TABLE OF CONTENTS

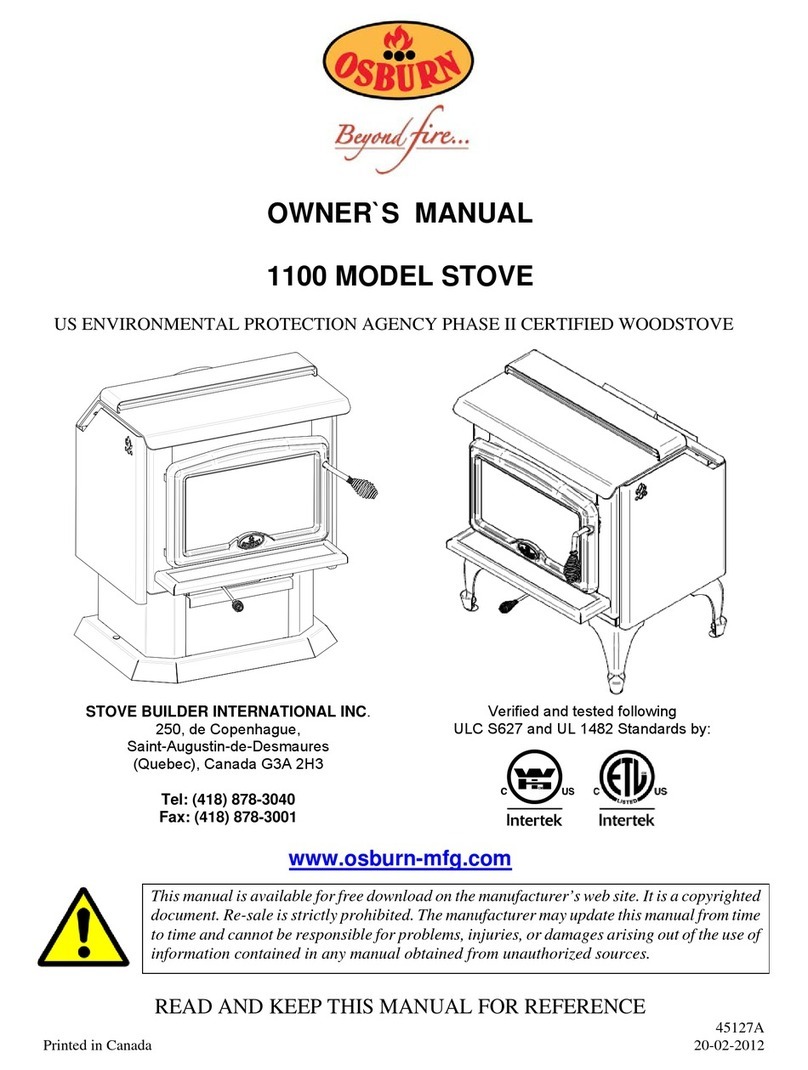

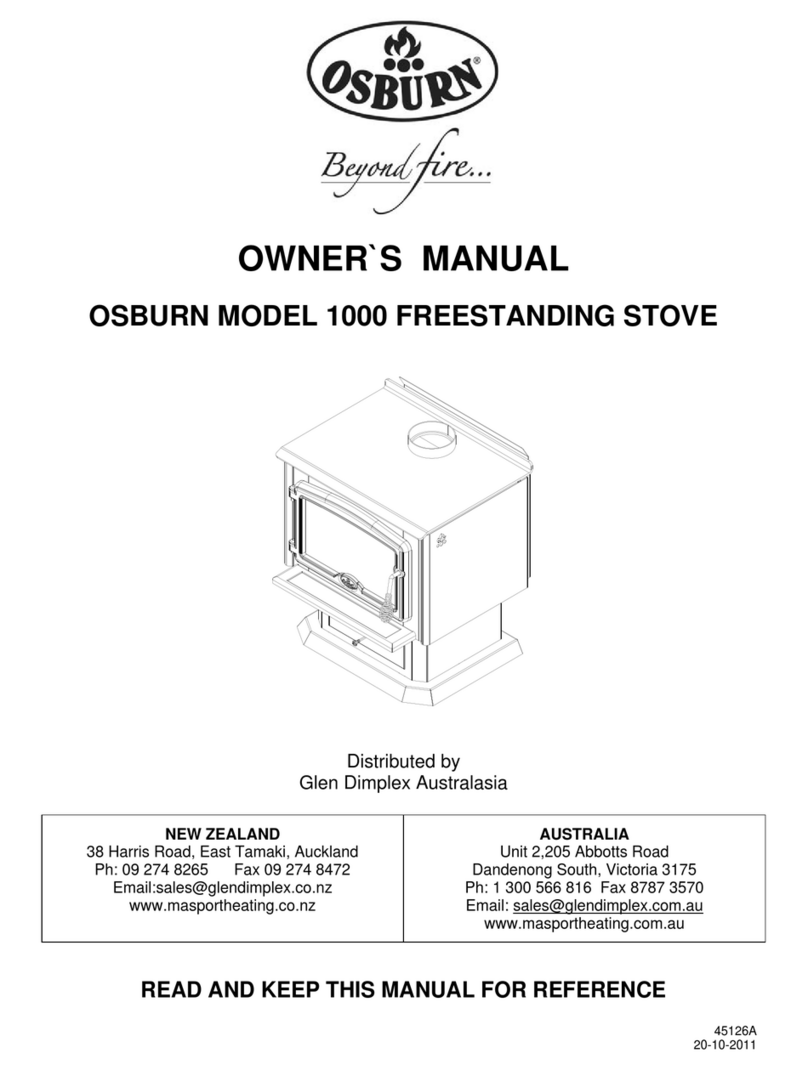

1.0 INTRODUCTION...............................................................................................................................................1

1.1 SPECIFICATIONS ..............................................................................................................................................1

1.2 FEATURES........................................................................................................................................................3

1.3 INTENDED USE ................................................................................................................................................3

1.4 GENERAL SAFETY ...........................................................................................................................................3

2.0 OPERATION ......................................................................................................................................................4

2.1 OPERATION SAFETY........................................................................................................................................4

2.2 LIGHTING INSTRUCTIONS................................................................................................................................5

2.3 HEAT OUTPUT ADJUSTMENT ..........................................................................................................................6

3.0 INSTALLATION................................................................................................................................................7

3.1 INSTALLATION & SAFETY NOTES ...................................................................................................................7

3.2 UNPACKING.....................................................................................................................................................7

3.3 INSTALLATION.................................................................................................................................................7

3.3.1 BEDROOM INSTALLATION...........................................................................................................................7

3.3.2 MINIMUM CLEARANCES TO COMBUSTIBLE CONSTRUCTION.....................................................................7

3.3.3 CHIMNEY VENT INSTALLATION..................................................................................................................8

3.3.3.1 DIRECT VENT ..............................................................................................................................................8

3.3.3.2 OPTIONAL B-VENT INSTALLATION...........................................................................................................13

3.3.4 GAS LINE INSTALLATION..........................................................................................................................13

3.3.5 THERMOSTAT, WALL SWITCH, OR REMOTE CONTROL INSTALLATION...................................................14

3.3.6 FIREBOX COMPONENT INSTALLATION......................................................................................................16

3.3.6.1 OPTIONAL EMBER INSTALLATION ............................................................................................................16

3.3.7 INITIAL FIRING..........................................................................................................................................17

3.3.7.1 MANIFOLD PRESSURE REGULATOR ADJUSTMENT ...................................................................................17

3.3.7.2 PILOT FLAME ADJUSTMENT......................................................................................................................17

3.3.7.3 ALTITUDE ADJUSTMENT...........................................................................................................................17

3.4 MANIFACTURED (MOBILE) HOME INSTALLATION ........................................................................................19

3.5 FIELD CONVERSIONS.....................................................................................................................................20

4.0 MAINTENANCE..............................................................................................................................................20

4.1 MAINTENANCE SAFETY.................................................................................................................................20

4.2 RECOMMENDED SERVICE..............................................................................................................................20

4.3 GLASS CLEANING..........................................................................................................................................20

4.4 BURNER & PILOT CLEANING ........................................................................................................................20

4.5 FIREBOX DISASSEMBLY & REASSEMBLY......................................................................................................21

4.6 FAN................................................................................................................................................................22

5.0 TROUBLE SHOOTING ...................................................................................................................................23

OSBURN LIMITED LIFETIME WARRANTY ...........................................................................................................24