7

S-176-9-E

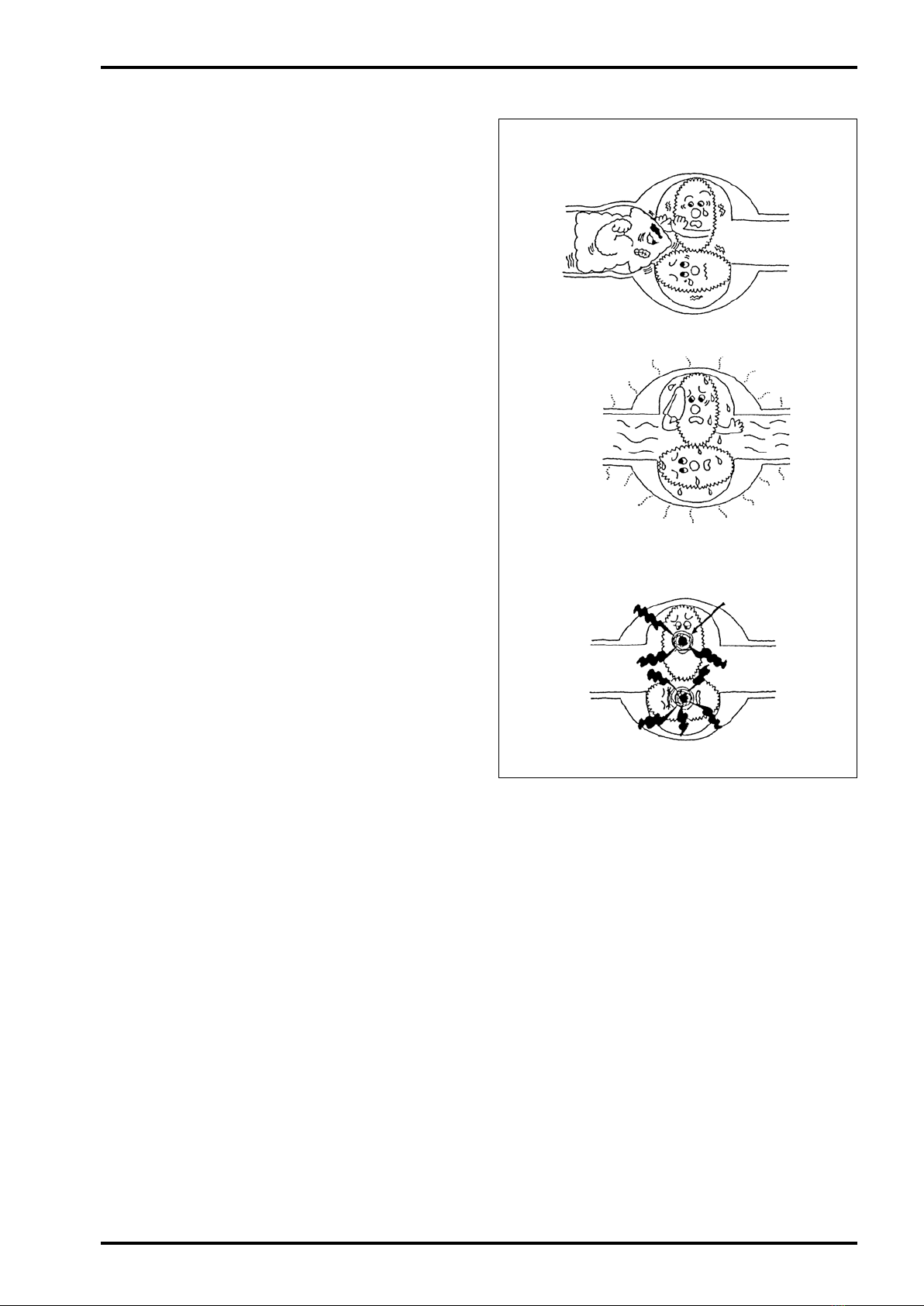

Excessive flow Rapid flow variation

Take precautions

against bearing burn!!

Rapid temperature variation

××

×

5.2 Operating Precautions

(1) When changing owrates:

In applications where the owrate varies or

where shutoff valve opening and closure takes

place in batch operation, avoid rapid changes

in owrate across the meter.

Operating the meter at owrates in excess of

the maximum allowable owrate will nullify the

guaranteed accuracy, reduce the meter life and

may result in faulty conditions, such as burn

of bearings or rotor-to-measuring chamber

contact.

(2) Where the temperature of metered uid

changes:

Avoid rapid temperature changes in the meter.

Temperature changes of the uid in the meter

should be held with in 3℃ perminute.

Extra care should be used particularly when

making a ow measurement in batch operation

without the provision of heat tracing of the

tubing where the fuid temperature differs from

atmospheric temperature.

If rapid temperature changes are anticipated,

heat trace the tubing assembly as well as

the meter.

(3) Liquids of low steam pressure:

Liquids with low viscosity and low steam

pressure can easily vaporize and their

temperature and pressure should therefore

be strictly controlled.

During operation, the temperature of bearings

in the meter usually runs higher than that of

the metered uid. Vapors around the bearings

can present problems, such as unusual noise

and bearing seizure.

(4) Highly corrosive liquids:

When you make a measurement of highly

corrosive liquids, appropriate materials should

be used for tanks and tubing assembly.

Heterogeneous materials originally contained

in the metered fluid, or certain substances

that have leaked out of the tanks and/or

tubing of inappropriate materials, may lead to

costly downtime, as a result of locked rotors,

for example, when they are allowed into the

measuring chamber.