User Manual Chapter 1

GFK-2749A Jan 2020

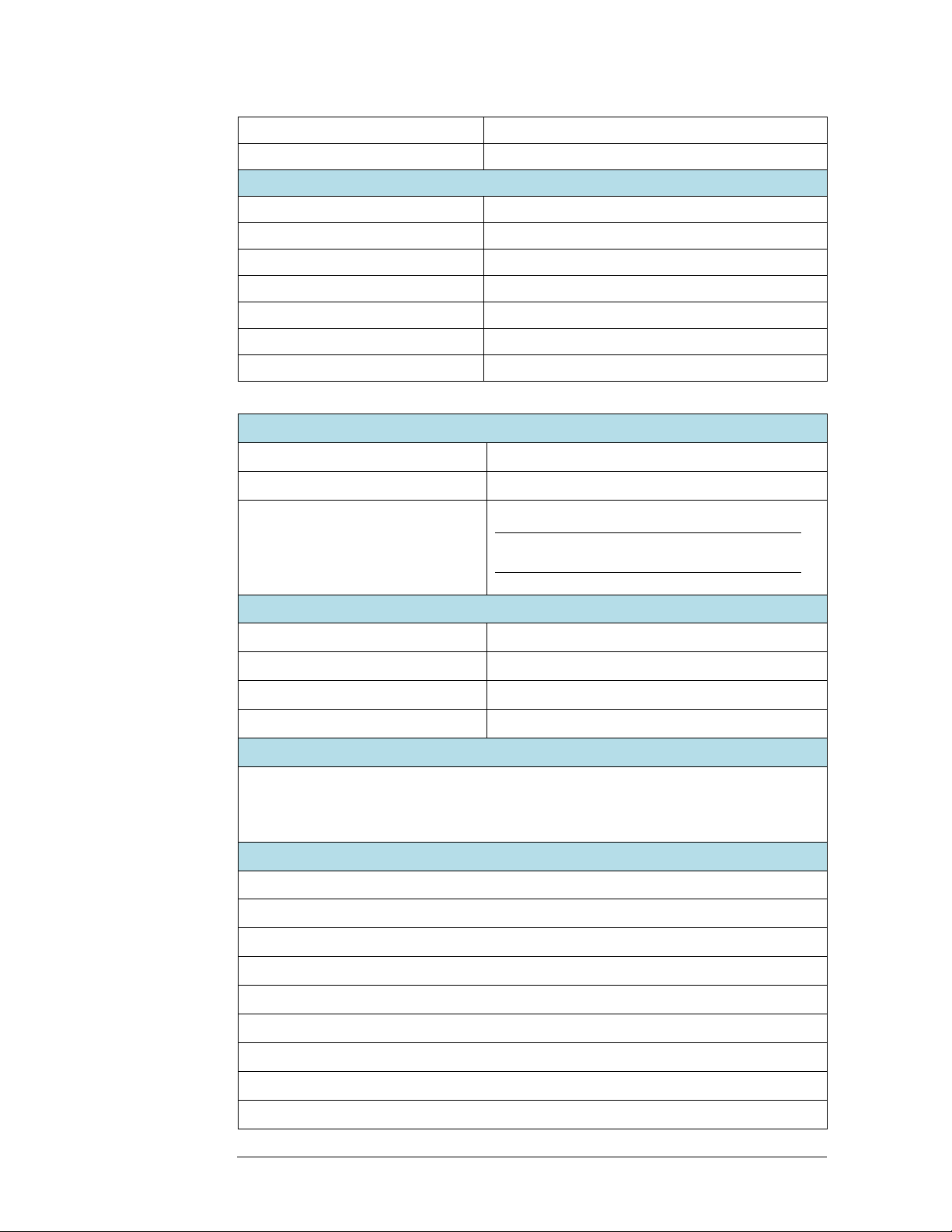

PSM Module Description and Specifications 1

Chapter 1: PSM Module Description and

Specifications

The Power Sync and Measurement (PSM) system monitors two independent three-phase

power grids. It incorporates advanced digital signal processor (DSP) technology to

continuously process three voltage inputs and four current inputs for each grid.

Measurements include RMS voltages, RMS currents, RMS power, frequency, and phase

relationship between the phase voltages of both grids.

The PSM module performs calculations on each captured waveform, with the DSP

processing the data in less than two-thirds of a power line cycle. The PSM module can be

used with wye or delta type three-phase power systems or with single-phase power

systems.

The PSM system can be used for applications such as:

•Electrical power consumption monitoring and reporting

•Fault monitoring

•Generator control features for generator to power grid synchronization

•Demand penalty cost reduction/load shedding

The PSM system consists of:

•PSM module –A standard IC694 module that mounts in an RX3i main rack. The PSM

module provides the DSP capability.

•Terminal Assembly –A panel-mounted unit that provides the interface between the

PSM module and the input transformers.

•Interface cables –Provide the GRID 1 and GRID 2 connections between the PSM module

and the Terminal Assembly.

1.1 PSM System Features

•Uses standard, user-supplied current transformers (CTs) and potential transformers

(PTs) as its input devices.

•Accurately measures RMS voltage and current, power, power factor, frequency, energy,

and total, three-phase, 15-minute power demand.

•Provides two isolated relays that close when the voltage phase relationships between

the two monitored grids are within the specified ANSI 25 limits provided by the RX3i

host controller. These contacts can be used for general-purpose, lamp duty or pilot duty

loads. Voltage and current ratings for these load types are provided on page 5.

•Provides a cable monitoring function that indicates when the cables linking the PSM

module and Terminal Assembly are correctly installed.

•Can be easily calibrated using the PACTM Machine Edition software to enter calibration

constants for the PSM module and Terminal Assembly.