Orwak 3110 User manual

Edition 4, From serial no. 106000-

Publ. no 4872223-00

OM 3110, 2012-02

O r w a k 3110

3110

OPERATING INSTRUCTIONS (IN THE ORIGINAL)

8

2

Please read the operating instructions BEFORE operating the machine.

Our warranty/product responsibility requires that:

• instructions are followed, and that no conversion or modication is carried

out.

• original spare parts, and hydraulic oils and lubricants recommended by the

machine manufacturer are used.

• at least one annual service is carried out.

The user of the machine is responsible for the safety checks, and for ensuring that

daily maintenance of the machine is carried out. The user is responsible for seeing to

it that defects are rectied, and that neither the user nor other persons are exposed

to danger.

The owner is responsible for ensuring that all laws and instructions are complied with

when using the machine.

This symbol means WARNING or DANGER – personal safety instruc-

tion!

This machine is designed for ONE-MAN OPERATION.

Only the operator is allowed in the working area of the machine. The working

areaisdenedundertheheadingTechnical data; Recommended space for

machine in operation.

Themachinemustnotbeoperatedifthesafetyfeatures(e.g.breakersand

guards)havebeendeactivated,damagedorremoved.

Lostordamagedpartsmustbereplacedwithoriginal spare parts.

Themachinemayonlybeoperatedbyapersonwhohasreceivedtraining

and has experience of the machine.

The machine has a high centre of gravity.Thepressplatemustbefully

loweredwhenthemachineismoved.Theareaimmediatelyaroundthe

machineanditsbaseshouldbecompletelylevel.

Installation,repairandservicingmustonlybeperformedbyqualied and

competentpersonnel,andinaccordancewiththeinstallationand

servicinginstructions.

The machine must notbeusedbyminors.

Neverclimbonthemachine!

When compacting plastic,themachinemustbesettoPlastic (lower press

force),see control panel.

Avoidcompactingmaterialsofdifferenthardnessinthemachineatthesame

time.(Ifthewastehasnotbeenproperlymixedanddistributedwellinthe

chamber,thiscanresultinanunevenloadonthepressplateanddamageto

the machine).

Useonlystrapsorstringrecommendedbythemachinemanufacturer.

SAFETY FEATURES

Themachineisequippedwiththefollowingsafetyeatures:abreakerswitchthatprevents

themachinefrombeingusedwhentheupperdoorisopen;mechanicaldoorinterlocks,

andguardsanddoorstoprotectagainstdangerousinterventioninthemachine.The

machineisalsoequippedwithanemergency stop. The above safety features must be

checked regularly; see section on weekly inspection and maintenance.

SAFETY

Safety................. 2

Control panel..... 3

Operating

instructions........ 4

Installation......... 5

Weekly

inspection and

maintenance..... 5

Technical

specications..... 6

Dimensional

drawing............... 6

Transport........... 6

CE..................... 7

CONTENTS

English

Errors and omissions excepted.

9

3

CONTROL PANEL

English

Paper - indicates that the

machine is set to compact

paperandcardboard.

Plastic - indicates that

the machine is set to

compact plastic. See

more under Technical

data.

Bale size - indicates the

selectedbalesize(small

–medium–large).

Thebalesizecanbe

xed.Contactyourlocal

distributorformoreinfor-

mation.

Up arrow -usedto

raise the press plate to

its normal position.

Down arrow -usedto

lower the press plate.

The press plate stops

UNDER PRESSURE

againstthebaleinits

down position (in the

caseofmanualbale

removal).

Start - starts a

compaction cycle

(in the case of ma-

nualstarting).

Emergency

stop -usedifa

compaction cycle

hastobestopped

immediately.

Bale light - this

light goes on when

thebaleisreadyto

beremovedfrom

the machine.

Service light - the

machinecancontinue

tobeoperated,but

authorisedservice

personalshouldbe

contacted

MAN - indicates that

the machine is set for

manualstarting.Tostarta

compactioncycle,thestart

buttonmustbepressed.

AUTO - indicates that

the machine is set for

automaticstarting.This

means that the machine

willautomaticallystarta

compaction cycle when the

upperdoorisclosed.

Temperature lights

Blue lights indicate that the

machine is cold. The machine can

stillbeoperated.

Red light indicates that the mach-

inehasoverheatedandCANNOT

beoperateduntilithasreturnedto

itsnormaltemperatureandthelight

hasgoneout.

Voltage light - this

light indicates that

there is power to the

machine.

RANGE OF APPLICATION

Themachineisahydraulicallyoperatedbalerintendedforcompactingbulkymaterialssuchascardboard,paperandplas-

tic.Themachinemayonlybeusedinareasthathavearoof,protectionagainstwind,andnormallighting.Themachineis

intendedforusewithinthetemperaturerange-10°Cto+40°C.Alow-temperatureoiland/orheatershouldbeusedattempera-

tureslowerthan+5°C.

Materials that are ammable or of an explosivenature,suchaspressurisedcontainersorthelike,whichcouldcause

injury,damage,reoranexplosionifexposedtopressureorsparks,must not be compacted in the machine.

3

4

2

5

6

7

13

9

10

14

15

16

16

12

8

11

1

4872303-00(VG9)

=

Paper Plastic

http://www.orwak.se/~/media/Movies/3110.ashx

10

4

English

OPERATING INSTRUCTIONS

Mounting the straps

1Openthestrapshuttersandthe

upperdooralltheway.Place

the strap rolls in the strap holder

compartment and insert the

strapsintothestrapfunnels.

2Whenthestrapendsarevisible

insidethechamber,thestraps

canbepulledforwardandout

throughtheirrespectiveslotsin

the lower door.

3Tie a knot in each strap and

secureintheslotsinthebeam

at the lower front edge of the

machine.

4Usingthestraphook,placethe

straps in the strap slots in the

bottomandalongthebackof

the machine.

Themachineisnowreadyforuse.

Compaction

5Distributethewasteevenly

insidethechamber.

6Closetheupperdoor–the

startbuttonwillglowgreen.

(If the machine is set to

“AUTO”anautomatic

compaction cycle will start

oncethedoorisclosed,and

step7willbeskipped.)

7Pressthestartbuttonfora

manualcompactioncycle.

Baling (full bale)

8Thebalelightwillash

whenthebaleisreadyand

canberemoved.

9Opentheupperdoorand

pullthestrapsoverthebale

andthroughtheslotsinthe

lower door.

10 Cutthestrapswiththeknife.

11 Place the strap ends that

are not tobetiedinsidethe

chamber.

12 Closetheupperdoor.

(If the machine is set to

“AUTO” the press plate will

lowerautomaticallyand

stop UNDER PRESSURE

againstthebaleinitsdown

position,andstep13willbe

skipped.)

13 Lowerthepressplateusing

the down arrow. The press

platewillautomatically

stop in its down position

andkeepthebaleUNDER

PRESSURE.

14 Tie the straps.

15 Raisethepressplateback

upusingtheuparrow.

16 Openthedoorsandremove

thebaleusingthebalecart.

WARNING!

Only the operator is

allowed in the working

areaofthemachine!

0

OFF

A

B10A

Min 0,6 m

Min 0,6 m

Box 58

576 22 Sävsjö

Sweden

Type Serial No

Product No Date

V

Weight

Hz kW A

** *

***

1

23

4

5

11

5

English

INSTALLATION

NOTE!Duringinspectionandmaintenance,servicingandtheremovaloftrappedwaste

etc:

1.Settomanualmode(MAN)onthecontrolpanel.

2. Disconnectthepowertothemachinebyremovingtheplugfromthewallsocket.

3. Do not work inside the machine.

WEEKLY INSPECTION AND MAINTENANCE

SAFETY CHECKS

- Check the shutter switch:itmustnotbepossibletostartthemachineiftheuppershutterisopen/opened.

- Check that the emergency stop is working.

- Check that all covers and guards are intact.

- Check that there are no oil leaks on the machine.

-Checkthattheelectricalsupplycableisintactandproperlyprotectedagainstimpact.

Ifanyfaultsarediscoveredinthefunctionslistedabove,themachinemustnotbeuseduntilithasbeen

repairedbyauthorisedservicepersonnel.

Servicin and repairs must only be carried out by qualied and competent personnel, and in accordance with the

machine manufacturer’s instructions.

Theservicelightwillcomeonwhenthemachinerequiresservicing.Contactauthorisedservicepersonnel.

When changing the oil: Contact the local authorities for guidance regarding the environmentally correct dis-

posal of waste oil. Miscibilitymustbetakenintoaccountwhenchangingand/ortoppinguptheoil.Themachine

comeslledwithmineraloilfromthefactory.

TROUBLESHOOTING:

First, check:

OVERLOAD PROTECTION

NORMAL TRIPPED

FUSE

3110 (mm)

1365

680 866

704

1990

458550

648

98

OK

2011-11-14

3115

1000002-00

380 kg

~950 mm

~1993 mm

(490 3110-00)

12

6

DIMENSIONAL DIAGRAM

TECHNICAL

SPECIFICATIONS

TRANSPORT

English

GENERAL DATA

Total weight: 340kg

Transportheight: 1,990mm

Dimensions:

Height: 1,990mm

Width: 866 mm

Depth: 680mm

Depth with open

door: 1,365mm

Recommended space for machine

in operation (working area):

Height: 1,990mm

Width: 2,066mm

Depth with open

door: 1,965mm

Loading aperture:

Height: 458 mm

Width: 704 mm

Bale size:

Height: approx.600mm

Depth: 500mm

Width: 700mm

Weight(paper): upto50kg

Weight(plastic): upto70kg

Noise level:

<62.3(±1.0)dB(A)(ISO11200&

11202)

Paint: Two-part paint and powder

coatwithphosphatisingasbase.

Colours:

Orange RAL2001

Grey RAL7032

ELECTRICAL DATA

Operating power: 230V,50Hz

Operating voltage: 24V

Electric motor: 1.1kW

Fuse rating: 10A

Protection class: IP 55

HYDRAULIC DATA:

Working pressure (paper): 115bar

Working pressure

(plastic): 90bar

Overload pressure: 140bar

Press force (paper): 4 tons

Press force (plastic): 3 tons

Surface pressure

(paper): 1.15kg/cm2

Surface pressure

(plastic): 0.9kg/cm2

Cycle time, total: 33 s.

Cylinder stroke length: 640mm

Oil volume: 6,2litres

Recommended oil:

+5°C to +60°C

ISOVG32-68,Mineraloil

Below +5°C

Aspecialoilorheatershouldbeused

atlowertemperatures.

Themachinehasahigh centre of gravity.Thepressplate must be fully lowered

whenthemachineismoved.

Manualmachine(MAN):Closetheshutter.Press‘Downarrow’onthecontrolpanel.

Automaticmachine(AUTO):Presstosettomanualmode(MAN)onthecontrolpanel.Close

theshutter.Press‘Downarrow’

Sävsjö2012-02-01

Box58

S-57622Sävsjö,

Tel:46-382-15700

Telefax:46-382-10607

3110 (mm)

1365

680 866

704

1990

458550

648

98

ABORWAK

Arne Isaksson

4903110-00 – 4903110-99

4903110-S001 – 4903110-S999

13

7

English

towhichthisdeclarationrelatesisinconformitywiththefollowingstandardsorothernormative

documentsinaccordancewiththeprovisionsofDirectives

declareunderoursoleresponsibilitythattheproductmodel

(serialnumberspeciedontherstpage)

ProductManagerandcompileroftechnicaldocumentation

EC DECLARATION OF CONFORMITY

2006/42/EEC(MachineryDirective)

2004/108/EEC(EMCDirective)

2006/95/EC(LowVoltageDirective)

2009/125/ECErPDirective(Energy-relatedProducts)

ThemachinefullstherequirementsofPL=

candcategory1accordingtoENISO13849-1:2008

EN60204-1 (SafetyofMachinery–ElectricalEquipmentofMachines)

EN61000-6-1 (EMCImmunityforresidential,commercialandlight-industrialenvironments)

EN61000-6-2 (EMCImmunityforindustrialenvironments)

EN61000-6-3 (EMCEmissionstandardforresidential,commercialandlight-industrial

environments)

EN61000-6-4 (EMCEmissionstandardforindustrialenvironments)

ENISO13849-1 (SafetyofMachinery–Safety-relatedpartsofcontrolsystems)

We

Sweden

Tel:46-382-15700

Fax:46-382-10607

Orwak is a world leader in compaction and baling solu -

tions for solid waste material at source. We develop,

manufacture and market a comprehensive range of

waste compactors, baling systems and “Brickman” bri -

quette presses for recyclable materials that make waste

management more profitable. This is where Orwak’s

unequalled technology, expertise and service support

make all the di erence. When you partner with Orwak,

you also gain access to the vast experience we have

built up since 1971.

Orwak is wholly owned by the Norwegian company

Tomra, a leading global player in providing integrated

solutions for recovering and recycling used packaging.

Leader in compaction

and baling solutions

AB Orwak

Box 58, SE-576 22 Sävsjö, Sweden

Tel: +46 382-157 00, Fax: +46 382-1007 6

E-mail: info@orwak.se

Table of contents

Other Orwak Garbage Disposal manuals

Popular Garbage Disposal manuals by other brands

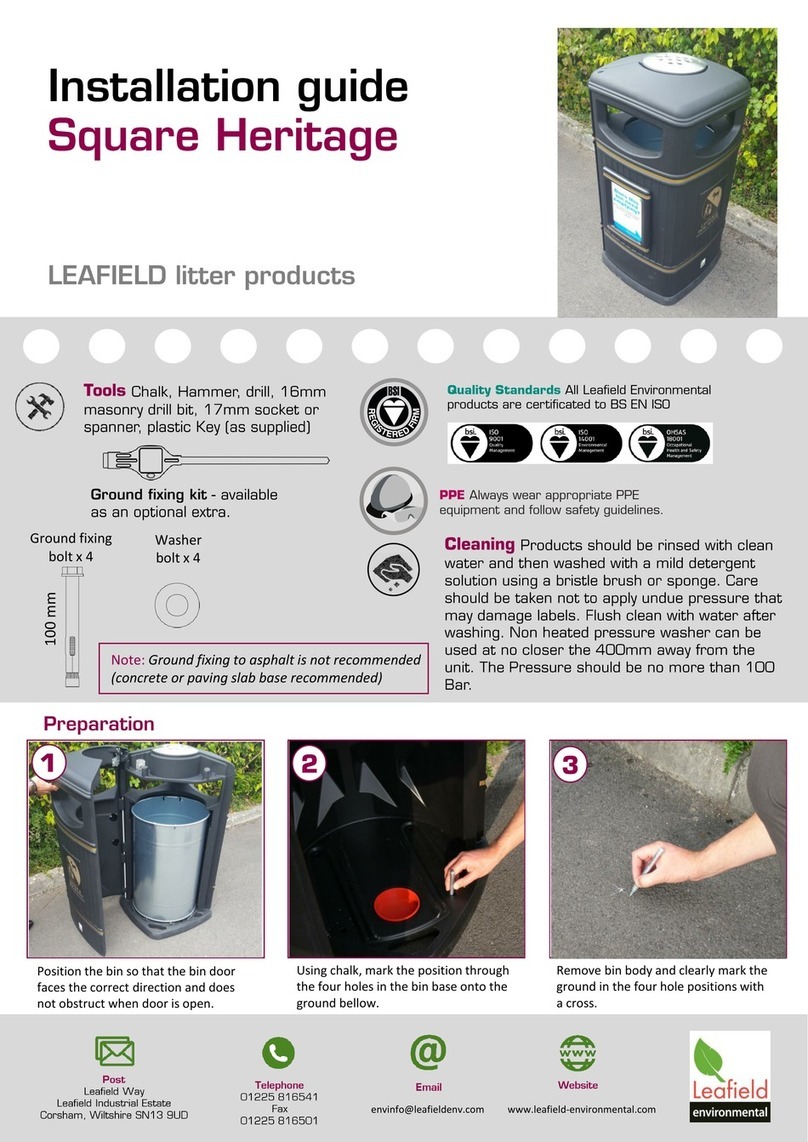

Leafield Environmental

Leafield Environmental Square Heritage installation guide

Frigidaire

Frigidaire FPDI103DMS Product specifications

GE

GE GFC530F - DirectWire 1/2 HP Continuous Feed... specification

InSinkErator

InSinkErator EVOLUTION 200-2 user manual

Meiko

Meiko WasteStar FC operating instructions

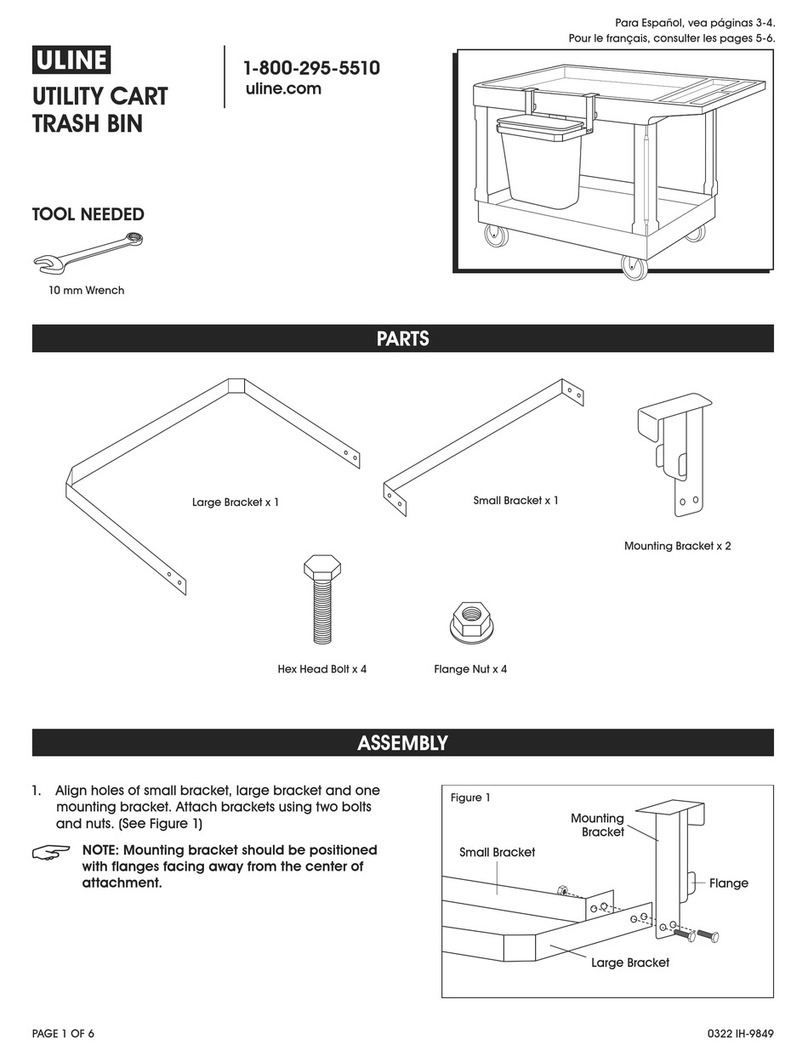

U-Line

U-Line H-9849 quick start guide