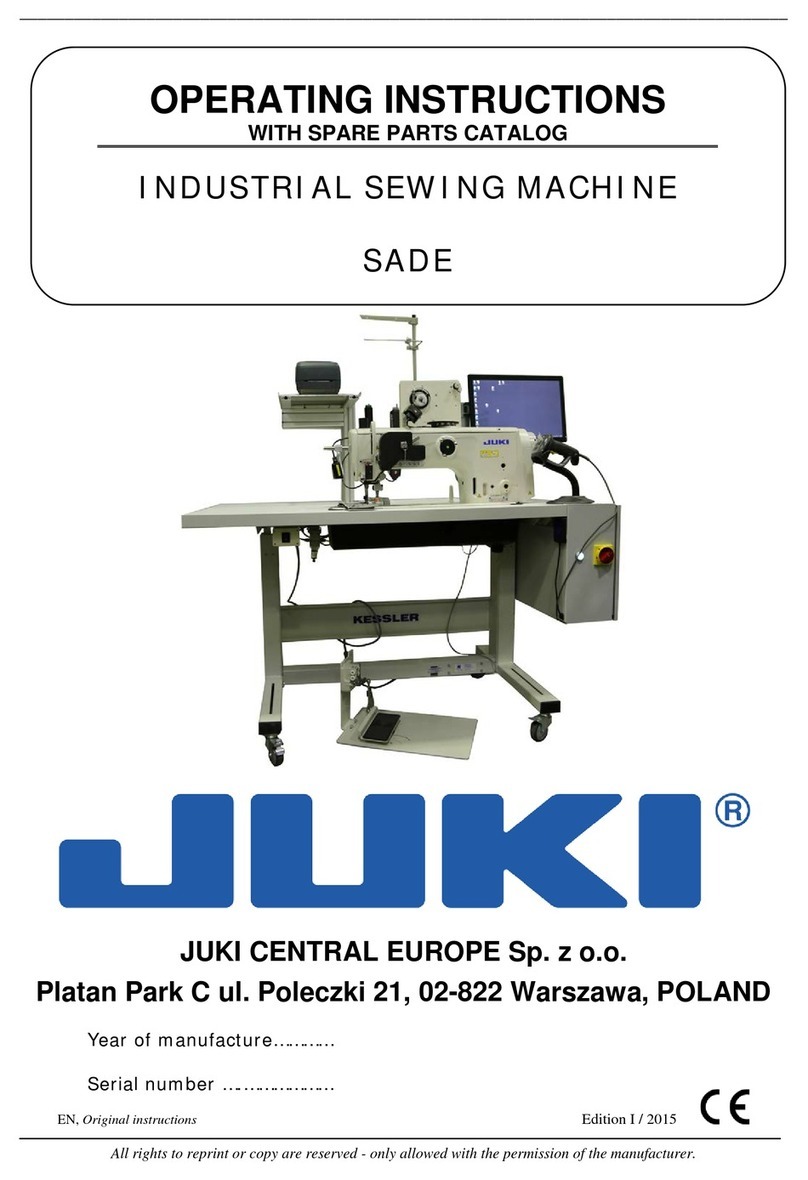

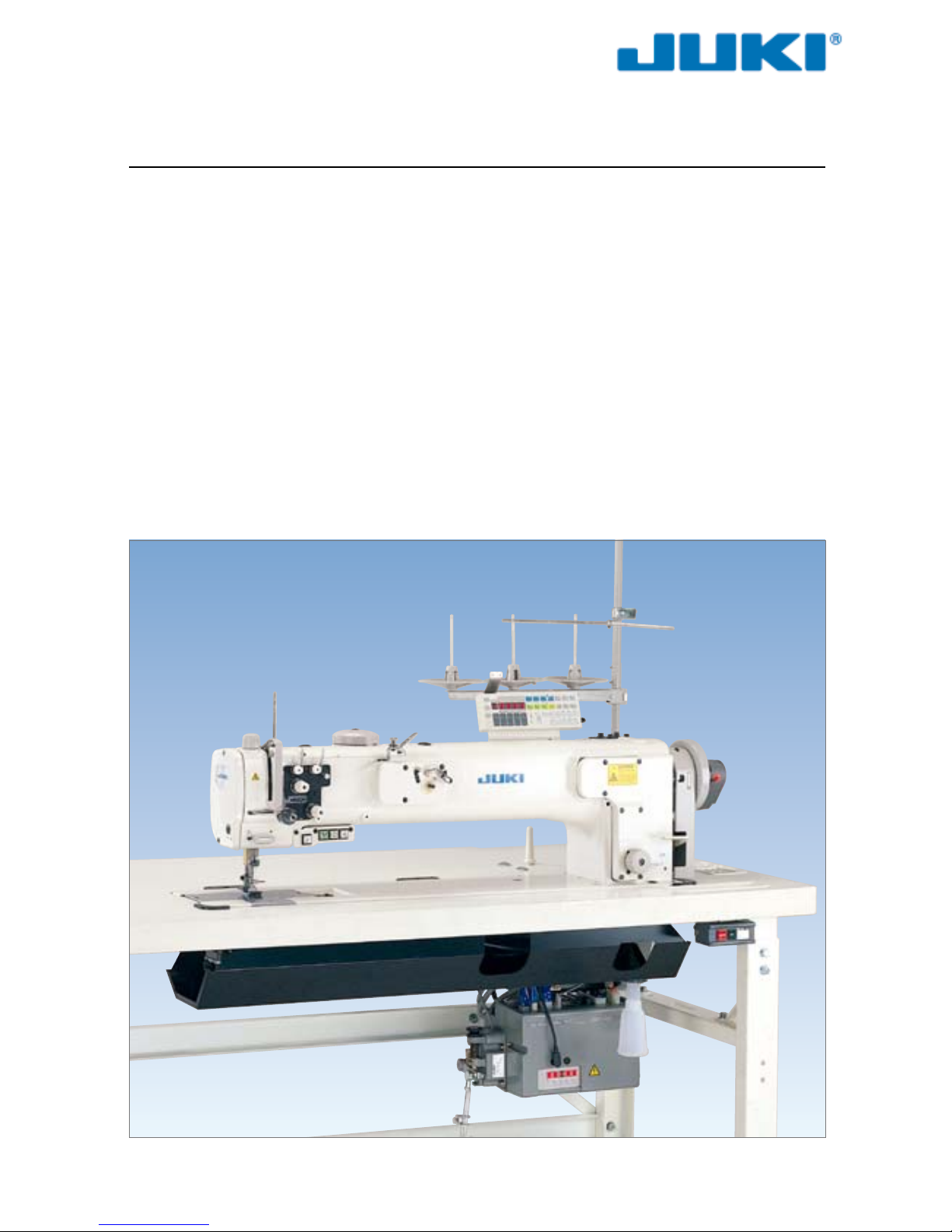

Distance from machine arm to needle as long as 650mm.

The machine responds outstanding it to the sewing of large,

heavy materials such as car seats and furniture.

Both the LU-2216N-7 (1-needle)

and LU-2266N-7 (2-needle) achieve

the maximum sewing speed of

3,000rpm. With this capability,

the machine demonstrates higher

productivity when sewing long

lengths of materials.

Higher productivity

With the long distance from the machine arm to the

center of the needle, a full 650mm, the machine is

ideally suited to reinforcement stitching processes for

attaching tape and intermediate sewing processes such

as topstitching for large work pieces.

Longer distance from machine arm to needle

With fully automatic lubrication, the

cumbersome task of oiling the machine by

hand is eliminated. Oil is forcedly

circulated through the face plate by a

plunger pump. This prevents oil leakage

from the face plate.

The machine adopts a fully

automatic lubricating method.

With its powerful feed and optimal

feed locus, the machine smoothly

feeds materials without stitch

gathering even when running at a

higher sewing speed.

Consistent feed efficiency

at higher sewing speeds

In processes such as the sewing of heavy

materials or hard-to-feed multi-layered

portions, a press on the DL switch instantly

change over the vertical stroke of the walking

foot and presser foot. The result is beautifully

produced seams without stitch gathering.

The standard machine lets the operator

adjust the vertical stroke of the walking

foot and presser foot (DL device).

The vertical stroke of the presser foot and

walking foot (amount of alternating vertical

movement) can be easily changed with the large

dial mounted on the top of the machine head.

The sewing speed is automatically regulated

based on the vertical stroke setting. This

ensures ideal sewing conditions at all times.

The vertical stroke of the walking

foot and presser foot can be

easily set and changed.

The gauge (hook, bobbin, walking foot, presser

foot and feed) used in the LU-2210N/-2260N

Series is also used in this model. All of the parts

used in your LU-2210N/-2260N sewing machines

can also be used in the LU-2216N/-2266N

machines. In addition, the knife and thread tension

components are also the same.

Some gauge used in the

LU-2210N/-2260N Series

The presser foot goes up as high as

16mm. This ample lift ensures easy

setting of heavy materials on the

machine and comfortable operation.

The presser foot lift is as

high as 16mm.

With the rigidly moving knife shaft

and optimal knife movement, the

thread trimmer cuts thick thread

without error.

Moreover, no adjustment is required

even when the yarn count is changed.

Thread trimming without fail

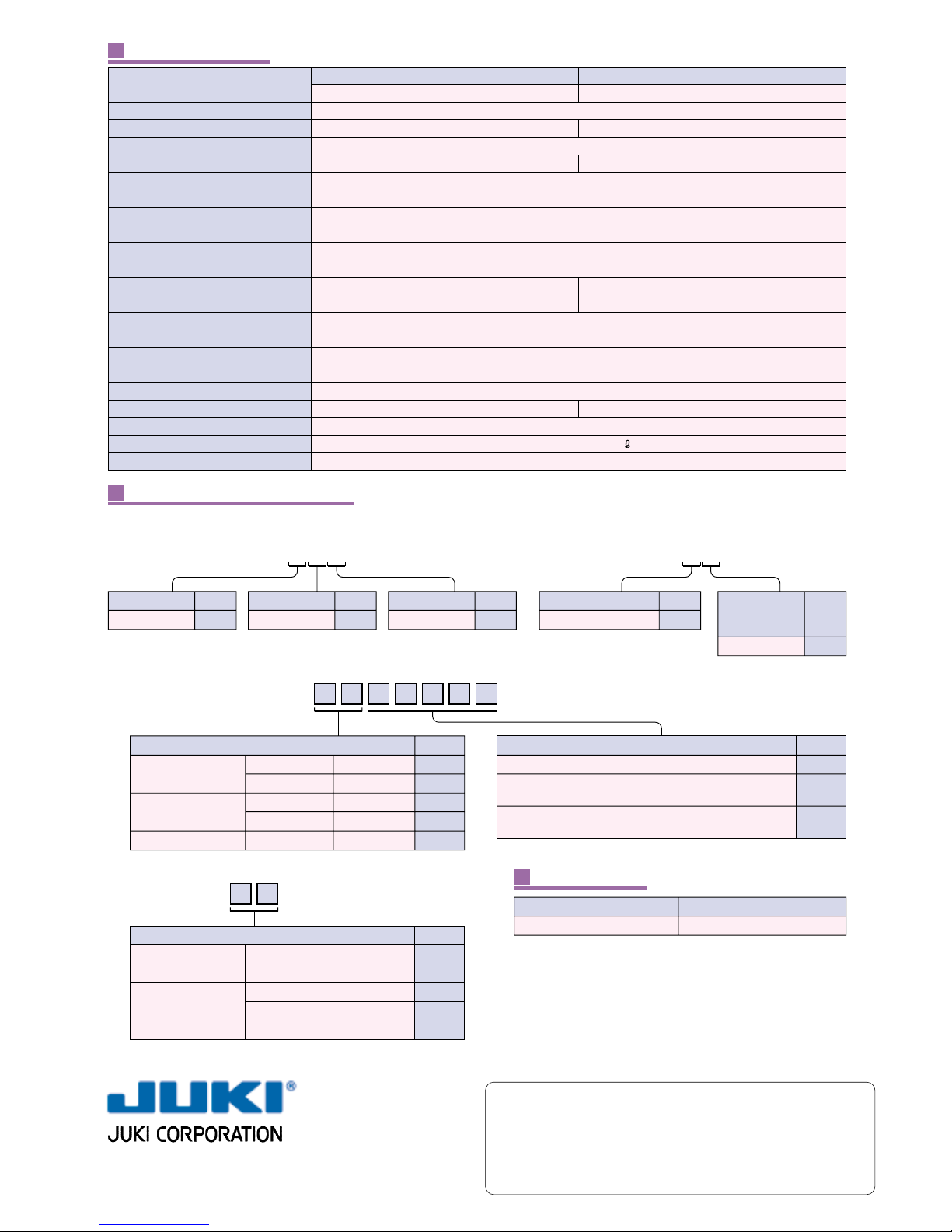

The SC-380 is provided with many

different standard functions, including

speed-control, soft-start, automatic reverse

stitching with the specified number of

stitches, constant-dimension stitching, and

overlapped (multi-layered) stitching. These

functions ensure sewing performance

optimally suited to the material and

process.

AC servomotor/controller

SC-380

The XC-E500 is provided with program sewing and

a host of other functions that contribute to increased

efficiency.

Operation panel that improves functions

of the sewing machine (optional)

LU-2266N-7 LU-2266N-7

LU-2266N-7

XC-E500

650

mm

16mm