Ossa TR280i Instruction manual

2

1. Motorcycle specications

2. Engine part

2.1 Assembling or dismantling the engine from the chassis

2.2 Assembly and disassembly of engine parts

2.2.1 Engine start

2.2.2 Clutch

2.2.3 Gears

2.2.4 Ignition

2.2.5 Cylinder head

2.2.6 Cylinder

2.2.7 Piston and rings

2.2.8 Ignition

2.2.9 Ignition inner cover

2.2.10 Crankshaft

2.2.11 Water pump

3. Cycle part

3.1 Periodic maintenance chart and torque values.

4. Electrical part

4.1 Electrical diagrams

4.2 Injection

4.2.1 Kscan

4.2.2 Kwrite

5. Manintenance

5.1 Cylinder cover

5.2 Cylinder

5.3 Piston and rings

5.4 Crank

5.5 Crankshaft

5.6 Clutch

5.7 Gears

5.8 Transmission

5.9 Bearings

5.10 Seals

5.11 Sparkplug

5.12 Motor oil

CONTENTS

3

MOTOR

Cubic capacity 272,2 cc

Type Single cylinder, two-stroke, inverted engine with reed block

air intake.

Cooling system Liquid

Bore x stroke 76x60 mm

Fuel injection EFI Kokusan Batery-less System

Ignition Volante magnético digital CDI Kokusan

Clutch Hydraulic

TRANSMISSION

Gearbox 6 speeds

Transmission transmission by gears, nal transmission by chain

Lubrication mixture 100% synthetic oil lubrication 0.9%

Transmission and clutch oil 350 cc. of Gear Extreme type 75 W oil.

CHASIS

Type Cr-Mo / Forged aluminium with patented Fuel Tank by OSSA

Front suspension Marzocchi Hydraulic Fork with 40 mm al. stanctions.

Adjustable rebound and compression.

Shock absorber Progressive hydraulic monoshock TTX OHlins with

adjustable rebound and compression

Front brake ø 185 mm disc and 4 piston caliper

Rear brake ø 150 mm disc with 2 piston caliper

Front Wheel 28 spoke rims and 2,75x21 tires

Rear wheel 28 spoke rims and 4,00x18 tubeless tire

Engine protector Made of AA7075 T6

Kickstart pedal Forged aluminium

Gearshift and brake pedals Forged aluminium with retactable tips.

WEIGHT AND DIMENSIONS

Wheelbase 1.328 mm

Seat heigth 655 mm

Ground clearance (unloaded) 340 mm

Fuel tank capacity 2,6 litros

Weight (no fuel) 64 Kg

OSSA Factory S.L. reserves the right to modify this manual without notice. Kokusan, Marzocchi, OHlins

are registered brands and the use of their name is under license.

TECHNICAL FEATURES

4

All operations on the engine of TR280i can be done without taking it appart from the chassis, except

when it is needed to work on the fuel pumps situated at the bottom of the fuel tank. For this case or to

work more comfortably on other operations, this is the procedure to disassemble the engine from the

chassis.

1. Take off the plastic lter cover and

seat base.

2. Take off the exhaust.

3. Take off the reed block and the throttle

body assembly.

4. Empty the cooling circuit and take off

the radiator.

ENGINE PART

5

ASSEMBLY AND DISASSEMBLY OF THE ENGINE FROM THE CHASSIS

9. Remove the bolts that hold the engine to the chassis,

to proceed with its disassembly.

8. Disconnect the cables from the injector.

7. Empty the clutch oil and remove the hose from the engi-

ne.

5. Take off the rear wheel, the swing arm, the shock absor-

ber and the brake pump from the chassis.

6

ENGINE PARTS

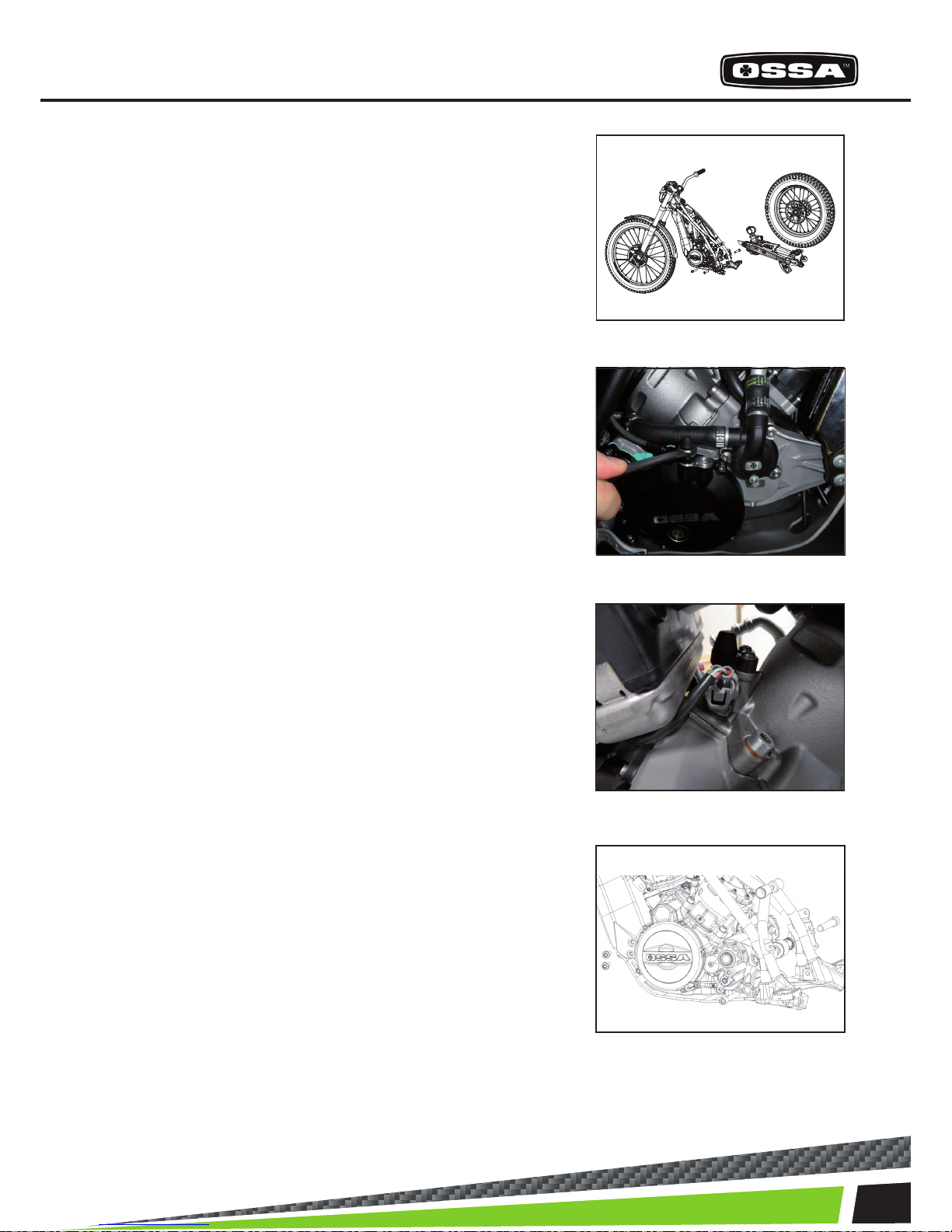

1- STARTING SYSTEM

Before taking appart the starting system, you must make sure the engine has no oil in the crankcase

leaning the bike to both sides. Also the clutch oil, removing the hose from the clutch cover.

Unscrew the 6 bolts that hold the clutch cover on the crankcase and take of the cover toghether with

the ignition system, kickstart pedal, shaft and gear.

Be careful to avoid damaging the gasket when removing the cover.

7

ENGINE ASSEMBLY AND DISASSEMBLY

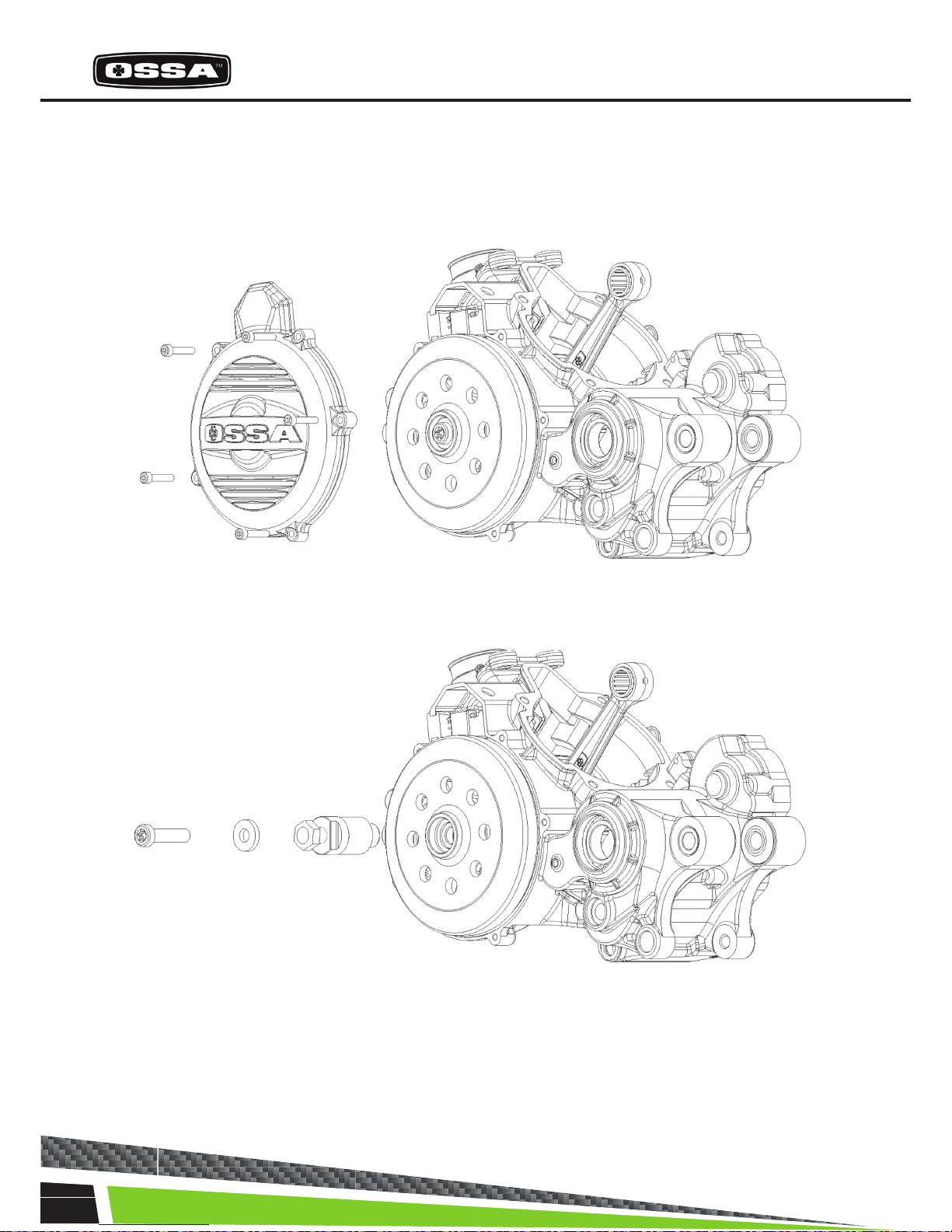

2- CLUTCH

Once the clutch cover is out, you can see the clutch system. Follow these steps to take it appart.

Take out the 18 bolts which hold the clutch spring support plate.

Take off the spring, the pressure plate and the 18 clutch release arms to access the clutch discs.

Remove the clutch discs.

8

ENGINE PARTS

3- GEAR SHIFTING ASSEMBLY

Once you have taken out the clutch discs, the clip that holds the countershaft sprocket, the sprocket,

the bushing with its two O-rings and the gear shifting pedal, we can separate the gear assembly from the

engine.

The gear system comes out toghether with the shift shaft, and the gear selector assembly. To take it out of

the crankcase, it is necessary to remove the 5 centering screwst; and with some gear engaged, proceed

to take it out, as shown.

Take off the elastic ring ‘circlip’, the sprocket and the

gear shifting pedal.

Remove the 5 bolts that x the gear assembly to the crankcase. To

be able to take out the 3 bolts situated behind the clutch crown, the

crown must be turned until the rounded spaces for the key coincide

with the bolt heads.

After removing them, the gear assembly can be taken out of the crankcase.

9

ENGINE ASSEMBLY AND DISASSEMBLY

4- CYLINDER HEAD

It is recommendable to take out the cooling system hoses which are connected to the cylin-

der head with zip-ties, and the temperature sensor. After this, the cylinder head can

be disassembled by unscrewing the 8 bolts which hold it toghether with the cylinder.

10

ENGINE PARTS

5- CYLINDER

Before taking the cylinder appart from the engine, it is recommendable to remove the hoses from the

cooling system. To proceed, the 4 bolts that x the cylinder to the crankcase must be taken out.

11

ENGINE ASSEMBLY AND DISASSEMBLY

6- PISTON AND RINGS

Once the cylinder is out, the next step is to take out the cylinder and the rings, removing the locking

snap rings and the piston pin, we can take the piston appart from the rod, and then remove the rings

if desired.

12

ENGINE PARTS

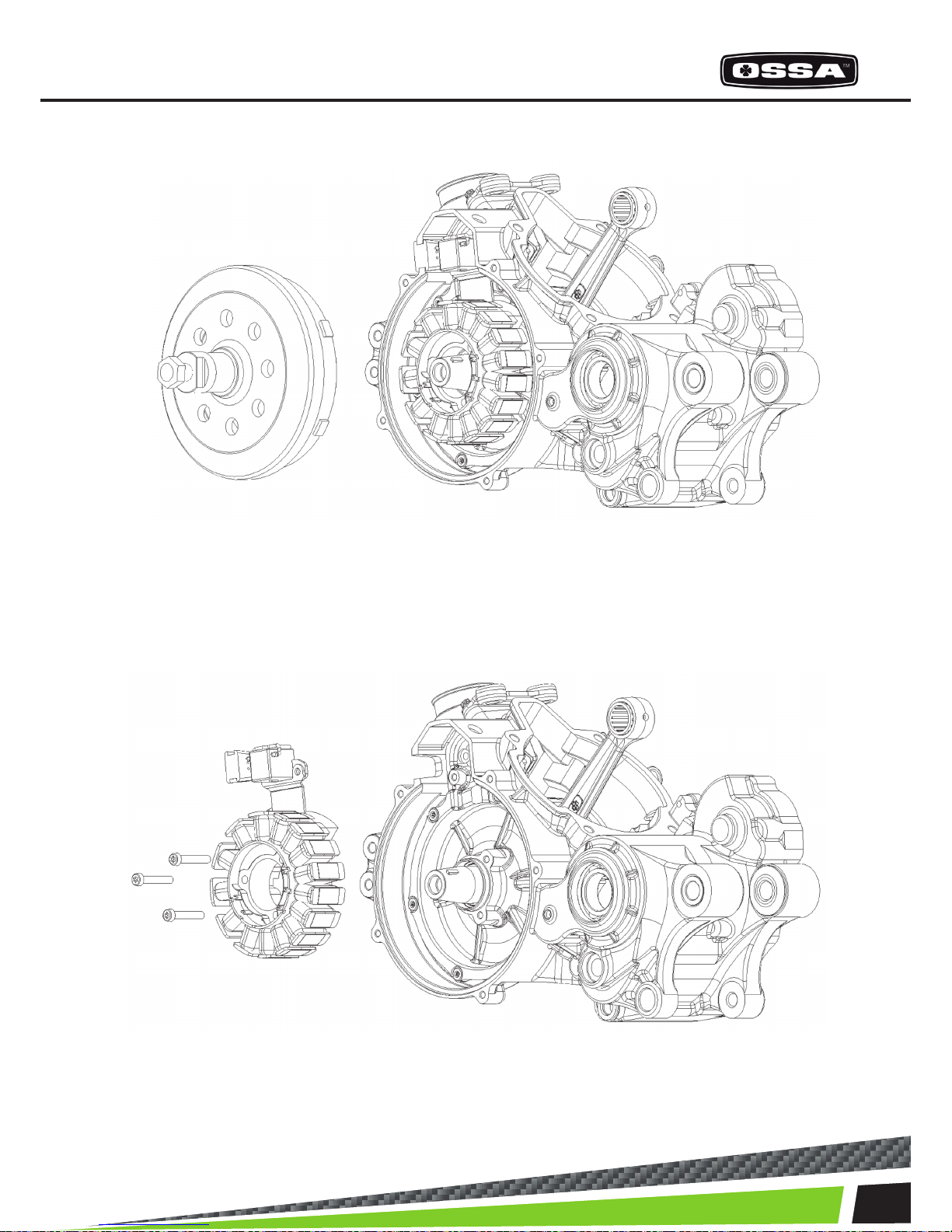

7- IGNITION SIDE

If we remove the ignition cover we can access the rotor. Once the rotor is out we can get to the stator.

Remove the 5 bolts from the ignition cover.

Using the special tool (included in the tool kit Ossa ref. 1499960211) we can take out the rotor.

13

ENGINE ASSEMBLY AND DISASSEMBLY

We can proceed to remove the stator, taking out the bolts that hold it toghether with the inner cranks-

haft cover, toghether with the pick-up.

14

ENGINE PARTS

8- INNER CRANKSHAFT COVER

Once the stator and rotor are out, the inner crankshaft cover can be removed. It is held toghether with

the crankshaft by 6 bolts. It is necessary to use the extractor kit which is part of the Ossa workshop

toolkit (ref. 1499960211). After this step, the crankshaft can be accessed.

After unscrewing the 6 bolts we attatch the extractor tool at the centre of the inner crankshaft cover

and we pull it out using the extractor that ts in the crankcase, while we screw the bolt in the middle.

15

ENGINE ASSEMBLY AND DISASSEMBLY

Using the tool we take out the inner crankshaft cover. Be careful to avoid damaging the gasket.

16

ENGINE PARTS

9- CRANKSHAFT

To remove the crankshaft it is necessary to use the special tools. (ref. 1499960211)

Follow these steps:

1

2

Unscrew the long pin that locks the bearing of the

crankshaft (1).

Heat up the area in the circle (2) with a heat

blower so that the crankshaft expands and makes

the extraction of the crankshaft easier.

17

ENGINE ASSEMBLY AND DISASSEMBLY

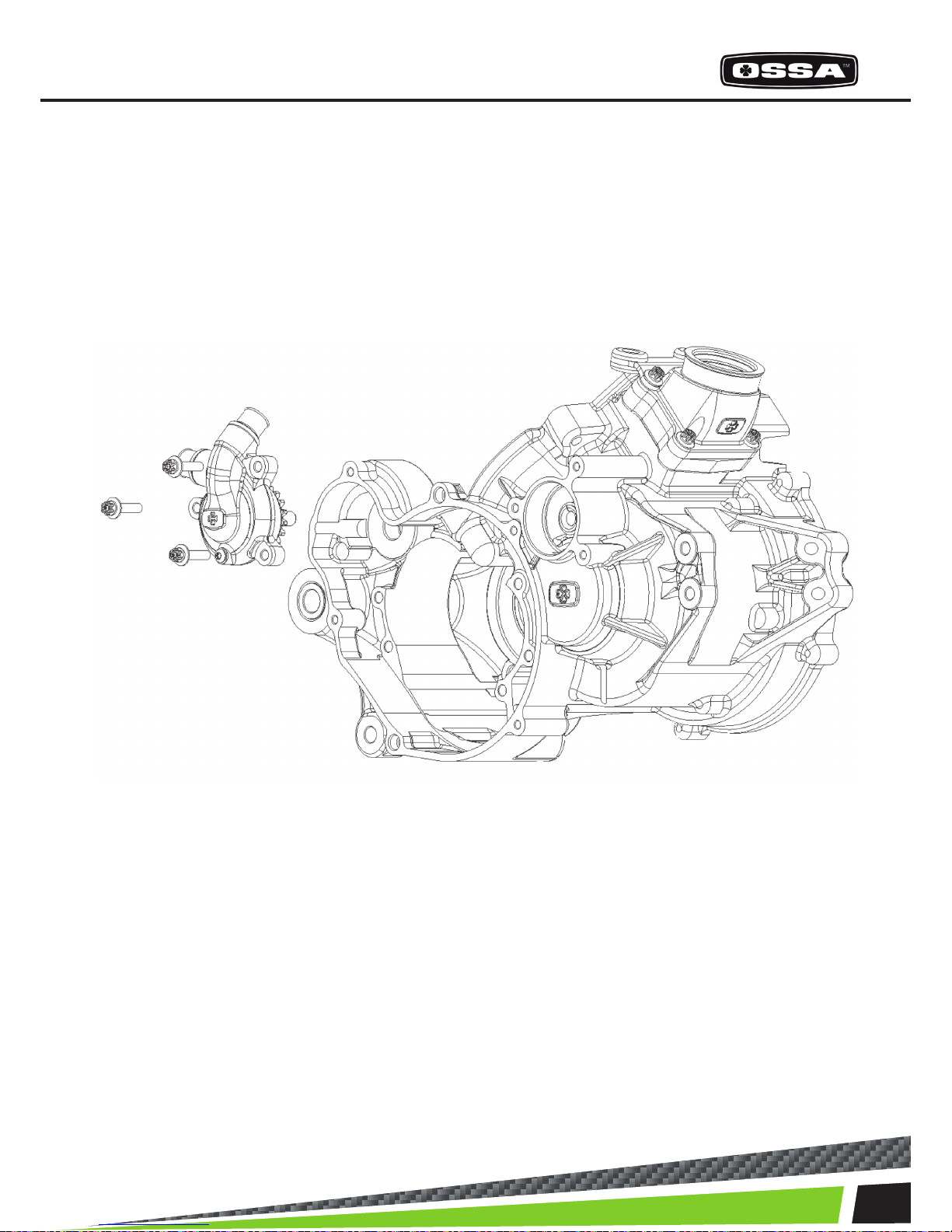

10- WATER PUMP

To remove the water pump, it is recommended to remove rst the rubber water hoses which are attat-

ched to it with metal zipties.

Take out the 3 bolts that hold the pump onto the crankcase.

The water pump can be removed.

18

ENGINE PARTS

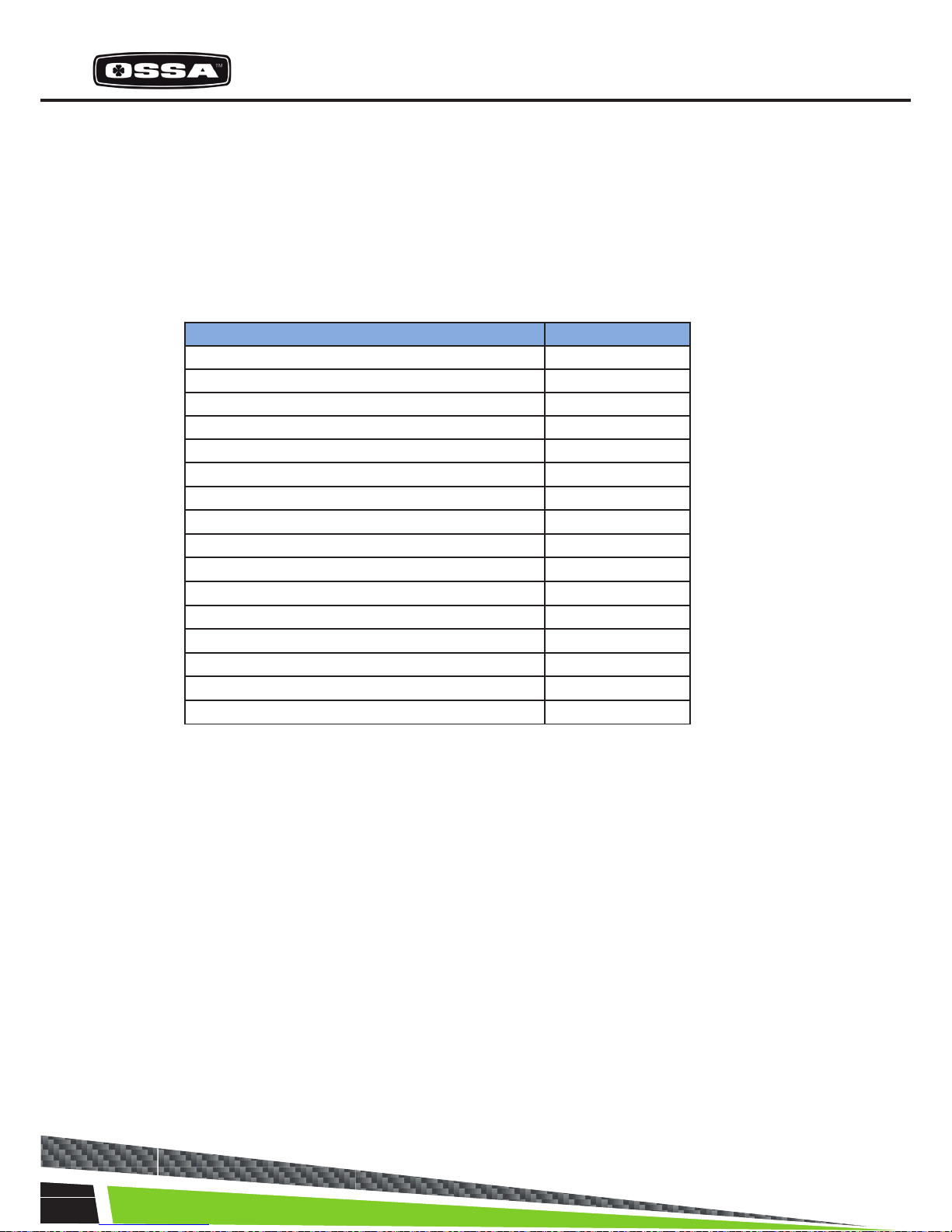

RECOMMENDED TORQUE VALUES FOR THE ENGINE BOLTS

PART TORQUE (N·m)

Spark plug 11

Ignition xing points 7-8

Clutch xing points 7-8

Cylinder bolts 25

Reed block 7-8

The 18 bolts for the clutch spring support plate 3-4

Water pump 7-8

Clutch cover 7-8

Rotor 40

Water tubing ngs 10

Ignion cover 7-8

Oil draining cap 12

Bolts for the kickstart pedal 12-13

Bolts for the gear shiing pedal 7-8

Cylinder head 8-9

Cylinder nut 25

19

ENGINE ASSEMBLY AND DISASSEMBLY

1499960211 OSSA WORKSHOP KIT

PRIMARY BEARING TOOL CRANKSHAFT TOOL

CLUTCH POSITION TOOL IGNITION & STATOR TOOL

1000960211

MOTOR SUPPORT TOOL

RECOMMENDED TOOLS FOR SERVICING THE OSSA TR280i ENGINE

PART TORQUE (N·m)

Spark plug 11

Ignition xing points 7-8

Clutch xing points 7-8

Cylinder bolts 25

Reed block 7-8

The 18 bolts for the clutch spring support plate 3-4

Water pump 7-8

Clutch cover 7-8

Rotor 40

Water tubing ngs 10

Ignion cover 7-8

Oil draining cap 12

Bolts for the kickstart pedal 12-13

Bolts for the gear shiing pedal 7-8

Cylinder head 8-9

Cylinder nut 25

20

CYCLE PARTS

RECOMMENDED PERIODIC MAINTEINANCE

PART CHECK ADJUST REPLACE WASH GREASE/

LUBE

Rear shock Every ride -- Every 2 years -- --

Front fork Every ride When re-

quired

Every 2 years -- --

Front fork oil -- -- 60 hours -- --

Brakes Every ride When re-

quired

If damaged -- --

Swingarm and linkage Every ride -- If damaged Every ride After washing

Secondary transmis-

sion

Every ride When re-

quired

If damaged Every ride After washing

Steering bearings Every ride -- If damaged -- After washing

Wheel bearings 30 hours -- If damaged -- After washing

Disc brake rotors Every ride When re-

quired

If damaged -- --

Tyres Every ride -- If damaged -- --

Rims Every ride -- If damaged Every ride --

Spokes Every ride 5 hours If damaged Every ride --

Chassis Every ride -- If damaged Every ride --

Fuel tank Every ride -- If damaged Every ride --

Bolts, nuts Every ride When re-

quired

If damaged Every ride --

Crankcase protector -- First ride If damaged Every ride --

Protecve sckers Every ride -- If damaged -- --

Other manuals for TR280i

2

Table of contents

Other Ossa Motorcycle manuals