DISCLAIMERS:

All information, illustrations and specifications in this manual are based on the latest information available at

the time of publishing. The illustrations used in this manual are intended as representative reference views only.

Moreover, because of our continuous product improvement policy, we may modify information, illustrations and/or

specifications to explain and/or exemplify a product, service or maintenance improvement. We reserve the right

to make any change at any time without notice. Some images may vary depending upon which model is shown.

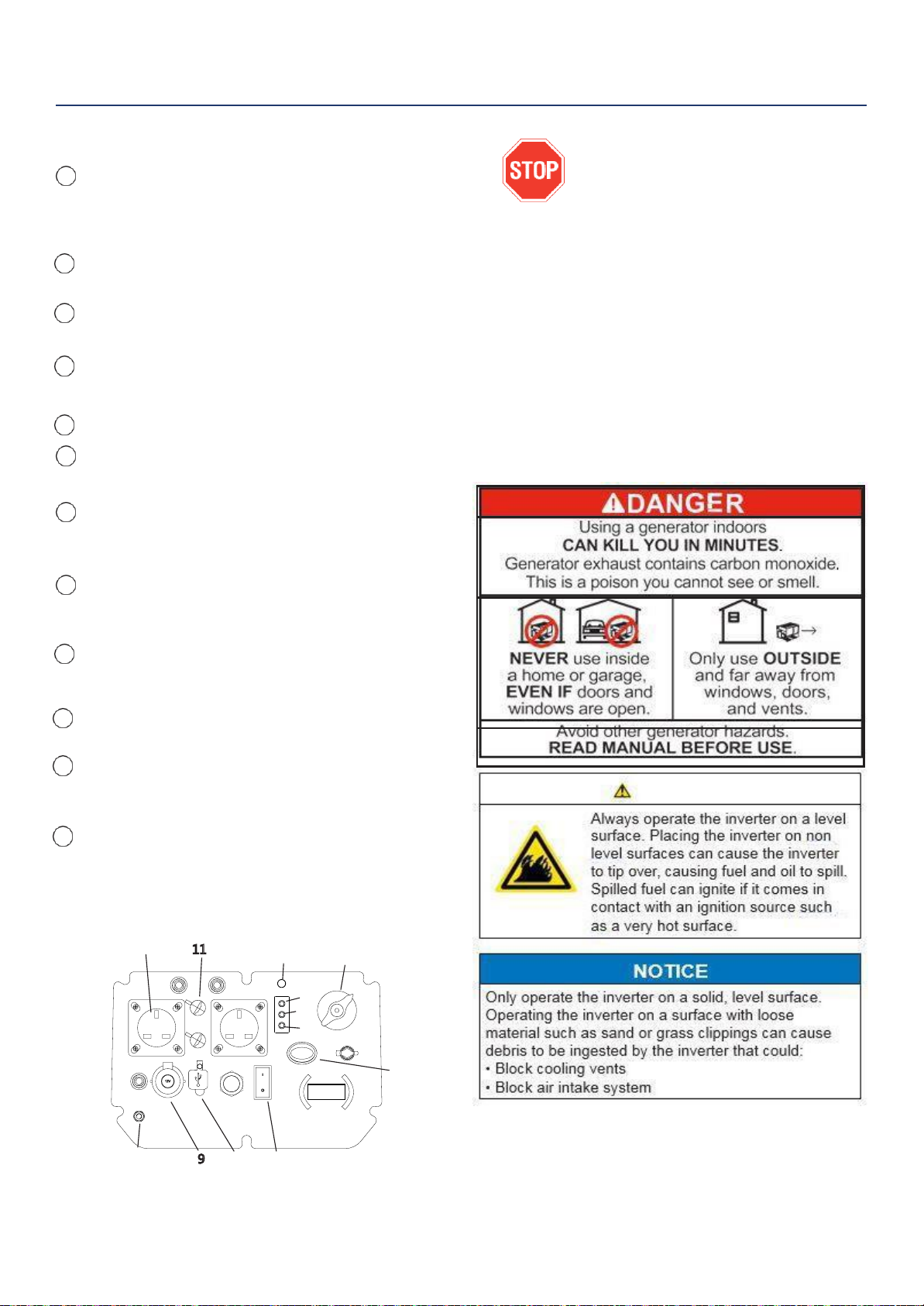

This manual contains important instructions for operating this generator. For your safety and the safety of others, be sure

to read this manual thoroughly before operating the generator. Failure to properly follow all instructions and precautions

can cause you and others to be seriously hurt or killed.

SAFETY..................................................................................................3

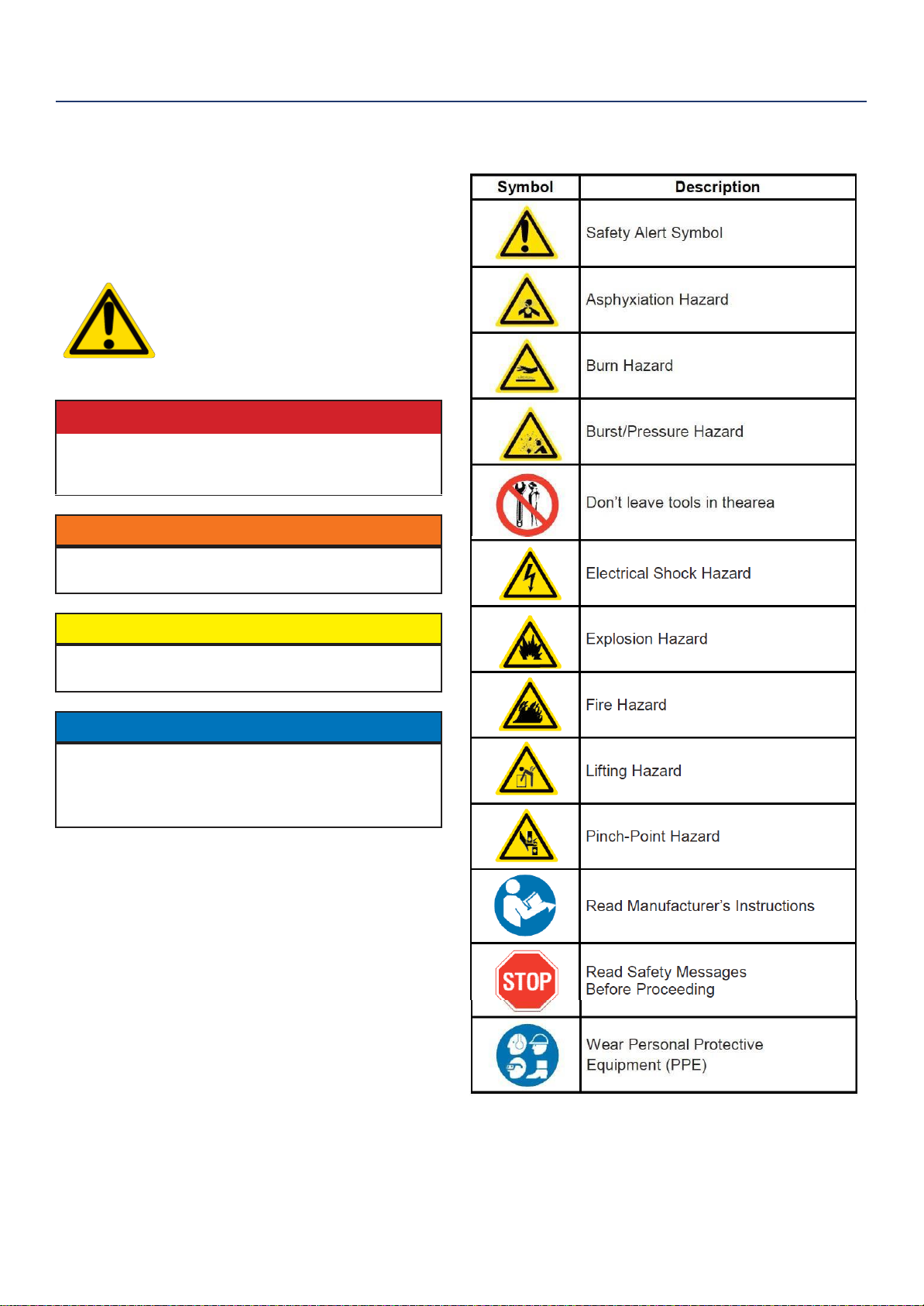

Safety Definitions.................................................................... 3

Safety Symbol Definitions....................................................... 3

General Safety Rules...............................................................4

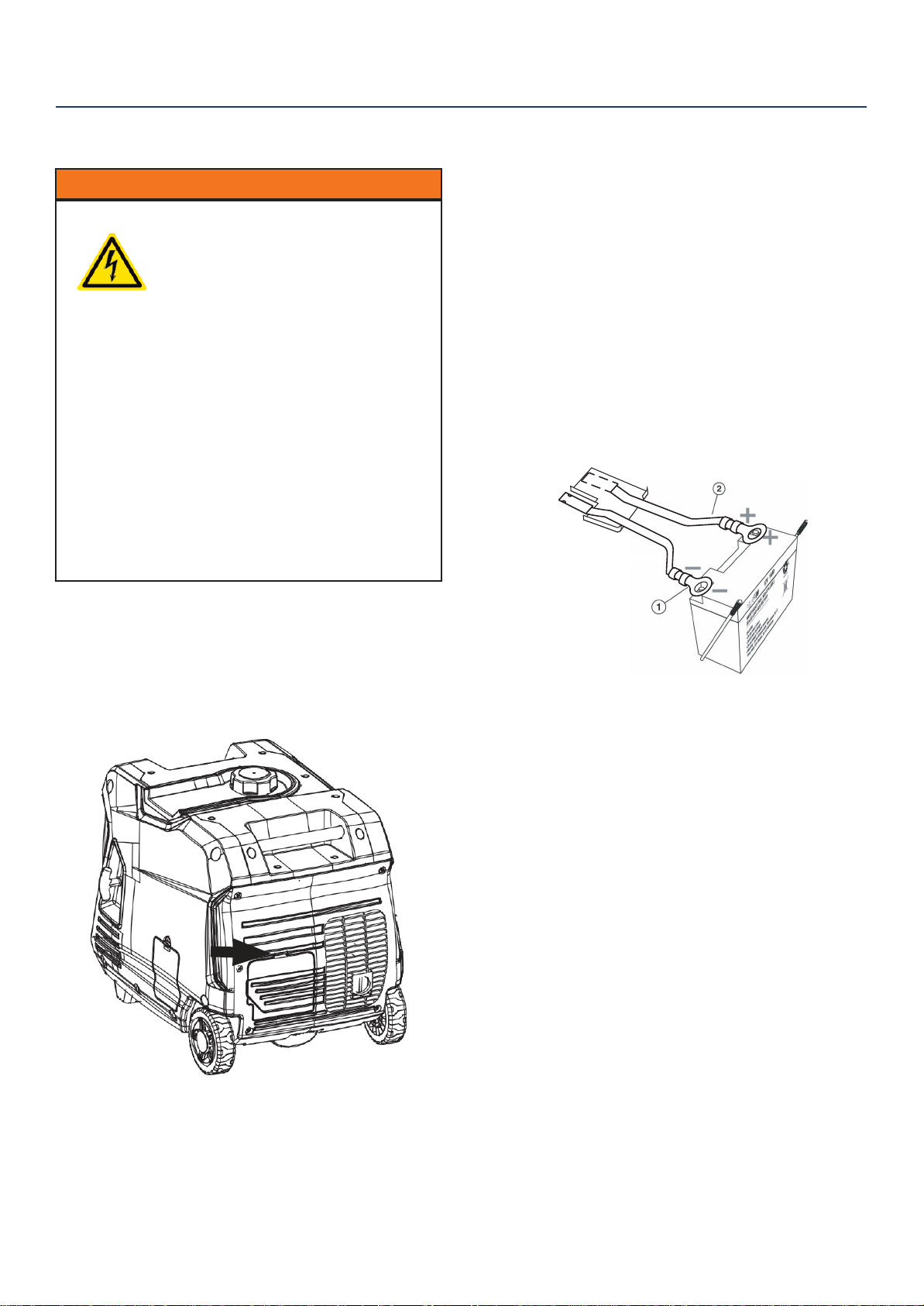

ASSEMBLY.............................................................................5

Hooking Up the Battery.............................................................5

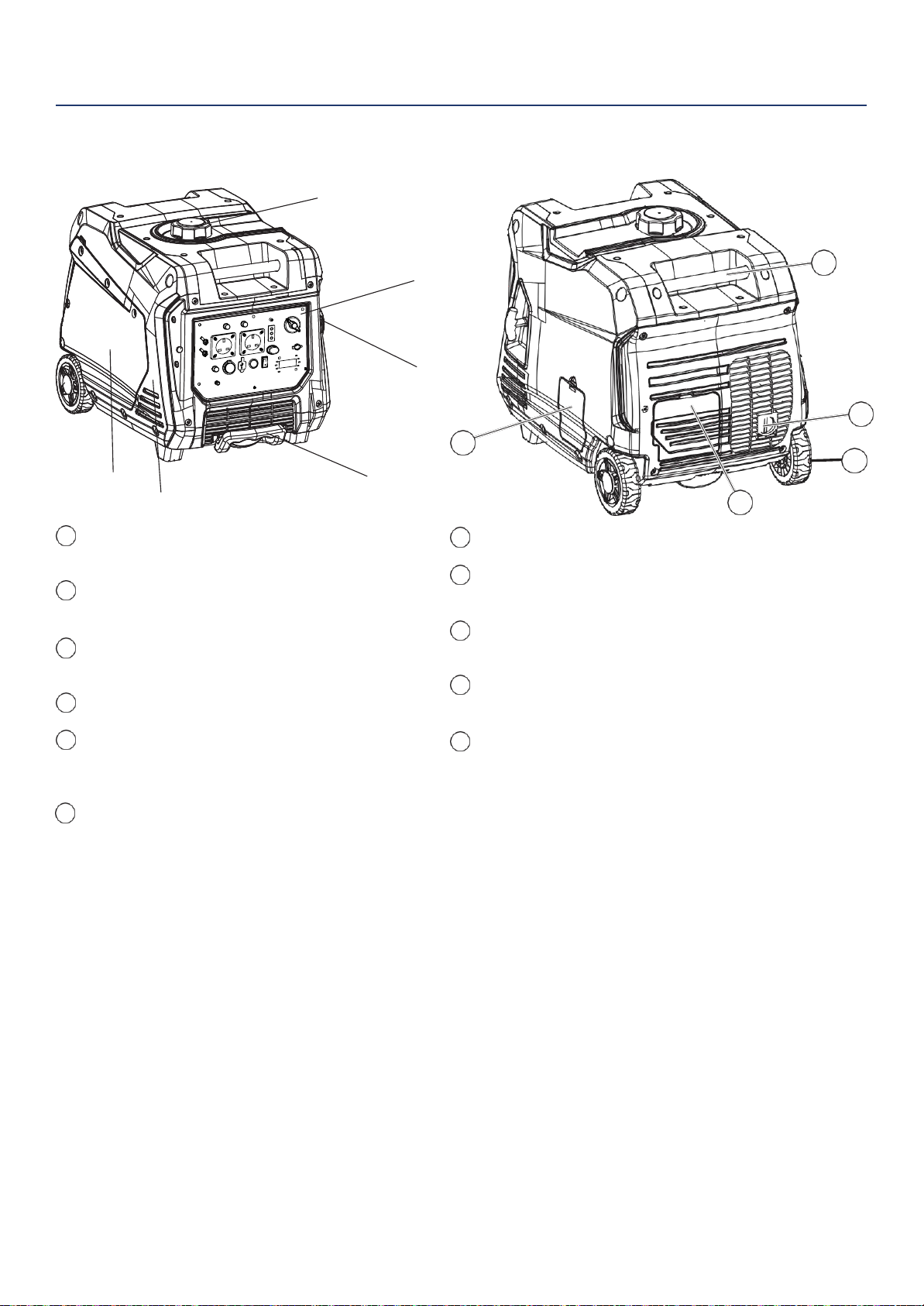

FEATURES..............................................................................6

Basic Inverter Features.............................................................6

Control Panel Features............................................................ 7

OPERATION.............................................................................8

Before Starting the Inverter.......................................................8

Location Selection.....................................................................8

Weather ....................................................................................8

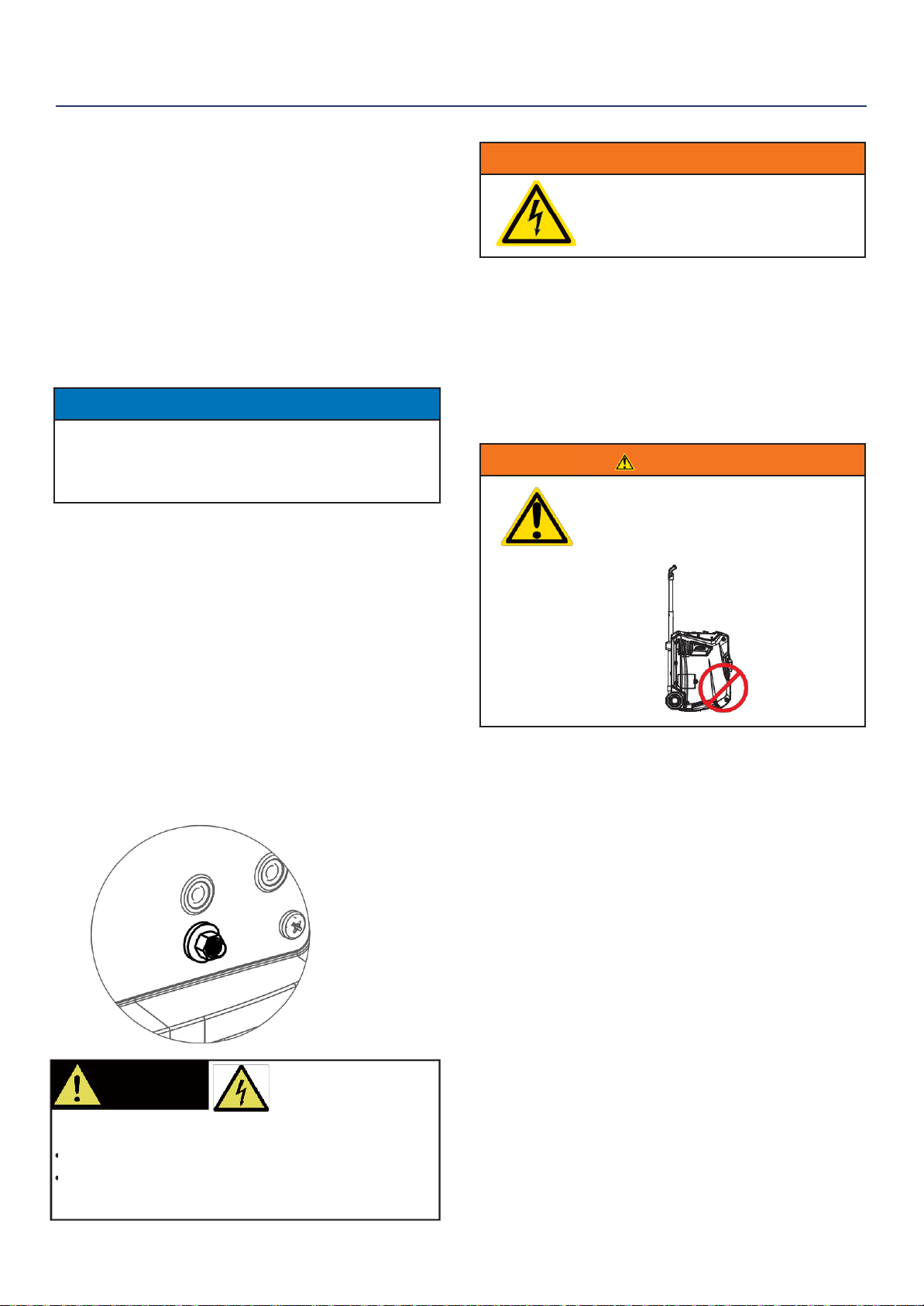

Grounding the Inverter.............................................................. 8

High Altitude Operation..............................................................8

Power Cord............................................................................... 9

Inverter Paralleling Operation ................................................... 9

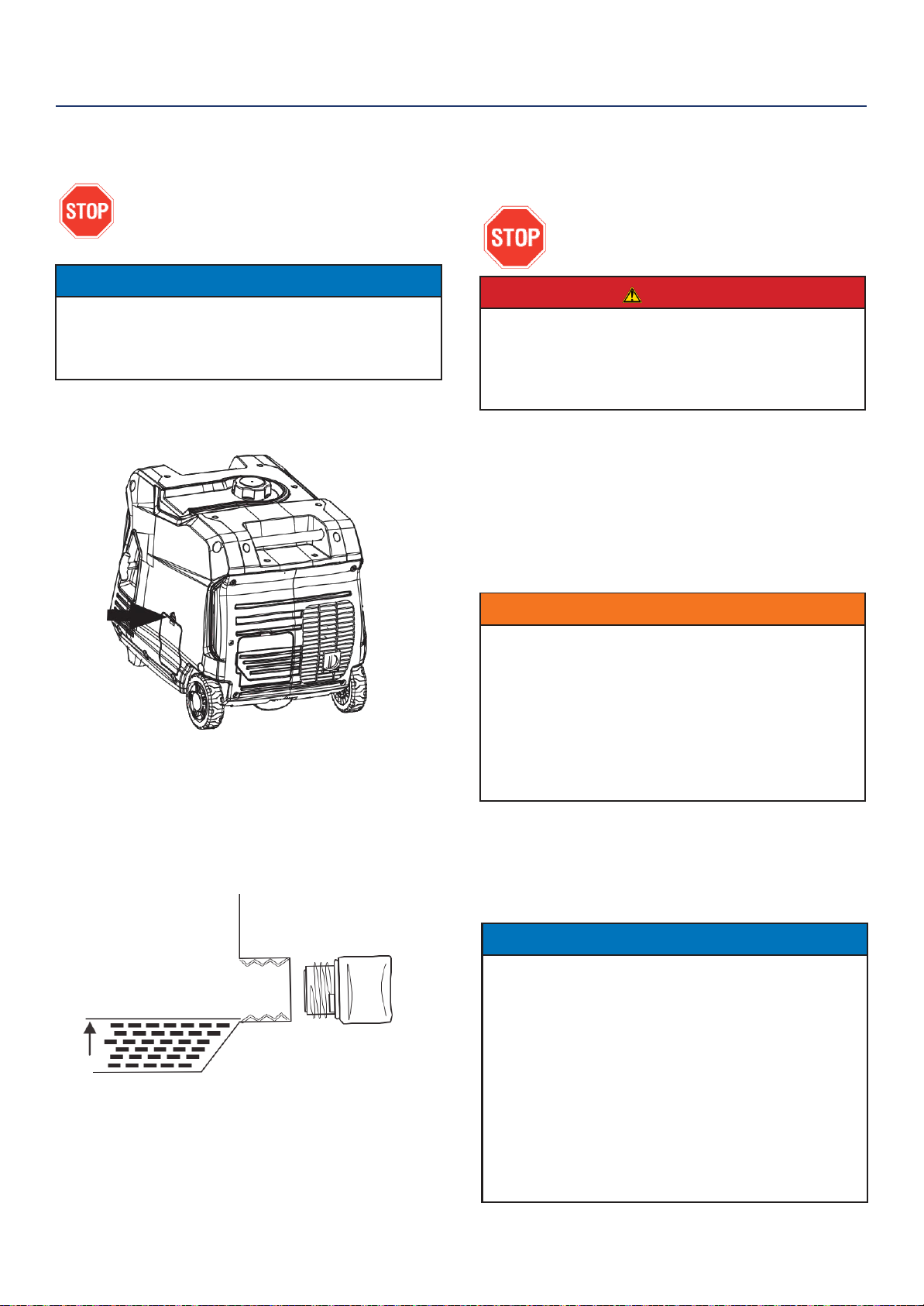

Initial Oil Fill..............................................................................10

Adding/Checking Engine Fluids and Fuel.................................10

Checking and/or Adding Engine Oil ..........................................10

Adding Petrol to the Fuel Tank..................................................11

Starting the Inverter...................................................................12

Electric Start..............................................................................12

Manual Start..............................................................................12

Wireless Remote Start...............................................................12

Stopping the Inverter.................................................................13

Using Efficiency Mode...............................................................13

Resetting the Reset Breaker.....................................................13

MAINTENANCE........................................................................14

Maintenance Schedule ............................................................14

Engine Oil Maintenance...........................................................15

Checking Engine Oil ................................................................15

Adding Engine Oil .................................................................... 15

Changing Engine Oil.................................................................16

Air Filter Maintenance...............................................................16

Cleaning the Air Filter...............................................................16

Draining the Float Bowl.............................................................17

Spark Plug Maintenance...........................................................17

Cleaning the Spark Arrestor......................................................18

Checking and Adjusting Valve Lash..........................................18

Cleaning the Inverter.................................................................19

Battery Service..........................................................................19

Storage .....................................................................................20

TROUBLESHOOTING...............................................................21

Recycling & Product Disposal...................................................22

Declaration of Conformity..........................................................23

Contact Details..........................................................................24