1

Input

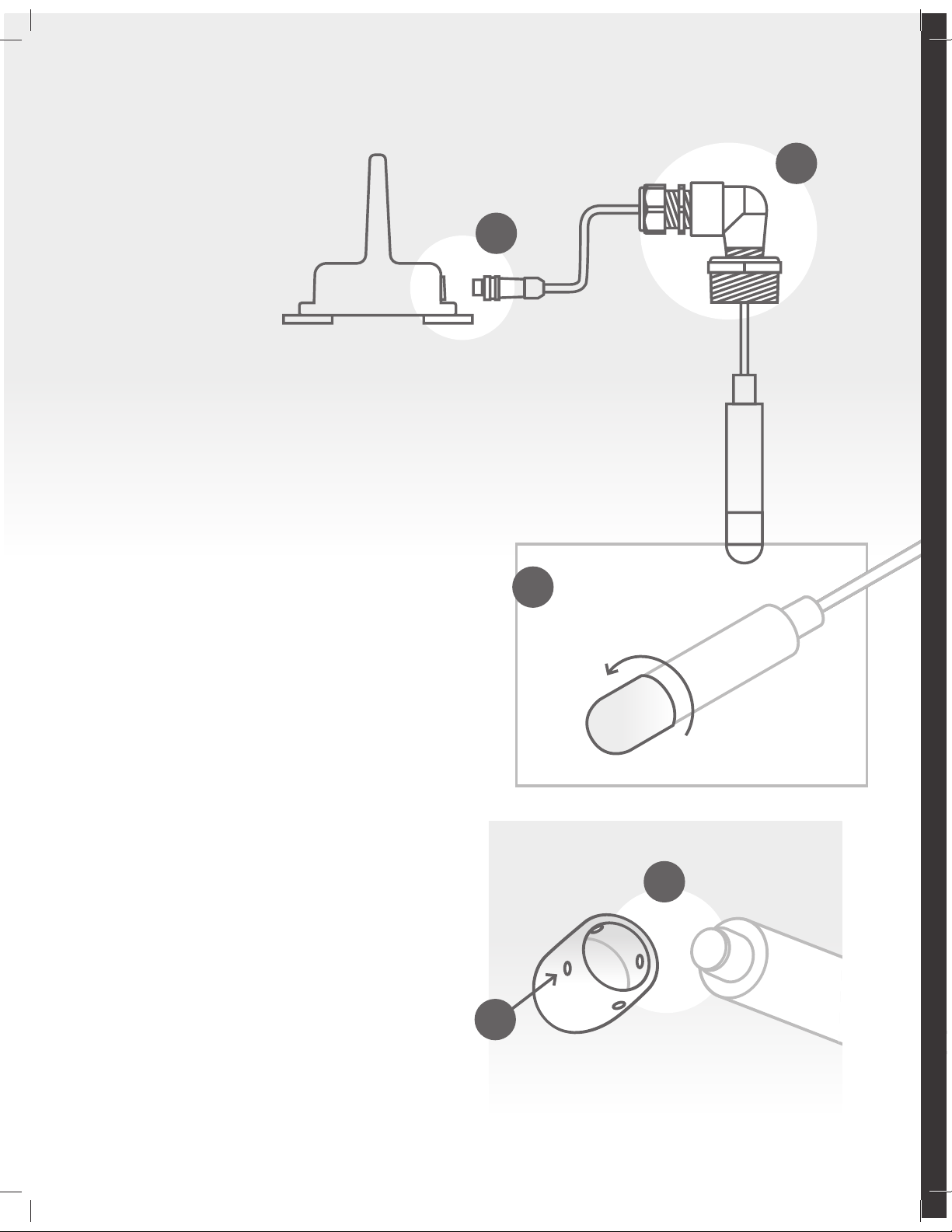

Hydrostatic Pressure transducer with dierential to

atmospheric pressure 0.5-4.5V non-ratiometric

Reporting & Outputs

Reporting Tank level (5% variation)

Low battery

High/Excessive draw

Fill Detection

Temperature

Data Interface API

Email (to supplier and/or

consumer)

Raw data

Online dashboard

Client mobile app

Automated Testing Network status

Lead sensor status

Battery status

Electrical Specifications

Battery Pack Hybrid LTC 3.6 VDC 7.2 VDC

Radio Specifications

Technologies 4G, LTE CAT1, CATM, NB IOT, 3G

Dual SIM

Bluetooth

Environmental Specifications

Operating & storage

temp. range -40˚C to 60˚C -40˚F to 140˚F

Relative humidity range 0% to 100%

Enclosure rating IP68

Warranty 5+ years

Option GPS (mobile tank)

Certifications

Monitors are third-party QPS Evaluation Services Inc.

Certified for use in hazardous locations

United States

Ratings Class I, Division 2, Groups

C-D, T3 Class I, Zone 2, AEx ic

[ia Ga] IIB T3 Gc

Standards applied:

UL 60079-0:2019 - UL 60079-11:2013

Canada

Ratings Class I, Division 2, Groups

C-D, T3 Ex ic [ia Ga] IIB T3 Gc

Standards applied:

CSA 60079-0:19 - CSA 60079-11:14

Dimensions

Height 14 cm 5.5 in

Width 14 cm 5.5 in

Depth 9.5 cm 3.5 in

Applications

Level Measurement in Bio-Fuels

Monitoring of Gasoline and Diesel Fuel Tanks

Level Measurements in Ballast Tanks

Level Measurements in Oil Tanks

Monitoring of Contain Coolant for Diesel Engines

Level Measurement in AdBlue Tanks

Level Measurement in Kerosene

Characteristics

MEAS TE pressure cell, 0.5% F.S.

Survives Harsh Environments

EMI/RFI Protection

Custom level ranges from 1.5 to 16m

PUR cable lengths

Order

Otodata Monitor with Hydrostatic Pressure Sensor

(Range 0-1.5ft) TM7530HP-001

Otodata Monitor with Hydrostatic Pressure Sensor

(Range 0-4.5ft) TM7530HP-002

Otodata Monitor with Hydrostatic Pressure Sensor

(Range 0-6.5ft) TM7530HP-003

Otodata Monitor with Hydrostatic Pressure Sensor

(Range 0-12.5ft) TM7530HP-005

Otodata Monitor with Hydrostatic Pressure Sensor

(Range 0-25ft) TM7530HP-009

Otodata Monitor with Hydrostatic Pressure Sensor

(Range 0-32ft) TM7530HP-011

Otodata Monitor with Hydrostatic Pressure Sensor

(Range 0-52ft) TM7530HP-017

This device complies with part 15 of the FCC Rules. Changes or modifications not expressly approved by the party responsible for compliance could void the user's authority to operate the equipment. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation. This device is compliant with Industry Canada's RSS standards for

license-exempt radio apparatuses. Authorized use depends on the following two conditions: (1) the device must not create radio interference, and (2) the device user must accept all radio interference, even if this interference could potentially impair

its functioning. This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee

that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment o and on, the user is encouraged to try to correct the

interference by one or more of the following measures: —Reorient or relocate the receiving antenna. —Increase the separation between the equipment and receiver. —Connect the equipment into an outlet on a circuit dierent from that to which the

receiver is connected. —Consult the dealer or an experienced radio/TV technician for help.

Specifications Fuel, lubricants, oil and more. A tank

monitor to suit your corporate needs.