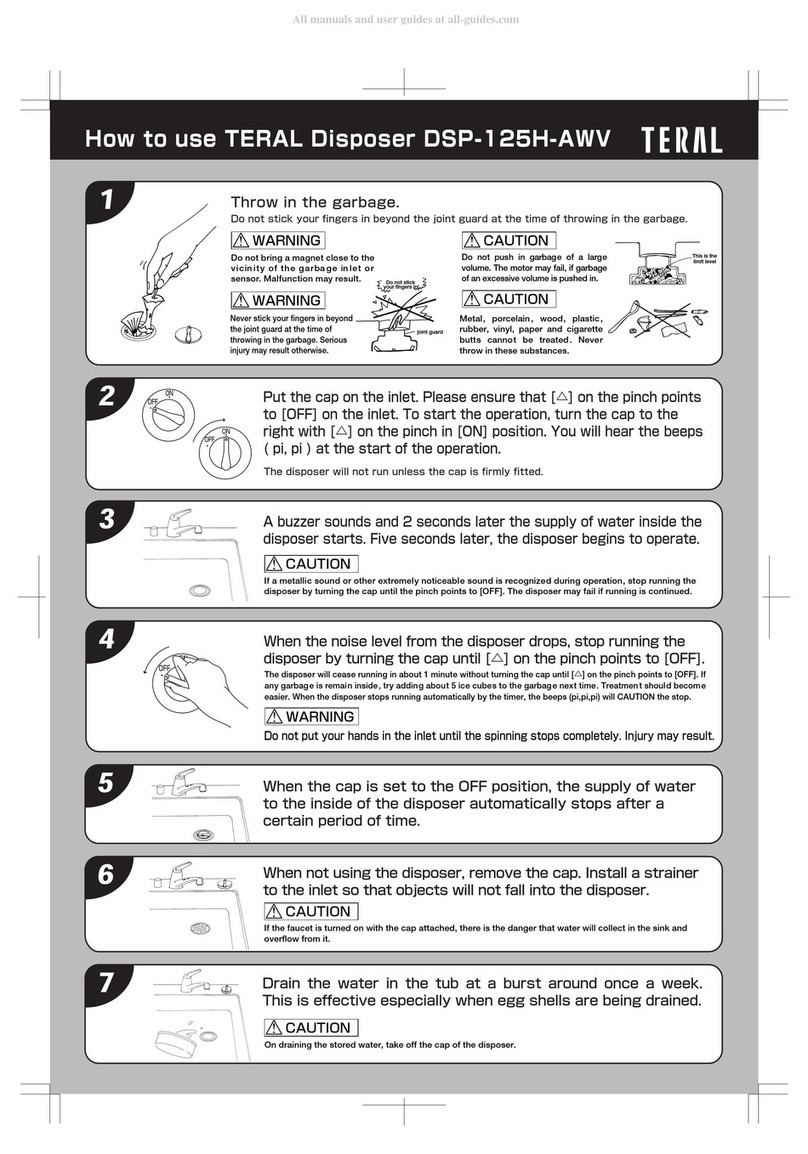

3

The anaerobic bacteria in the digester

biodegrade the organic waste, producing

biogas in the process.

In addition to biogas, the

system produces a

nutritious, natural fertilizer.

A patented mechanism regulates gas

pressure when the biogas is used, enabling a

steady, even pressure at the end device.

The generated biogas passes through an

active filter to remove any unpleasant odors

and trace amounts of hydrogen sulfide, and

is stored in the gas tank.

A special pressure release

mechanism releases excess

gas once the gas tank is filled

to capacity.

Organic waste is fed into

the digester tank, which

is filled with water.

1

2

5

3

4

6

introduction

The HOMEBIOGAS household biogas system turns organic waste like food scraps and animal manure into biogas, which can

be used for cooking, and natural liquid fertilizer, which can be used for gardening.

Biogas is generated in the system by the anaerobic (without oxygen) fermentation of organic matter. Biogas is a ammable

gas that is lighter than air, composed mainly of methane and carbon dioxide.

HomeBiogas is a biological system: performance is aected by environmental conditions and may vary due to physical lo-

cation and ambient temperature.

The system operates as a continuous-ow system: organic waste is fed into one end, and gas

and fertilizer are emitted constantly from the other as long as the system is active and being

fed. (Fertilizer is produced whenever liquid & waste are added into the system)

Organic waste is fed into

the digester tank, which is

lled with water.

The anaerobic bacteria in the digester

biodegrade the organic waste, producing

biogas in the process.

In addition to biogas, the

system produces a nutritious,

natural fertilizer.

A special pressure release

mechanism releases excess

gas once the gas tank is lled

to capacity.

The generated biogas passes through

an active lter to remove any unpleasant

odors and trace amounts of hydrogen

sulde, and is stored in the gas tank.

A patented mechanism regulates gas pressure

when the biogas is used, enabling a steady, even

pressure at the end device.