Drain

Plug Fill

Plug

Fig. 16

Fig. 17

Fig. 18

6

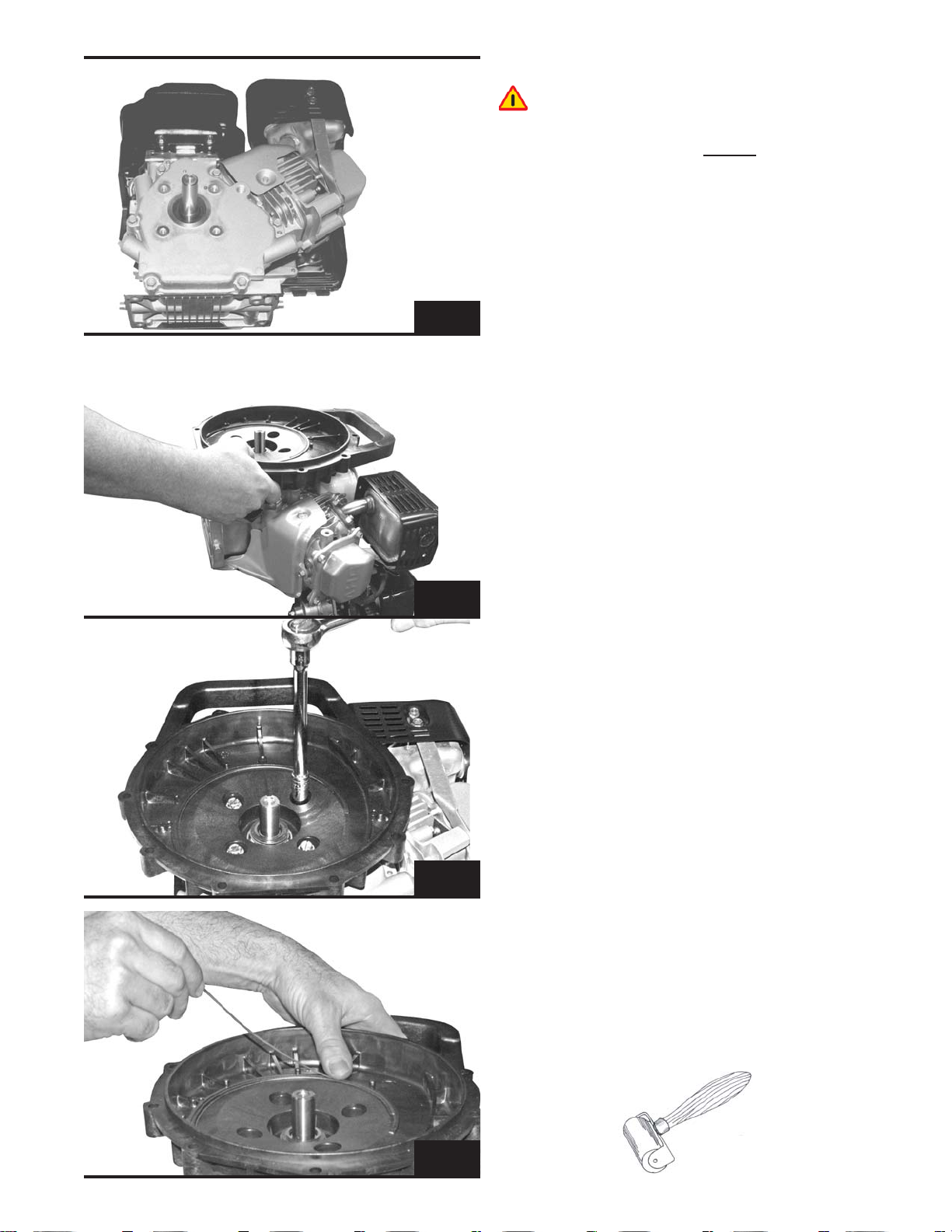

12) Place the pump body (Ref. #42) onto the

bracket so the discharge opening (large hole on

side of body) is toward the bracket handle (Fig.

#16). Install the ten body screws (Ref. #21). You

will need a 3/8" socket or flat head screwdriver

for the screw head.

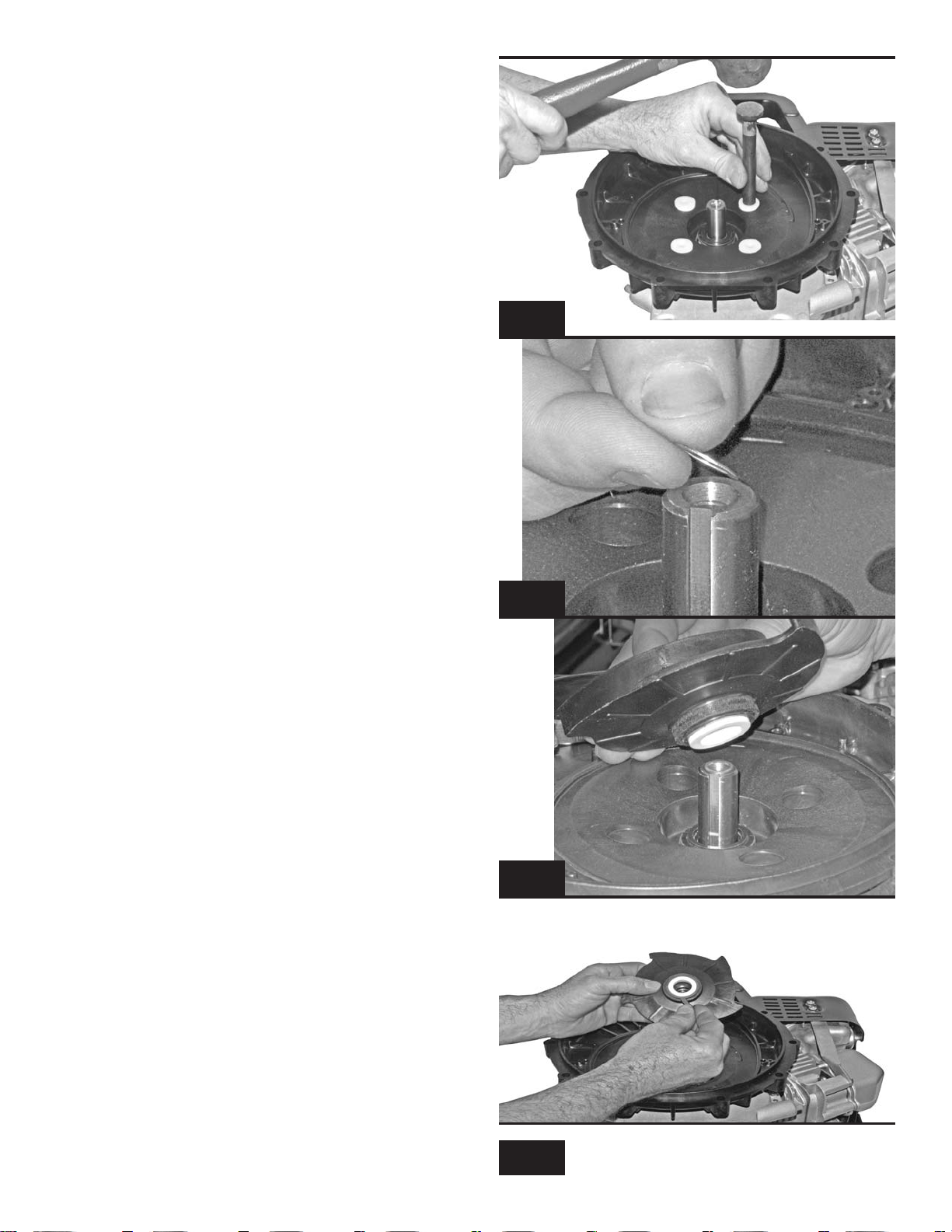

13) Tighten the screws in a clockwise rotation

aroundthe pump (Fig.17). Startatthe screw just

to the left of the drain plug (Ref. #23). Tightening

inthissequencehelpspreventpinchingthecheck

valve and body o-ring.

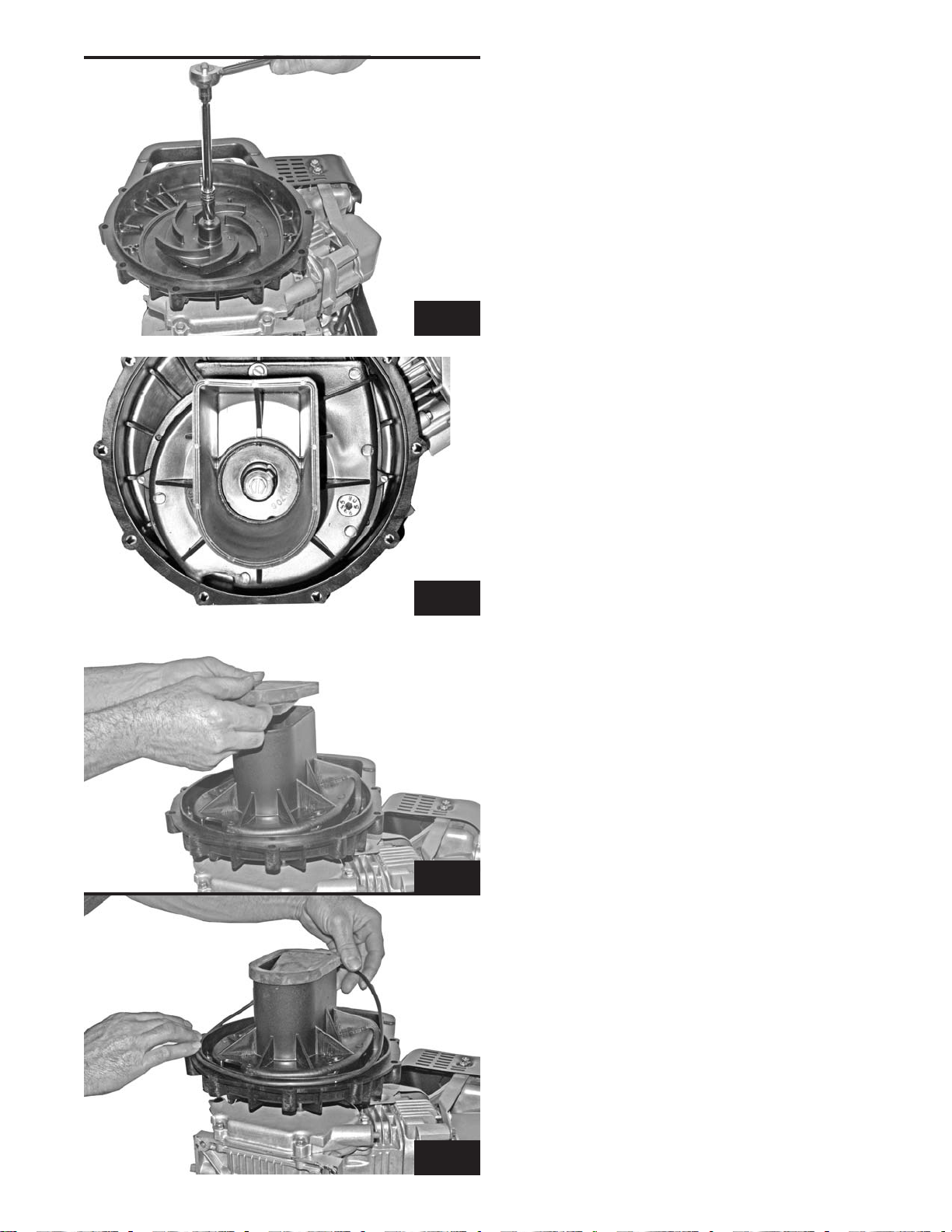

14) Placeo-rings(Ref.#25&22)onthefillerplug

(Ref. #24) and drain plug (Ref. #23).

15) Install the drain plug and filler plug (Fig. 18).

Tightenonlyhandtight.DONOTUSEAWRENCH.

16) Apply the appropriate labels to the pump.

The red, white & black warning label should be

applied on the left side of the pump body. The

pump model number label should be applied on

the right side of the pump body.

17) With pump fully assembled, turn the drive

shaft to insure clearance of impeller between

the bracket and volute face. Should you hear an

internalscrapingnoise,disassemblethepumpto

the impeller. Adjust amount of impeller shims to

correct the problem. Reassemble and check for

clearance one more time.

18) Use Teflon tape when install-

ing threaded fittings or elbows in the

pump discharge and suction. 1½" or 2

fittings - 10-12 wraps of Teflon®tape on the

suctionfittingsandelbow,6wrapsondischarge

nipple. 3" fittings - 15 wraps with ¾" Teflon®

tape on suction, discharge and elbow fittings;

6 wraps on discharge nipple.

DO NOT OVERTIGHTEN. ONE FULL TURN

WITHAWRENCH PASTHAND TIGHTis usually

sufficient to prevent leakage.

19) Afterpumpassembly,refertopumpoperator's

manual for proper operating procedures.