OutBack Power FXR Series User manual

Quick Start Guide

Specifications

FXR™ and VFXR™ (A) Series Inverter/Charger

900-0213-01-00 REV B

Do not copy or distribute without permission.

This Quick Start Guide is printed in unbound format. The pages can be read in any order, or shown alongside one another.

WARNING: Fire/Explosion Hazard

Do not place combustible or flammable materials within 12 feet (3.7 m) of the equipment. This unit employs mechanical relays and is not

ignition-protected. Fumes or spills from flammable materials could be ignited by sparks.

WARNING: Personal Injury

Use safe lifting techniques and standard safety equipment when working with this equipment.

IMPORTANT:

Clearance and access requirements may vary by location. Maintaining a 36” (91.4 cm) clear space in front of the system for access is

recommended. Consult local electric code to confirm clearance and access requirements for the specific location.

IMPORTANT:

These instructions are for use by qualified personnel who meet all local and governmental code requirements for licensing and training

for the installation of electrical power systems with AC and DC voltage up to 600 volts. This product is only serviceable by qualified

personnel. All system wiring must comply with national and local codes and regulations.

This product is designed and tested for stationary applications only. It is not listed or warranted for mobile use.

NOTE:

This document is for installation of a single inverter. For stacking of multiple inverters, product specifications, functions, applications,

and programming instructions, see the FXR and VFXR product literature.

This document assumes the use of the MATE3s system display. For menu navigation, see the system display product literature.

This document contains hyperlinks and QR codes leading to the product literature at www.outbackpower.com.

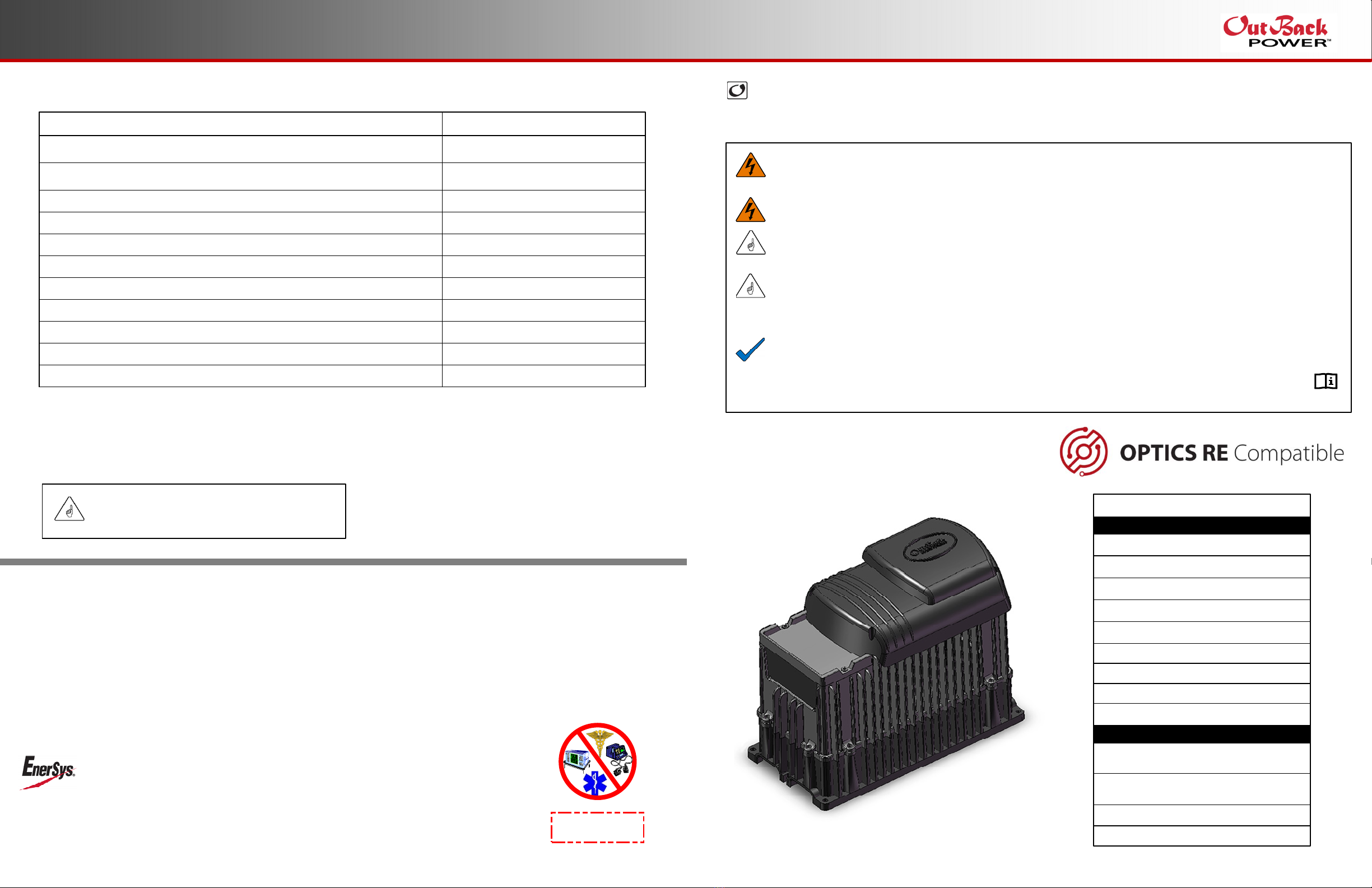

FXR (A Series)

Sealed Inverter

with Turbo Fan

Inverter/Charger

AC Enclosure (with Bypass Assembly)

DC Enclosure (with Inverter Disconnect)

System Display and Controller (MATE3s™)

PV Charge Controller

Communications Manager

Main Electrical Panel and

Distribution Subpanel (Load Panel)

Battery Bank

Battery Monitor

Other Components

FLEXpower™ System Products

Major System Components

Photovoltaic (PV) Array and Combiner

AC Source Utility Grid, or

AC Generator

Remote Temperature Sensor (RTS)

Surge Protector

Specification Value

Rated Temperature Range (meets component specifications; however, please note

that the inverter output wattage is derated above 25°C)

Operational Temperature Range (functions, but not rated for operation; does not

necessarily meet all component specifications)

Storage Temperature Range

IP (Ingress Protection) Rating of Enclosure

Environmental Category

Wet Locations Classification

Relative Humidity Rating

Pollution Degree Classification

Maximum Altitude Rating

–4°F to 122°F (–20°C to 50°C)

–40°F to 140°F (–40°C to 60°C)

–40°F to 140°F (–40°C to 60°C)

IP20

Indoor, Unconditioned

Wet locations: No

93%

PD 2

6561’ (2000 m)

All FXR inverters can deliver their full rated wattage at temperatures up to 25°C (77°F). The FXR

maximum wattage is rated less in higher temperatures. Above 25°C, each inverter model is derated by

a factor of 1% of that model’s rated wattage for every increase of 1°C. This derating applies to all

power conversion functions (inverting, charging, selling, offsetting, etc.)

Overvoltage Category (AC Input) 3

Overvoltage Category (DC Input) 1

Environmental Specifications

IMPORTANT:

This inverter is intended for indoor use only. Failure to

adequately protect the inverter will void the warranty.

IMPORTANT:

Not intended for use with

life support equipment.

Warranty

The warranty for this product can be downloaded from

https://www.outbackpower.com/resources/warranty/procedures

A copy is available by sending a self-addressed envelope to the address

noted to the left.

World Headquarters

2366 Bernville Road

Reading, PA 19605 USA

+1 610-208-1991 / +1 800-538-3627

EnerSys EMEA

EH Europe GmbH

Baarerstrasse 18

6300 Zug Switzerland

EnerSys Asia

152 Beach Road

Gateway East Building #11-08

Singapore 189721 / +65 6508-1780

For more information visit www.enersys.com ©2017 EnerSys. All Rights Reserved. Trademarks and logos are the property

of EnerSys and its affiliates unless otherwise noted. Subject to revisions without prior notice. E.&O.E.

Contact Information

Mailing Address: 3767 Alpha Way

Bellingham, WA 98226 USA

Web Site: www.outbackpower.com

Date and Revision

September 2022, Revision B

1

Installation

Requirements

oThe FXR and VFXR inverter/chargers are intended for

indoor installation only.

oEnsure the mounting surface is strong enough to

handle 3 times the total weight of all the components.

oThe inverter has four 0.313" (8 mm) mounting holes

( ), one in each corner. Use fasteners in all corners.

oDue to the variance in other mounting methods, OutBack

Power only endorses the use of FLEXware mounting

products. Use M6 × 20 mm machine screws, one per

corner, to attach the inverter to the mounting plate.

Follow the instructions with each mounting system.

oMount and secure each component before attaching any

wiring.

oWhen the inverter is used with other metal chassis, make

sure that all chassis are grounded. Use either metal-to-

metal contact or separate ground wires as appropriate.

oFor more information, see the FXR Installation Manual.

See QR code above.

Tools Required

oWrench and socket sets; should include

Torque and ratchet wrenches

oWire cutters/strippers

oInsulated screwdriver set (flat and Phillips);

should include

Miniature flat screwdriver for AUX connections

oLong-nose pliers

oHigh-resolution voltmeter

900-0213-01-00 REV B

Do not copy or distribute without permission.

If it becomes necessary to

remove the Turbo Fan:

1. Remove the screws at the four

corners of the Turbo Fan.

2. Remove the compartment cover.

3. Unscrew the AUX+ and AUX–

terminal screws.

4. Remove the wires.

5. Remove the Turbo Fan.

IMPORTANT:

Use correct fasteners to secure the inverter to the

mounting surface. OutBack cannot be responsible for

damage to the product if it is attached with

inadequate fasteners.

IMPORTANT:

While sealed FXR models are more tolerant of incidental

dust and moisture than VFX models, none of these products

are intended for installation outdoors. Failure to adequately

protect the inverter from weather will void the warranty.

DC Cover or Turbo Fan Attachment

FXR inverters are equipped with either the DC

Cover or the Turbo Fan. To attach either cover,

put the cover in place and insert a screw at each

corner using a Phillips screwdriver. Make

certain the red and black battery terminals are

installed before attaching the cover.

As part of attaching the Turbo Fan, follow the

wiring instructions below.

Install the wires in the AC Wiring Compartment to make

the Turbo Fan operational. The AUX+ and AUX–

terminals receive the red (+) and black (–) wires.

Tighten with a Phillips screwdriver.

To safely run the wires into the AC compartment, pass

the wires through the notch in the compartment cover.

Notch Edge of Cover

Compartment

If necessary, the green terminal block can be

unplugged by pulling it gently away from the AC board.

A

A A

A A

7.5"

(19.0 cm)

15.5"

(39.4 cm)

Make certain the AUX programming is

correct for proper fan operation.

14.0"

(35.6 cm)

12.0"

(31.8 cm)

12.0"

(31.8 cm)

12.0"

(31.8 cm)

Materials in Box

oInverter

oQuick Start Guide

(this document)

oBattery terminal

covers, red/black

o“WARNING ELECTRICAL SHOCK” sticker

oAC plate

oDC Cover (DCC) or Turbo Fan

oRemote Temp. Sensor (RTS)

oSilicone grease packet

Height with DCC

Height with Turbo Fan

1

IMPORTANT

This product requires batteries for operation.

The required nominal voltage is either 12, 24, or

48 Vdc, depending on model.

The default inverter/charger settings assume a

deep-cycle stationary lead-acid battery, such as

OutBack Power’s EnergyCell RE or NC series

batteries. Ensure the settings are appropriate

for the specific batteries used in the system.

Protection for the battery circuit external

to this product must be provided by the installer.

Protection for the AC circuit external to this

product must be provided by the installer.

For more information, see the FXR Installation

Manual.

Wiring Data

Ground Lug

1

AC Neutral

Terminals

2

3

4

Battery Positive Stud

Battery Negative Stud

5

AC Hot Out Terminal

6Ground Terminals

Inverter On/Off Jumper

7

8

AC Hot In Terminal

9

10

Inverter On/Off Terminals

Auxiliary Terminals

11

12

13

14

Temperature Sensor Port

Communication Port

Battery LED Indicators

Status LED Indicators

900-0213-01-00 REV B

Do not copy or distribute without permission.

DC Wiring Notes

oBattery cables should be no longer than 10 feet (3 m) each to minimize voltage loss and other possible effects.

oTurn off DC circuit breakers before proceeding.

oTie, tape, or twist cables together to reduce self-inductance. Run positive and negative cables through the same

knockouts and conduit.

oEach inverter battery terminal is a threaded stud which accepts a ring terminal lug. Use crimped and sealed copper ring

lugs with 5/16 inch (0.79 cm) holes, or use compression lugs.

oInstall overcurrent devices according to applicable codes.

oThe DC terminals must be installed in an enclosure to meet the requirements of some local or national codes.

AC Wiring Notes

oRecommended conductor size is #6 AWG (16 mm2) or 0.021 in2.

oInverter output varies with model. Size the loads accordingly.

oThe transfer relay is rated 60 Aac; AC input and output may need to be protected with branch-rated circuit breakers of

maximum 60 Aac size to meet applicable code requirements.

oThe neutral terminals are common. Typically only one is used.

oOnly one AC source can be wired at a time. Use an external selector switch if more than one source is available.

Generator Notes

A generator should be sized to provide enough power for maximum loads and charging at the same time.

Minimum generator size is recommended to be twice the power of the inverter(s) due to overload and/or

balancing issues.

1

2

3

4

5

5

6

7

8910

11

12

13 14

6

Inverter

(Wattage/Voltage)

Nominal

DC Amps

(Derated 125%)

Conductor Size

(Minimum)

Breaker

Size

(Minimum)

FXR2012A

VFXR2812A

FXR2524A

VFXR3524A

FXR3048A

VFXR3648A

Terminal Location

Inverter DC Terminals

Battery Terminals

200 4/0 AWG (120 mm2) or 0.186 in2250 Adc

280 4/0 AWG (120 mm2) or 0.186 in2250 Adc

125 2/0 AWG (70 mm2) or 0.109 in2175 Adc

175 4/0 AWG (120 mm2) or 0.186 in2250 Adc

75 1/0 AWG (70 mm2) or 0.109 in2125 Adc

90 1/0 AWG (70 mm2) or 0.109 in2125 Adc

Torque Requirements

60 in-lb (6.9 Nm)

See battery manufacturer’s recommendations

CAUTION:

Equipment Damage

When connecting battery cables to the

inverter, observe the proper polarity.

Incorrect connection can damage or

destroy the equipment and void the

product warranty.

!

M8 x 1.25 Stud

Insulator

Mounting

Surface

Battery

Terminal Post

Lock Washer

Battery Cable Connections

13 mm Nut

Battery

Cable

Lug

CAUTION: Fire Hazard

Do not stack battery terminal hardware

in any other order than shown here.

Stacking terminal hardware in any other

order can overheat the terminals.

Other devices may be installed on

the same inverter studs above the

hardware shown here.

!

Grounding Notes

oThis product meets the IEC requirements of Protection Class I.

oThis product must be connected to a permanent wiring system that is grounded according to the IEC 60364 TN standard.

oThe input and output circuits are isolated from ground. The installer is responsible for system grounding according to all

applicable codes.

oThe central AC ground terminals are common. Typically only one is used.

WARNING: Shock Hazard

For safety, the neutral and ground conductors should be mechanically bonded. OutBack Power

does not bond these conductors within the inverter. Some codes require the bond to be made at the

main panel only. Make sure that no more than one bond is present in the AC system at any time.

For all installations, the negative battery conductor should be bonded to the grounding system at

only one point. If the OutBack Power GFDI is present, it can provide the bond.

Terminal Location Minimum Conductor Size Torque Requirements

Central AC Terminals

DC Box Lug

#10 AWG (0.009 in²) or 6 mm² 25 in-lb (2.8 Nm)

#6 AWG* (0.025 in²) or 16 mm² 45 in-lb (5.1 Nm)

*Accepts up to 1/0 AWG (70 mm² or 0.109 in²) wire. The DC Cover or Turbo Fan must be removed before making the ground connection.

Flat Washer

1

1

CAUTION: Fire Hazard

Before energizing, confirm that all hardware

is installed as shown on the Installation page.

Stacking battery terminal hardware in any

other order can overheat the terminals.

!

900-0213-01-00 REV B

Do not copy or distribute without permission.

Energize/Startup

Procedures

De-energize/Shutdown

Procedures

WARNING: Lethal Voltage

Review the system configuration to identify all possible sources of

energy. Ensure ALL sources of power are disconnected before

performing any installation or maintenance on this equipment.

Confirm that the terminals are de-energized using a validated

voltmeter (rated for a minimum 1000 Vac and 1000 Vdc) to verify

the de-energized condition.

WARNING: Lethal Voltage

The numbered steps will remove power from the inverter and

charge controller. However, sources of energy may still be

present inside the wiring boxes and other locations. To ensure

absolute safety, disconnect ALL power connections at the source.

WARNING: Burn Hazard

Internal parts can become hot during operation. Do not remove

the cover during operation or touch any internal parts. Be sure to

allow them sufficient time to cool down before attempting to

perform any maintenance.

To de-energize or shut down the OutBack Power devices:

1. Open the AC circuit breakers.

2. Open the DC circuit breaker for the battery.

3. Open the PV circuit breaker, if present.

4. Open the ground-fault circuit breaker, if present.

5. Open the FLEXnet DC circuit breaker, if present.

6. Verify 0 Vdc on the DC input terminals of the inverter by placing the

voltmeter leads on and .

7. Verify 0 Vdc on the PV charge controller terminals, if present.

8. Verify less than 5 Vac on the AC output circuit terminals

and .

9. Verify less than 5 Vac on the AC input circuit terminals

and .

2

3

4

4a 4b

Pre-startup Procedures

After opening the AC and DC enclosures:

1. Double-check all wiring connections. Ensure all torque values are met.

See Wiring Data on the other side of this sheet.

2. Inspect any enclosures to ensure no tools or debris were left inside.

3. Disconnect all AC loads at the backup (or critical) load panel.

4. Disconnect the AC input to the inverter system at the source.

5. If a mechanical interlock is used, place it in the normal (non-bypass) position.

6. Using a digital voltmeter, verify 12, 24, or 48 Vdc at the battery source. Confirm the polarity.

These instructions assume the use of AC and DC wiring boxes of OutBack Power models.

To energize or start up the OutBack Power devices:

1. Close the DC circuit breaker from the battery bank to the inverter.

2. Using a digital voltmeter, verify 12, 24, or 48 Vdc on the DC input terminals by placing the

DVM leads on and . Confirm that the voltage and polarity are correct for the inverter

and charge controller models.

3. If PV is installed, verify the correct voltage and polarity at the charge controller terminals.

4. Close the ground-fault circuit breaker, if present.

5. Close the PV input circuit breakers, if present.

6. Close the circuit breaker for the FLEXnet DC, if present.

7. Using the system display, perform any necessary programming, particularly for the size of the

AC input source(s). See Sheet 3 for the Profile Wizard.

8. The factory default state for all FXR inverters is OFF. Using the system display, turn the

inverter to the ON state.

9. Using the DVM, verify the inverter AC output on the AC output circuit terminals and .

10. Without closing the inverter system’s AC input circuit breakers: Using the DVM, test the

voltage of any input AC source(s).

11. Connect the AC source. Close the inverter system’s AC input circuit breakers.

Using the DVM, verify 120 Vac on the AC input circuit terminals and .

NOTE: After a brief delay, the inverter’s transfer relay will activate unless the inverter’s

settings have been changed. Using the system display, verify the input source and the

inverter’s charging function. After verification, disconnect the AC source.

12. Replace the covers on the AC and DC enclosures.

13. Close the AC output circuit breakers. Turn on the AC disconnects at the load panel

and test the inverter’s output while operating loads.

1 2

5

4

2

1

6

5

3a 3b

12

2

1

3

6

65

4a4b

1

3

4

Functional Test Points

Battery Negative (–) Terminal

Battery Positive (+) Terminal

AC HOT IN Terminal

AC NEUTRAL IN Terminal*

AC HOT OUT Terminal

AC NEUTRAL OUT Terminal*

*Terminals 3b and 4b are electrically common.

1

2

3a

3b

4a

4b

3a 3b

4a 4b

1 2

4a4b

12

3

2

4

11

5

3a 3b

3a 3b

CAUTION: Equipment Damage

Incorrect battery polarity will damage the equipment.

!

12

NOTES:

o

o

If a system display is not present, the inverter must be

turned off or on using an external switch or the ON/OFF jumper.

See the Installation Manual for more instructions.

1

If any of these tests do not function as described, or for other

troubleshooting, see the Operator’s Manual.

2

900-0213-01-00 REV B

Do not copy or distribute without permission.

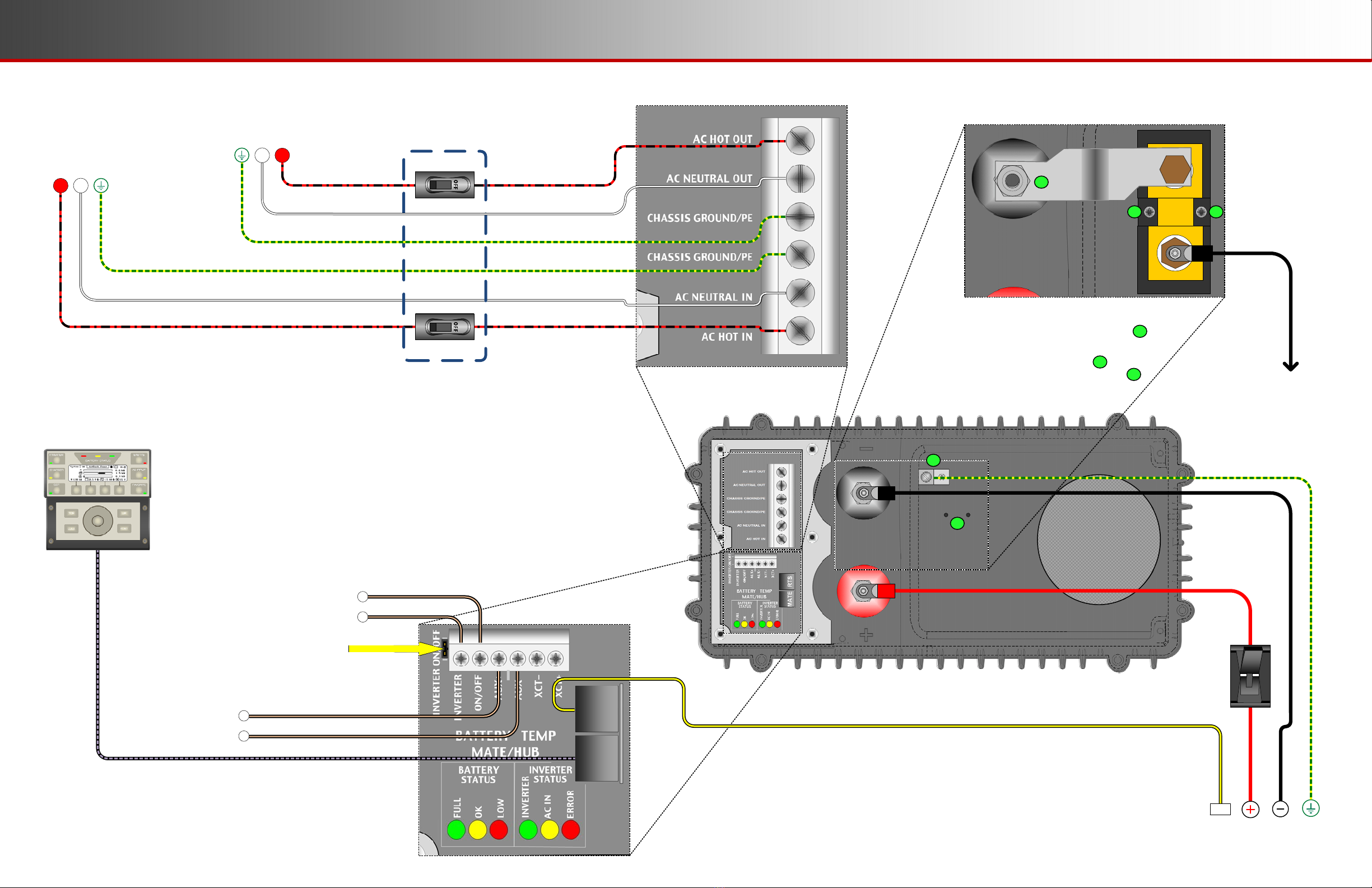

Wiring

AC

Main Panel,

Grounded,

with

AC Source

AC

Subpanel

with Loads

Battery Bank

MATE3s System

Display

On/Off

Switch

or

Rapid

Shutdown

Also

Remove

On/Off Jumper

Auxiliary Device

or Generator Start

(if used)

AC

Bypass Interlock

(if used)

With Shunt (if used)

When installing a shunt for use with the FLEXnet DC

or a similar battery monitor, remove the ground lug .

Attach the shunt using the threaded holes .

The shunt connects to the negative terminal as in .

The negative cable connects to the shunt.

1

2

2

1

2 2

3

3

FXR Inverter

L1 N

L1N

RTS

2

Setup and Programming

900-0213-01-00 REV B

Do not copy or distribute without permission.

!

Inverter Status LED Indicators

Green

Yellow

Red

Inverter on (solid) or standing by (flash)

AC source in use (solid) or standing by (flash)

Inverter error or warning (see manual)

Green

Yellow

Red

12.5 Vdc or higher

11.5 to 12.4 Vdc

11.4 Vdc or lower

Color

Battery Status LED Indicators

25.0 Vdc or higher

23.0 to 24.8 Vdc

22.8 Vdc or lower

50.0 Vdc or higher

46.0 to 49.6 Vdc

45.6 Vdc or lower

12 V Inverter 24 V Inverter 48 V Inverter

Monitoring

A

B

Profile Wizard

In the MATE3s system display, the Profile Wizard allows quick setup of parameters that apply to all systems. The Profile Wizard is

reached from the Main Menu as shown in

B

.

The Profile Wizard is useful for rapid setup of multiple parameters including date, time, battery charging, AC source size and limits, and

System Type. It can also configure functions such as High Battery Transfer and Grid Use times. Note that these two functions are not

available if the System Type is set to Off Grid.

NOTE: The Wizard does not configure the entire system. It does not select AC input modes for the FXR inverter, parameters for

automatic generators, or “fully charged” parameters if the FLEXnet DC battery monitor is in use. If settings are made in the wrong order,

the Wizard can overwrite some customized settings. See MATE3s Programming Guide for more information.

3

The firmware revision of all devices can be confirmed by navigating from the Main Menu as shown in

A

. Upgrades to the firmware

revision can be downloaded from the OutBack Power website.

4

Profile Wizard

New Profile Initialized

Back Continue

Wizard Date & Time

16:56

13 May 2022 Fri

Back Continue

Wizard System Type

System Type Grid Tied

System Voltage 48 VDC

Array Wattage 1000

Battery Type FLA Capacity 500 Ah

Back Continue

Grid Tied

Main Menu

Settings >>

Profile Wizard >>

Device Data Logs >>

Event Logs >>

Firmware Update >>

Profile Wizard

Profile Wizard

New Profile >>

Existing Profile >>

Restore Profile >>

New Profile

System Configuration

System Information >>

Save / Store Configuration >>

Firmware Version >>

Date and Time >>

LCD Display >>

Firmware Version

Firmware Versions

MATE3s 001.001.000

1:VFXR3648A 001.006.063

2:VFXR3648A 001.006.063

Main Menu

Settings >>

Profile Wizard >>

Device Data Logs >>

Event Logs >>

Firmware Update >>

Profile Wizard

Settings Menu

System >>

Inverter >>

Charge Controller >>

Battery Monitor >>

MATE3s >>

System

A

Wizard AC Configuration

AC Output Voltage 120 VAC

AC Phase Single

AC Input Breaker Size 60 A

Maximum Output Load 33 A

Back Continue

120

Wizard AC Input Limits

Grid Lower Voltage Limit 105 VAC

Grid Upper Voltage Limit 132 VAC

Gen Lower Voltage Limit 108 VAC

Gen Upper Voltage Limit 140 VAC

Back Continue

105

Wizard Generator Configuration

Generator Installed N

Generator Type AC Size 5.0 kW

Generator Start Manual

AUX Output Device Port 1

Back Continue

N

Wizard Battery Charging

Absorb Voltage 57.6 VDC Time 1.0

Float Voltage 54.4 VDC Time 1.0

Equalize Voltage 60.0 VDC Time 3.0

Re-Float Voltage 44.0 VDC

Back Continue

The FLEXnet DC (FN-DC) is a battery monitor which

measures DC current flow on one or more shunts.

It provides battery state-of-charge (SoC) information.

Exact measurements and programming are performed with

the system display. (See the system display and FLEXnet

DC literature.) The LED indicators shown below provide

approximate measurements of the battery state of charge.

FLEXnet DC Battery Monitor

oA green indicator (FULL) means the batteries have an adequate charge. It does

not always mean they are full.

oA yellow indicator (OK) means the batteries are somewhat discharged.

oA red indicator (LOW) means the batteries are greatly discharged and may require

attention. A low battery error may be accompanied by a red STATUS indicator.

The STATUS indicators show the inverter’s operating condition as shown below.

Green

Color

Red

Yellow

Yellow

Yellow ≥ 80%

≥ 70%

≥ 60%

≥ 60% off, < 60% solid, < 50% blinks

Battery State of Charge

FN-DC LED Indicators

> 90% (blinks if charge parameters are met)

After commissioning and programming the FXR system, perform a full battery charge.

Reset the FN-DC by unplugging the communications cable and then plugging it back

in. (The system must be energized at the time.) The FN-DC will reset to 100% SoC,

matching the batteries if they have been charged.

NOTE: The user must program the FN-DC with correct values for battery capacity

and charging requirements. The factory default values may not be correct. If not

programmed accurately, the FN-DC readings and LED indicators will not be accurate.

The same is true if the shunt(s) are not wired correctly. See the FLEXnet DC

Overview Guide for more information.

5

LED Indicators

The inverter has two sets of LED indicators. (See Sheet 2 for locations.)

The BATTERY indicators show the approximate battery state.

NOTE: Due to different system states, battery voltage does not always indicate an

accurate state of charge. The FN-DC is more accurate.

See the inverter Operator’s Manual for full descriptions of these LED indicators.

A

This advances the display to the Setup

Complete screen.

BIf the FLEXnet DC is installed, the

display advances to the Shunt screens.

If the FLEXnet DC is not installed, see .

C

If the System Type is Grid Tied or Backup, the

display advances to the Grid Use Schedule

screens. If the System Type is Off Grid, see .

B

C

CAUTION: Equipment Damage

These procedures should be done by a qualified installer who is trained on programming inverter power systems. Failure to set accurate

parameters for the system could potentially cause equipment damage. Damage caused by inaccurate programming is not covered by the

limited warranty for the system.

IMPORTANT

Ensure all settings are correct for the system. The Profile Wizard can be used for rapid setup. For Grid Support functions it may be

necessary to load a .GIP file. This document assumes the use of the MATE3s System Display.

Verify the firmware revision of all OutBack Power devices before use. The FXR inverter and system display may not communicate or

operate correctly unless their firmware is above a specified revision number. Radian inverters with firmware revision 001.006.061 or

higher must use the MATE3s system display.

For firmware and .GIP file installation, see the Installation Manual. For settings and functions, see the Operator’s Manual.

If FN-DC

is installed...

If

System Type

is

Grid Tied

or

Backup

...

B

C

A

Wizard Grid Use Schedule

Period 1 Enable N

Weekday Use 0:00 Drop 0:00

Weekend Use 0:00 Drop 0:00

Back Continue

N

Wizard Grid Use Schedule

Period 2 Enable N

Weekday Use 0:00 Drop 0:00

Weekend Use 0:00 Drop 0:00

Back Continue

N

Wizard High Battery Transfer

Mode Disabled

Grid Connect 48.0 VDC Delay 60 Min

Grid Disconnect 52.0 VDC Delay 60 Min

Grid Connect SOC 60% Disconnect SOC 95%

Back Continue

Disabled

Wizard Grid Use Schedule

Period 3 Enable N

Weekday Use 0:00 Drop 0:00

Weekend Use 0:00 Drop 0:00

Back Continue

N

Wizard Battery Monitor

Shunt A

Connection Inverter

Back Continue

A

Wizard Battery Monitor

Shunt A

Connection Inverter

Back Continue

B

Wizard Battery Monitor

Shunt A

Connection Inverter

Back Continue

C

Profile Wizard

Setup Complete

Exit Program Save

45

231

2

1

Other manuals for FXR Series

3

This manual suits for next models

7

Table of contents

Other OutBack Power Batteries Charger manuals