T-518-9-E

3

■WIRING INSTRUCTIONS

1. Cables

Recommended cables for field wiring are 2-conductor, shielded, chloroprene cabtyre cables (JIS C3311) or

2-conductor, shielded, vinyl cabtyre cables (JIS C3312) 1.25 mm2to 2.0 mm2in sectional area of the conductor

unless otherwise specified.

2. Transmission Length

The maximum transmission length is typically one kilometer when cables 2 mm2in conductor area conforming

to JIS C3311 or C3312 are used.

NOTE : If it exceeds one kilometer, consult factory.

3. Conduit work is suggested.

Cable connections : PG30D …… Rc3/4 (internal thread)

PG30DEP …… G3/4 (internal thread)

NOTE : Conduit should be connected by screwing in at least five threads.

4. MODEL PG30DEP (ameproof construction) Conduit Work

(1) Use steel conduit conforming to the requirements specified in JIS B8305.

(2) Conduit accessories, such as boxes, universals and couplings, should conform to the requirements

specified in JIS C0903.

(3) Sealing work should be taken into consideration where necessary.

(4) After thread engagement, externally apply a coat of non-drying compound.

5. Inductive Interference Prevention

Field wiring should be routed sufficiently away from existing power cables or power circuits, if any, to

prevent potential stray current pickup. If you want to use both a non-engineering-unit pulse generator and an

engineering-unit pulse generator, a separate cable should be used for each of them.

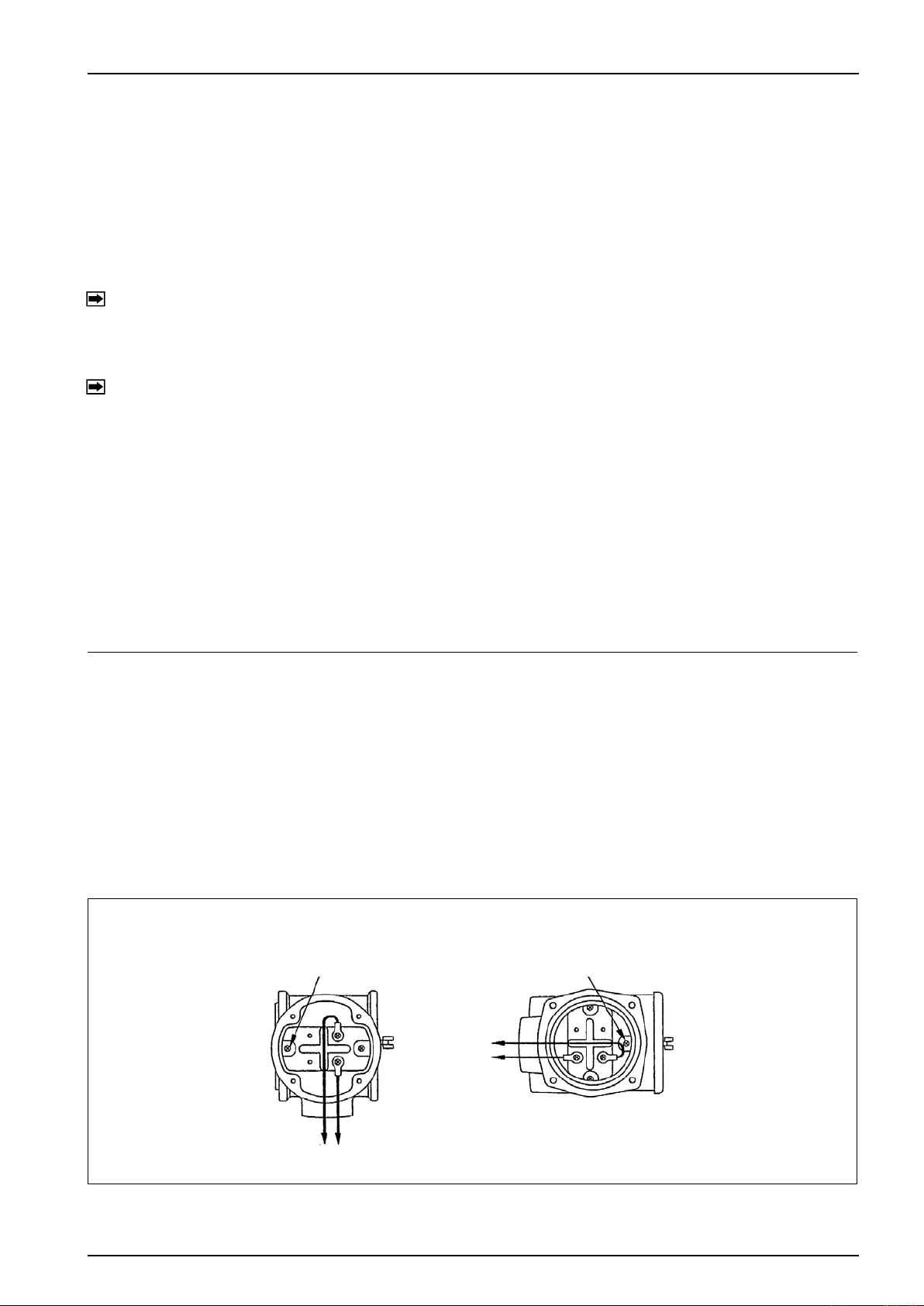

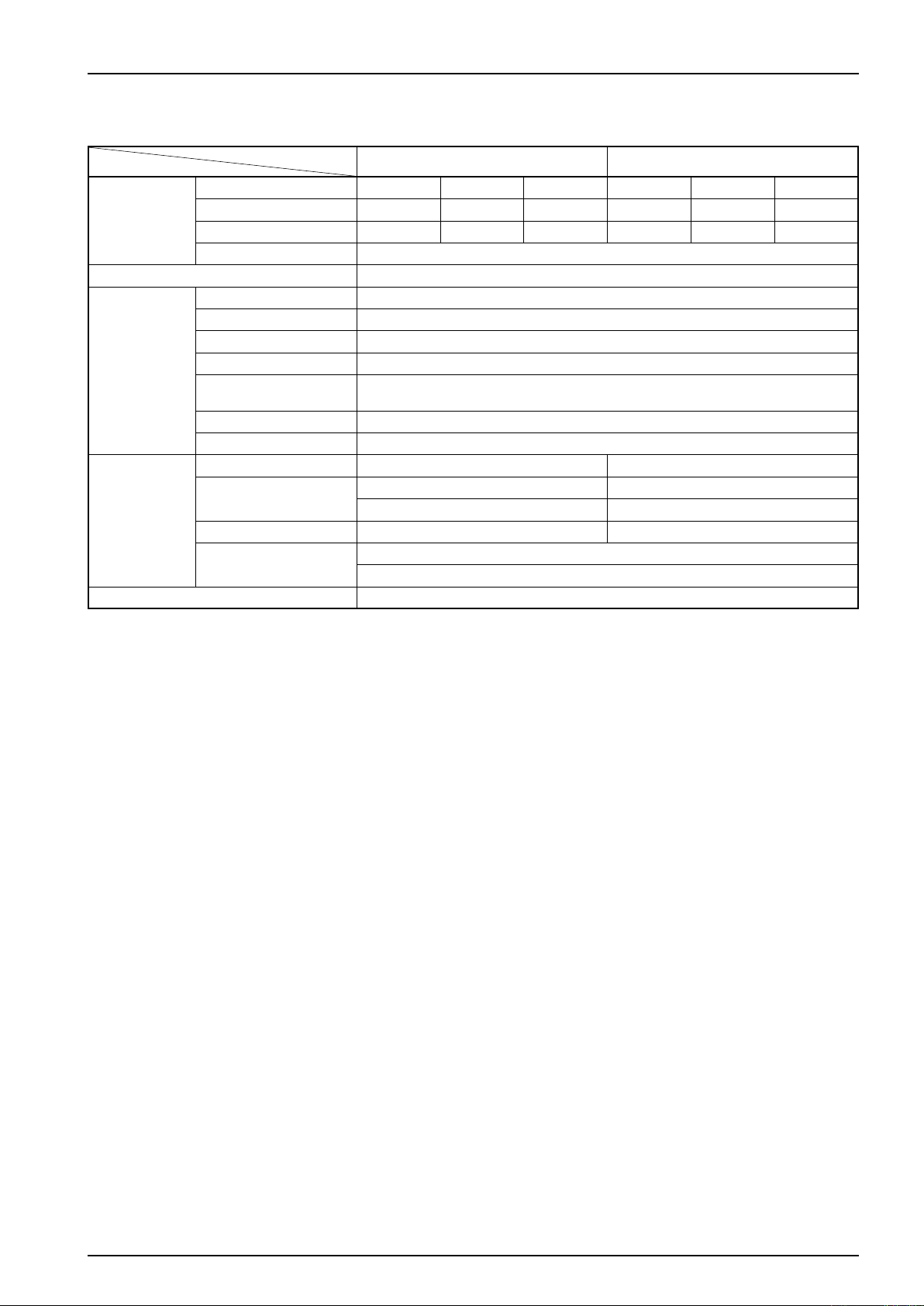

Wiring Connections

Removing the PG30D/PG30DEP outer housing lid (306) provides access to the 2-post terminal block.

Referring to the wiring connection label found on the back of the lid, make electrical connections correctly.

Terminal Identification 2 …… SIG (red)

3 …… 0V (black)

●In case of grounding on the pulse generator side

◎Model PG30DEP has a ground terminal. Use this terminal to earth ground.

◎Model PG30D is not provided with a ground terminal. So, take off the screw shown in the figure below and

earth ground using a lug.

GROUND TERMINAL

Fig. 3

IF GROUNDING IS REQUIRED,

USE THIS TERMINAL.

PG30D PG30DEP