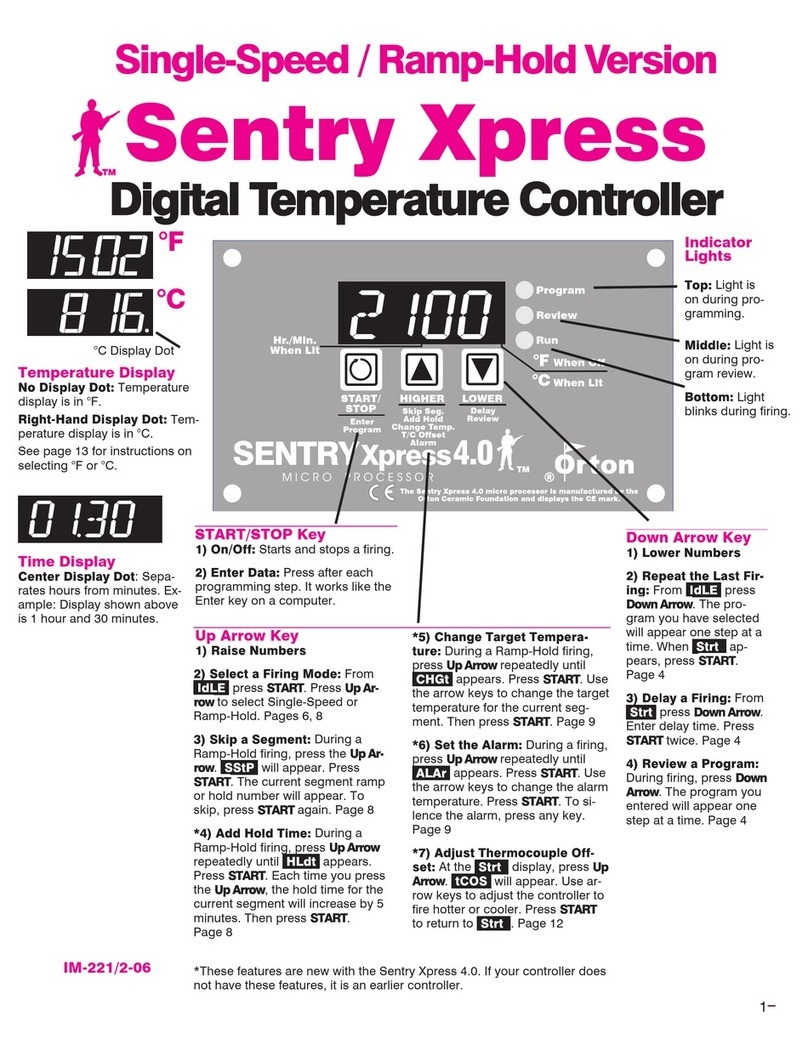

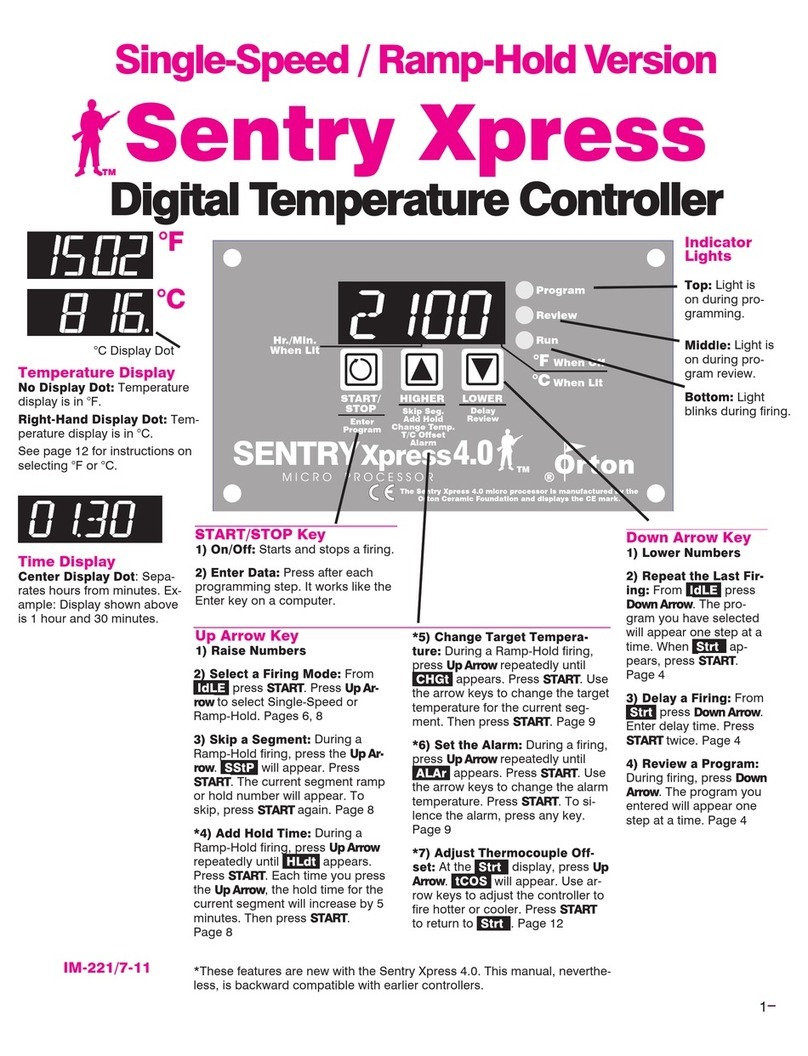

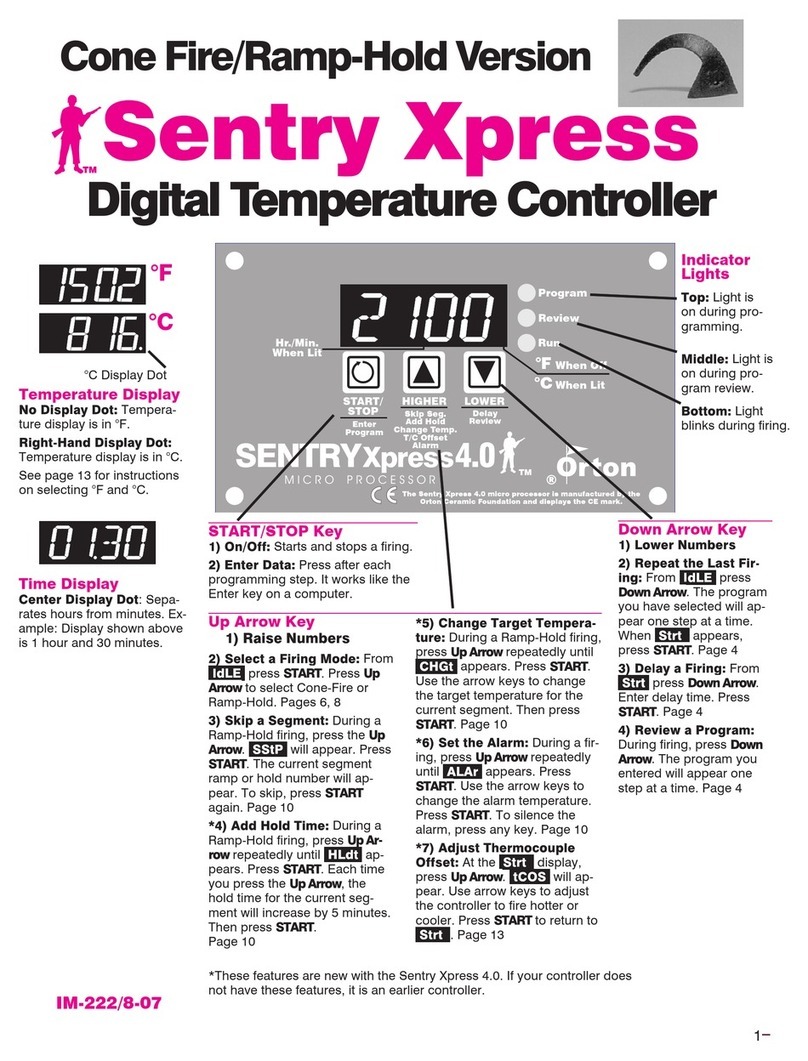

Time and Temperature Display. . 5

Operations Begin from IdLE . . . . 5

Thermocouple Inspection. . . . . . 5

Theory of Operation . . . . . . . . . . 6

2 Programming. . . . . . . . 6

The Stop/Back Key . . . . . . . . . . . 6

Correcting Entries . . . . . . . . . . . . 6

Storing User Programs . . . . . . . . 6

Firing a Stored User Program. . . 7

Rate . . . . . . . . . . . . . . . . . . . . . . . 7

Programming Steps . . . . . . . . . . 7

Hold . . . . . . . . . . . . . . . . . . . . . . . 8

Repeat Firings . . . . . . . . . . . . . . . 8

Program Review . . . . . . . . . . . . . 8

Programming a

Cooling Segment . . . . . . . . . . . . 8

CPLT . . . . . . . . . . . . . . . . . . . . . . 8

Temperature Overshoot . . . . . . . 9

AOP Fan . . . . . . . . . . . . . . . . . . . 9

A Practice Program . . . . . . . . . . . 9

3 Sample Firing

Programs . . . . . . . . . . . . 9

Heat Treating a Knife Made from

D-2 High Carbon Steel . . . . . . . 9

Glass Fusing Schedule . . . . . . 9

Glass Slumping Schedule . . . 10

4 Other Features . . . . . 10

The Add Time Key. . . . . . . . . . . 10

Delay Fire . . . . . . . . . . . . . . . . . 10

Present Status . . . . . . . . . . . . . . 11

The Alarm . . . . . . . . . . . . . . . . . 11

Skip Segment . . . . . . . . . . . . . . 11

Editing a Segment

During Firing . . . . . . . . . . . . . . . 11

5 Multiple-Zone Kilns. . 12

An Overview . . . . . . . . . . . . . . . 12

Thermocouple Failure

In a Multiple-Zone Kiln . . . . . . . 12

Power Output Lights . . . . . . . . . 12

Testing Multiple-Zone

Elements . . . . . . . . . . . . . . . . . . 12

Zone Temperature

Difference (DIFF) . . . . . . . . . . . 12

Two-Zone Kilns: Adjusting Heat in

the Center Section (CAdJ) . . . . 13

Zone Temperature

Display (T123) . . . . . . . . . . . . . 13

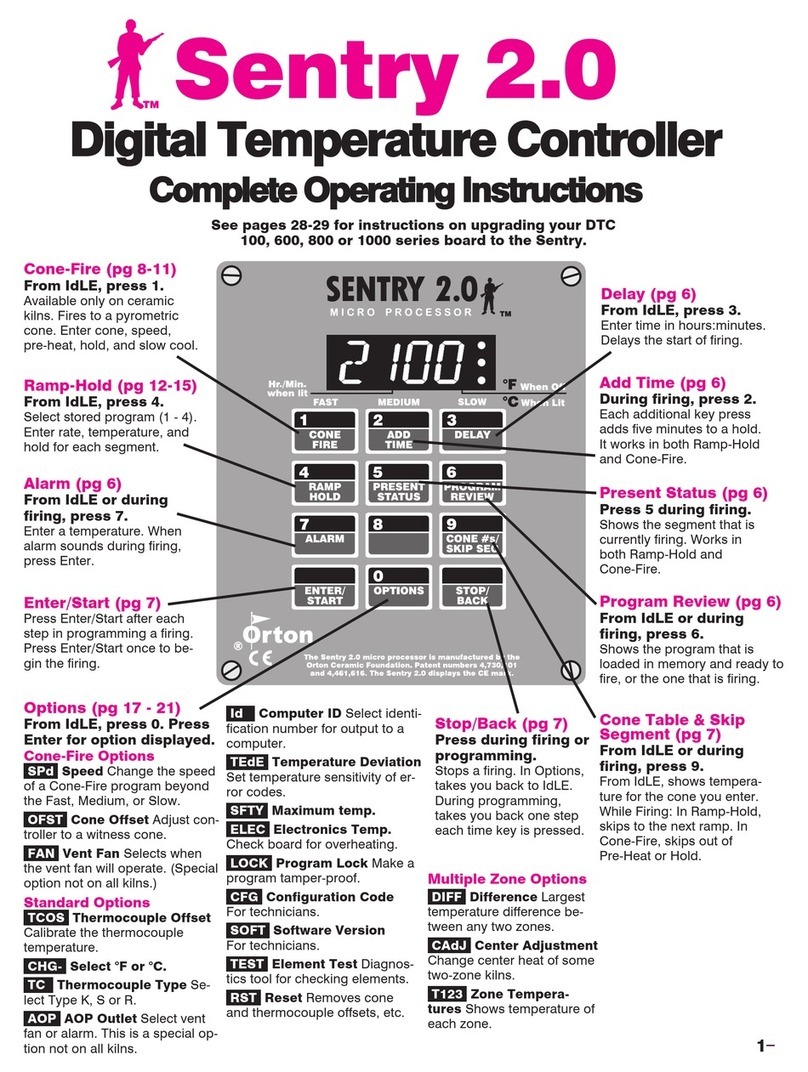

6 The Options Key . . . . 13

Thermocouple Offset (TCOS). . 13

Multiple-Zone

Thermocouple Offset . . . . . . . 14

Selecting °F or °C (CHG-) . . . . . 14

°F/°C Temperature

Conversion Formula. . . . . . . . 14

Thermocouple Type (TC) . . . . . 14

AOP Outlet (AOP) . . . . . . . . . . . 15

Computer ID (ID). . . . . . . . . . . . 15

Temperature Deviation (TEDE). 15

Maximum Temperature (SFTY). 15

Electronics

Temperature (ELEC) . . . . . . . . . 16

Program Lock (LOCK) . . . . . . . 16

Configuration Code (CFG) . . . . 16

Software Version (SOFT) . . . . . 16

Element Test (TEST) . . . . . . . . . 16

Reset (RST) . . . . . . . . . . . . . . . . 16

7 Error Messages. . . . . 17

FTC / Failed to Cool . . . . . . . . . 17

FTH / Failed to Heat . . . . . . . . . 17

LTdE / Low Temperature

Deviation . . . . . . . . . . . . . . . . . . 17

PF / Power Failure. . . . . . . . . . . 17

BAdP / Bad Programming . . . . 17

ETH / Electronics Too Hot . . . . 17

FAIL / Thermocouple Failure . . 17

FTL / Firing Too Long . . . . . . . . 17

HTdE / High Temperature

Deviation . . . . . . . . . . . . . . . . . . 18

PF 2 / Power Failure . . . . . . . . . 18

PF 3 / Power Failure . . . . . . . . . 18

The “LId” Display . . . . . . . . . . . 18

PLOG Error Codes . . . . . . . . . . 18

TCdE / Uneven Multiple-Zone

Temperatures . . . . . . . . . . . . . . 18

TCR / Thermocouple

Leads Reversed. . . . . . . . . . . . . 18

8 Power Failures . . . . . 19

Using Ceramic Witness Cones

After an Extended

Power Failure . . . . . . . . . . . . . . 19

When the Kiln Shuts

Off Too Soon. . . . . . . . . . . . . . . 19

Appendix A:

Display Messages . . . . 20

Appendix B:

Upgrading Instructions 22

Upgrading the DTC 100, 600, 800

& 1000 Series to the Sentry . . . 22

Appendix C:

Quick Programming. . . 24