5

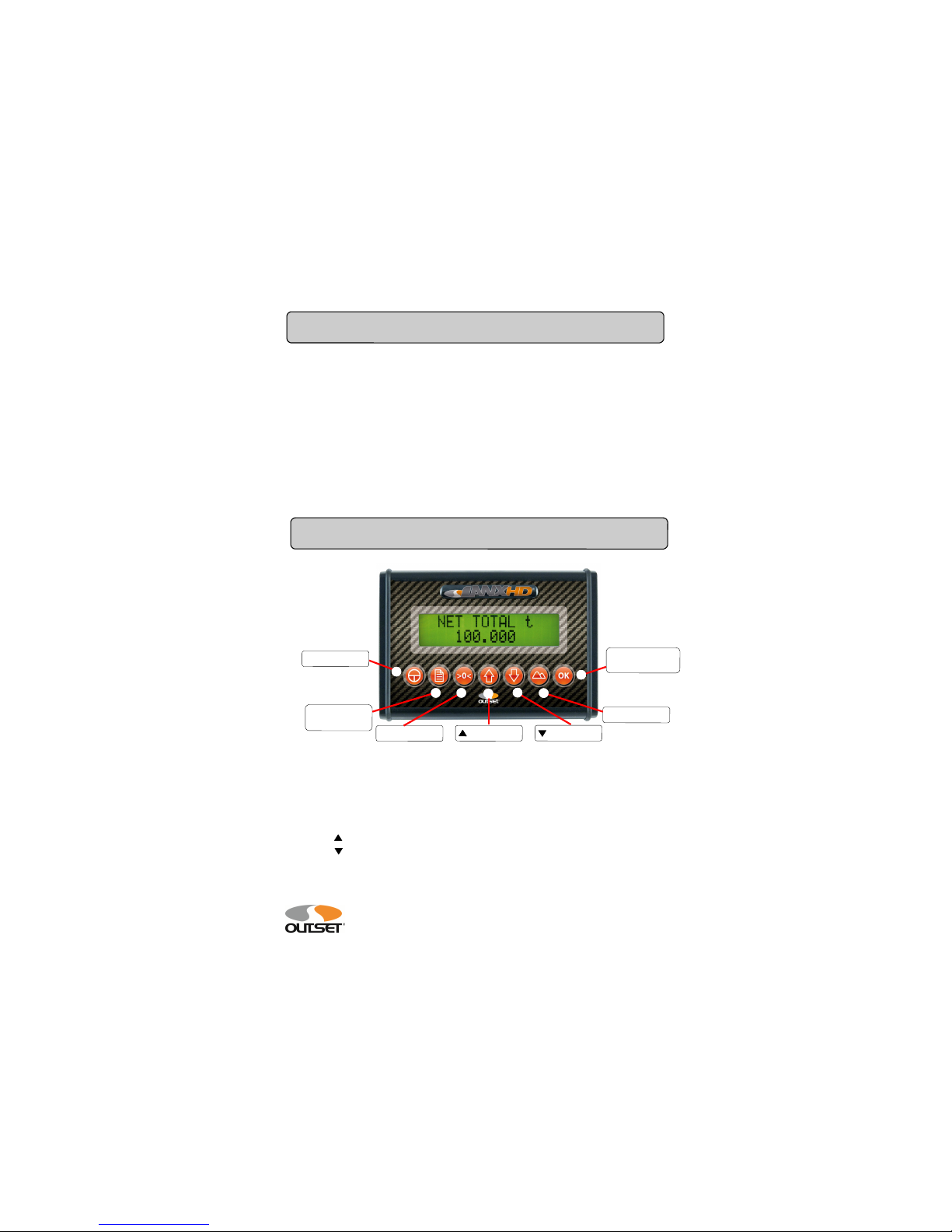

LANX HD

®

is protected with a pin code that unlock other different features and

setup menu available only for the person in charge of the vehicles. To unlock the

setup menu with the PIN CODE see the “Calibration manual”.

The standard features available for the user are: operator selection, print load, lo-

loads Database (save loads Database), diagnostic, edit materials, edit operators,

tare button and materials selection button.

LANX HD

®

, in addition to indicating the net and gross weight loaded on the vehicle

and memorizing it automatically, also performs other secondary functions which can

be set using the Functions and OK buttons.

4.1 Operator selection

This function allows the user to select until 32 operators or loading destinations.

• Press Functions to display:

• Press OK to enter the function

• Scroll and through the functions to select the operator or the loading desti-

nations

• Press the OK button to confirm the operation.

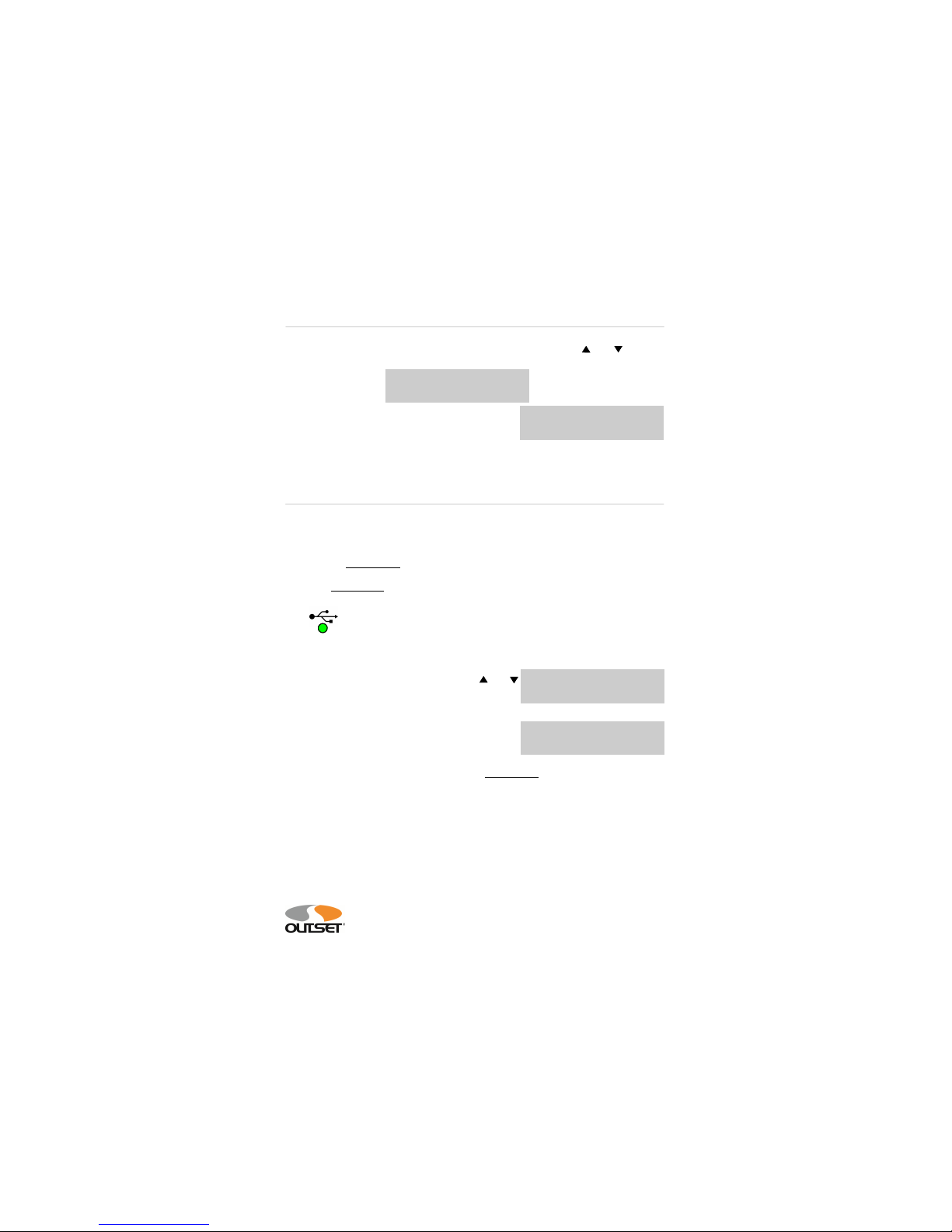

4.2 Print loads

This function allows the user to print the weights measured during the day. The

date, time, operator/destination and material loaded during the entire workday is

printed on the ticket.

• Press Functions and button to display:

• Press OK button to print

• Example of a printed ticket:

• Press the Functions button to cancel the

operation

To display or print the daily, weekly or monthly

weights, see the “Loads Database” section and it

is necessary to enter the protective PIN CODE to

unlock the functions.

3PIN CODE

4Functions

General

GeneralGeneral

General

OPERATOR SEL.

OPERATOR SEL.OPERATOR SEL.

OPERATOR SEL.

***************************************************

LANX

....

OUTSET srl

....

31/01/2011 19.30

********************ID TRUCK*******************

***************************************************

*** MATERIAL 01 ***

*** OPERATOR/DESTINATION ***

31/01/11 08.30 kg 75100

31/01/11 09.15 kg 77200

31/01/11 10.47 kg 75150

--------------------------------------------------------

TOTAL 227450

--------------------------------------------------------

*** MATERIAL 02 ***

31/01/11 11.15 kg 75100

31/01/11 12.05 kg 77200

--------------------------------------------------------

TOTAL 152300

-------------------------------------------------------

General

GeneralGeneral

General

PRINT LOADS

PRINT LOADSPRINT LOADS

PRINT LOADS