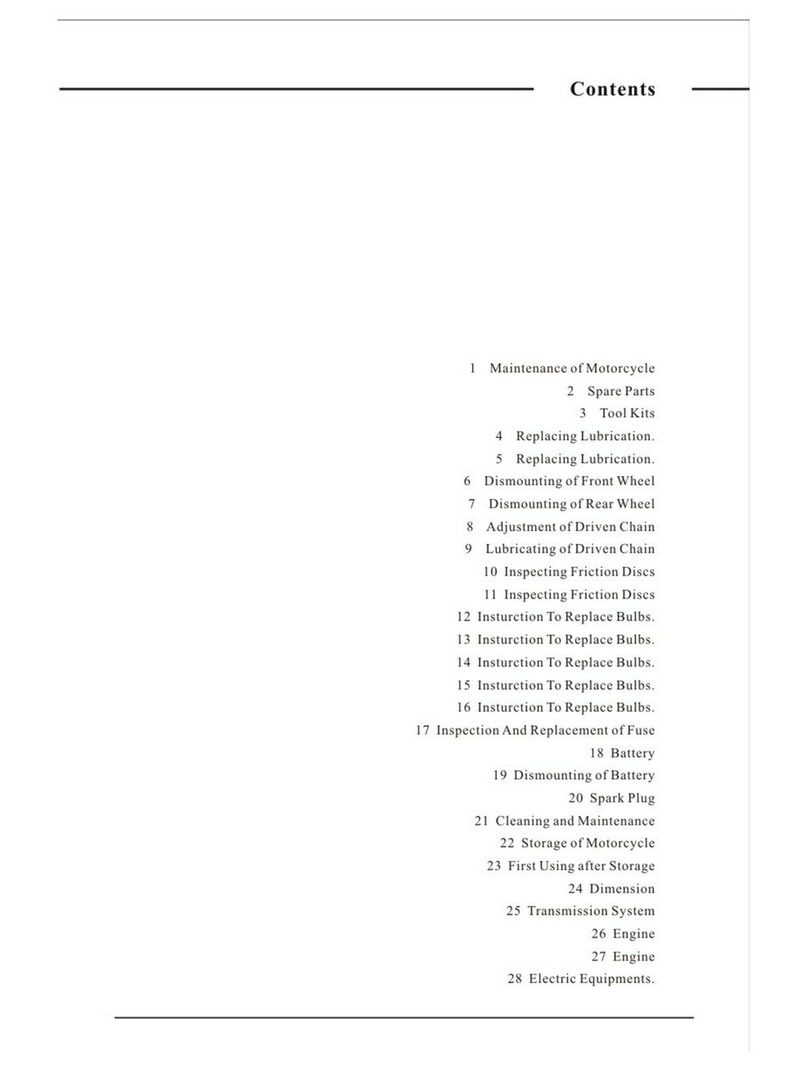

9

after the first 500 km is necessary to replace the oil content of the front forks (see chapter on

changing the oil in the front forks).

5th OPERATING INSTRUCTIONS

Check before each trip

Visually inspect the brake fluid level (SYNTOL HD 205 of type DOT-3) and the hydraulic braking

system for leaks. Check function of brake switch. When the fluid level falls below half-way in the

control window, top up fluid. Inspection is performed while the handlebars are in the middle position.

(Fig. 3)

Check whether there is fuel in the tank and oil in the engine/gearbox. Inflow from the fuel tank to the

carburettor is controlled by a valve lever (Fig. 5):

1st, lever down ... ... ... ... ... ... ... ... ..fuel main supply on

2nd, lever horizontal ... .. ... ... ... ..... fuel off

3rd, lever up ... ... ... ... …. …... ... .... reserve

Check the engine oil: the level is measured after cleaning dipstick but without screwing it back into the

engine (see Fig.13).

Check function of electrical equipment, brake function, check engine for oil leaks, chain tension (see

Fig.16 & Fig.17 a), check the condition and pressure of tires.

Starting the engine

Insert the key and turn it to start position, open the fuel valve, open the carburettor choke lever (see

Figure 9) (see the description in chapter "Adjusting the carburettor“ and press the Start button on

the handlebar. Let the engine warm up for a time at low RPMs. After engine warm-up, turn the choke

off. After starting, check that all the electrical equipment works.

Ride

When starting off, pull in the left hand clutch lever, engage first gear with the left foot.

Move the lever to the bottom of the foot shift lever and the stop release (Fig. 4). Slowly release the

clutch lever while accelerating.

When you reach about 10-20 km / h, change up to the next gear.

Gearshift: 5.gear

4.gear

3.gear

2. gear

N - neutral

lever down - 1st gear

At the end of a trip, set the gear lever into neutral, the ignition key to “off“ position and shut off the fuel

supply (see Figure 1, Figure 4, Figure 5).

Securing Motorcycle

The motorcycle has two sets of keys (one spare), and this key:

- Locks the standard controls: handlebars can be locked while aligned to the right. Insert the

key into the lock, turn it to the right, push in the brass head lock, then turn they key to the left

and remove it. Handlebars are now locked. Unlocking is performed the opposite way.

- Locks and secures the seat (Fig. 20)

Insert the key into the lock, turn to the right and pull the lock outward.

Lift the seat in front for about 10-15 cm upward and move it forward to remove the seat from