Table of Contents

Section -1 Introduction

UNDERSTANDING FLUX DENSITY..................................... 1-1

MEASUREMENT OF FLUX DENSITY .................................. 1-2

PRODUCT DESCRIPTION .................................................... 1-4

APPLICATIONS ..................................................................... 1-4

Section - 2 Specifications

SPECIFICATIONS ................................................................. 2-1

MODEL 5170 / 5180 SPECIFICATIONS ................................ 2-2

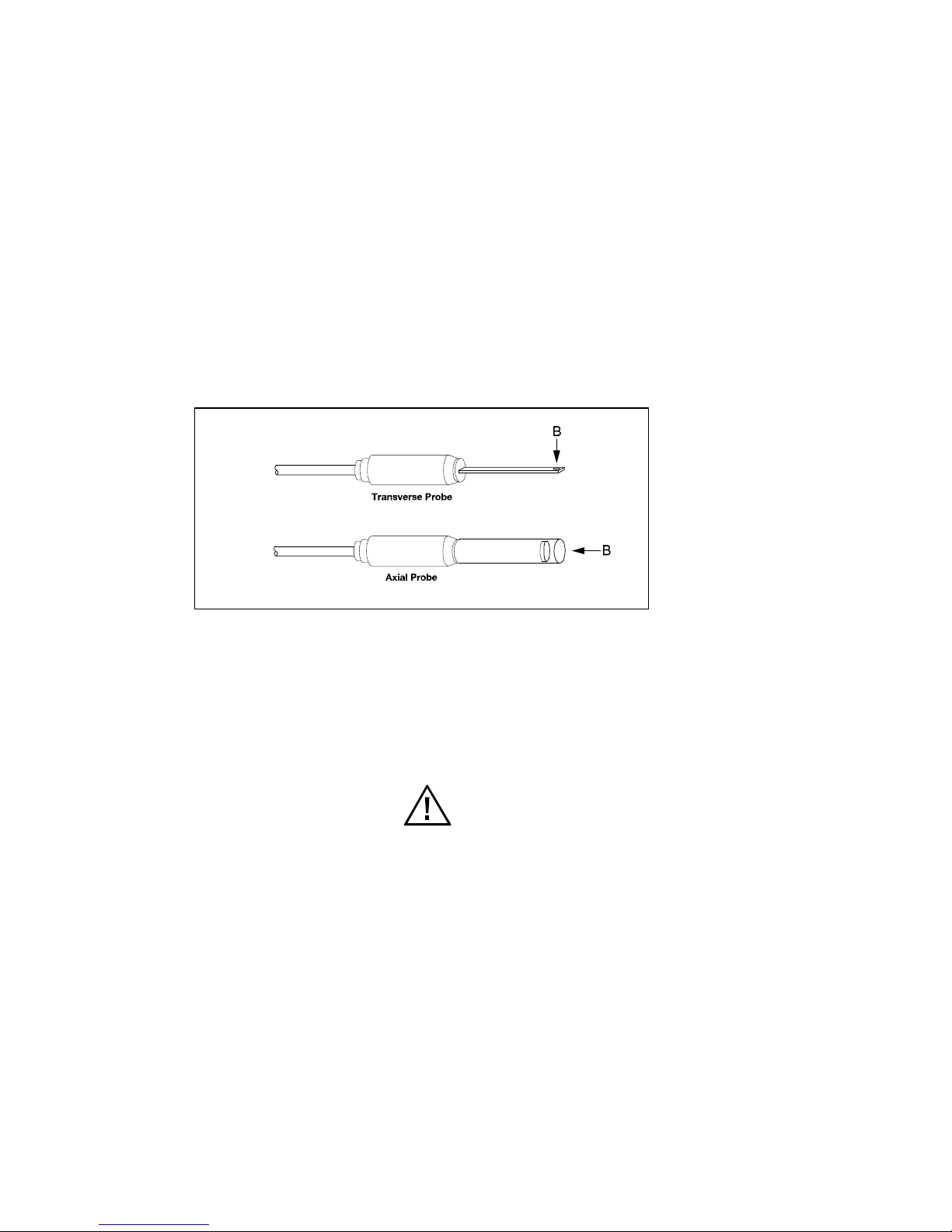

STANDARD TRANSVERSE PROBE ..................................... 2-3

STANDARD AXIAL PROBE ................................................... 2-4

LOW FIELD AXIAL PROBE ................................................... 2-5

ZERO FLUX CHAMBER ........................................................ 2-6

Section - 3 Operating Instructions

OPERATOR SAFETY ............................................................ 3-1

OPERATING FEATURES ...................................................... 3-2

INSTRUMENT PREPARATION ............................................. 3-3

POWER-UP ............................................................................ 3-4

POWER-UP SETTINGS ......................................................... 3-5

LOW BATTERY CONDITION ................................................. 3-6

OVERRANGE CONDITION .................................................. 3-6

AC OR DC MEASUREMENT SELECTION ............................ 3-6

UNITS OF MEASUREMENT SELECTION ............................ 3-6

RANGE SELECTION ............................................................. 3-7

HOLD MODE SELECTION .................................................... 3-8

MIN / MAX HOLD USAGE ..................................................... 3-9

PEAK HOLD USAGE ............................................................. 3-9

ZERO FUNCTION .................................................................. 3-10

AUTOMATIC ZERO FUNCTION ............................................ 3-11

MANUAL ZERO FUNCTION .................................................. 3-12

RELATIVE MODE .................................................................. 3-13

AUTOMATIC RELATIVE MODE ............................................ 3-14

MANUAL RELATIVE MODE .................................................. 3-15

ANALOG OUTPUT FUNCTION ............................................. 3-16

ANALOG OUTPUT USAGE ................................................... 3-17

SOURCES OF MEASUREMENT ERRORS .......................... 3-19

MORE DETAILS ON AC MODE OPERATION ...................... 3-20

MORE DETAILS ON DC MODE OPERATION ...................... 3-21

Section - 4 Remote Operation

USB INTERFACE CONNECTION …......................………… 4-1

REMOTE COMMAND STANDARDS …………....................….. 4-1

COMMAND FORMAT ……..............................……………...….. 4-1

ERROR BUFFER …………................................…………….….. 4-2

STATUS REGISTERS ……........................................…….....… 4-2

INFORMATION FOR REMOTE OPERATION …....................... 4-3

OTHER GENERAL 5180 FILE INFORMATION ….................… 4-4

STATUS BYTE AND REQUEST FOR SERVICE (RQS) …....… 4-5

STANDARD EVENT REGISTER ………................................… 4-7

MEASUREMENT EVENT REGISTER ……............................… 4-8

OPERATION EVENT REGISTER ……...................................… 4-8

QUESTIONABLE EVENT REGISTER …..........................…….. 4-8

“COMMON” COMMAND SYNTAX ……..........................……… 4-9

“COMMON” COMMANDS ……….......................................…… 4-10

SCPI COMMAND SYNTAX ……......................................…….. 4-12

SCPI COMMANDS …………...........................................……… 4-13

ERROR MESSAGES AND COMMANDS …..................………. 4-15

STATUS COMMANDS ……....................………….……….…… 4-16

MODE COMMANDS……….....................................……………. 4-17

RANGE COMMANDS …….......................................…...……… 4-18

HOLD COMMANDS ………...........................................……..… 4-19

ZERO COMMAND …………...............................................…… 4-20

RELATIVE COMMANDS ………..................................………… 4-20

MEASUREMENT COMMAND ….............................…………… 4-20

ANALOG OUTPUT COMMAND …....................................……. 4-21

OPERATION COMPLETE STATUS .......................................... 4-22

MODEL 5100 ERROR CODES ….........................................…. 4-23

WARRANTY

N