OSHIMA OB-700 User manual

-

1

-

欢迎使用“欧西玛”带状式裁剪机

Thank you for choosing “OSHIMA”BAND KNIFE CUTTING MACHINE

使用前,请详阅

BEFORE using,PLEASE READ CAREFULLY

OB-700 OB-700A OB-700EA

OB-900 OB-900A OB-900EA

OB-1200 OB-1200A OB-1200EA

使用说明书

OPERATING MANUAL

-

2

-

1.(

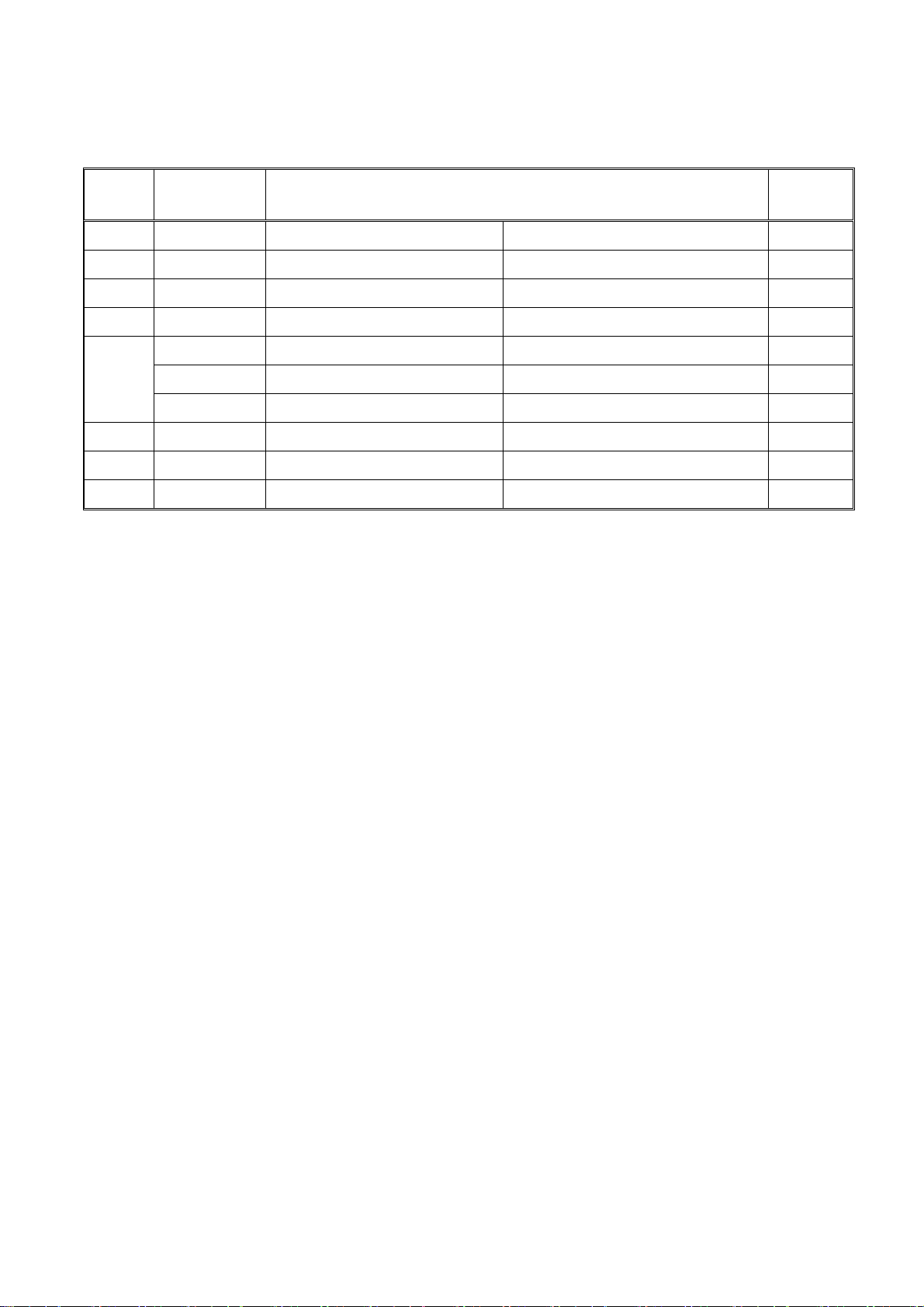

SPECIFICATIONS)

Model

OB-700/EA OB-700A/I OB-900/EA OB-900A/I OB-1200/EA OB-1200A/I

Power

3P/380V 1P/220V 3P/380V 1P/220V 3P/380V 1P/220V

Table Size

1200*1500mm 1500*1800 mm 1500*2400 mm

Cutting Capacity

180mm 180mm 280mm

Arm Length

700mm 900mm 1200mm

Knife Size

0.45*10* 3500 mm 0.45*10*3860mm 0.45*10*4560 mm

Net Weight

265kg 285kg 320kg

Packing volume

1500*700*1700mm 1600*700*1700mm 1920*800*1800mm

2.OPERATING METHOD

1.1 Connect to correct voltage.

1.2 Machine must do the horizontal adjustment and equip knife with right angle against to

surface of table.

1.3 Press down “ON” of “KNIFE”, and then knife will work automatically. Press down

“ON” of air, and then the wind will blow out from table.

1.4 There are two sets of oil tanks inside machine. Please inject silicon oil when oil runs out.

1.5 Knife should be grinded once it can’t cut fabric smoothly. Machine attaches grinder, so

knife will be edgy after grinding just need to push the holder of grinder.

1.6 All bearings must be injected “oil” every half a year to reduce the noise and increase

bearings’ lives.

1.7 There are blowing holes on the table. Please always keep them clear to avoid stemming

and influencing the power of blower.

1.8 Please adjust the knife applicably when replace a new knife. Don’t adjust the knife too

loose or too tight.

3.CAUTION

a) Please wipe the oil on the knife when you install the knife. The oil on the knife is for

rustproof purpose.

b) Please take the tape off. The parts No for the tape on the driving pulley is NO.700A006

4.NOTES FOR USAGE & MAINTENANCE

a) Please operate the touch panel gently.

b) Please keep the oil tank clean and fuel all the time.

c) When the band is not sharpened, please use the grinding device to sharpen the band.

d) When grinding stone is worn out, please adjust the lever to keep the two pieces of

-

3

-

grinding stones work evenly.

e) Please always keep the machine and its parts clean (such as: electronic components,

blower, and bearings ) and fuel them.

f) Once the knife band is worn out, please replace to prevent from danger.

g) After moving and installing machine, please do keep machine in horizontal.

h) Please do not replace any parts of the machine, and do leave the maintenance to

professional technician.

i) Before operating, please do read the instruction manual.

【B】ASSEMBLY

1Assembly of frame (see fig.3).

Mount the upper frame (1) on the lower frame (2). Tighten the two positioning bolts (1-1)

first and other bolts next. Remove the tension pull cover (18). Attach the lower knife

cover (20) to the lower frame

(2) and the rear tension

pulley cover (18-1).

(Caution)

Tighten the upper and lower

frame joining bolts positively.

Otherwise, vibration may be

caused.

2Assembly of table (see fig. 4

and 5.)

Mount the cutting table (3)

by aligning the tapped holes

of the table liners (3-1) with

the table fastening screw

holes (3-2). Fasten the table

(3) with the bolts (3-3). Slip

the blower hose (11-1) onto

the air mouthpiece (3-4) and

fasten the hose with a hose clamp. Attach the switch box (8) to the cutting table (3). Plug

the connector of the control cable (25) into the control panel (9) and fasten the plug with

the screw (25-1). (The screw is supplied by attaching it to the control panel.)

-

4

-

3Assembly of knife (see fig.6.7.and

8.)

A new knife is coiled. Uncoil the knife carefully.

Install the knife to the pulley (B) and hold the knife on the pulley

with the knife clip. Install the knife similarly on the pulley (C).

4 Finally install the knife on the pulley (A). Turn the tension

handle (14) till stopper screw comes into contact with metal

plate (2) to stretch the knife. On completion of stretching,

remove the knife clips and turn the pulleys by hand.

The knife will be naturally settled in the middle of the pulleys.

(Caution)

Disconnect the power supply plug for safety prior to installing

the knife. It is recommended to put on stainless

steel mesh gloves (safety gloves) for installing

the knife.

5Assembly of grinder (see fig. 9)

Set the grinding stone grit tray (6-7) to the

grinder cover.

Slip the grinder unit (7) onto the shaft

(7-3) and push the unit inwards till it

comes into contact with the

positioning collar (7-4).

Align the point of the knob (7-1) with

the V-groove of the shaft (7-3) and

screw in the knob.

Screw in the wing screw (7-2) too.

Finally attach the front cover (7-5).

-

5

-

6Securing cutter frame (see fig.10)

Carry the frame to the cutting shop. Set the frame to a desired operating height with the

adjusting screw (21). Lock the position with the nuts (21-1) attaching the table legs (4) to

the underside of the table (3) with screws.

Turn and lower the table support screws (4-1) till they come into contact with the sole

plates (22).

Lock the screws (4-1) with the nuts

(Caution)

If the table support screws are turned down excessively, the cutting table and the cutter

frame are raised. Do not turn the screws

excessively.

【C】SWITCH FUNCTIONS

7. Switch box (see fig.11.)

Power supply switch: turns on and off the entire

power supply of the band knife cutter.

Blower switch: Turns on and off

the blower.

8. Control panel (see fig.12.)

Speed indicator: Indicates knife

speed. (Unit: m/min) The display

lights up indicating knife speed

during the running of the knife,

and flashes during at rest.

Up/down key: Change knife

speed. Continue to press for

changing speed at a high rate.

Speed can be changed regardless

of whether the knife is running or

at rest.

Start key: Starts up the knife.

Stop key: Stop the knife.

(Caution)

To stop the knife: must use the

stop key on the control panel (9).

If the knife is stopped when

power off, push button on the

switch box (8). Failure of the

inverter may be caused.

-

6

-

【D】CUTTING OPERATION

9. Cutting (see fig.13.)

Switch on the power supply. Turn on the blower. An air

layer is formed between cloths to be cut and the table

surface so that the cloths can be moved lightly on the

table.

Holing the cloths with both hands, feed them to the

knife. They are cut outstandingly sharply. Set the knife

guide (6) to a minimum possible height. Two knobs

(6-1 & 6-2) are provided for raising or lowering the

knife.

When not using the cutter. Lower the knife down to the

table surface for safety.

(Caution)

Exercise extreme care with the knife during cloth cutting. It is recommended, to put on

stainless steel mesh gloves (safety glove) for safety.

10. Knife speed

Clothes can be cut well as knife speed increases. However, if cloths of synthetic fibers or

others melted by heat at a high speed, the cut edges melt and adhere.

Lower knife speed and make the felt of the silicon oil tank located above the grinder

touch the knife. Melting and adhesion of the cut edge is eliminated and cloths are cut

sharply.

11. Grinding (see fig.14.)

Grind the knife if the knife becomes dull or cut cloth edges are foul.

Pull the grinder lever when the knife is running, the knife will be ground sharp in 4 to 5

seconds grinding is ended by pushing the lever away. The faster the knife speed is, the

more ground the sharper is.

12. Inverter trouble shooting

The protection device may work to prevent break down of the inverter or motor.

If the devices work, the speed indicator of the control panel shown if fig. 12 shows an

-

7

-

error code and the motor comes to standing.

To reset the protection function, eliminate the cause of failure and press the stop key

(reset key) on the control panel (9).

Be sure the motor is dead standing when pressing the stop (reset) key.

【E】GRINDER

13. Normal grinding condition (see fig.15.16.and 17.)

It is normal to have sparks generated

during the grinding process and later the

knife edge will be ground as (a). If the

knife edge is not even as (b) & (c),

please remove the grinding stone (A) &

(B).

The wheels can be shifted in the

directions shown by arrows by

turning the knobs (7-7) shown in fig. 17 clockwise or counterclockwise.

On completion of adjustment, tighten the lock (7-8) firmly.

14. Shapes of knife edge is up to the fabric types (see fig.18. and 19.)

Grind the knife edge as illustrated in fig.18 depending on the type of fabrics to be cut.

Shift the wheels in the directions shown by arrows to change the shape of the knife edge.

15.

-

8

-

Wear of knife and grinding stones (see fig.20.)

The knife or the grinding stones are worn if the knife is not ground (or sparks are not

generated when the grinder lever is pulled.)

Loosen the lock nut. Pull the grinder lever. And turn the wing screw counterclockwise

slowly. (The dimension marked by “ * “ fig.20 reduces and the grinding stone nears the

knife.)

Locate a position where sparks are generated normally and tighten the lock nut firmly.

16. Grinding stone replacement

If the knife is not ground though the grinding stone position has bee adjusted in the

correct method. The wheels are worn out. Replace the wheel.

Remove the nut (7-9) shown in fig.17 and replace the wheels with now wheels.

17. Wavy knife

The following reasons are conceivable if the knife becomes wavy. Check for every

reason.

a) Knife deflection due to low knife tension.

(Stretch the knife by turning the tension handle till the stopper (1) comes into

contact with the stopper (2) as illustrated in fig.8 on page 6.)

b) The wheel is pressed against the knife more than necessary. (Refer to para.15.)

c) The wheels run out.

(Align the wheels satisfactorily. Replace the both wheels if they run out because of

wear.)

-

9

-

【F】REPLACEMENT OF KNIFE

18. When to replace

The width of a brand new knife is 10mm and reduces little by little each time ground.

Replace the knife if the width is reduced to about 3mm.

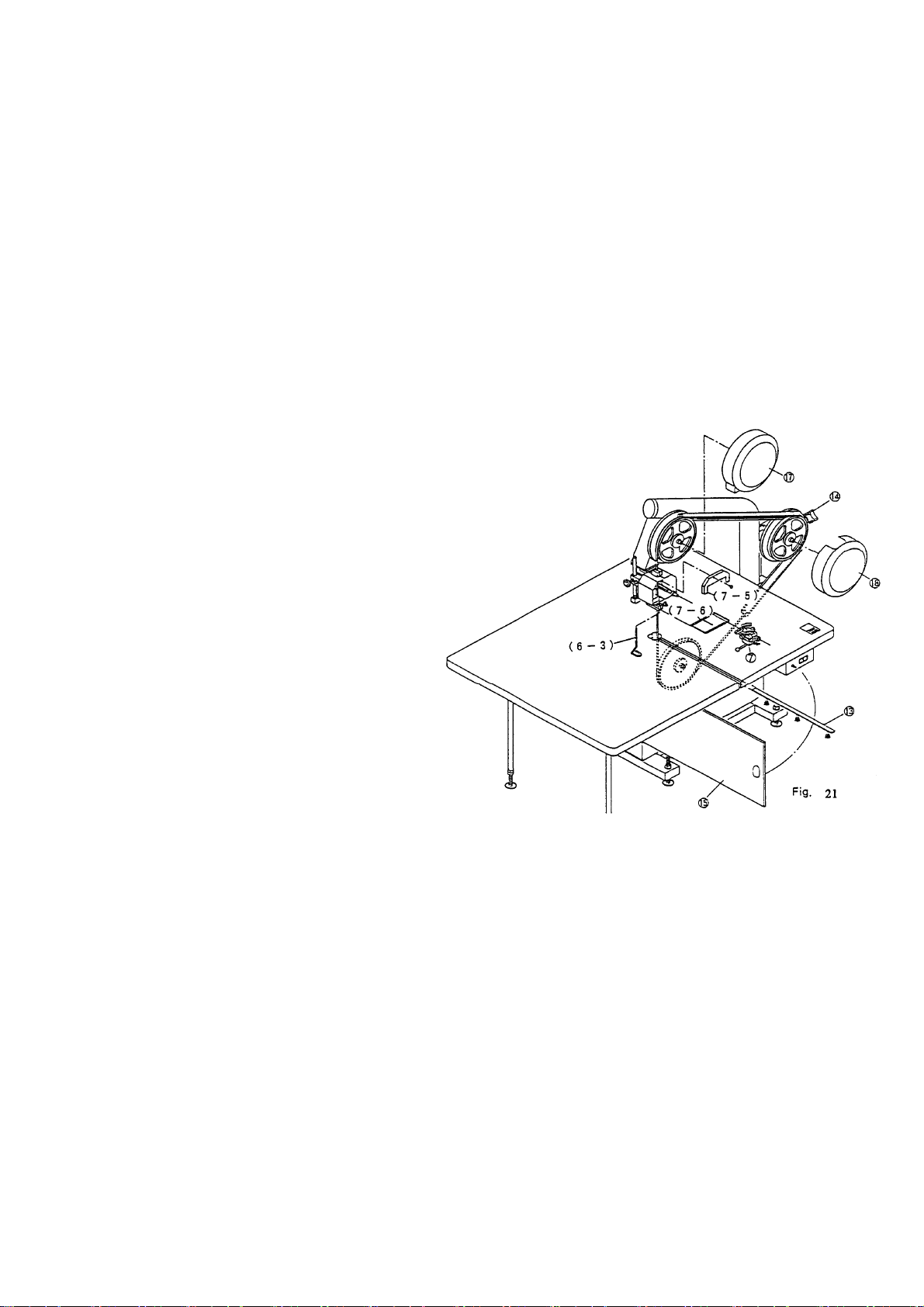

19. Removal of knife (see fig.21)

a) Remove the table plate (13).

b) Remove the safety fitting (6-3) of the knife guide.

c) Remove the grinder front cover (7-5) and the screws from the grinder (7).

d) Remove the top pulley cover (17) and the tension pulley cover (18).

e) Open the front cover (15).

f) Turn the tension handle to slacken the knife.

g) Remove the knife with extreme

care.

The knife installation

dimensions are given in para.3

on page 4.

(Caution)

Disconnect the power supply

cable plug from the outlet prior

to starting knife replacement.

It is recommended to put on

stainless steel mesh gloves

(safety gloves) for safety when

replacing the knife.

【G】OTHER

1. If there is lighting, stop the operation of the cutter and disconnect the power supply

cable from the outlet because the inverter may be damaged by lighting surge.

2. Disconnect the power supply cable from the outlet if the cutter is not being operated

for a long period of time.

3. Press the power supply off pushbutton switch on the switch box if the power supply

is interrupted during operation.

4. Maintenance

Open the pulley cover and the front cove and remove cut cloth waste etc. by a

vacuum cleaner etc. at regular intervals.

Each time the knife is ground. Remove grit from the grit tray by a vacuum cleaner

etc.

Fill the silicon oil tank located above the grinder with silicon oil at regular intervals.

-

10

-

-

11

-

機械

零件目錄

No.1

序號

Ref No

部件編號

Parts No

部件名稱規格

Description

數量

Customer

1 ZA3321 磨刀石Φ65*Φ59*Φ7.8*13 Grinding stone 2

2 700AB035 左砂輪軸芯 Axis for left wheel 1

3 700AB036 右砂輪軸芯 Axis for right wheel 1

4 JB2061 單列向心球軸承 608ZZ Bearing 2

5 700AB025 磨刀座固定杆 Fixed rod for the grinding base 2

6 ZW0065 梅花手 M6*35L Bearing 2

7 700AB038 右砂輪座 Base for right wheel 1

8 JH1032 圓錐形壓縮彈簧 Compressed spring 1

9 700AB037 左砂輪座 Base for left wheel 1

10 700AB021 砂輪滑座 Sliding base 1

11 700AB022 砂輪座 Base for wheel 1

12 700AB023 磨刀座擋片 Stopper for the grinding base 1

13 700AB024 磨刀座調節輪 Adjusted wheel for grinding base 1

14 700AB028 磨刀座調節杆 Adjusted rod for grinding base 1

15 700AB026 調整輪固定螺帽 Fixed nut for grinding stone 1

16 700AB027 磨刀座調節環 Adjusted ring for grinding base 1

17 ZW0334 刀具合蓋 175*85*15 Cover 1

18 700AB013 砂輪固定軸心 Fixed axis 1

19 700AB014 砂輪止滑圈 Ring 1

20 700AB043 刀具合固定座 Fixed base 1

21 700AA017 固定塊 Fixed block 1

22 ZW0053 梅花手柄(M8*40L) Shaft 1

23 700AB016 升降軸心 Axis (for OB-700/900) 1

1200AB001

升降軸心 Axis(for OB-1200)1

24 700AB011 刀座固定塊 Fixed block for the knife base 1

25 700AB017 刀座 Knife base 1

26 ZW0053 梅花手柄(M8*40L) Shaft 1

27 700AB018 墊塊 (刀座內) Wad (inside the knife base) 2

28 700AB051 刀帶擋杆 Stop rod for the band knife 1

-

12

-

-

13

-

機械

零件目錄

NO.2

序號

Ref No

部件編號

Parts No

部件名稱規格

Description

數量

Customer

1 JB2004 針狀軸承 NTB2035 Needle bearing 1

2 JH1081

壓縮彈簧ψ6.5*ψ35*105L*10 圈

Compressed spring 1

3 JB1025 軸承 UCF205 Bearing 1

4 JB1001 軸承 BLFL6J Bearing 1

5 700AB010 調整座擋板 Stopper for the adjusted base 1

6 700AB020 刀帶輪調整杆 Adjusted rod for the band knife 1

7 700AB062 手輪 3” Wheel 1

8 700AB050 刀帶輪軸心”短” Bearing for the band knife (short) 1

9 700AB046 刀片下底護罩 Cover for the knife 1

10 700AB041 刀帶輪 Band knife 1

11 JF3001

錐形止環ψ24*ψ21.3*ψ20*5

Stop ring 1組

12 700AB047 刀片下蓋護罩 Cover for the knife 1

13 700AB012 墊圈 Pad 1

14

ZW0336 刀蓋 555MM(鋁軌) Knife cover(FOR OB-700) 2

ZW0338 刀蓋 650MM Knife cover(FOR OB-900) 2

ZW0348 刀蓋 850MM Knife cover(FOR OB-1200) 2

-

14

-

-

15

-

機械

零件目錄

NO. 3

序號

Ref No

部件編號

Parts No

部件名稱規格

Description

數量

Customer

1 DM0201-2 鼓風機 220V Blast furnace 1

2 700AB034 傳動皮帶輪(小) Wheel for pass belt (small) 1

3 ZW0132 仿中古輪(美國輪)3” Wheel 4

4 700AB053 水平調整杆”長M18*220L Horizontal adjusted rod 4

5 DM0142

三相交流馬達(鋼板)4P 11HP 卧

Motor 1

6

700AA001 下層機組 Plate(for OB-700) 1

900AA001 下層機組 Plate(for OB-900) 1

1200AA001 下層機組 Plate(for OB-1200) 1

-

16

-

-

17

-

機械

零件目錄

NO.4

序號

Ref No

部件編號

Parts No

部件名稱規格

Description

數量

Customer

1 JB1025 培林 UCF205(需車溝) Bearing 1

2 700AB012 墊圈 Pad 1

3 JF3001

錐形止環ψ24*ψ21.3*ψ20*5

Stop ring 1組

4 700AB042 傳動皮帶輪(大) Wheel for pass belt (big) 1

5 JB1025 培林 UCF205 Bearing 1

6 JB2061 單列向心球軸承 608ZZ Bearing 1

7 JP0229 三角皮帶 B-37 Triangle belt 1

8 JB1027 培林 UCFC206 Bearing 1

9 JG6371 刮刀 37*20*0.5 Knife 1

10 JB1026 培林 UCF206 Bearing 1

11 700AB049 刀帶輪軸心”中

Axis for band knife wheel (medium)

1

12 700AB044 刀片上底護罩 Cover for knife 1

13 700AB041 刀帶輪 Wheel for band knife 1

14 JF3001

錐形止環ψ24*ψ21.3*ψ20*5

Stop ring 1

15 700AB012 墊圈 Pad 1

16 700AB045 刀片上蓋護罩 Cover for knife 1

17 700AB048 刀帶輪軸心”長”

Axis for band knife wheel (long)

1

18 700AB032 轉動刀帶輪 Turning wheel for band knife 1

19 JF3001

錐形止環ψ24*ψ21.3*ψ20*5

Stop ring 1

20 700AB012 墊圈 Pad 1

-

18

-

-

19

-

機械

零件目錄

NO.5

序號

Ref No

部件編號

Parts No

部件名稱規格

Description

數量

Customer

1 1200AA013 进風口 Wind outlet 1

2 700AA016 支撐杆 Holding rod 2

3 700AB054 水平調整杆”短”M18*195L Horizontal adjusted rod (short) 2

4

700AB029/030

刀具上導片/刀具下導片 Knife guide 1

5 ZA3253 工作臺 1500*1200*35MM Working table(for OB-700) 1

ZA3255 工作臺 1800*1500*35MM Working table(for OB-900) 1

ZA3256 工作臺 2400*1500*35MM Working table(for OB-1200) 1

6 DZ0301-1 變頻器 BBVFD007B21A Inverter 1

7 700AB031 刀具導片調節杆 Adjusted rod for the knife guide 1

8 700AA022 臺板固定片 Fixed plate for the table 4

-

20

-

This manual suits for next models

8

Table of contents