8

JH-DC OPERATOR INSTALLATION GUIDE

TROUBLESHOOTING

Operatorfails to start:

A. Makesure youhave poweratthemaster distributionpanel

andthat thepower hasnot beenturned off.

B. Thesecondary fuseonthe controlboardmay haveblown.

Replacethe fuse(refer tocontrolbox partsliston page23.

Motor operates, but door does not move:

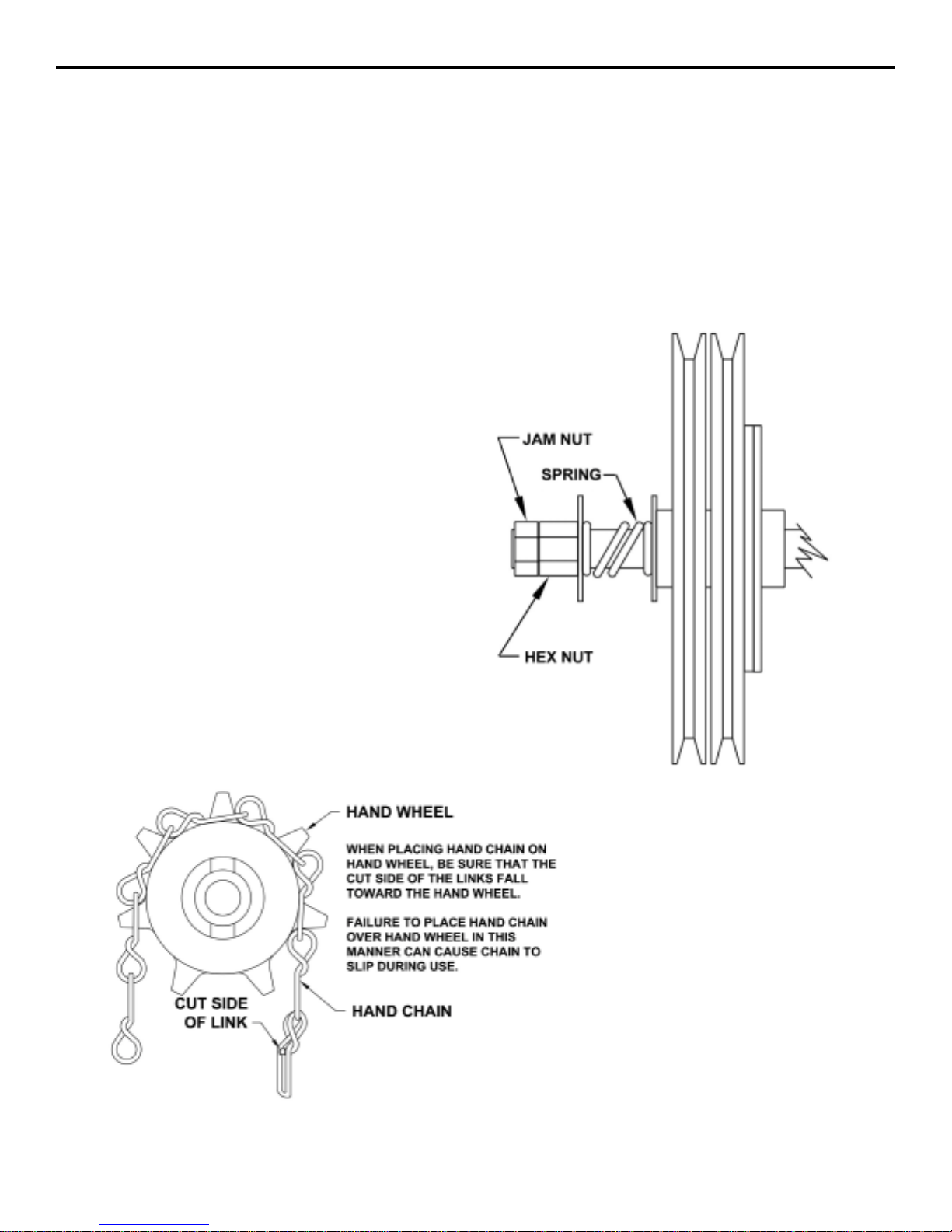

A. Inoperators withtorque limitersand friction padclutches,

check for signs of slipping. You can mark the pulley and

clutchwith ayellow orwhite greasepen andwatch forthe

lines to move apart if slipping is taking place. Adjust the

torque limiter tighter if this is the problem.

B. Checkfor brokenchain orworn belts.

C. Check allsetscrews onpulleys andsprockets andtighten

them if necessary, and check for keys which may have

fallenloose fromkeyways.

Motor sounds like it is working harder than normal:

A. Make sure the door is moving freely and without binding

throughoutits entiretravel.

B. Checkthe drivechain forobstructions (ifthe operatorhas

one).

Limit switch getting out of time:

A. Checkfor propertension onalllimitchains tobesurethere

is no jumping taking place. Mark one tooth and its corre-

sponding link and run the door. If the marks have moved,

the chain is skipping.

B. Check the setscrews in the limit sprockets for tightness.

In rotary limit boxes, check the rotary limit nut for sloppi-

ness or stripped threads. Replace if necessary.

C. Check the detent plate in the limit switch box to see that

theedge ofthe detentplateis insertedintothe V-grooveof

both nylon limit nuts (see page 5).

Door stopping part way open or closed

(but no visible obstruction):

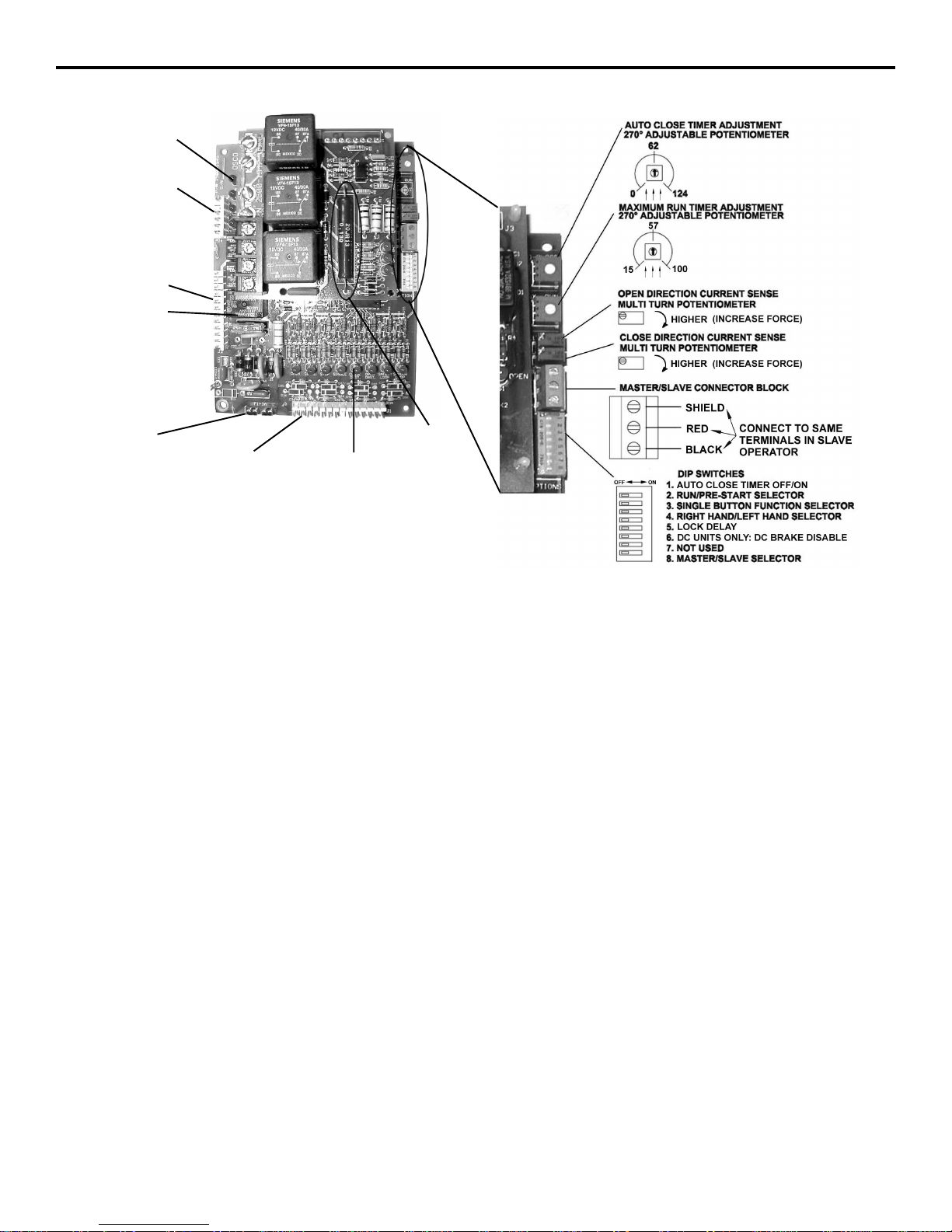

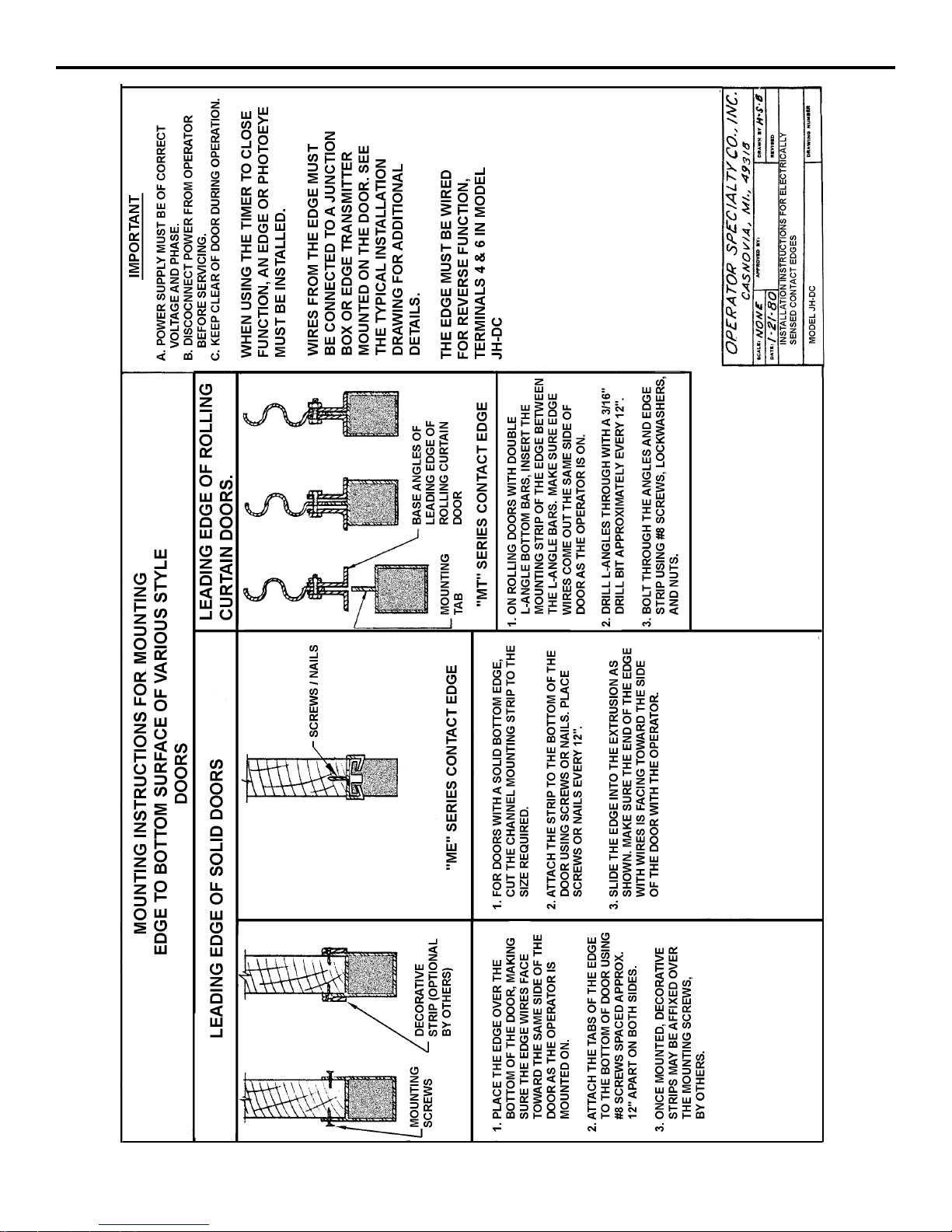

(Also see page 13 for additional information regarding

control board adjustments)

A. The control board may have received a false obstruction

input triggered by current sensing set too low. Make sure

the door moves freely through its entire travel before ad-

justing the current sensing.

B. The maximum run timer may have counted down and ex-

pired. This can be caused by having the timer set too low,

if a chain or belt is broken, or if a sprocket or pulley is

slipping. When the timer expires, the door stops and the

stop button must be pressed to reset the operator.

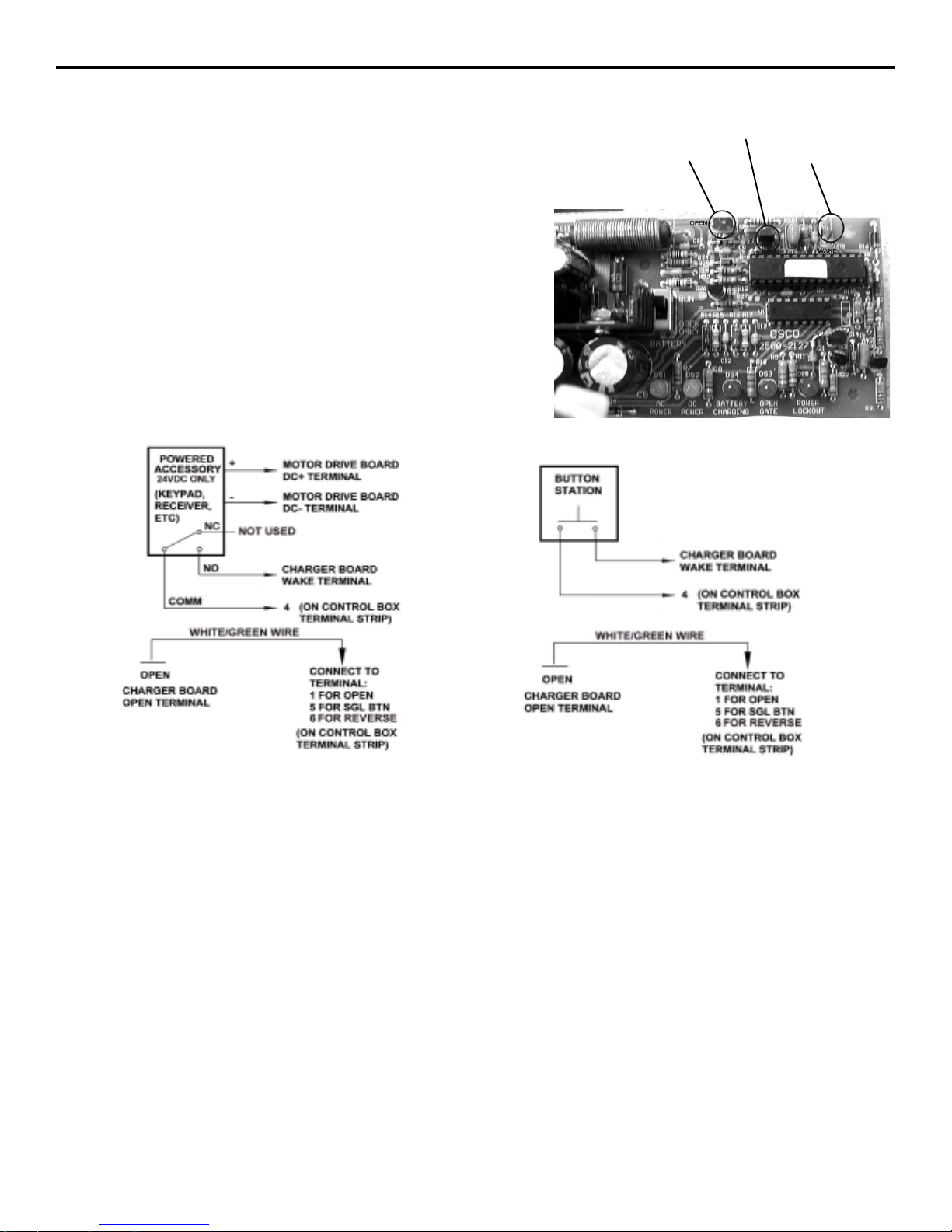

C. An obstruction signal from an accessory wired to the ob-

structioninput mayhave triggeredfalsely.Check thecon-

trol board for lit L.E.D. indicators for any of the following

inputs: safety, shadow, open obstruction, close obstruc-

tion, stop, etc. If any are lit when the operator should be

running, remove all devices hooked to that function and

hookthem uponeat atimeand trytorun theoperator until

theproblemdevice isfound. Referto page17 fordetailson

thecontrol boardindicators.

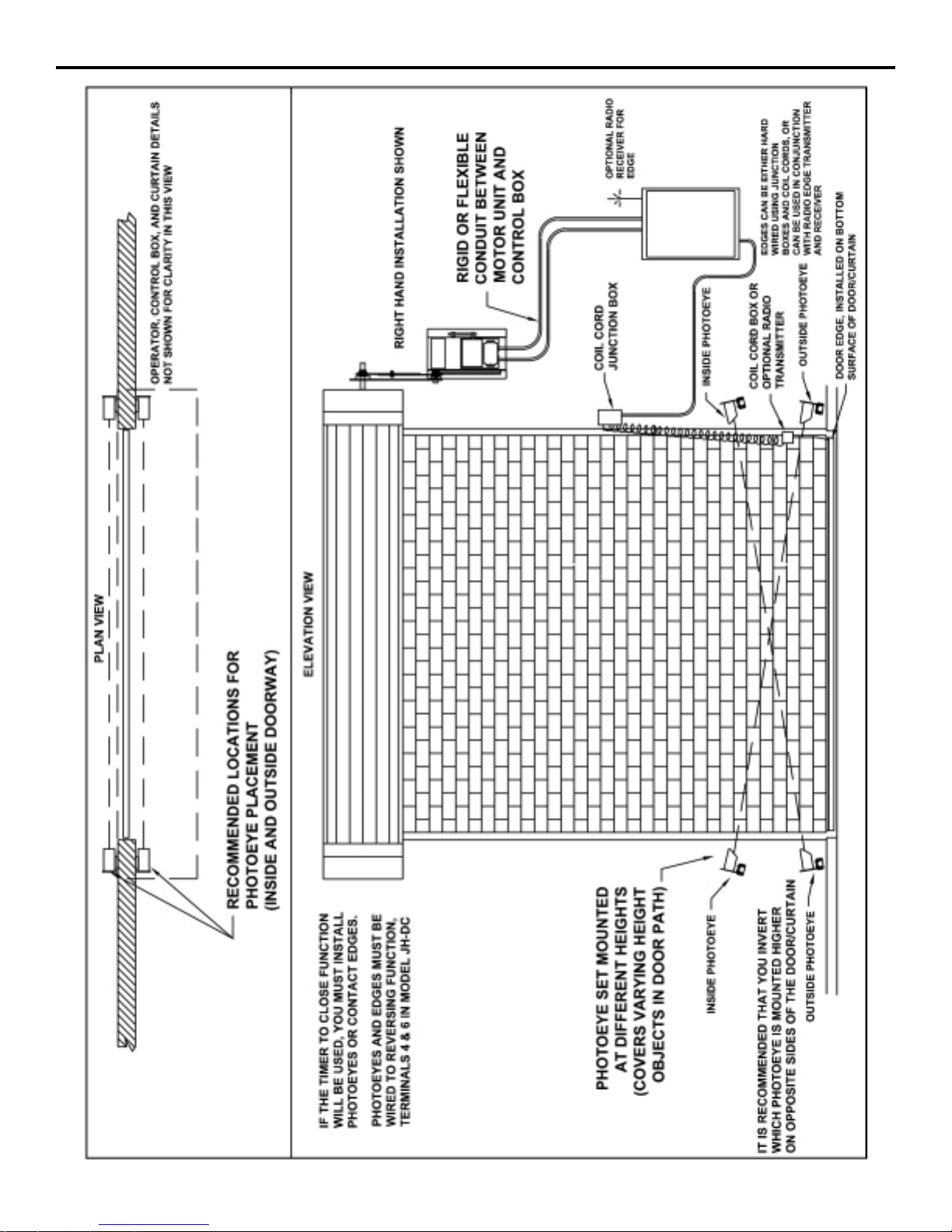

Doorstaying open withautomaticsystem:

A. If there are vehicle detectors in your operator which are

connected to reverse, one of your loops or loop detectors

may be sending a false signal. Disconnect the wire har-

ness by pulling harness off the loop detector and try run-

ningthe operator.

B. An opening or reversing device may be stuck or malfunc-

tioning. Try disconnecting these devices and hook them

backup oneata timeandtry runningtheoperator untilthe

malfunctioningdeviceisfound.

C. Make sure the close limit switch isn’t activated. If it is, the

operator will think the door is already closed.

HOW TO ORDER REPLACEMENT PARTS

Use the part numbers listed on the parts list pages. Contact your local OSCO dealer or distributor to order parts.

1. Supplythe modelnumber andserialnumber ofyour operator.

2. Specifythe quantityof piecesneeded andorder bypart numberand nameof part.

3. State whether to ship by freight, truck, parcel post, UPS or air express.

4. Statewhether transportationcharges areto beprepaid orcollect.

5. Specify name and address of person or company to whom parts are to be shipped.

6. Specify name and address of person or company to whom invoice is to be sent.

TechnicalService assistance is alwaysavailable atOSCO. If afterfollowing thetroubleshooting suggestions aboveand

your operator still does not function properly, contact OSCO’s Technical Service Department direct at 1-800-333-2508.