PAJ Sensor A/S • Grundtvigs Allé 163 • DK-6400 Sønderborg

Tel: +45 74 43 71 81 • Fax: +45 74 43 71 91 • CVR: 3459-1229 • www.paj.dk • e-mail: paj@paj.dk

APPROVALS: ISO 9001, ISO 14001, ISO 13485, IEC 61340-51 & IPC-A-610 CLASS 3

03-01-0501-CRJ-04 Side 2 af 53

Table of contents

Table of contents .........................................................................................................................................................................................2

Introduction......................................................................................................................................................................................................3

Safety Advice ..................................................................................................................................................................................................4

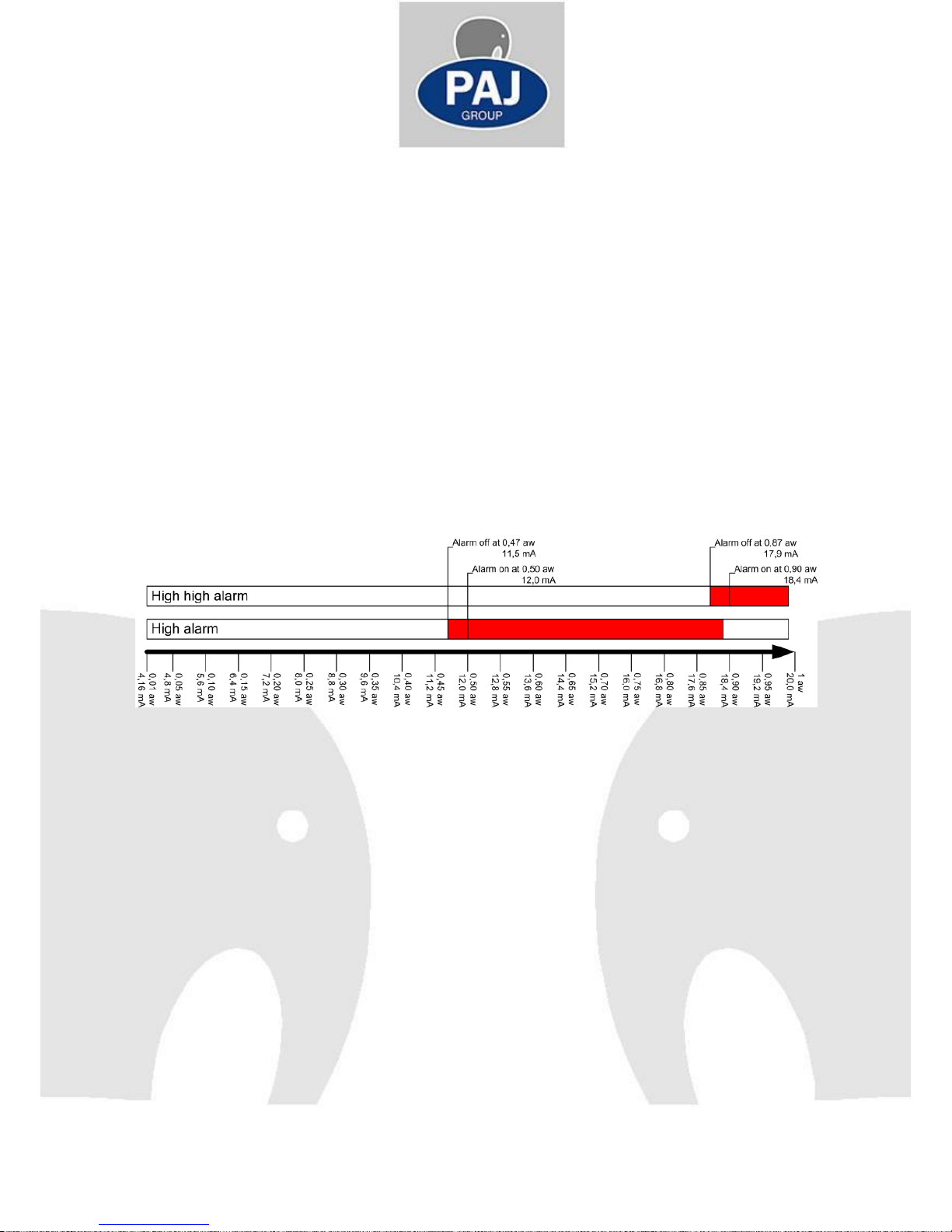

Function...............................................................................................................................................................................................................6

Normal operation.........................................................................................................................................................................................7

Failure indication..........................................................................................................................................................................................8

Self test for alarm functions...............................................................................................................................................................9

Before installation ....................................................................................................................................................................................11

WIO Sensor dimensions in mm.....................................................................................................................................................14

Terminal box dimensions in mm..................................................................................................................................................16

WIO Integrated (WIOI) dimensions in mm ........................................................................................................................17

Technical data, Sensors ......................................................................................................................................................................19

Technical Data Terminal Box ..........................................................................................................................................................22

Technical Data Terminal Display Box.......................................................................................................................................23

Technical Data Terminal Box Alarm ..........................................................................................................................................26

Technical Data Terminal Box Alarm Buzzer........................................................................................................................29

Technical data, WIOI (WIO Integrated) ................................................................................................................................33

EC-Declaration of Conformity.........................................................................................................................................................39

Appendix A1: Install 1 Terminal Box with 1 display.......................................................................................................................42

Appendix A2: Install 1 Terminal Box with no display ....................................................................................................................43

Appendix A3: Install 2 Terminal Boxes with 2 display ..................................................................................................................44

Appendix A4: Install 2 Terminal Boxes with 1 display ..................................................................................................................45

Appendix A5: Install 2 Terminal Boxes with 1 display ..................................................................................................................46

Appendix A6: Install 3 Terminal Boxes with 3 display ..................................................................................................................47

Appendix A7: Install 3 Terminal Boxes with 2 display ..................................................................................................................48

Appendix A9: CABLE Specification .............................................................................................................................................49

Appendix A10: Error / failure FAQ..............................................................................................................................................50

Company Information...........................................................................................................................................................................53