Sime SHP M PLUS 021 User manual

Chiller and Inverter Air/Water heat pumps with axial fan

User-Installer Manual

SHP M PLUS

Models

021 - 026 - 028 - 032

Fonderie SIME S.p.A. 6332358 – 02/2022 – R4

----------------------------------------------------------------------------------------------------------------------------------------------

This manual has been created for informative purpose. The company declines any responsibility for the results of any projecting or any installation based on the explanations

and/or on the technical specifications provided in this manual. It is besides forbidden the reproduction under any form of the texts and of the figures contained in this manual.

"This manual is a translation from the official italian language version. For reasons of environmental respect the Company will not provide the hard copy in the original language

which could be directly requested or downloaded from the Company website at any time. In case of any dispute, the original language manual will be the trusted one".

Chillers and Inverter Air/Water heat pumps with axial fan

2

04 02-2022 EM AR

Added warnings for users of metal implants, added sound power to

technical data table according to EN 12102:2017, adjusted notes to technical data

table

03 01-2022 EM AR

Modied compressor oil type, modied heat pumps SEER, modied maximum absorbed

power and current values, correcon current and maximum absorbed power heat pump

fans 0121, 0126, correct sound power reference to the standard (UNI EN ISO 9641-1).

02 10-2021 EM AR

0121, 0126 data update for fan change, heat pumps condion A7W45 size 0121 and con-

dion A35W18 size 0121, 0126 data update, added data version BT, change of Lw values,

change of centre of gravity and dampers posion, added maintenance indicaons, modied

voltage tolerance chap. 6

01 07-2021 MS AB Updated cap. 5.9

00 01-2021 EM AR First emission

Rev Date Compiled Approved Note

Code Serie

MUI01040120001.04 Chillers and Inverter Air/Water heat pumps with axial fan

3

Chillers and Inverter Air/Water heat pumps with axial fan

Sommario

1.PURPOSE AND CONTENTS OF THE MANUAL..................................................................... 5

1.1 HOW TO KEEP THE MANUAL....................................................................................... 5

1.2 GRAPHIC SYMBOLS USED IN THE MANUAL................................................................. 5

2. NORMATIVE REFERENCES.................................................................................................. 5

3. PERMITTED USE................................................................................................................. 6

4. GENERAL SAFETY GUIDELINES........................................................................................... 6

4.1 WORKERS' HEALTH AND SAFETY ................................................................................. 7

4.2 PERSONAL PROTECTIVE EQUIPMENT .......................................................................... 8

4.3 SAFETY SIGNS .............................................................................................................. 8

4.4 REFRIGERANT SAFETY DATA SHEET ............................................................................. 9

4.5 SPECIFIC R32 GAS WARNINGS ................................................................................... 10

4.6 R32 GAS CHARGE....................................................................................................... 10

4.7 R32 GAS DISPOSAL .................................................................................................... 10

4.8 SAFETY RULES FOR R32 GAS TRANSPORT AND STORAGE .........................................10

5. INSTALLATION.................................................................................................................. 10

5.1 GENERAL.................................................................................................................... 10

5.2 TRANSPORT AND STORAGE LIMIT TEMPERATURE .................................................... 11

5.3 LIFTING AND HANDLING............................................................................................ 11

5.3.1 Liing mode ........................................................................................................... 11

5.4 POSITIONING AND MINIMUM TECHNICAL CLEARANCES..........................................12

5.5 DIMENSIONS ............................................................................................................. 14

5.5.1 Model SHP M PLUS 0121, SHP M PLUS 0126 ......................................................... 14

5.5.2 Model SHP M PLUS 0128, SHP M PLUS 0132 ......................................................... 15

5.6 CENTRE OF GRAVITY AND DAMPERS LOCATION ....................................................... 15

5.7 ACCESSING THE INNER PARTS ................................................................................... 16

5.8 PLUMBING CONNECTIONS ........................................................................................ 17

5.8.1 Features of the circuit water .................................................................................. 17

5.8.2 Hydraulic diagram inside the unit........................................................................... 18

5.8.3 Drainage system ..................................................................................................... 18

5.8.4 Filling / Discharge of the plant................................................................................ 19

5.8.5 Service sleeves ....................................................................................................... 19

5.9 ELECTRICAL CONNECTIONS ....................................................................................... 20

5.9.1 Access to electric panel .......................................................................................... 20

5.9.2 Power supply.......................................................................................................... 21

5.9.3 User terminal block ................................................................................................ 21

5.9.4 Control logics.......................................................................................................... 23

5.9.5 Fuses....................................................................................................................... 23

5.10 FUNCTIONAL DIAGRAMS......................................................................................... 24

5.10.1 i-32V5C Midi......................................................................................................... 24

5.10.2 SHP M PLUS .......................................................................................................... 25

6.STARTUP .......................................................................................................................... 26

6.1 SWITCHING ON THE UNIT.......................................................................................... 26

7. INSTRUCTIONS FOR THE USER ........................................................................................ 26

Chillers and Inverter Air/Water heat pumps with axial fan

4

8. Shutdowns for long periods ............................................................................................ 26

9. MAINTENANCE AND PERIODIC CHECKS .......................................................................... 27

9.1 CLEANING THE FINNED COIL ..................................................................................... 28

9.1.1 Cleaning the lled coil treated with the an-corrosion method ............................28

9.2 CLEANING OF EXTERNAL SURFACES .......................................................................... 29

9.3 EXTRAORDINARY MAINTENCE................................................................................... 29

10.DECOMMISSIONING...................................................................................................... 29

11.RESIDUAL RISK............................................................................................................... 30

12.TECHNICAL DATA............................................................................................................ 34

12.1 TECHNICAL SHEET i-32V5C MIDI ............................................................................. 34

12.2 TECHNICAL SHEET SHP M PLUS ............................................................................... 35

12.3 UNIT AND AUXILIARY ELECTRICAL DATA.................................................................. 37

13.OPERATING LIMITS ........................................................................................................ 37

13.1 EVAPORATOR WATER FLOW RATE ........................................................................... 37

13.2 COLD WATER PRODUCTION (SUMMER MODE)....................................................... 37

13.3 HOT WATER PRODUCTION (SUMMER MODE)......................................................... 37

13.4 AMBIENT AIR TEMPERATURE AND SUMMERISED TABLE ........................................ 37

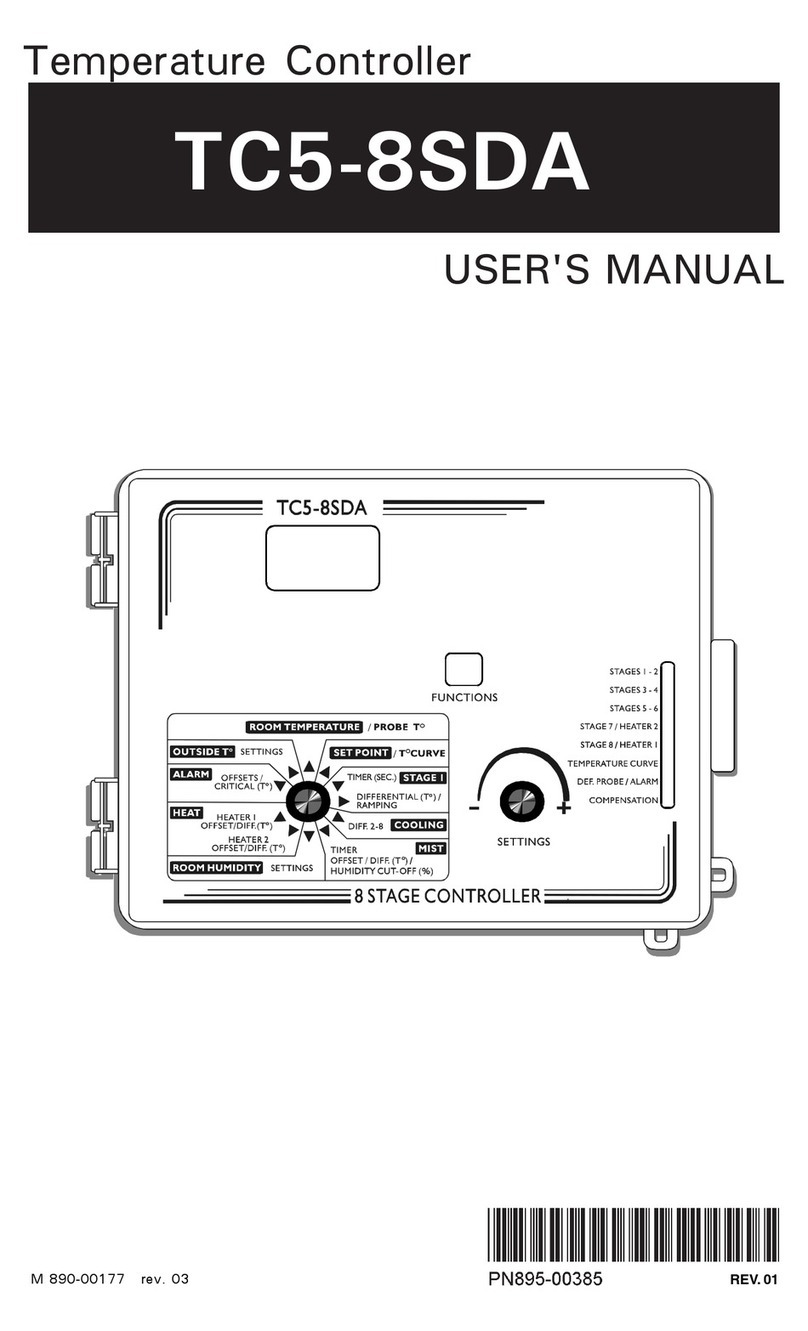

14.USER INTERFACE - CONTROLLER ................................................................................... 39

14.1 MENU ...................................................................................................................... 40

14.2 SETPOINT MENU ..................................................................................................... 40

14.3 ALARM MENU[Err] .................................................................................................. 41

15.TROUBLESHOOTING ...................................................................................................... 41

5

Chillers and Inverter Air/Water heat pumps with axial fan

The manual of the units contains all the necessary informaon for oponal use of the equipment under safe condions for the operator.

1. PURPOSE AND CONTENTS OF THE MANUAL

This manual provides basic informaon as to the selecon, installaon, operaon and maintenance of the unit. It is intended for the operators

of the appliance and it enables them to use the equipment eciently, even if they do not have any previous specic knowledge.

personnel”.

-

The manual describes the machine at the moment it was sold. It must therefore be considered adequate with respect to the state-of-the-art in

terms of potenality, ergonomics, safety and funconality.

The company also performs technological upgrades and does not consider itself obliged to update the manuals of previous machine versions

which could even be incompable. Therefore make sure to use the supplied manual for the installed unit.

The user is recommended to follow the instrucons contained in this booklet, especially those concerning safety and roune maintenance.

HOW TO KEEP THE MANUAL

The manual has to always be kept together with the unit it refers to. It has to be stored in a safe place, away from dust and moisture. It must be

accessible to all users who shall consult it any me they are in doubt on how to operate the equipment.

The company reserves the right to modify its products and related manuals without necessarily updang previous versions of the reference

material. We also decline any responsibility for possible inaccuracies in the manual if due to prinng or transcripon errors.

The customer shall store any updated copy of the manual or parts of it delivered by the manufacturer as an aachment to this manual.

The company is available to give any detailed informaon about this manual and to give informaon regarding the use and the maintenance of

its own units.

GRAPHIC SYMBOLS USED IN THE MANUAL

2. NORMATIVE REFERENCES

Units have been designed in compliance with the following direcves and harmonized standards on the safety of machinery:

EC direcves , 2014/35/UE, 2014/30/UE, 2011/65/UE, 2012/19/UE, 2014/68/UE

• Standard UNI EN 12735-1

• Standard CEI EN 60335-1, CEI EN 60335-2-40, CEI EN 55014-1, CEI EN 55014-2

• EN 50581

• EN 14276

And the following direcves, regulaons and standards on ecodesign and energy labelling:

• Community direcve 2009/125/UE and subsequent transposal

• UE Regulaon 2017/1369

• UE Regulaon 811/2013

• UE regulaon 813/2013

• EN 14511-1:2018, EN 14511-2:2018, EN 14511-3:2018, EN 14511-4:2018

• EN 14825:2018

Chillers and Inverter Air/Water heat pumps with axial fan

6

3. PERMITTED USE

• The company excludes any contractual and extra contractual liability for damage caused to persons, animals or objects, by incorrect instal-

laon, seng and maintenance, improper use of the equipment, and the paral or supercial reading of the informaon contained in this

manual.

• These units are built for the heang and/or cooling of water. Any other use not expressly authorised by the manufacturer is considered

improper and therefore not allowed. The uid to be used is exclusively water or a mixture of water and glycol in case of low water tempera-

tures

-

• All the work must be executed by skilled and qualied personnel, competent on the exisng regulaons in country of installaon. The

installaon place and the water and electric circuit must be established by the plant designer and must take into account both technical

requirements as well as any applicable local laws and specic authorisaons.

• All the work must be executed by skilled and qualied personnel, competent on the exisng regulaons in country of installaon.

• This appliance is intended to be used by expert or trained operators in shops, light industry and in factories, or for commercial use by

non-expert personnel.

• The appliance may be used by children at least 8 years old and by persons with reduced physical, sensory or mental capabilies or without

experience or the necessary knowledge as long as they are supervised or aer they themselves have received instrucons on the safe use

of the appliance and understand the relevant dangers. Children must not play with the appliance. The cleaning and maintenance which the

user is expected to carry out on the unit cannot be done by children without supervision.

• Direct interacon with the device by people with electrically controlled medical devices, such as pacemakers, is forbidden, as harmful in-

terference may be created. It is recommended to keep adequate distance from unit installaon, as indicated by the medical system used.

4. GENERAL SAFETY GUIDELINES

Before starng any type of operaon on the units, every operator must be perfectly familiar with the operaon of the machine and its controls

and must have read and understood all the informaon in this manual.

7

Chillers and Inverter Air/Water heat pumps with axial fan

-

WORKERS' HEALTH AND SAFETY

The European Union has issued some direcves regarding the safety and health of workers, including: 89/391/CEE, 89/686/CEE, 2009/104/CE,

86/188/CEE and 77/576/CEE, and subsequent amendments which every employer is obliged to follow and have followed. We observe therefore

that:

The unit works with R32 refrigerant, which is included in the list of greenhouse gases (GWP 675) which are subject to the requirements in EU

regulaon n. 517/2014 called “F-GAS” (mandatory in the European zone). Among the provisions of this regulaon, it sets forth that operators

working on systems running with greenhouse gases be in possession of a cercaon, issued or acknowledged by the competent authories,

aesng that they have passed a test authorising them to perform this work. In parcular

• Up to 3kg total refrigerant in the appliance: category 2 cercaon.

• 3 kg and more total refrigerant in the appliance: category 1 cercaon.

The gaseous form of R32 refrigerant is heavier than air and if released into the environment, most of it tends to concentrate in poorly venlated

areas. Inhaling it can cause dizziness and sensaons of suocaon and can develop lethal gas if in contact with naked ames or hot objects (see

the refrigerant’s safety data sheet).

Pay aenon to the fact that refrigerant uids can be odourless

For any operaon on the heat pump system:

-

Chillers and Inverter Air/Water heat pumps with axial fan

8

PERSONAL PROTECTIVE EQUIPMENT

When operang and servicing the units, the following personal protecve equipment must be used:

-

-

SAFETY SIGNS

The unit features the following safety signs, wich must be complied with:

Moving parts.

9

Chillers and Inverter Air/Water heat pumps with axial fan

REFRIGERANT SAFETY DATA SHEET

Name: R32

HAZARDS IDENTIFICATION

Main hazards:

Specifi c hazards:

FIRST AID MEASURES

General informa� on:

Inhala� on:

Eye contact:

Skin contact:

FIRE FIGHTING MEASURES

Ex� nguishing media:

Specifi c hazards:

Specifi c methods:

ACCIDENTAL RELEASE MEASURES

Personal precau� ons:

Environmental precau� ons:

Cleaning methods:

HANDLING AND STORAGE

Handling:

technical measures/precau� ons:

Advice for safe use:

Storage:

EXPOSURE CONTROLS/PERSONAL PROTECTION

Control parameters:

Respiratory protec� on:

Eye protec� on:

Hand protec� on:

Hygienic measures:

PHYSICAL AND CHIMICAL PROPERTIES

Colour:

Odour:

Boiling point:

Flash point:

Rela� ve gas density (air=1)

Rela� ve liquid density (water=1)

Solubility in water:

STABILITY AND REACTIVITY

Stability:

Materials to avoid:

Decomposi� on products

hazardous:

TOXICOLOGICAL INFORMATION

Acute toxicity:

Local eff ects:

Long term toxicity:

ENVIRONMENTAL INFORMATION

Global warming poten� al

GWP (R744=1):

Ozone Deple� on Poten� al ODP

(R11=1):

Disposal considera� on:

Chillers and Inverter Air/Water heat pumps with axial fan

10

SPECIFIC R32 GAS WARNINGS

The R32 refrigerant gas:

• is odourless;

• is ammable, but only if there are naked ame;

• it may cause an explosion, but only if a given concentraon in air is reached.

It is a good pracce to follow these guidelines:

• do not smoke near the unit;

• ax a no smoking sign near the unit;

• keep the premises where the unit is installed properly aerated;

• do not pierce or burn the unit;

• do not place the unit near ignion sources, such as naked ames, electric heaters etc.;

• every extraordinary maintenance or repair on the unit must be performed by skilled technicians or qualied personnel;

• a gas leak test must be performed aer installaon.

R32 GAS CHARGE

• ensure the R32 is not contaminated by any other types of refrigerant;

• keep the gas cylinder in an upright posion when charging;

• apply the appropriate label on the unit aer charging;

• do not charge more refrigerant gas than needed;

• when charging is completed, perform leak tests before the operang test;

• once all the above operaons have been completed, a second leak test should be performed.

R32 GAS DISPOSAL

• do not dispose of the gas in areas at risk of explosive mixtures forming with air The gas should be disposed of in an appropriate torch with

backring stop device. Contact the supplier should you require operang instrucons.

SAFETY RULES FOR R32 GAS TRANSPORT AND STORAGE

Before opening the unit’s packaging, ensure there are no gas leaks in the environment with an appropriate gas detector. Ensure there are no re

ignion sources near the unit.

No smoking is allowed near the unit.

Transport and storage must be performed in accordance with the naonal regulaons in force. Specically, according to ADR provisions, the total

maximum quanty by transport unit in terms of net mass for ammable gases is 333 kg.

5. INSTALLATION

GENERAL

When installing or intervening on the chiller unit, it is necessary to strictly follow the rules listed in this manual, to observe all the indicaons on

the unit and however to take all possible precauons. Failure to comply with the rules reported on this manual can create dangerous situaons

The company must be informed, within 8 days, of the extent of the damage. The Customer should prepare a wrien statement of any severe

damage.

-

11

Chillers and Inverter Air/Water heat pumps with axial fan

-

Do not perforate or burn.

TRANSPORT AND STORAGE LIMIT TEMPERATURE

Minimum storage temperature [°C] -10°C

Maximum storage temperature [°C] +50°C

LIFTING AND HANDLING

The handling must be performed by qualied personnel, properly equipped with appropriate tools to the weight and the encumbrance of the

unit, in compliance with safety regulaons of accident prevenng.

It is recommended:

1. check the weight on unit technical label or on table of tecnical data;

2. check moving the unit there are no disconnected paths, ramps, steps, doors that could aect the movement and damage the unit;

3. make sure the unit stands while moving;

4. Before handling the unit, check that the equipment is suitable for liing and preserving the integrity of the unit;

5. check the unit center of gravity and align it with liing point;

6. perform liing only by one of the listed procedures;

7. Before starng handling make sure the unit is in stable equilibrium.

Following liing moes are allowed:

• forkli truck

• ropes/chains + sling bar

Make sure to tension the liing ropes gradually and check their correct posioning.

Chillers and Inverter Air/Water heat pumps with axial fan

12

Liing through forkli truck

Liing through ropes

POSITIONING AND MINIMUM TECHNICAL CLEARANCES

All models of the range are designed and constructed for outdoor installaons.

It is advisable to create an adequately sized support base for the unit. The units transmit a small amount of vibraons to the ground: it is none-

theless advisable to apply vibraon dampers between the base frame and support surface.

SUSPENDED INSTALLATION IS FORBIDDEN.

-

-

It is very important to avoid recirculaon between intake and delivery air, so as not to downgrade performance of the unit or even to interrupt

its normal operaon.

In this case,it is absolutely necessary to guarantee the minimum service spaces listed below.

13

Chillers and Inverter Air/Water heat pumps with axial fan

B1

B

B2

C

A2

A

A1

MODEL A1 A2 B1 B2

mm 400 700 1500 400

In the event of side-by-side units, the minimum Lmin distance between them is

700 mm.

Lmin

Covering with canopies or placing near plants or walls should be avoided to

prevent air circulaon.

Chillers and Inverter Air/Water heat pumps with axial fan

14

In the event of winds stronger then 13,9-17,1 m/s (strong wind according to the

beaufort scale) the use of wind barriers is recommended.

We always invite you to make an environmental impact assessment based on the power and sound pressure data shown in chapter "Technical

data" and the sound emission limits based on the installaon area of the unit , with reference to the DPCM of 14/11/1997. An assessment must

also be made if the unit is installed in the proximity of workers according to D. LGS. 81/2008 Art. 189 and following.

DIMENSIONS

788

58

85

A

C

675

B

Dimensions and weights

Model

A - Lenght mm 1600

B - Depht mm 680

C - Height mm 1315

Shipping weight kg 250

kg 240

IN/OUT: 1”M G

E: power supply input

15

Chillers and Inverter Air/Water heat pumps with axial fan

Dimensions and weights

Model

A -Length mm 1600

B - Depth mm 680

C - Height mm 1315

Shipping weight kg 265

kg 255

IN/OUT: 1”1/4 M G

E: power supply input

CENTRE OF GRAVITY AND DAMPERS LOCATION

In the following tables, we report the posion of the centre of gravity of each machine, with reference to the dimensions shown in the image.

P1 P2

P3 P4

A

B

Xa

Yb

Models Shipping

weights [kg]

weights [kg] A [mm] B [mm] Xa [mm] Yb [mm]

SHP M PLUS 021,

026 250 240 1600 680 1040 320

SHP M PLUS 028,

032 265 255 1600 680 1035 330

The ideal installaon posions of the dampers for each type of machine are shown in the below images.

P1 P2

P3 P4

333 313

960

Chillers and Inverter Air/Water heat pumps with axial fan

16

ACCESSING THE INNER PARTS

[ 1 ]

[ 2 ]

A

B

1. Remove the two access panels to the components compartment by removing the screws as shown in gure 1.

2. To access the power supply terminal block, remove panel A by unscrewing the screws as shown in gure 2.

3. To access the user terminal block, remove panel B by unscrewing the screws as shown in gure 2.

4. Insert the cables in the cableshot provided on the rear side of the machine to connect them to the system.

5. Close the electrical panel and the access panels to the machine components compartment using the screws previously removed.

PLUMBING CONNECTIONS

The plumbing connecons must be made in accordance with naonal and/or local regulaons; pipes can be made of steel, galvanised steel or

PVC. Pipes must be accurately sized according to the nominal water ow rate of the unit and the pressure drops of the water circuit. All pipes

must be insulated with closed-cell material of adequate thickness. The chiller must be connected to the pipes using new exible joints, not re-

used ones. The water circuit should include the following components:

• Well thermometers to monitor the circuit’s temperature.

• Manual gate valves to isolate the chiller from the water circuit.

• Metal Y lter and dirt separator (installed on the return pipe) with metal mesh no larger than 1 mm. (obligatory to mantain the validity of

the guarantee).

• Loading group and exhaust valve where necessary.

-

17

Chillers and Inverter Air/Water heat pumps with axial fan

-

To guarantee correct operaon of the unit, the water must be appropriately ltered (see the instrucons at the start of this paragraph) and there

must be only a minimum amount of dissolved substances. The maximum allowed values are shown below.

MAXIMUM CHEMICAL-PHYSICAL PROPERTIES ALLOWED FOR THE CIRCUIT WATER

PH 7,5 - 9

Electrical conducvity 100 - 500 μS/cm

Total hardness 4,5 – 8,5 dH

Temperature ˂ 65°C

Oxygen content ˂ 0,1 ppm

Max glycol quanty 40 %

Phosphates (PO4) ˂ 2ppm

Manganese (Mn) < 0,05 ppm

Iron (Fe) < 0,3 ppm

Alkalinity (HCO3) 70 – 300 ppm

Chloride ions (Cl-) < 50 ppm

Sulphate ions (SO4) < 50 ppm

Sulphide ions (S) None

Ammonium ions (NH4) None

Silica (SiO2) < 30 ppm

Chillers and Inverter Air/Water heat pumps with axial fan

18

Herein below the hydraulic diagrams for connecon to the unit

W-IN

W-OUT

KA1

DV1

RV1

FC1

AV1

TE

IN1

P1

EV1

TE

OUT1

LEGEND

EV 1 PLATE HEAT EXCHANGER W-IN WATER INPUT

DV 1 DISCHARGE VALVE W-OUT WATER OUTPUT

RV 1 RELIEF VALVE P 1ELECTRONIC CIRCULATOR

TE IN 1WATER INLET TEMPERATURE PROBE-

SONDA AV 1 AUTOMATIC AIR VENT VALVE

TE OUT 1USER OUTLET WATER TEMPERATURE

PROBE FC 1 FLOW SWITCH

--- Accessory installed on board

In each unit a safety valve with 6 bar opening pressure included all the same

The units all of them adopt drainage holes on the basement for the condensate draining which can leach from the pipes of hydraulic and refrig-

erant circuits, and to discharge the generated water during defrosng cycles.

TO ALLOW ICE FORMATION UNDER THE UNIT WITHOUT DAMAGING IT BY FREEZING.

19

Chillers and Inverter Air/Water heat pumps with axial fan

-

When it is required to top up the circuit or to adapt the glycol level, please use the service valve. Unscrew

and remove the cap from the service valve (A) and connect a 14 or 12 mm pipe (inside diameter - check the

valve model installed on your unit), connected to the water mains, to the hose connector and then drain the

circuit by unscrewing the specic ring nut (B). Aer the end of the operaon, reghten the ring nut (B) and

screw the cap back on (A).In any case it is recommended to use an external valve to ll the system which can

be set up by the installer. B

A

If the unit must be completely drained, rst close the manual inlet and outlet shuers (not supplied) and then disconnect the pipes on the water

inlet and outlet so that the liquid in the unit can drain (to make this operaon easier, it is advisable to install two external drain cocks between

the unit and the manual shuers on the water inlet and outlet).

The unit is ed with an air venng valve to automacally remove air that has built up in the circuit, prevent-

ing undesirable eects such as premature corrosion and wear, lower performance and low exchange output.

The device also features a safety funcon because, in the event of exchanger breakdown, it allows the refrig-

erant gas to escape outside, prevenng it fro being conveyed to the internal terminals.

The valve can be kept in a closed posion by closing the plug on the drain; by loosening the plug, the valve

remains in open posion and air is discharged automacally.

-

ELECTRICAL CONNECTIONS

Check that the power supply matches the unit’s electric nominal data (voltage, phases, frequency) displayed on the rang plate on the unit’s

side panel. The electric power connecons must be made in accordance to the wiring diagram enclosed with the unit and in conformity with

naonal and internaonal standards (providing general circuit breaker, residual current devices for each line, proper earthing of the plant, etc.).

Chillers and Inverter Air/Water heat pumps with axial fan

20

-

The following is the procedure for accessing the electric panel.

[ 1 ]

[ 2 ]

A

B

1. Remove the two access panels to the components compartment by unscrewing the screws as shown in gure 1

2. To access the power supply terminal block, remove panel A by unscrewing the screws as shown in gure 2.

3. To access the user terminal block, remove panel B by unscrewing the screws as shown in gure 2.

4. Insert the cables in the grommets provided on the rear side of the machine to connect them to the system.

5. Close the electrical panel and the access panels to the machine components compartment using the screws previously removed.

-

This manual suits for next models

3

Table of contents

Popular Temperature Controllers manuals by other brands

dirna Bergstrom

dirna Bergstrom 1001238153 User handbook

Automationdirect.com

Automationdirect.com Solo user manual

Honeywell

Honeywell NOTIFIER FST-951-SELFT Installation and maintenance instructions

Trane

Trane TCONT401AN21MA Comfort Control owner's manual

ELREHA

ELREHA EE 38-1 Series operating instructions

AKO

AKO 156332 manual