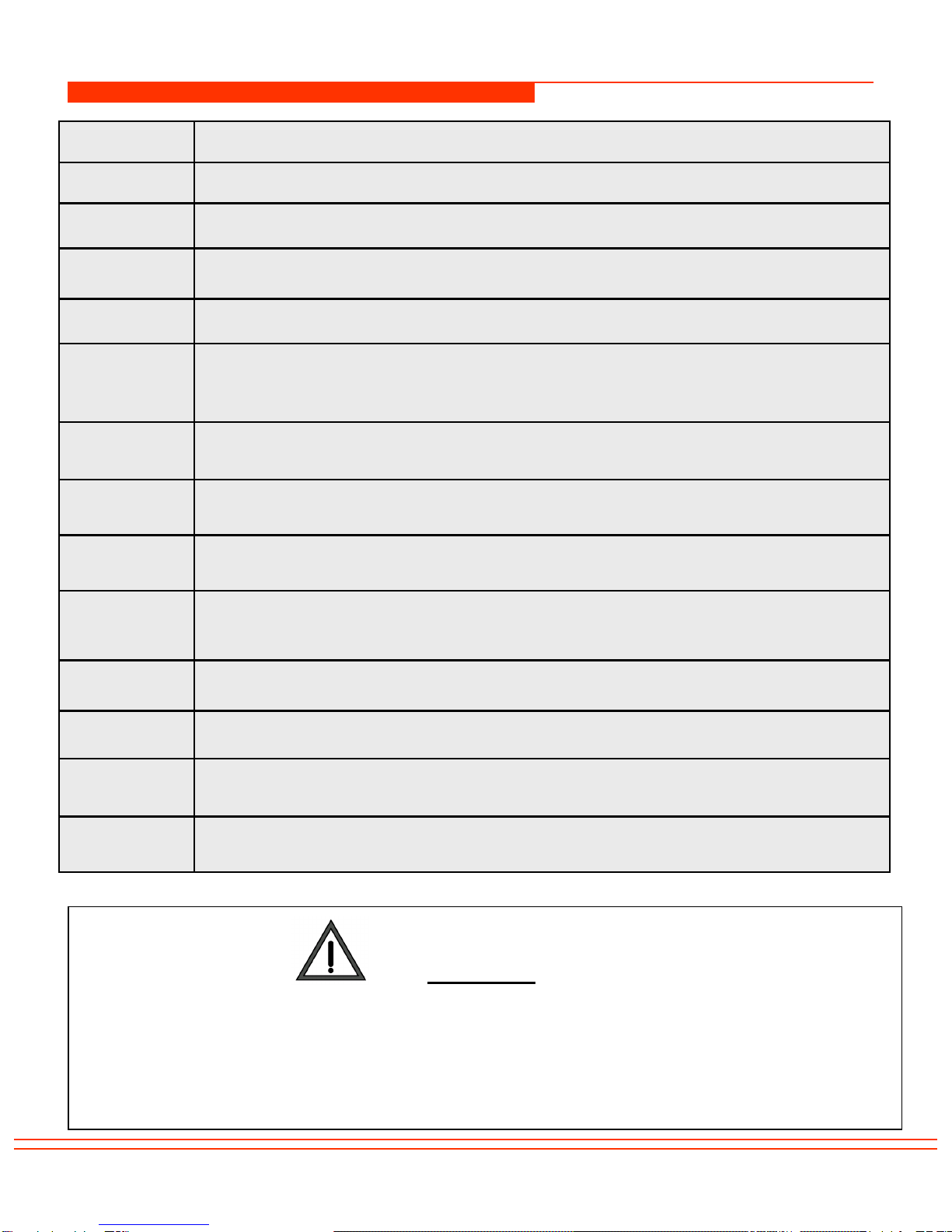

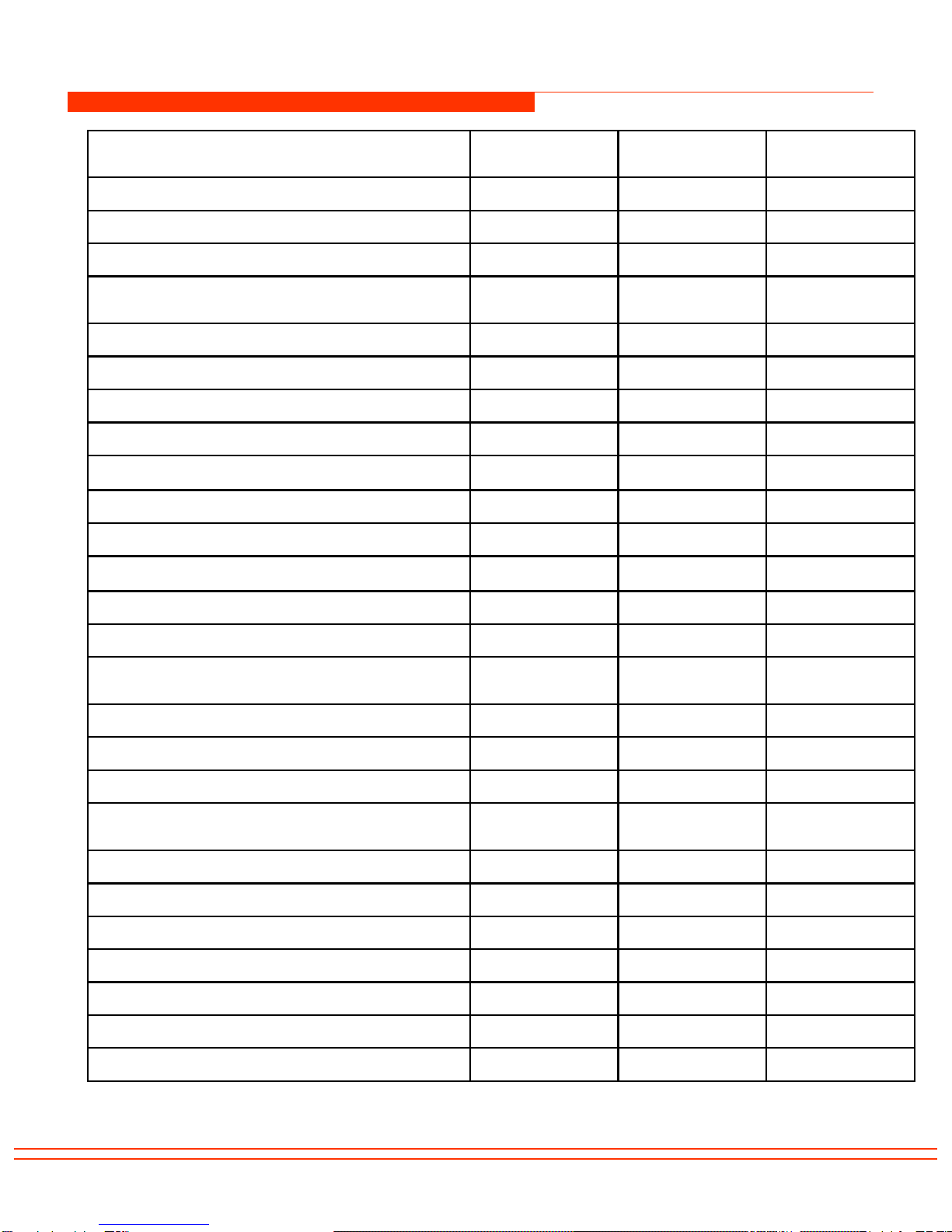

TECHNICAL DATA

4/19

Technical Data OBM 1080 D OBM 1080 DS OBM 1080 D PLUS

TOTAL ELECTRICAL INPUT (KW) 9,66 9,66 9,66

SUPPLY VOLTAGE (VAC) 400 400 400

WORKING FREQUENCY (Hz.) 50 50 50

POWER SUPPLY CABLE (Number of cores x mm²) 5 x 4 5 x 4 5 x 4

WASHING CAPACITY (DISH/HOUR) 1080(max) 1080(max) 1080(max)

WASHING CAPACITY (TRAY/HOUR) 67(max) 67(max) 67(max)

WASHING TANK CAPACITY (LT) 42 42 42

BOILER TANK CAPACITY (LT) 7 7 7

WASHING WATER TEMPERATURE (°C) 55 -60 55 -60 55 -60

RINSING WATER TEMPERATURE (°C) 80 –85 80 –85 80 –85

WATER INLET PRESSURE (Bar) 2 –62 –62 –6

WATER INLET TEMPERATURE (°C) 50 50 50

WASHING PUMP POWER (KW) 0,66 0,66 0,66

RINSING PUMP POWER (KW) 0,37 0,37 0,37

HEATING POWER (WASHING TANK) (KW) 3 3 3

HEATING POWER(BOILER TANK) (KW) 9 9 9

MAXIMUM NOISE (dBA) 85 85 85

GROSS WEIGHT (KG) 115 (±5) 115 (±5) 115 (±5)

DIMENSIONS (Width-Length-Height) (mm) 670 x 785 x 1440 670 x 785 x 1440 670 x 785 x 1440

BASKET DIMENSIONS (mm) 500 x 500 x 105 500 x 500 x 105 500 x 500 x 105

CLASS 1 1 1

PROTECTION CLASS IP X5 IP X5 IP X5

PROGRAM 5 5 5

DETERGENT PUMP NO YES YES

POLISH PUMP NO YES YES

DRAIN PUMP NO NO YES