OSTLING PinMark UMC box User manual

U

UM

MC

C

b

bo

ox

x

Ö S T L I N G

Markiersysteme GmbH

Broßhauser Str. 27

42697 Solingen - Deutschland

Tel.: +49 (0) 212 - 26 96 0

Fax.: +49 (0) 212 - 26 96 199

www.ostling.com

Edition: 04/2006

The document was written in the Technical documentation department of the company

ÖSTLING Markiersysteme GmbH.

All rights at this documentation, in particular the right of the duplication and spreading as well

as the translation are at ÖSTLING Markiersysteme GmbH, also for the case of patent right

registrations. No part of the documentation may be reproduced in any form without previous

written agreement of the company ÖSTLING Markiersysteme GmbH or processed, multiplied

or spread using electronic systems. Mistake and technical subject to change.

ÖSTLING Markiersysteme GmbH

ÖSTLING Markiersysteme GmbH is not responsible for any errors in this documentation. A

liability for indirect and direct damage, which develops in connection with the supply or the

use of this documentation, is impossible, as far as this is legally permissible.

B_PM_UMCbox_en00.doc

ÖSTLING Markiersysteme GmbH Table of contents

0-3

Table of contents

Chapter 1 Safety

1

For your safety ......................................................................................... 1-2

2

Definitions................................................................................................. 1-2

3

Operational safety.................................................................................... 1-3

3.1

Intended use of the marking system ....................................................... 1-3

3.2

Measures taken by the user/operator ..................................................... 1-4

Consider warning plates and references.............................................. 1-4

Personnel instruction............................................................................ 1-4

Duty to care in handling the marking system ....................................... 1-5

Use of intended spare parts and operational funds ............................. 1-5

3.3

Measures of the manufacturer ................................................................ 1-6

4

Danger overview....................................................................................... 1-7

Chapter 2 Set-up

1

Installation and Set-up of the Marking System ..................................... 2-2

1.1

Installing the software ............................................................................. 2-3

1.2

Built-in units............................................................................................. 2-4

2

Measures to prevent electronic interference ........................................ 2-5

2.1

Complying with interference suppression as per CE .............................. 2-6

Chapter 3 Description

1

Short description...................................................................................... 3-2

2

Technical data .......................................................................................... 3-2

2.1

Marking units ........................................................................................... 3-2

2.2

Control UMC box..................................................................................... 3-3

2.3

Software .................................................................................................. 3-3

B_PM_UMCbox_en00.doc

0-4

Table of contents ÖSTLING Markiersysteme GmbH

3

Description of the components .............................................................. 3-4

3.1

Marking unit............................................................................................. 3-5

Unit design ........................................................................................... 3-5

Marking heads...................................................................................... 3-6

Combination unit with marking head.................................................... 3-7

3.2

Marking tools ........................................................................................... 3-7

Examples for marking tools.................................................................. 3-8

3.3

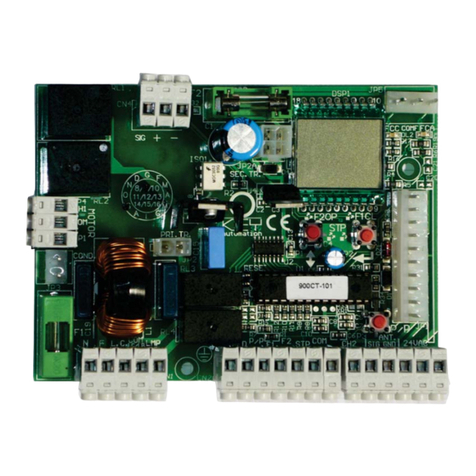

Control UMC box................................................................................... 3-10

4

External communication ....................................................................... 3-11

Chapter 4 Operation

1

Operating devices and indicators .......................................................... 4-3

1.1

Pushbuttons ............................................................................................ 4-3

1.2

Status-LEDs ............................................................................................ 4-4

2

Basics of operation.................................................................................. 4-5

2.1

Text fields, Masks and Projects .............................................................. 4-5

2.2

Switching on and off the control.............................................................. 4-6

Switching on the control ....................................................................... 4-6

Switching off the control ....................................................................... 4-7

2.3

Brief instruction: marking a workpiece .................................................... 4-7

3

Working with masks ................................................................................ 4-8

3.1

Creating a text field ................................................................................. 4-8

Creating a new text field....................................................................... 4-9

Editing a text field............................................................................... 4-11

3.2

Working with wildcards.......................................................................... 4-12

3.3

Creating objects .................................................................................... 4-12

Creating a counter.............................................................................. 4-13

Creating the object "Date and Time".................................................. 4-15

Creating the object "User Input"......................................................... 4-16

Creating a shift index.......................................................................... 4-17

3.4

Saving masks........................................................................................ 4-19

4

Working with projects............................................................................ 4-20

4.1

Saving a mask and adjustments as project .......................................... 4-20

4.2

Opening a project.................................................................................. 4-21

5

Marking a workpiece.............................................................................. 4-22

5.1

Preview on marking............................................................................... 4-22

5.2

Starting the marking .............................................................................. 4-23

6

Further functions.................................................................................... 4-24

6.1

Importing data ....................................................................................... 4-24

6.2

Changing the mode............................................................................... 4-25

B_PM_UMCbox_en00.doc

ÖSTLING Markiersysteme GmbH Table of contents

0-5

7

System control ....................................................................................... 4-26

7.1

Reading out diagnostic data.................................................................. 4-26

7.2

Operating the marking head in manual operation................................. 4-28

7.3

Displaying marking head parameters ................................................... 4-29

7.4

Displaying marking head origin............................................................. 4-30

7.5

Selecting the marking tool..................................................................... 4-31

7.6

Setting options....................................................................................... 4-32

Selecting the language....................................................................... 4-32

Selecting software adjustments ......................................................... 4-33

Changing the start mode of the control .............................................. 4-34

8

Fonts........................................................................................................ 4-35

8.1

Default font ............................................................................................ 4-35

8.2

Further fonts .......................................................................................... 4-36

Chapter 5 Maintenance

1

General Guidelines for maintenance...................................................... 5-2

1.1

Maintenance overview ............................................................................ 5-3

1.2

Lubricants................................................................................................ 5-3

2

Mechanical parts ...................................................................................... 5-4

2.1

Maintenance overview ............................................................................ 5-4

2.2

Maintenance instructions ........................................................................ 5-5

Exhaust air silencer.............................................................................. 5-5

Toothed belts of the axes..................................................................... 5-6

Slides of the axes ................................................................................. 5-8

3

Pneumatic parts ....................................................................................... 5-9

3.1

Maintenance overview ............................................................................ 5-9

3.2

Maintenance instruction ........................................................................ 5-10

Pneumatic maintenance unit.............................................................. 5-10

Chapter 6 Connector pin lists

1

Marking head ............................................................................................ 6-2

1.1

Plug to UMC box ..................................................................................... 6-2

1.2

Stepping motors ...................................................................................... 6-3

Colour coding ....................................................................................... 6-3

Circuit ................................................................................................... 6-3

2

Control UMC box...................................................................................... 6-4

2.1

Socket BU1 to marking head .................................................................. 6-5

2.2

Socket BU2 ............................................................................................. 6-6

2.3

Serial port START ................................................................................... 6-7

3

Connection cable for marking head ....................................................... 6-8

B_PM_UMCbox_en00.doc

0-6

Table of contents ÖSTLING Markiersysteme GmbH

Chapter 7 Index

Chapter 8 Drawings, parts lists

Chapter 9 EC declaration of conformity

Chapter 10 Service request

B_PM_UMCbox_en01.doc

ÖSTLING Markiersysteme GmbH Safety

1-1

Chapter 1

Safety

1

For your safety ......................................................................................... 1-2

2

Definitions................................................................................................. 1-2

3

Operational safety.................................................................................... 1-3

3.1

Intended use of the marking system ....................................................... 1-3

3.2

Measures taken by the user/operator ..................................................... 1-4

Consider warning plates and references.............................................. 1-4

Personnel instruction............................................................................ 1-4

Duty to care in handling the marking system ....................................... 1-5

Use of intended spare parts and operational funds ............................. 1-5

3.3

Measures of the manufacturer ................................................................ 1-6

4

Danger overview....................................................................................... 1-7

B_PM_UMCbox_en01.doc

1-2

Safety ÖSTLING Markiersysteme GmbH

1 For your safety

The UMC box coining unit has been developed as the newest, state-of-the-art

marking system concerning safety and reliability.

We confirm that the UMC box marking system meets the fundamental safety

and health requirements of the EEC machine guideline 98/37/EG. We provide

the "EEC conformity explanation", and the CE-indication on the marking

system.

The type plate is together with the CE-indication on the back of the UMC box.

We, as manufacturers of the marking system, want to make you, as operators,

completely familiar with the UMC box marking system. An extensive chapter

has been devoted to all the safety concepts of the marking system, and refers

to possible dangers and measures to take.

Note

Consideration must be taken into account that generally accepted safety rules,

and rules for the prevention of accidents goes beyond these references.

2 Definitions

... is the range in the periphery of the marking system, in which safety or the

health of a person is endangered by the stay in this range.

... is the person, in whose working area the marking system is set up and

operated.

... are the persons, who are responsible for transport, list, start-up, enterprise,

maintenance including cleaning and repair of the marking system.

Danger area

User

Operator/

Personnel

B_PM_UMCbox_en01.doc

ÖSTLING Markiersysteme GmbH Safety

1-3

3 Operational safety

The marking system is built according to the latest state-of-the-art technology,

and reliability in service.

From this marking system, however, dangers can proceed if it is used by un-

trained personnel inappropriately, or to not intended use. This can result in:

•Dangers for the safety of the operator.

•Impairment of the marking system and further real values of the user.

•Impairment of the efficient work of the marking system.

3.1 Intended use of the marking system

The UMC box coining unit is a marking system for marking products through

coining.

Intended use means in addition:

•The setting up conditions prescribed by the manufacturer must be kept and

maintenance work must be accomplished.

•The installation of the marking system and its operation must stand in

conformity with the valid national regulations of the user country. For their

observance the user is responsible.

Impermissible is:

•Arbitrary changing or changes of the marking system by the user or opera-

tor.

•Each function, which could impair safety.

We assume no liability from not intended use!

Each use going beyond that is not considered as intended. For material

damage and personal injuries resulting from this, the manufacturer is not

responsible; the risk for this carries alone to the user.

B_PM_UMCbox_en01.doc

1-4

Safety ÖSTLING Markiersysteme GmbH

3.2 Measures taken by the user/operator

Consider warning plates and references

Within operation and handling of the marking system, dangers can arise if not

handled with proper care. In this manual, operating instructions are given,

including appropriate warning references in the front. In addition, warning plates

can be found on the marking system.

Note

Mind the warning references!

Mind the commands and interdictions of the warning references. They serve for

your protection.

These warning references include:

•A symbol.

•References to the source and the kind of the danger.

•Instructions, how you can avoid the danger.

Example:

Heavy soiling impairs the marking system!

Marking system does not work efficiently any more.

With heavily soiled ambient air use bellows (option) as cover.

Maintain marking system regularly.

Personnel instruction

The marking system may be served, waited and repaired only by authorized,

trained and instructed personnel.

Work on the electrical and pneumatic equipment may be implemented only by

specially trained specialists.

In addition, the following measures must be taken before the personnel begins

the work of using the marking system:

•Instructs over arising dangers.

•The user must obligate, to the extent necessary, the personnel for carrying

protective clothing and gloves.

•Competencies for operation, maintenance and repair must be clearly

specified, so that under the aspect of safety no unclear authority arises.

•Read the technical documentation of the marking system. It is recommen-

ded to the user to be confirmed in writing in each case that the personnel

has read and understood the technical documentation.

B_PM_UMCbox_en01.doc

ÖSTLING Markiersysteme GmbH Safety

1-5

Duty to care in handling the marking system

Guarantee perfect condition of the installation:

•The user and/or the circle of acquaintances assigned by him may operate

the marking system exclusively in the perfect condition.

•The user must ensure cleanliness and clarity of the work place at the mar-

king system by appropriate instructions and controls.

•The user must provide for sufficient circulation of fresh air in the work

spaces.

•The operator must announce occurring changes (including the operational

behaviour) of the marking system which impair safety, immediately to the

user. In addition, the marking system must be examined at least once per

shift for outwardly recognizable lack and damage.

With all work that concern transport, installation, start-up, operation, main-

tenance and repair, the prescribed switching-off procedures must be kept:

•With any adjustments, maintenance or repairs, the marking system must

always be switched off over the MAIN SWITCH. Exceptions to it, with which

the marking system must remain switched on with appropriate work, are

noted in the manual in each case.

•With work on pneumatics:

- Turn off and lock the compressed air supply.

- Wait at least 5 s after turning off the compressed air supply, until the

pressure diminishes itself.

- Examine whether the operating pressure dropped on 0 bar. Read off

the current operating pressure from the appropriate manometer.

Use of intended spare parts and operational funds

Original parts and accessories are particularly designed and manufactured for

the marking system. Spare parts to use as original parts and accessories, which

are not supplied by the manufacturer of the marking system, are not examined

and approved by the manufacturer. The installation and/or the use of such

products can possibly change the constructionally given characteristics of the

marking system and endanger safety.

Note

For damage which results from the use of non-original parts and accessories

and/or inadequate installation or exchange of original parts and accessories, the

manufacturer assumes absolutely no liability or responsibility.

B_PM_UMCbox_en01.doc

1-6

Safety ÖSTLING Markiersysteme GmbH

When using the intended operational funds the instructions for use must be

kept. As far as a safety data sheet (European guideline 91/155/EWG) of the

manufacturer for operational funds is prescribed, the references made there

must be considered obligatorily, like e. g.:

•Chemical characterization.

•Physical and safety-relevant data.

•Transport.

•Regulations.

•Safety measures, Storage and Handling.

•Measures to be taken in case of fire and accidents.

•Toxicological information.

•Ecological information.

This applies in particular to the adequate disposal of operational funds. For this

the safety data sheet indicates the prescribed kind of disposal and the waste

key. The safety data sheet can be requested with the manufacturer of the

operational funds.

3.3 Measures of the manufacturer

All marking systems are series equipped, complete with all necessary safety

devices. During operation, all safety rules and rules for the prevention of acci-

dents must be kept.

Movable, sharp-edged parts!

Risk of injury.

Do not reach into the marking head during the marking.

Do not reach into the traversing range of the marking tool during the mar-

king.

When coining, the carbide point of the marking tool is brought to oscillating by

compressed air. Then the carbide point is moved. The stroke of the marking

tools is approx. 1 - 5 mm. Therefore reaching into the danger area is only

possible with difficulty. Due to the low force, with which the carbide point

oscillates, heavy injuries of the operator are to be excluded.

Coining

B_PM_UMCbox_en01.doc

ÖSTLING Markiersysteme GmbH Safety

1-7

4 Danger overview

The following chart outlines potential hazardous risks and endangerment to

one's life from the marking system. Through construction and design, as well as

implementation of safety devices as defined by the EEC machine guideline

98/37/EG, will prevent dangers and promote safety to personnel. If the user of

the marking system can provide additional measures for the prevention of

dangers, the user finds these additional measures in the following chart.

Type of endangerment Spot of endangerment Danger Additional measure

Mechanical endangerment

•By squeezing

•Marking tool

•Marking head

Risk of injury

Risk of injury

Do not reach into the

danger area.

•By cutting and

chopping off

•Marking tool

•Marking head

Risk of injury

Risk of injury

Do not reach into the

danger area.

Electrical endangerment

•By electrical contact

•Directly with parts that

are normally under

voltage.

•Indirectly with parts that

are under voltage in

failure.

Danger of life

Danger of life

-

-

Endangerment caused by

breakdown or failure

•Failure in power supply

•Drives

•Control voltage

Risk of injury

Risk of injury

-

-

Tab. 1

B_PM_UMCbox_en01.doc

1-8

Safety ÖSTLING Markiersysteme GmbH

B_PM_UMCbox_en02.doc

ÖSTLING Markiersysteme GmbH Set-up

2-1

Chapter 2

Set-up

1

Installing and setting up the marking system....................................... 2-2

1.1

Installing the software ............................................................................. 2-3

1.2

Built-in units............................................................................................. 2-4

2

Measures to prevent electronic interference ........................................ 2-5

2.1

Complying with interference suppression as per CE .............................. 2-6

B_PM_UMCbox_en02.doc

2-2

Set-up ÖSTLING Markiersysteme GmbH

1 Installation and Set-up of the Marking System

1. Install the marking system in compliance with all safety rules.

2. Supply the marking head with oiled and cleaned compressed air via the

designated connection.

1 26-pin plug of the connection cable

2 21-pin plug of the connection cable

3 21-pin connection at the marking head

Connection cable for marking head and marking head Fig. 10372

4 MAIN SWITCH

5 Fuse 2 A, T

6 Connection line cord

7 Serial port RS232

8 Serial port foot switch

9 Connection BU2

10 26-pin connection BU1

11 Grounding screw

Back side of the control UMC box Fig. 10388

3. Tuck the 21-pin plug of the connection cable (2) into the 21-pin connection

(3) at the marking head. Ensure the coding pin of the plug is inserted into

the flute of the connection.

4. To screw the plug: turn the outer ring of the plug clockwise.

5. Fix the grounding wire of the connection cable under a screw of the housing

of the marking head.

B_PM_UMCbox_en02.doc

ÖSTLING Markiersysteme GmbH Set-up

2-3

6. Tuck the 26-pin plug of the connection cable (1) into the 26-pin connection

BU1 (10) on the back side of the control UMC box. Ensure the coding pin of

the plug is inserted into the flute of the connection.

7. To screw the plug: turn the outer ring of the plug clockwise.

8. Fix the grounding wire of the connection cable with the grounding screw

(11).

9. Tuck the hollow plug of the 24 V power supply into the connection line cord

(6).

10. Attach the line cord of the24 V power supply to the supply voltage (115/

230 V, 50/ 60 Hz).

11. Connect the serial port RS232 (7) with the serial port of the PC via the PC

connecting cable.

12. Install software PinWare on the PC (see below).

13. If desired attach foot switch to the serial port foot switch (8).

14. Tuck E-STOP dummy plug into the connection BU2.

15. Switch on the control via MAIN SWITCH (4).

1.1 Installing the software

1. Insert CD with software PinWare into the CD drive.

2. To install the software:

- If CD auto start is active: wait until the installation menu is displayed.

- Select Install [...].

- Follow the instruction on the monitor.

or

- To start the installation manually: select Start > Run... in Windows.

- Select Browse....

- Select the file 'Setup.exe' on the CD.

- Follow the instruction on the monitor.

3. Reboot the PC.

B_PM_UMCbox_en02.doc

2-4

Set-up ÖSTLING Markiersysteme GmbH

1.2 Built-in units

Horizontal (on the left) and vertical installation of the marking head Fig. 10262

All marking heads are supplied ready for use. The following points must be con-

sidered when installing the marking head into a production line:

•Built-in units must be installed adjustable to allow subsequent aligning

and/or exact adjusting of the distance tool tip - workpiece.

•Use a bellows (option) as cover if the unit is operated in a heavily soiled

working environment. This cover can be used only with horizontal instal-

lation of the unit.

Marking head 5 / 9 with coining tool WE2 and bellows (option) Fig. 10276

B_PM_UMCbox_en02.doc

ÖSTLING Markiersysteme GmbH Set-up

2-5

With vertical/lateral installation of the marking head (front of the marking head

shows upward), the following points must be additionally considered:

•Marking tool can move down by itself, since the driving motors are dead

after switching off the marking equipment and possess no automatic

locking.

•Bellows (option) cannot be used.

•The y

•Y-axis is the axis with the shorter traverse path. The marking head may be

inserted only with perpendicular Y-axis (see Fig. 10262, page 2-4).

2 Measures to prevent electronic interference

The following general references secure a trouble-free operation of an electrical

system:

•Take the main power supply directly from the switch cabinet feed.

•Signal cables must not be laid together with cables carrying power.

•Signal cables may not be laid with cables from units that would cause inter-

ference (e. g. contactors, power motors). Otherwise use shielded mains

cable and ground the shielding at one end. The same applies for the auxi-

liary power supply for controllers and isolating amplifiers.

•Sources of severe interference such as contactors and motors should be

suppressed with RC components. Within the switch units only use

switching equipment and other devices that have been suppressed by RC

combinations, for example. It is necessary to note the standard codes of

practice for electrical work (VDE, DIN and the corresponding EN).

•The reference value output must be shielded. The shielding must be groun-

ded at one end.

•Controllers and switchover relays for the manual setting of reference values

should be placed as close as possible to the program encoder. If it is not

possible to do this, an isolating amplifier is to be installed in the reference

value output immediately behind the program encoder.

B_PM_UMCbox_en02.doc

2-6

Set-up ÖSTLING Markiersysteme GmbH

2.1 Complying with interference suppression as per CE

The marking system UMC box, coining unit, is designed and build according to

the regulations of the electromagnetic compatibility guideline. To ensure

interference suppression the following points must be considered:

•Use shielded control cables to connect all external components (e. g.

marking head, foot switch, signal inputs and outputs) to the connection BU2

(DB37) at the control. At the back of the control the shielding of all the

cables must be connected at the controller end to the grounding screw (11,

Fig. 10388, page 2-2) via a cable that must be kept as short as possible.

•The grounding screw of the control UMC box must be connected to the

system ground (at the power supply feed) via a separate grounding cable.

When integrating the control into a more sophisticated production line the

grounding screw must be connected with the central ground supply point of

the line via a separate grounding cable. The cross-section of the cable

should be at least 2.5 mm

2

.

•Length connection cable control - marking head max. 2 m.

•Cable foot switch two-core with shielding, a two-pole jack plug made of

plastic must be used.

•Length cable foot switch max. 3 m.

•Lay the connection cable control - marking head and the cable foot switch

separately from any possible sources of interference (see also paragraph

2).

•The following should be noted when connecting external components to the

control UMC box:

- The components used (e. g. monitor, printer) must likewise comply

with the CE standards for industrial use.

- Length connection cable control - external component max. 2 m. Shiel-

ded cables and plugs with metal housings must be used.

- If connections to or from the serial port (RS232) cause functional

errors, change over from this type of connection to one that is not

subject to interference (e. g. RS485, fiber optic connection, galvanic

separation through an opto-electronic coupler).

Table of contents