Automation Systems AUSTRALIA TiTAN 2410 User manual

Titan 2410

Advanced Digital Sliding Gate System

REV 0

Step by Step Simple Installation

Guide on Page 2

Automation Systems

Australia

Table of Contents

1

Specifications, Dimension and Tools Required

2

Step By Step Installation Guide

3

Installation Layout/Wiring Layout

4

Motor Installation

5

Motor Installation Continued

6

Controller Layout and Display Screen Status

7

CERO Standalone Solar System Connection

8

Battery Backup Connection, Power Transformer Connection

9

SPEED, TIME and SENS Trim pot Adjustments, System Menu Hierarchy

10

Basic Menu (operating logic)

11

Basic Menu continued ( wireless learning, automatic closing time, working time learning, fast speed

level and Motor Test)

12

Core Menu (manual time adjustments, gate direction, photocell, stop, limit switch polarity)

13

Core Menu continued (special detector, soft start, opening edge, closing edge, manned depot mode)

14

Core Menu continued (light output, auxiliary light output, receiver mode

15

Remote Learning (detailed)

16

Remote Deleting (detailed), Remote Usage

17

Enrolment, Wireless Keypad Learning (detailed), Automatic Closing Timer

18

Motor Test

19

Learn Time Calibration/Gate Calibration

20

Photocells Dukie and Dukie+

21

Special Detector Dukie and Dukie+

22

Traffic Light, Driveway Light, Alert Strobe and Warning Lights

23

Tekno Wi-Fi Switch, Loop Detector, Tekno K1 Keypad

24

Tekno GSM Intercom, Digital Weekly Timer, Push Button

25

Emergency stop button, amplify antenna

26

Fill In Enrolment List

27

Warranty Terms

Page 1

Operating Voltage

24V AC/24V DC

Standby Consumption

~40mA

Battery Backup

Yes

Speed

22-36 CM/S

Motor Limit

N/C Micro Switch

Torque

27 NM

Duty Cycle

90%

Light Output

Warning 12VDC 1A MAX / Secondary Relay Max 3A

Accesories Power

12V DC (250mA)

Safety Inputs

Photocell, Detector, Safety Edge

Operation Temprature

-10°C to +60°C

Remote Button Capacity

250

Specifications

Dimensions

Typical Tools Required

2/2.5mm Flat Head for

Terminal Connections

Socket & Spanner

Sets

Drill and Drill Bits

Masonry and Metal

Multi Meter

(not essential)

Wire Stripper

318

17

170

25mm Conduit

MAX.

80

80

1

2

.

9

4

m

m

Gate Length (mm)

Gate Weight (Kg)

3500

mm

600 Kg

1000 Kg 1000 Kg

300 Kg

400 Kg

800 Kg

4000

mm

5000

mm

6000

mm

7000

mm

8000

mm

*Tested ratings are level gate installations and does not take into account

inclined installations

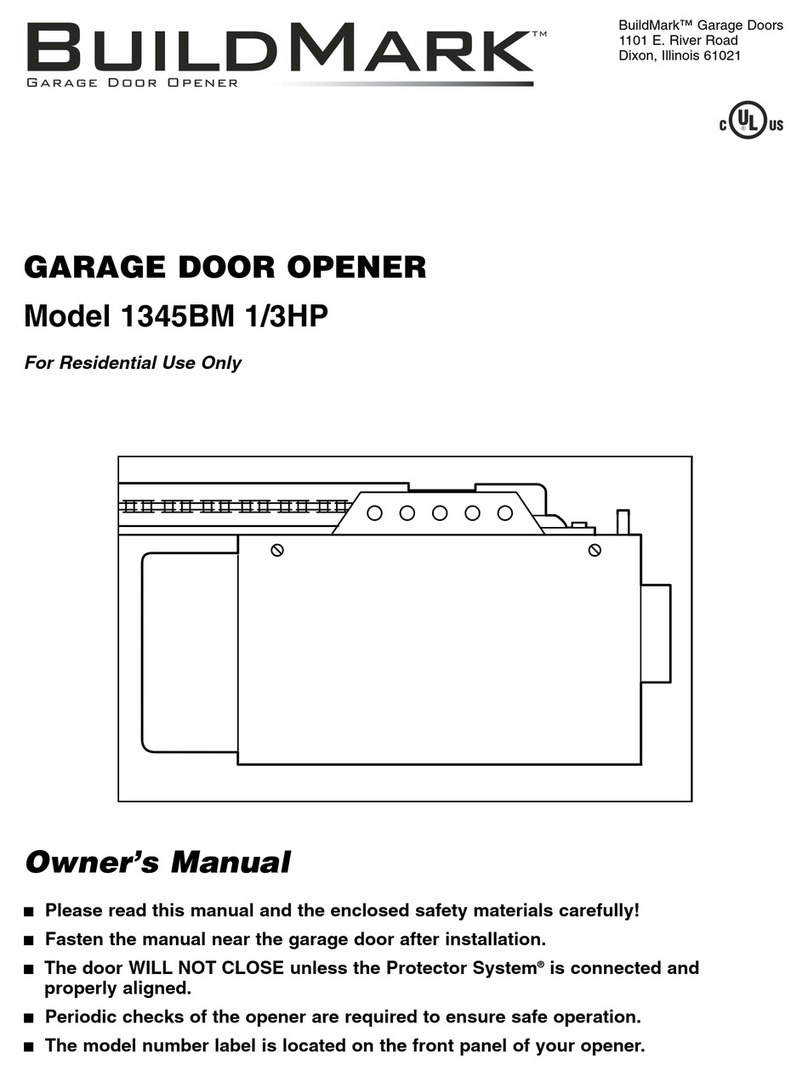

Page 2

Connect in WIRED accesories

Install gate motor, rack and limit

strikers

Turn on the Power Point

Connect Battery Backup (if

applicable)

Connect Solar System

Turn ON the load output on the solar

regulator

Configure applicable safety devices,

Photocell type, special detector and STOP

Test Safety Devices

Run the motor Test

Automatic Learning Cycle

Test system using a remote

Set the automatic closing timer (if

required)

Adjust SPEED, TIME and SENS

TROUBLESHOOTING

Set the correct direction by following the

troubleshooting

Pair remotes and wireless keypads

Set the gate operating Direction

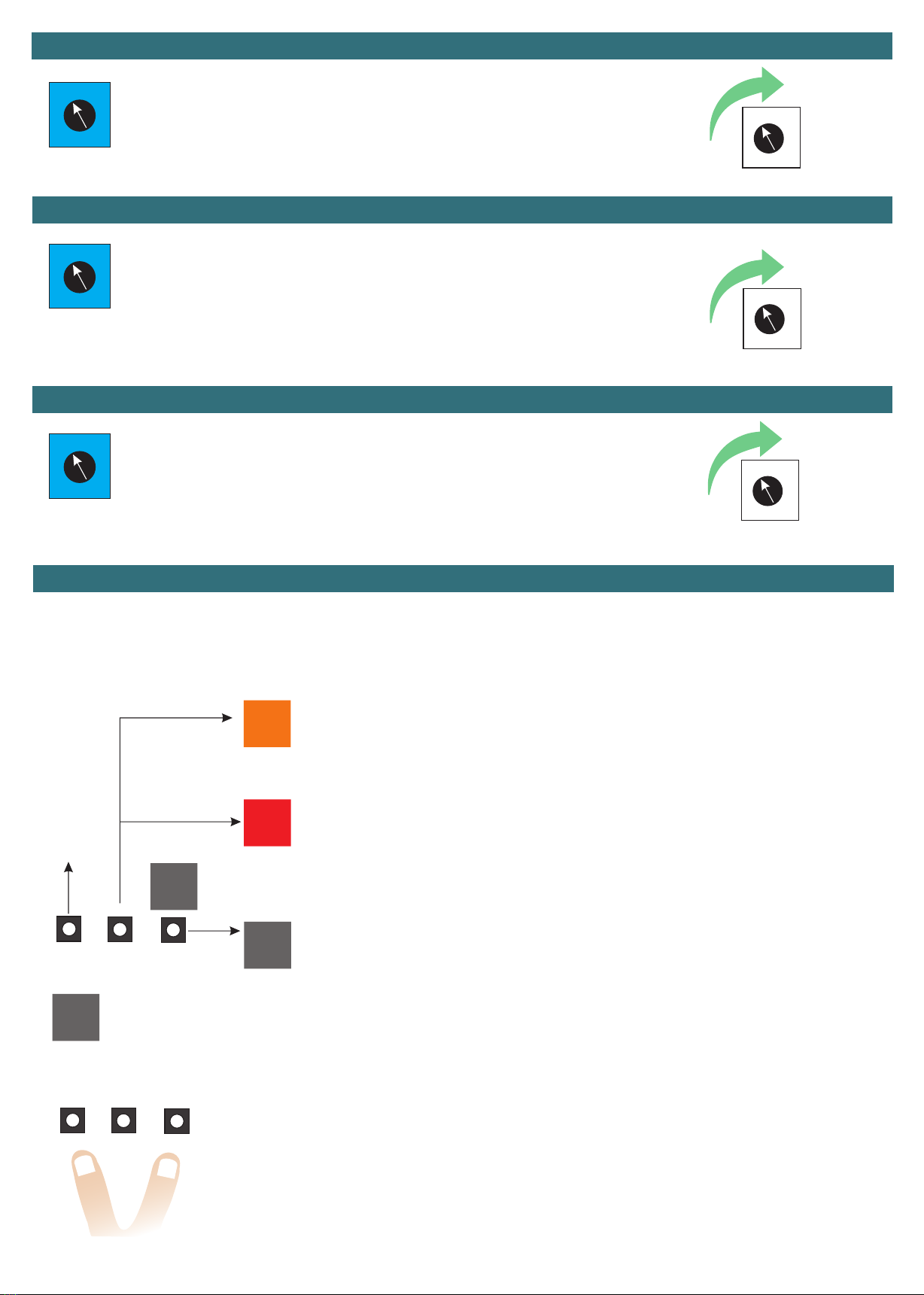

Step by Step Installation Guide

See accessories pages or there specific manuals

Remote’s are Pre-set

if purchased

with the system

Electric System Path Solar System Path

PAGE. 7

PAGE. 7

PAGE. 8

PAGE. 12

PAGE. 15

PAGE. 18

PAGE. 19

PAGE. 18

PAGE.9

PAGE. 17

PAGE. 20/PAGE. 21

PAGE. 20/PAGE. 21

To manually release (disengage clutch):

1. Slide the key cover UP

2. Insert the key (fits only one way into the cylinder) and turn the key clockwise.

3. Turn the lever one full turn clockwise (360°)

Gate can now be moved by hand.

To return to automated mode (engage clutch):

1. Turn the lever one full turn counter-clockwise (360°)

2. Insert the key (fits only one way into the cylinder) and turn the key counter-clockwise.

3. Slide the key cover DOWN

Gate cannot be moved by hand and is ready for automated use.

Manual Release

Page 3

L

C

F

D

G

M

H

N

O

I

A

Number

Accesory

Requirments

A

Gate Motor

Power by transformer or Solar

C

Entry Keypad

Dex 4 (wireless), All others wired to gate controller by 4 core cable

D

Exit Keypad

Dex 4 (wireless), All others wired to gate controller by 4 core cable

E

Gate Stop

Physically Mounted Hardware Item. Mandatory Stop to prevent accident or injury incase of

failure

F

Induction Loop

Housed inside gate controller with 1 core cable for the driveway loop

G

Photocell Transmitter

No cable required for Dukie+, Standard Dukie 2 core Cable to gate controller

H

Photocell Receiver

4 Core cable to gate controller

I

Gate Controller Power Source

Mains, Outdoor Transformer or Solar Panel to the Gate Controller

J

Meeting Point

Physically Mounted Hardware Item

K

Gate Top Guide

Physically Mounted Hardware Item

L

Ground Track

Physically Mounted Hardware Item

M

ADDITIONAL Photocell

Transmitter

Optional Additional Safety Device, No cable required for Dukie+, Standard Dukie 2 core

Cable to gate controller

N

ADDITIONAL Photocell

Receiver

Optional Additional Safety Device, 4 Core cable to gate controller

O

Automatic Light

2 core cable to gate controller

Optional Wireless Dukie+

Optional Wireless DEX 4

Optional Wireless DEX 4

Additional Safety Sensor M/N is optional

Optional Wireless Dukie+

FENCE FENCE

POST

GATE

POST

Installation Layout

E

K

J

Page 4

Step 1

Step 2

Step 3

Step 4

Identify the OPENING direction of your gate based on the illustrations below.

Gate opens to the LEFT or RIGHT is always made from the inside looking towards the street (outside).

Mark the centre of the mounting holes of the base plate, note the orientation of the large conduit entry hole.

The base plate should be positioned within 50mm from the support post/edge of the driveway.

The base plate is positioned 55mm away from the backside of the gate to achieve the correct base distance for the

limit switch spring and gear rack alignment. The motor distance can be fine tuned when installing to the base plate.

Drill the four fixing hole using a 10mm masonry drill, ensure that the holes are cleaned

thoroughly in preparation to install the dyna bolts.

Install the base plate ensuring it is stable, if unstable against the concrete (can tilt back and

forth) install with washers from the under side (with at least a 10mm ID) to achieve level.

The dyna bolt will slip through the base plate then the washer. Tighten the dyna bolts.

Install the gate motor to the metal base plate, ensure the front of the plate (side facing the

gate) is flush with the front of the gate motor.

RIGHT

HAND SIDE

OPENING

Final Travel

RIGHT HAND SIDE OPENING

LEFT

HAND SIDE

OPENING

Final Travel

LEFT HAND SIDE OPENING

Inside Property

Outside Outside

3.20 mm

50

mm

Edge of

support post/driveway

Conduit opening to the LEFT

50mm

5.92 mm

GATE

3.20 mm

50

mm

Edge of

support post/driveway

Conduit opening to the LEFT

50mm

5.92 mm

GATE

⌀10mm

Flush Faces

Motor Installation

titan 2410

Automation Systems

Australia

Page 5

Step 5

Step 6

Step 7

Step 8

Manually Release the gate motor and set the gate 250mm from the open position .

Sit a piece of gear rack on top of the motors pinion gear and level it according to the

gates current level (adjustable later), allow for a 2-3mm clearance (backlash) between

the top of the pinion tooth and the base of the gear rack.

Screw in the first piece of gear rack in place using self drilling metal screws in the

CENTRE of the elongated hole.

Slide in the next adjoining piece of gear rack and close the gate by hand til the pinion is

centred to the ne piece of gear rack that has been added, once again as per the

previous step the rack should be levelled according to the gates current level

(adjustable later), once again allow for a 2-3mm clearance (backlash) between the top of

the pinion tooth and the base of the gear rack.

Screw the piece of gear rack in place using self drilling metal screws in the CENTRE of

the elongated hole.

Repeat this step until the gate has gear rack installed across its entire length.

Install the TWO bolts to each striker plate.

OPEN the gate til 50mm before it touches the gate stop.

Install the striker plate to the gear rack THE SPRING SHOULD BE BENT to 45°, the

striker plate CLAMPS to the gear rack and does not require any holes to be drilled.

CLOSE the gate til 20mm before it touches the meeting points base.

Install the striker plate to the gear rack THE SPRING SHOULD BE BENT to 45°, the

striker plate CLAMPS to the gear rack and does not require any holes to be drilled.

Cut off any EXCESS gear rack using an angle grinder, ensure the motor cover is installed and the excess rack is in the furthest possible and safe

position away from the motor, cutting will produce sparks due to the racks steel core, ensure no stray sparks reach the gate motor to avoid damage.

Slip on the side covers on each side to cover the mounting bolts.

Move the gate to the half way point and engage the clutch and proceed to Motor Testing

Manually open and close the gate at a very slow speed, observe that the gear rack always retains the 2-3mm clearance backlash.

If the gate feels tight in certain areas most likely the backlash is less than advised, loosen the gear rack piece and adjust to correct then re-test.

If the gate feels loose in certain areas or the rack slips off the pinion most likely the backlash is greater than advised, loosen the gear rack piece and

adjust to correct then re-test.

Approx.

100mm

Base of gear

rack

to concrete

1 4 . 1 7 m m

Pinion

2-3 mm space between the

Top of Pinion Tooth

and the gear rack root

0 . 7 7 m m

Gate has travelled all the way to the right and has engaged the spring Gate has travelled all the way to the left and has engaged the spring

Page 6

Automation Systems

Australia

Premier SL24

SP

–-

99

Ec

dt

oP

Fo

PS

Pc

Eo

cL

Fc

.

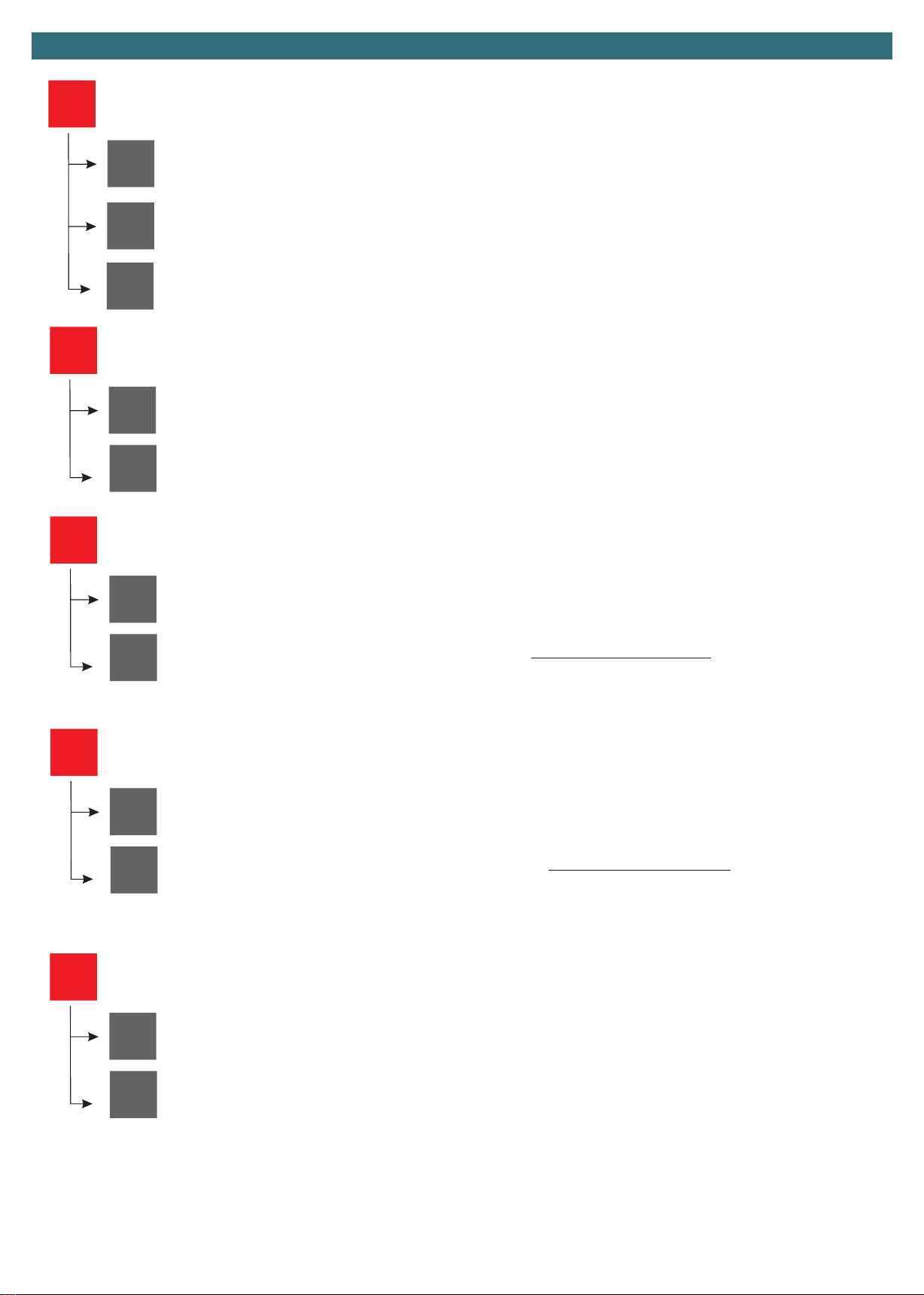

Display Screen Status

Controller Layout

Safety Status

General

Standby

Automatic Closing Timer

STOP Input Active

Photostop Input Active

(Special Detector)

Detector Input Active

(Special Detector)

Edge Input Active

(Opening Edge)

Edge Input Active

(Closing Edge)

Photocell Input Active

Opening

Fast Speed 0.5 Second Flash

Slow Speed 1 Second Flash

Full Open Position

Closing

Fast Speed 0.5 Second Flash

Slow Speed 1 Second Flash

Full Close Position

Battery Backup Mode

(Flashes)

UP

SPEED SENS TIME

MODE DOWN

8.8.

PD/CL

ST/OP

ANT

ANT

GND

COM

PS/DT

PT/EC

COM

LO

LC

SP/E0

COM

LPW

OUT 12V

LIGHT

Courtesy

Gate Open

RED GREEN C

M

PC

315

16 21

25

30 31

29

26 27 28

+

+

+

-

-

-

1

2

345678910 11 12 13 14 15

16 17 18 19

24

20

23

21

22

33

+

-

34

32

24V AC

DC - DC +

FUSE

32. 15A Fuse

33. Battery Terminal

34. 24V AC Input/ 24V DC Solar REGULATOR Input

16. +12V DC Accessories (ENERGY SAVER)

17. -12V DC Accessories (ENERGY SAVER)

18. Light Output + (Transformer voltage)

19. Lock Output -

20-21. Motor Terminal

15. Negative for Constant Accessories Output

14. Constant 12V Accessories Output (Regulated)

13. Limit Switch Common Blue

12. SP/E0 (Open Edge Device/STOP Input)

11. Limit Switch White

10. Limit Switch Black

9. COMMON to 8 & 12

8. PT/EC (Closing Edge Device)

7. Special Detector

6. Photocell Input (Configurable for N/O or N/C Circuit)

5. COMMON to 3,4,6 & 7

4. Pedestrian/Close Input (N/O Circuit)

3. Start/Open Input (N/O Circuit)- Set by operating logic

25. Digital Display

26. UP Button

27. MODE/OK Button

28. DOWN Button

2. ANT GND

1. Antenna

22. Red Light Relay (3A Max)

23. Green Light /Courtesy Relay (3A Max)

24. RELAY COMMON

29. Slow Speed Adjustment (SPEED)

30. Obstacle Detect Adjustment (SENS)

31. Slow Speed Travel Time (TIME)

St

oP

Pd

cL

Operating Input Status

Start Input Active

Open Input Active

Pedestrian Input Active

Close Input Active

Operating Logic

Operating Logic

Operating Logic

Operating Logic

St At

St At

oc oA cd

oc oA cd

Page 7

A standalone solar system is a totally off grid solution used for green energy initiatives or simply when its not possible to run power to the

gate system. To conserve power constant power draw devices such as wired keypads are not to be used, the alternative is a wireless

keypad as they use there own batteries.

+

-

Controller

CERO Standalone Solar System Connection

+

-

24V AC

BATT DC - DC +

Shelf Lower

Position

+

+

-

-

Link Wire

Link Wire

B1

B1

B2

B2

1. A solar panel CANNOT be installed under a tree, it

requires sun to charge and maintain the batteries.

2. A solar system is often maintenance free BUT the

batteries may require a external charge in the winter

months due to lack of sun (rare).

3. Constantly powered accessories such as wired keypads

will increase the standby current draw, solar panel or

battery upgrades may be required if sufficient collection is

not achieved.

Solar

Panel

Battery

System

Load

Output

+++

---

MENU SET

Multiple Panels in Parallel

Solar

Panel

+-

17aH Battery System

+

+

-

-

Battery

System

+-

Link Wire

Link Wire

Solar

Panel

Battery

System

Load

Output

+++

---

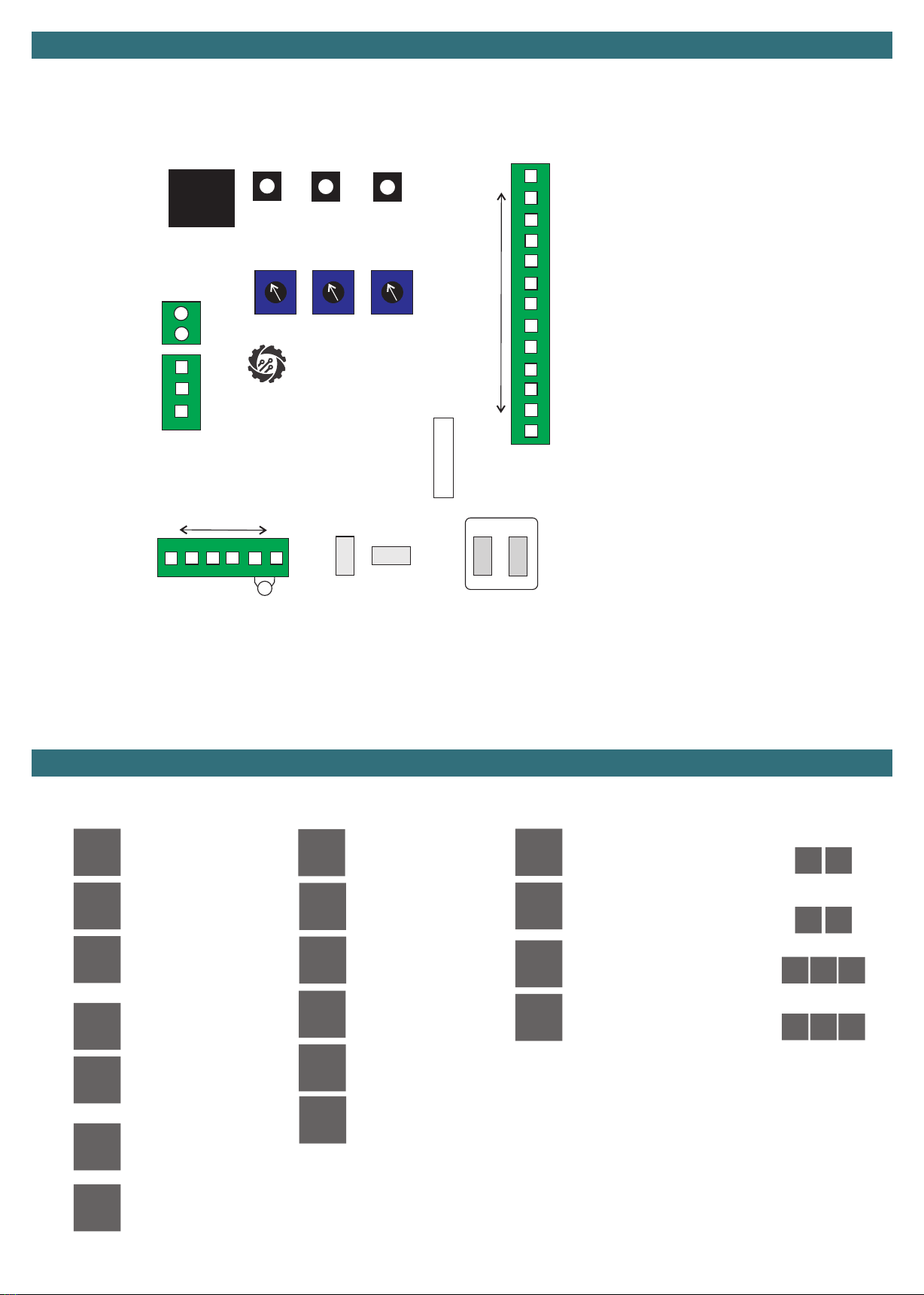

Page 8

+

-

24V AC

BATT DC - DC +

+

+

-

-

Transformer BLUE Low Voltage Common

Transformer BROWN LOWER OUTPUT

(LOW VOLTAGE)

Transformer GREEN HIGHER OUTPUT

(LOW VOLTAGE)

The battery backup will allow for uninterrupted usage in case of a power disruption. The battery backup system can operate the gate for

a period of 24 to 36 hours during the power disruption. Once the power is restored the system will automatically recharge the battery

system ready for the next use.

Note: When in battery backup mode the slowdown is disabled automatically to overcome any difference in speed.

The transformer on a mains powered system is the primary source of power, it takes the high voltage input and transforms to low voltage

which is connected to the controller. By default the controller uses the lower of the two outputs (brown wire) which is typically suggested

for most gate installs however incase required due to gate forces it would be suggested to swap the lower output (brown wire) for the

higher output (green wire).

HIGH VOLTAGE

LN

Battery Backup Connection

Battery Pack SLA Batteries

Multi Output Toroidal Transformer (Internal)

To connect the battery backup simply plug the

two pin connector in the correct orientation

into the battery port on the controller.

To connect the battery backup plug in the spade

connectors according to the above illustration then

plug the two pin connector in the correct

orientation into the battery port on the controller.

LINK

+

+

-

-

24V AC

24V AC

BATT

BATT

DC -

DC -

DC +

DC +

Where a power point is not available at the gate the Outdoor Transformer is used as the primary source of power, it takes the high

voltage input and transforms to low voltage which is connected to the controller through the low voltage extension cable for a maximum

distance of 120 metres.

Outdoor Low Voltage Weatherproof Transformer

Junction Box

Outdoor

Transformer

LOW VOLTAGE

Extension

Cable

Page 9

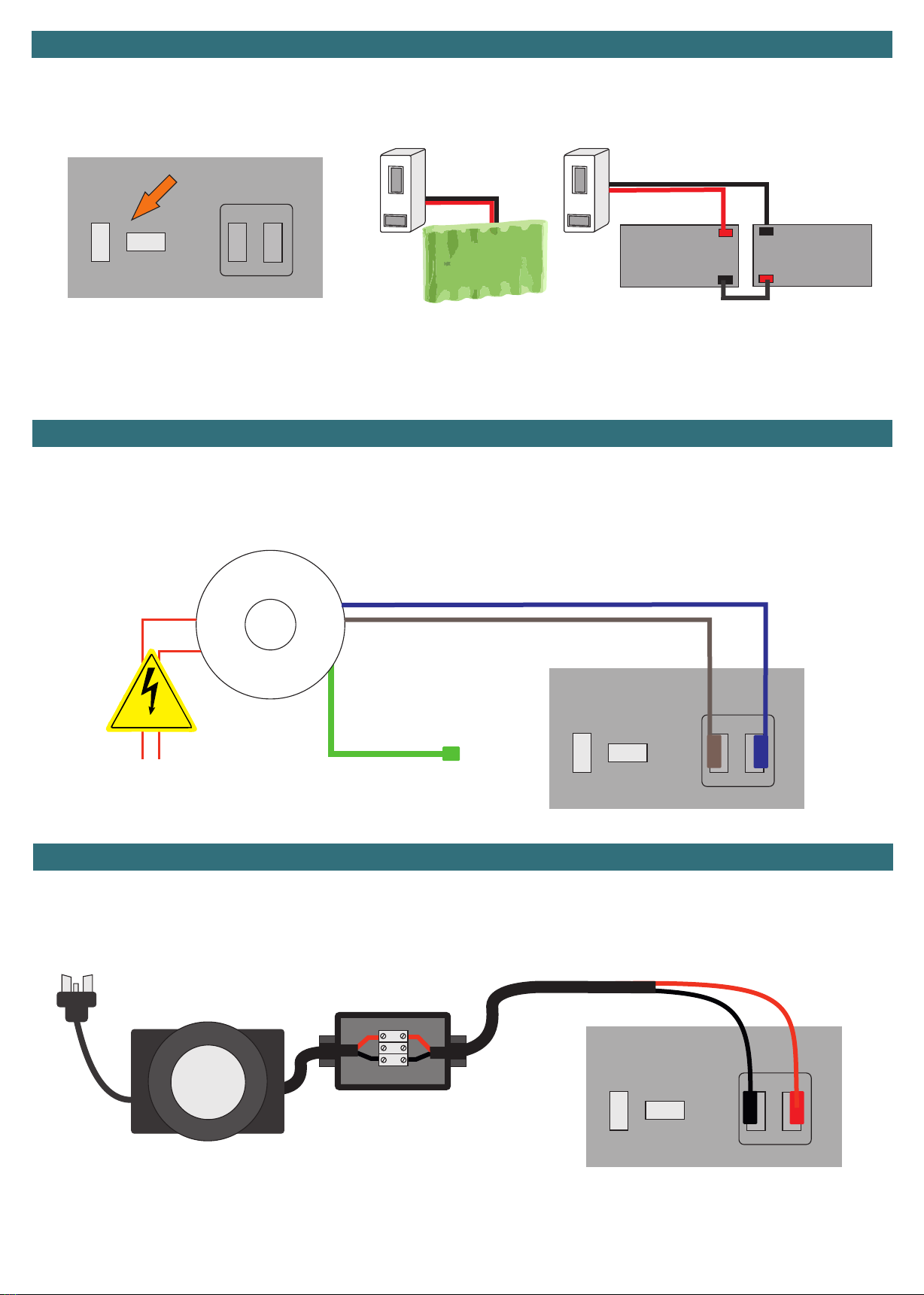

SPEED

SPEED

SENS

TIME

SENS

TIME

The “SPEED” Trim pot is the slow speed trimmer allowing a fine tuning of the SLOW Speed

portion of the operating cycle, Typically adjustment range is 20% to 50% from the

slowest speed (minimum) depending on gate size, weight and inertia.

Slowest Speed

Most Sensitive

(Least Push)

Later Slow

Down Point

Fastest Speed

Least Sensitive

(Most Push)

Earlier Slow

Down Point

The “SENS” Trim pot is the pressure sensing adjustment before the controller

recognises cut-off. Gate and Environmental factors will determine how high or low to

adjust based on gate weight and the required power to operate the motor.

Setting too high will affect how quickly the controller will shut off under load or

accident. setting too low can cause the controller to shut off too early (too sensitive)

and cause intermittent operations.

The “TIME” Trim pot is the adjustment in where the controller introduces the slow

down speed. A TOO late position may cause the gate to stop more abruptly as it

has not had enough time to decrease the speed of movement.

A TOO early position may cause difficulties in overcoming resistance points within

the sliding moment of the gate and also creates a slower operating cycle time which

may be undesirable.

“SPEED” Slow Speed/De-acceleration Adjustment

“SENS” Obstuction/Overcurrent Adjustment

“TIME” Slow Down Position Adjustment

–-

c 1

EH

tN

oL

UP

UP

MODE

MODE

DOWN

DOWN

FROM STANDBY Press MODE Once to reach the Base Menu

Contains Logic Setting, Automatic Closing Time Setting , Learning Times and Remote Learning

(See Pages 10 and 11)

FROM STANDBY HOLD MODE for FOUR SECONDS to reach the CORE Menu Contains Primary

Adjustments for operation and configuration

(See Pages 12,13 and 14 )

FROM STANDBY Press Down, this is a shortcut to Remote Learning

Complete Remote Learning and Deleting can be reached through the Base Menu

EXIT will take you back one level

From preliminary menus it will return to standby

From any setting menu it will cancel the change and return you to the preliminary menu

If in a setting adjustment and you wish to cancel press UP and DOWN together momentarily to return back

one level.

If in a preliminary menu it will function the same as scrolling to exit.

Press MODE

Press

Down

HOLD

UP

Hold MODE

Preliminary Menu (BASIC)

Preliminary Menu (CORE)

STANDBY

Remote

Learning

Shortcut

Automatic

Learning

Shortcut

System Menu Hierarchy

Throughout the manual to simplify identification the two preliminary menus will be displayed with a coloured background as illustrated

below, any sub-menus and exit will be displayed with a grey background.

Page 10

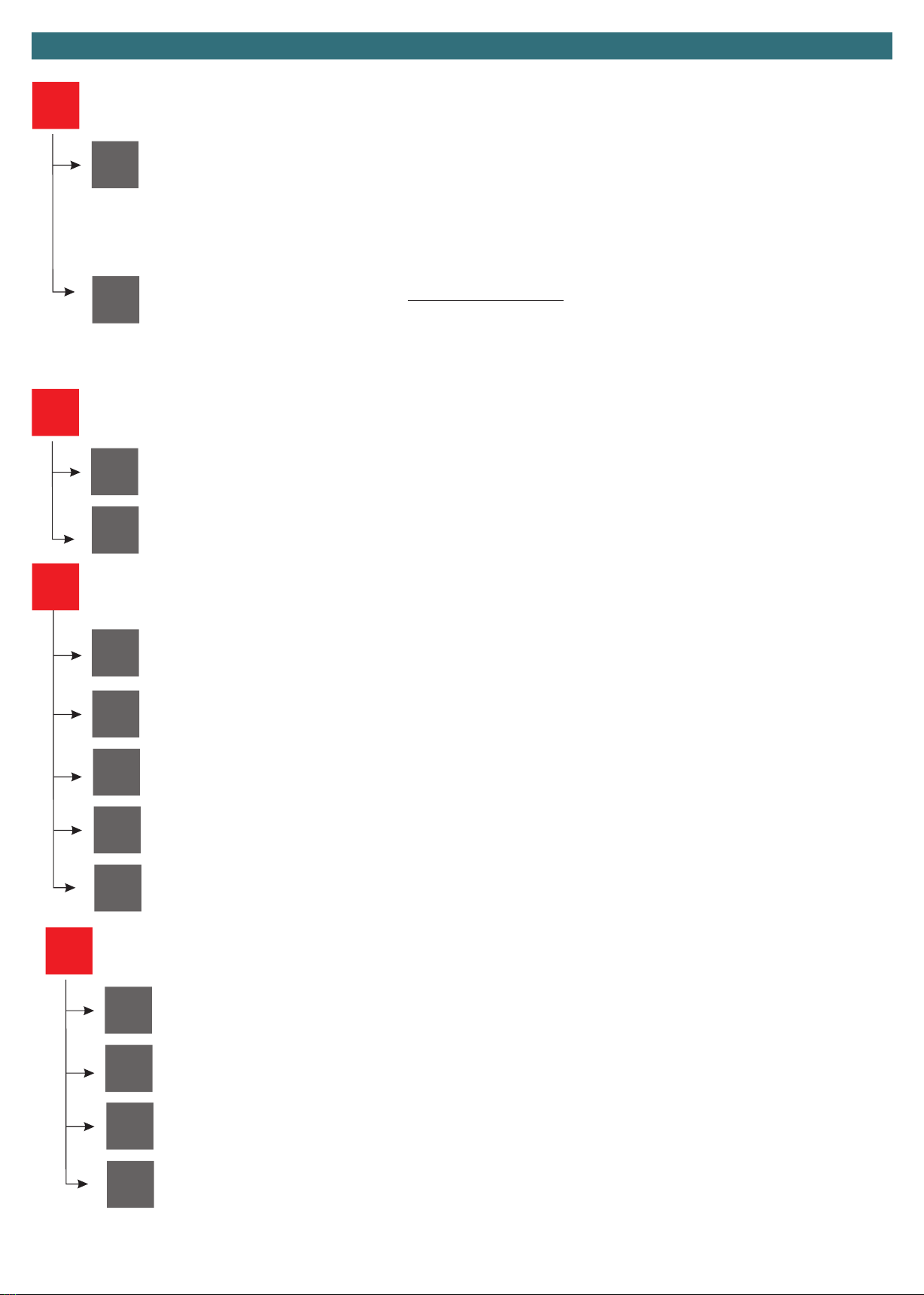

oL

St

At

oc

oA

cd

Setting the system Operating Logic (Default Standard)

Standard

Operates OPEN/CLOSE by remote and/or wired-wireless accessories

Standard WITH Automatic Closing Timer Adjust the Automatic Closing Timer in SP menu

Operates OPEN remote and/or Wireless Accessories with an automatic closing timer (can still

be closed earlier by remote and/or wired-wireless accessories)

Timer can be cancelled using the STOP feature

Typical Complex

Operates OPEN/CLOSE by remote and/or wired-wireless accessories with the WIRED input

terminals switching to loop detector mode OPEN Terminal and CLOSE Terminal

Typical Complex WITH Automatic Closing Timer Adjust the Automatic Closing Timer in SP menu

Operates OPEN/CLOSE by remote and/or wired-wireless accessories with the WIRED input

terminals switching to loop detector mode OPEN Terminal and CLOSE Terminal along with an

automatic closing timer (can still be closed earlier by remote and/or wired-wireless accessories)

Timer can be cancelled using the STOP feature

Secure Complex Mode WITH Automatic Closing Adjust the Automatic Closing Timer in SP menu

Ignores additional commands during opening, automatic closing by the adjustable timer ONLY,

no other methods to close

Basic Menu

OPEN

OPEN

/STOP/

CLOSE

OPEN

OPEN

N/A

Ped. OPEN

/STOP/

CLOSE

CLOSE

CLOSE

Driveway

Light

Driveway

Light

Driveway

Light

Driveway

Light

Cancel Automatic Closing Timer

Stop/Cancel Automatic Closing Timer

Stop

Stop/Cancel Automatic Closing Timer

Lc

c 1 c3

c2 c4

Remote Channels

oc

oA

cd

Operating Logic

St At

oL

OPEN

OPEN

OPEN

OPEN

/STOP/

CLOSE

Ped. OPEN

/STOP/

CLOSE

CLOSE

CLOSE

N/A

Terminal 4

(PD/CL)

Wired Input Terminals

Terminal 3

(ST/OP)

“OPEN” only commands always restart an automatic closing timer (if applicable).

any “STOP” command by remote control always cancels the automatic closing timer (if applicable).

any “CLOSE” command will bypass the automatic closing timer (if applicable) and close the gate.

Page 11

Lt Learn Working Times Starts the learning procedure

dN

EH

o1

c1

Motor Test (operate gates manually)

Exit the menu

Opens the gate

Hold MODE to Operate

Closes the gate

Hold MODE to Operate

Basic Menu continued

FS Fast Speed Level (Default 10 ) 1 0 Sets the fast speed Percentage of input voltage

(slow speed adjustment is by Trim Pot)

03= Minimum (30%)

10= Maximum (100%)

Lc

SP Automatic Closing Time (Default 10 seconds)

c 1

99

c2

rt

c3

rn

c4

ra

Remote and Wireless Keypad Learning/Deleting

Detailed Page 15 & 17,

C1 Command

C2 Command

Delete WITH the wireless component present

Driveway Light Command Learning

Delete by memory position

STOP Command Learning

Delete the entire memory (format)

Only valid when using an OPERATION LOGIC oL that uses automatic closing

01= Immediate Close

2-299= Delayed automatic Closing Time by the set value in Seconds

Page 12

tN

Gd

t1

rh

Lf

tc

tp

Manual Adjustment of Working Time Menu (fine tuning of times)

Gate Direction (Default Right Hand Opening)

Full Operation Working Time of Motor

Right Hand Opening

Left Hand Opening

Courtesy Light Time

(In multipliers of 10, eg. 01=10 Seconds, 60=600 Seconds)

Pedestrian Working Time

Core Menu

Pc

nc

no

Sets the controller to accept NORMALLY CLOSED photocell

Sets the controller to accept NORMALLY OPEN photocell OR NO PHOTOCELL CONNECTED

Photocell Input

SP

nc

no

Sets the controller to accept NORMALLY CLOSED Stop Button

Sets the controller to accept NORMALLY OPEN Stop Button OR NO STOP Button CONNECTED

STOP Button Input

LS

nc

no

Sets the controller to accept NORMALLY CLOSED limit switches

Sets the controller to accept NORMALLY OPEN limit switches

Limit Switch Polarity

Page 13

Eo

Ec

dS

SP

dS

no

no

nc

nc

An

An

Disabled

Stop Button Input mode (set stop button N/O or N/C by the SP menu.

Disabled

Normally Open Circuit

Normally Open Circuit

Normally Closed Circuit

Normally Closed Circuit

Analogue Edge with 8K2 Resistance

Analogue Edge with 8K2 Resistance

Opening Safety Edge Input (Default ds)

Closing Safety Edge Input (Default ds)

Core Menu continued

SF

PS

dt

Photostop Mode (Normally Closed Circuit)

Similar to a typical photocell input but also incorporates the opening cycle.

1. During opening it will pause gate till clear

2. During auto close it will restart the timer

3. During close it will stop the gates and re-open

4. Whilst closed it will inhibit the operation of opening until clear again

Detector Mode (Normally Open Circuit) OR NO SENSOR CONNECTED

Used to signal the system that the gate has been used and is ready to close.

1. If detected whilst opening it will finish the opening then IMMEDIATELY close

2. Whilst closing it will re-open gate then IMMEDIATELY close the gate

3. Whilst open it will tell the gate to close

Special Detector Input (Default dt)

SS

YS

nt

Instead of starting motor(s) at full speed the operation begins at a reduced speed then ramps to full speed

Feature is disabled

Soft Start

Page 14

rN

NN

1 b

YS

4b

nt

One Button Mode for Open-Stop Close and Another Button for Pedestrian Open-Stop-Close

STRONGLY RECOMENDED

Enables the manned deport mode, the operator presses the button according to the allowed quantity of vehicles

to pass through, the system uses a photocell to count the vehicles then will automatically close the gate.

Four Button Layout

Normal Operation

Receiver Mode (1 Button/4 Button Receiver Mode) (Default 1b)

Manned Depot Mode (only suitable for NON automatic closing Logics)

Core Menu continued

bL

LH

YS

cr

nt

oG

Gr

Flashing illumination ON/OFF during the cycle

Driveway light output, set in working time (operates by individual remote button and also gate operation button),

(Green and Common terminals)

Static illumination during the cycle

Strobe light output, is on in all statuses except closed (Green and Common terminals)

Traffic Light Mode

Green and Common terminals when gate is in the open position

Red and Common terminals all other times

Light Output Mode

Auxiliary Light System Mode

d2

So

YS

YS

nt

nt

Factory Default the Settings

Full-time Photocell and Photostop Check / Only Vitals (Solar Mode)

Restore to Factory Default (Wireless memory is not affected)

Check photocell/photostop Inputs before beginning and during the

cycles. N/C Logics Only

Cancel without change

Check photocell/Photostop Inputs at all times including standby. N/C

and N/O Logics

Page 15

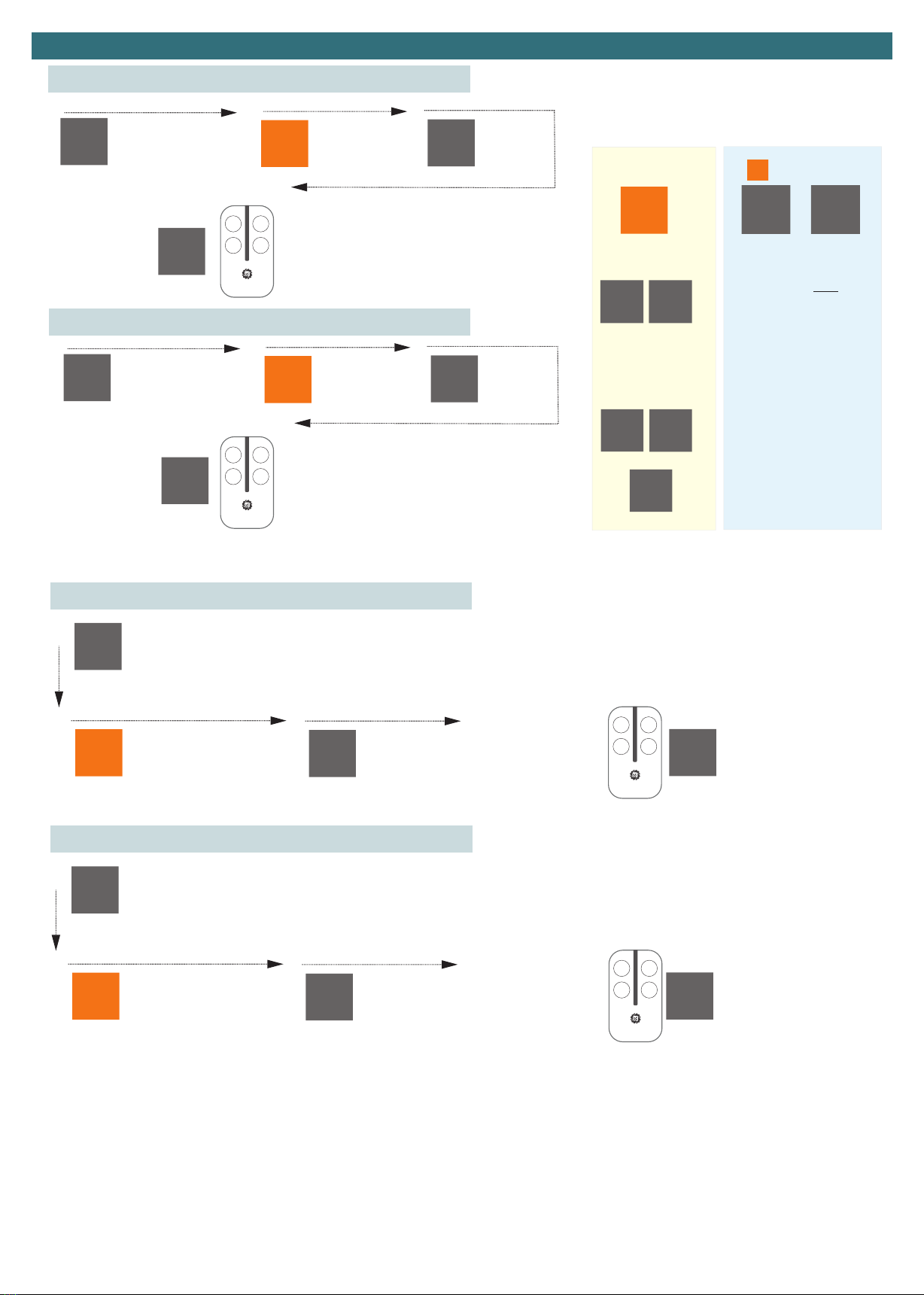

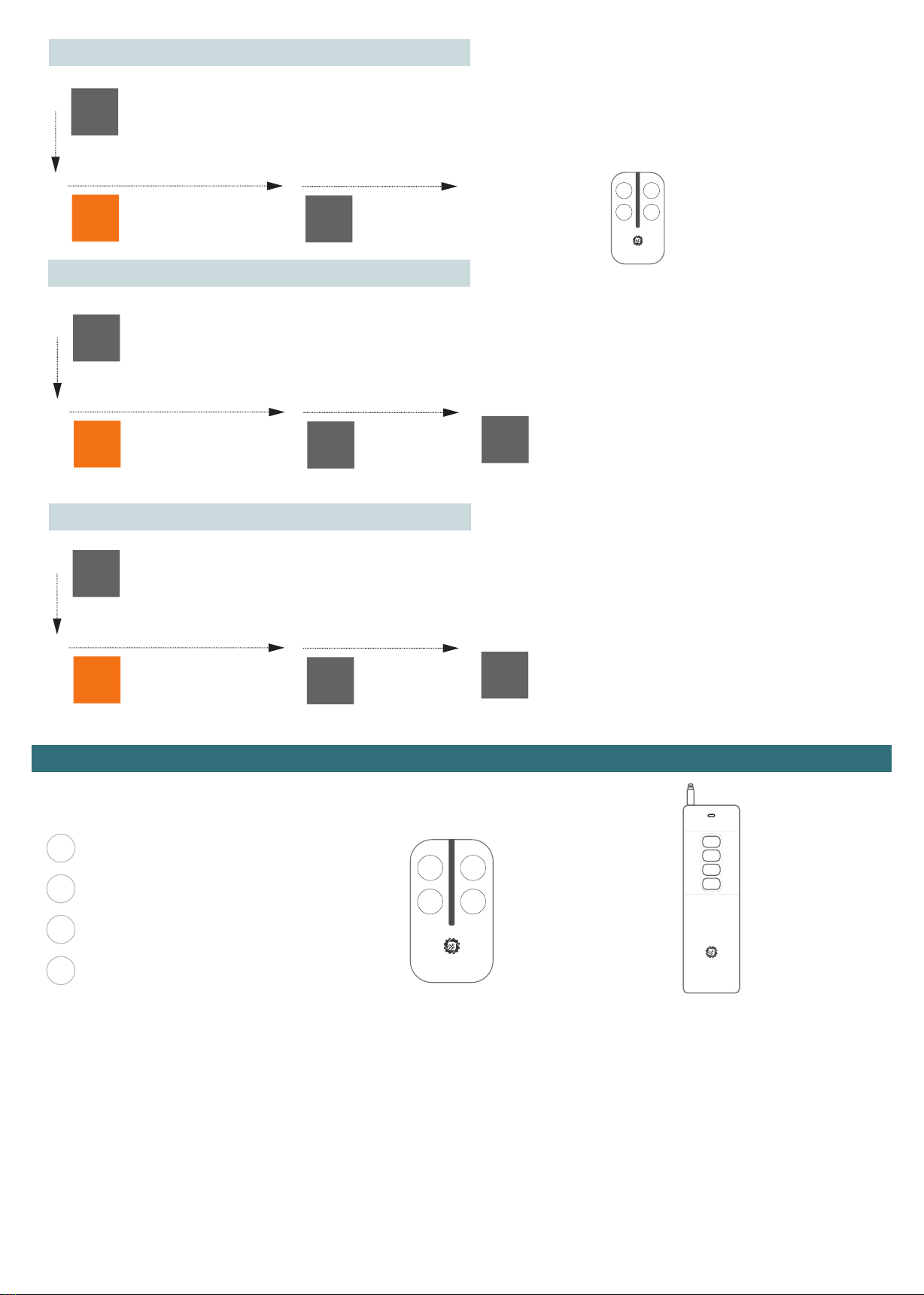

Remote Learning

From the standby screen

press the MODE button

once

From the standby screen

press the MODE button

once

Cycle to Lc and press

MODE

Cycle to Lc and press

MODE

Cycle to c3

Cycle to c4

The display will also show

you the enrolled position it

has been stored in the

memory, this can be noted

incase you wish to delete a

specific remote later.

The display will also show

you the enrolled position it

has been stored in the

memory, this can be noted

incase you wish to delete a

specific remote later.

Press the button you

wish to use on the

remote

Press the button you

wish to use on the

remote

–-

–-

Lc

Lc

c3

c4

9

12

1

1

2

2

3

3

4

4

C3 Driveway Light Learning

C4 Remote STOP command Learning

From the standby

screen press the SET

button once

From the standby

screen press the SET

button once

Cycle to Lc and

press SET

Cycle to Lc and

press SET

Cycle to c 1

Cycle to c 2

The display will also show you the enrolled position

it has been stored in the memory, this can be

noted incase you wish to delete a specific remote

later.

The display will also show you the enrolled position

it has been stored in the memory, this can be

noted incase you wish to delete a specific remote

later.

Press the button you wish to use on the remote

Press the button you wish to use on the remote

–-

–-

Lc

Lc

c1

c2

3

6

1

1

2

2

3

3

4

4

C1 Command Learning

C2 Command Learning

OPEN

OPEN

/STOP/

CLOSE

OPEN

N/A

Ped. OPEN

/STOP/

CLOSE

CLOSE

Lc

c 1 c2

Remote

Channels

oc oA

cd

Operating Logic

St At

oL

Residential

Commercial &

Industrial

Automation Systems

Australia

B

D

A

C

Automation Systems

Australia

B

D

A

C

Automation Systems

Australia

B

D

A

C

Automation Systems

Australia

B

D

A

C

Page 16

From the standby screen

press the MODE button

once

From the standby screen

press the MODE button

once

From the standby screen

press the MODE button

once

Cycle to Lc and press

MODE

Cycle to Lc and press

MODE

Cycle to Lc and press

MODE

Cycle to rn and

press MODE

Cycle to rA and

press MODE

Cycle to rt

Cycle to the enrolment

number you wish to delete

and press MODE

Cycle to YS and press MODE

to confirm deleting all

remotes

OR

Cycle to nt to cancel

Press the button on the

remote you wish to

delete

–-

–-

–-

Lc

Lc

Lc

rn

rA

rt

04

YS

1

1

1

2

2

2

3

3

3

4

4

4

Delete by remote button

Delete by enrollment number

Delete entire memory

COperate a garage door, driveway light etc.

BOperate Pedestrian Open - Stop - Close

(also stops the automatic closing timer if pressed during the countdown)

AOperate this Gate Open - Stop - Close

(also stops the automatic closing timer if pressed during the countdown)

DOperate another Gate Open - Stop - Close

(also stops the automatic closing timer if pressed during the countdown)

Remote Usage

Automation Systems

Australia

A

B

C

D

Maximum Clear Line

of Sight 800 Metres

Operating Distance

STX4L

Automation Systems

Australia

B

D

A

C

Maximum Clear Line

of Sight 100 Metres

Operating Distance

STX4K

Automation Systems

Australia

B

D

A

C

Page 17

Automation Systems

Australia

B

D

A

C

Identify the enrollment Number

Wireless Keypad Learning

From the standby Screen press each button on the remote INDIVIDUALLY, the number displayed on the screen upon each button press is

the enrollment number, one remote MAY have multiple enrollment numbers based on the paired features

–- –-

05 06

Button is enrolled as

05

Button is enrolled as

06

No Response, Not

Enrolled

No Response, Not

Enrolled

From the standby screen

press the MODE button

once

From the standby screen

press the MODE button

once

Cycle to Lc and press

MODE

Cycle to Lc and press

MODE

Cycle to c 1

Cycle to c2

The display will also show

you the enrolled position it

has been stored in the

memory, this can be noted

incase you wish to delete a

specific remote later.

The easist way to pair a keypad is to take it to the gate controller BEFORE installing onto the post or fence. The installation steps below

detail the procedure using the default codes. It is suggested to change the codes AFTER completing the procedure and testing using

the default code.

Default code 1111= Channel 1 of Keypad, Default code 2222= Channel 2 of Keypad

The display will also show

you the enrolled position it

has been stored in the

memory, this can be noted

incase you wish to delete a

specific remote later.

Type 1111

Type 2222

–-

–-

Lc

Lc

c1

c2

1 1

12

1

1

2

2

3

3

4

4

Operation Command Learning

Pedestrian Gate

From the standby screen

press the MODE button

once

Cycle to oL and

press MODE

For residential homes

select At

For apartments,

complexes, industrial

see Operating Logic

Options Page 10

To set the time cycle to SP

01= Immediate Close

2-299= Delayed automatic

Closing Time by the set value in

Seconds

DEFAULT IS 10 Seconds

once complete

cycle to EH to

return to standby

–-

oL At

1

2345

SP EH

Setting the Automatic Close Timer

Display example up to 99 Seconds Display example GREATER than 99

Seconds and up to 199 Seconds

Display example GREATER than 199

Seconds and up to 299 Seconds

9.9.

99.

99

Page 18

From the standby screen

press the MODE button

once

Cycle to dn and press MODE

Cycle to o1 and HOLD MODE, whilst holding set it will OPEN and It will

stop on the limit switch, release the MODE Button.

* IF the gate does NOT stop on the limit switch, or too early see “Troubleshooting LS” below.

*If the gate Closes instead of Opening see “Troubleshooting MP” below.

Cycle to c2 and

HOLD set, whilst holding set it will CLOSE and It will

stop on the limit switch, release the MODE Button.

IF the gate does NOT stop on the limit switch see

“Troubleshooting LS” below.

Cycle to EH to return to

previous menu

–- dn

o2 c2

EH

1

34

2

The purpose of motor testing is to identify the correct operating procedure before the time travel calibration. The information that can be gained from

the motor test is if the motors are wired:

a) Correct polarity meaning they operate in the correct direction according to the control board.

b)The limit switches have been correctly set for the OPEN and CLOSED position. This test can be repeated an unlimited amount til all is set correctly.

Troubleshooting MP

If the gate(s) close whilst using the open feature this is easily resolved and must be rectified prior to moving forward.

1. Return to Standby

2. Go to the Advanced Menu

3. go to Gd Gate Direction Menu

4. Select the appropriate Direction being rh for Right Hand Opening and LH for Left hand opening

5. Restart the Motor testing procedure

Troubleshooting LS

If the gate(s) travel past the desired stop point OR stops too early the limit switch stiker is mis-configured and will need to be adjusted/set.

1. Confirm which of the limit switch metal striker plates is not set correctly (open limit/close limit)

2. Adjust /install the relevant limit switch striker.

NOTE: Safety Inputs are disabled during this stage

Motor Test Mode

Table of contents