Ultimo aggiornamento: 14/02/11

2

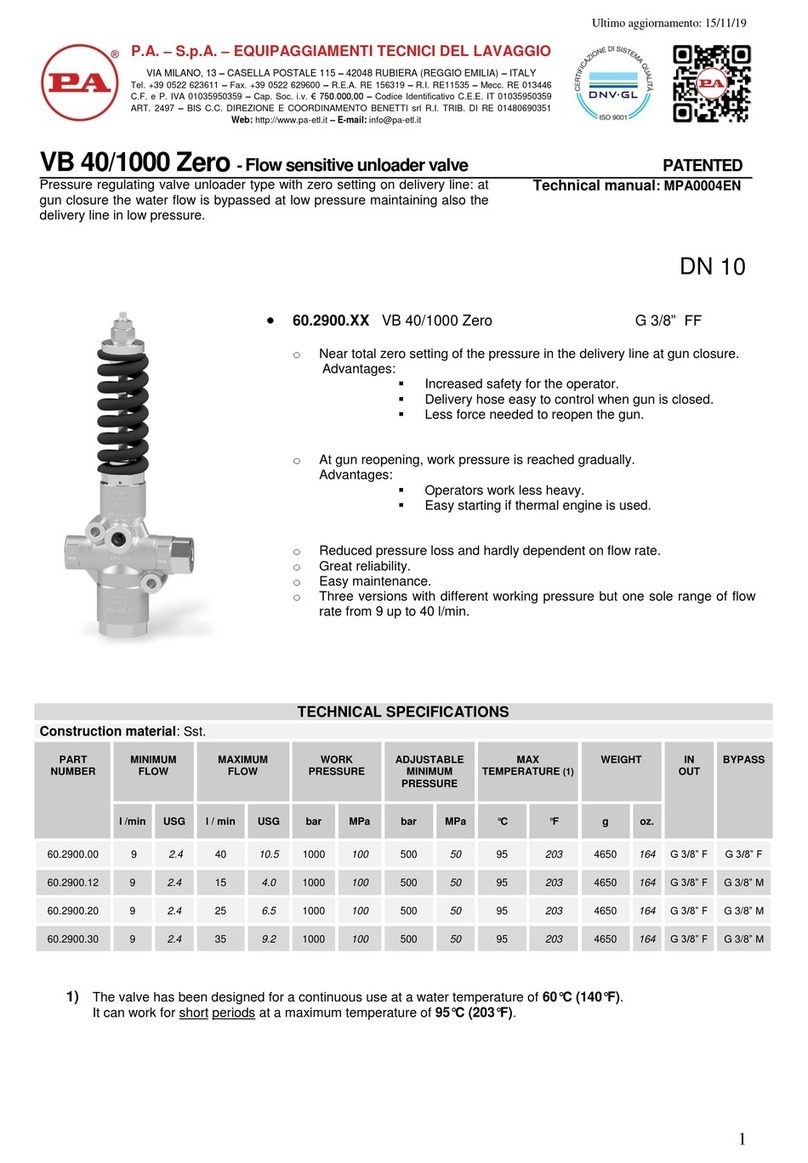

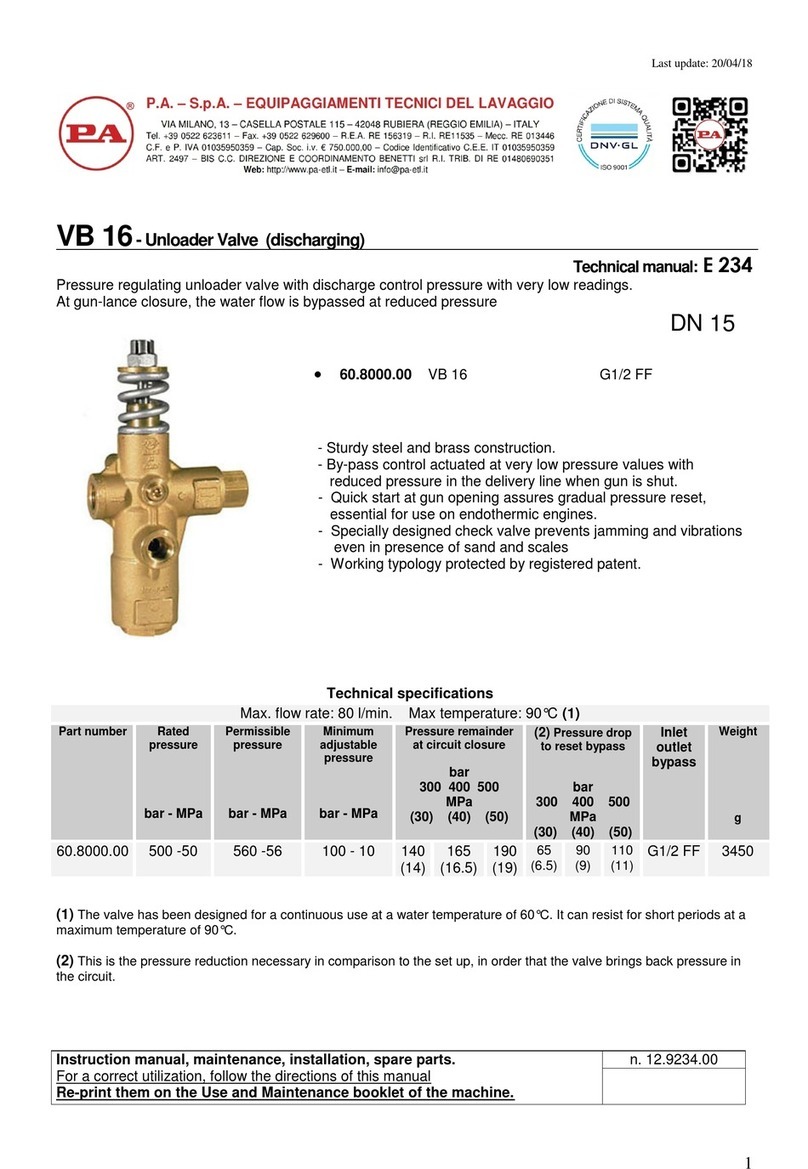

DIMENSIONAL DRAWING

SELECTION

This product is intended to be incorporated on a finished machine. This product is to be utilized with clean fresh water, even slightly

additivated with normal detergents. For use involving different or corrosive liquids, contact the PA Technical department. Appropriate

filtration should be installed when using impure liquids. Choose the valve in line with the working data of the machine where to be

installed (permissible pressure, maximum flow rate and rated temperature of the system). In any case, the pressure of the machine

must not exceed the permissible pressure imprimed on the valve.

OPERATIONS

The valve regulates the maximum pressure of the system by variating the flow discharged through the bypass. The adjustment is

made by altering, by means of a piston, the position of a shutter which partially closes the bypass opening. At gun closure, a check

valve closes isolating the part of the circuit downstream of the valve: the pressure increase that remains trapped is used to activate

the complete aperture of bypass. All the flow supplied by the pump is therefore discharged at low pressure through the bypass and the

pump works at low pressure.

INSTALLATION

This accessory, on a system that produces hot water, must be fitted upstream of the heat generator. On a system that generates hot

water, it is advisable to fit in accessories that limit the accidental increase of fluid temperature.

Always install a safety valve.

It is recommended to use a nozze with a flow rate that, at gun opened, allows to discharge from the valve bypass at least 5% of the

flow supplied by the pump in order to obtain a constant pressure figure, and easy adjustment and to avoid troublesome pressure

spikes at gun closure.

If the nozze wears out, the working pressure decreases. To reset pressure back to work level, it is necessary to replace the worn out

nozzle. When a new nozzle is fitted, re-setting of the system to its original working pressure is necessary.

DISCHARGE SYSTEM AND WATER ADDUCTION

It is recommended to install the valve with bypass discharge into a tank. We advise also that the tank be fitted with deflectors in order to

reduce eventual turbolence and air bubbles, generated by the immission of the bypass flow, which could be harmful for the pump. With

elevated flow or near to the maximum flow of the valve, the installation with bypass recycle direct to the pump could cause harmful

pressure spikes, resulting extremely dangerous for the pump.