STARTING THE ENGINE WITH WALBRO 37CARBURETOR

If the circuit is empty you must press the button located on

the top of the carburetor (fig 17) and at the same time pump

gasoline with Primer (fig 14) until you feel that you have

reached the carburettor.

When you have reached you have to prime one more time so

that gasoline goes into the carburettor.

ENSURE THAT THE BUTTON RETURNS BACK TO ITS

ORIGINAL POSITION AND IS NOT PRESSED INWARD.

1º) Check that the starter cable is not blocked and that the return spring works properly.

Check that the NUT which holds the gas is NOT TIGHT and not locking the throttle lever.

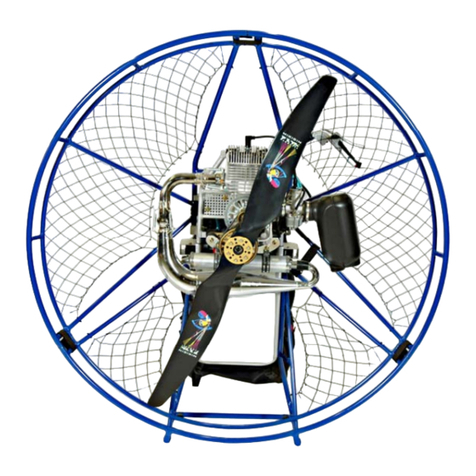

2º) Lock the propeller with the security TAPE system that the propeller covers INCLUDE

(fig 12)

.

3º) Leave the accelerator supported as shown in the picture

(fig 20)

, WITH THIS ENGINE WE DO NOT NEED TO ACCELERATE

WHILE PULLING THE STARTER.

4º) Take the safety position as pictured

(fig 21

)

(fig 22

).

5º) Use a gentle progressive and firm tug (fig 23); a strong pull is unnecessary because the Polini Thor 200 starts easily.

6º) Once started take the throttle to have the engine under control at all times. Allow the engine to run slowly for a few seconds

at idle and turn it off.

7º) Remove the safety tape and propeller covers

(fig 12

).

8º) Repeat steps 3, 4 and 5 to restart the engine.

1º) Check that the starter cable is not blocked and that the return spring works properly.

Check that the NUT which holds the gas is NOT TIGHT and not locking the throttle lever.

2º) Leave the accelerator supported as shown in the picture

(fig 20)

, WITH THIS ENGINE WE DO NOT NEED TO

ACCELERATE WHILE PULLING THE STARTER.

3º) Take the safety position as pictured

(fig 21

)

(fig 22

).

4º) Use a gentle progressive and firm tug (fig 23); a strong pull is unnecessary because the Polini Thor 200 starts easily.

5º) Once started take the throttle to have the engine under

control at all times.

TECHNIQUE TO START THE POLINI THOR 200

FLASH START COLD WITH FULL GASOLINE CIRCUIT:

FOR YOUR SAFETY, YOU CAN RESTART IT WITH THE ENGINE IN THE BACK. PULLING PROGRESSIVELY WITH

BOTH HANDS AND THE THROTTLE ON THE RIGHT HAND SIDE.

WITH THE ENGINE WARM YOU CAN START IT DIRECTLY

ON YOUR BACK

(fig

17

)

WARM START WITH FULL GASOLINE CIRCUIT:

NEVER START IT WITHOUT PROPELLER.

Adjustment screw low; as if it were a clock is pressed without

straining and the equivalent opens up to 40 minutes on the clock

wheel. This is the basis of factory regulation. From this position

according to the atmospheric conditions can lock or unlock carefully

(in comparison with the clock, this setting should never be greater

than 5 minutes of the clock).

Regulation screw high; factory base adjustment is 2 turns.

Idle screw

Button to prime the carburetor (fig 17).

THIS IS THE FACTORY SETTING. UNDER NO

CIRCUMSTANCES SHOULD YOU MODIFY THIS SETTING,

TO OPEN IT OR TO CLOSE IT, AS THE RISK IS HIGH OF

DANGEROUSLY BORING A HOLE IN THE PISTON.

11

2

3

4

2

3

4