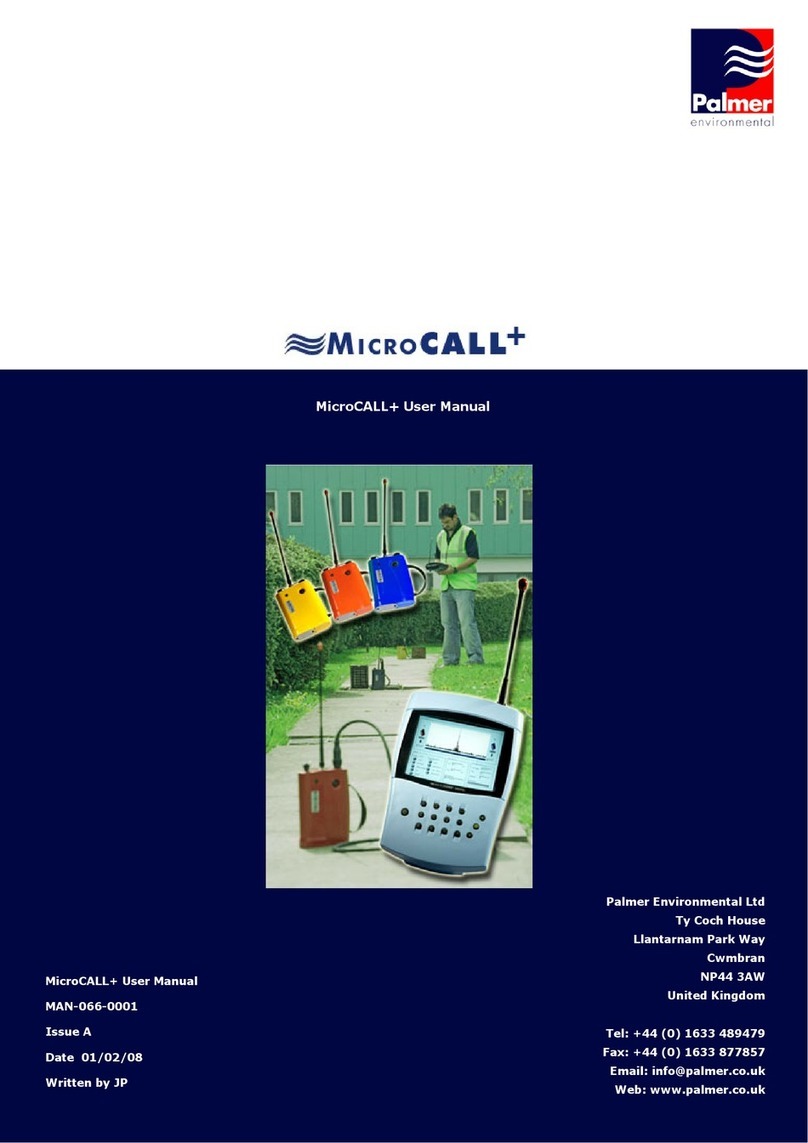

Palmer RM-10 User manual

Thank you for purchasing an in-line refractometer. This instruction manual is designed to

guide you to understand the functions and characteristics of the sensor. Before using the

instrument, please read this manual carefully to ensure safe and correct use. Please keep this

manual for future reference.

In-line Refractometer

Instruction Manual

RM-10、RM-20

1. Working principle 3

2. Typical application 4

3. Structural design 4

4. Technical specifications 5

5. Safety precautions and instructions for use 5

6. Product accessories and wiring definition 7

7. Installation Precautions 7

8. Operation instructions 9

9. Maintenance and troubleshooting 11

10. Relation graph between concentration value and refractive index 11

Contents

1. Working Principle

In-line Refractometer Instruction Manual

The in-line refractometer is composed of a light source, Prism, a light receiver and a signal

modulation circuit. The light source emits a stable light signal through the prism to contact

the measured medium, and the corresponding refractive index is generated by the concen-

tration of the measured medium. The optical device calculates the refractive index of the

collected refracted light source to obtain the corresponding concentration through the data

algorithm. Since the concentration is affected by temperature, the internal temperature

calibration is adopted to reduce the influence of temperature drift.

3

Water-based solutions

Light source Light source

refraction

acceptance

Light source

Refraction

Acceptance

Output Signal

Water-based solutions

Light source

refraction acceptance

Light source

Prism

1

2

6

5

2. Typical application

Food Industry Beverage

industry

Fruit and jam

processing

Starch sweetener Sugar and

sweeteners

Water-based

solutions

4

3

4

3. Structural design

In-line Refractometer Instruction Manual

4. Technical specifications

Measure range:

Output :

Power:

Display menu:

Working Temperature:

Accuracy:

Protection grade:

Max Pressure:

High and low limit settings

Wetted parts material:

RM-10 ( 0-15%) ,RM-20 ( 0-50%)

4-20mA , RS485

DC12~24V

Brix (%), Temperature (T), Refractive index(nD)

10℃~60℃

±0.3%

IP65

2Mpa

Buttons can be set

Prism: sapphire, Prism stage: SS304 , SS316L (can be customized)

Safety precautions

5. Safety precautions and instructions for use

Please read this manual carefully, and fully understand the functions and operations of each part of the

instrument before use, and check whether each part of the instrument is working properly before use.

Perform necessary inspections and parameter adjustments according to the instruction manual.

√

x

x

OFF

OFF

√

5

In-line Refractometer Instruction Manual

When measuring substances harmful to the

human body, please take care of protective

measures

If the instrument starts to overheat, smoke or

emit an unusual smell, turn off the power

immediately

Do not disassemble or modify this instrument

Do not measure corrosive media

Do not put water or samples to all parts other

than the surface of the prism

When not in use for a long time, please turn

off the power

instructions for use

2000m

10~60℃

Use the instrument at an altitude

of less than 2000 meters (altitude)

Use this instrument indoors;

The operating environment

temperature is between 10℃~60℃;

Do not suddenly change the

ambient temperature of the

instrument;

Do not use the instrument

in a place with a lot of dust and

strong vibration;

Do not place the instrument

in a humid place;

Do not put heavy objects on

the instrument;

Do not install the instrument

in direct sunlight or near a heating

source;

Do not install in dusty or

exposed to corrosive gas

environment;

When installing, please pay

special attention to avoid strong

impact on the instrument.

6

In-line Refractometer Instruction Manual

24V Power + ,

Red

24V Power - ,

Black

2. 4-20mA-

Black

3. RS485-

Green

4. RS485+

Yellow

1. 4-20mA+

Red

Plug wiring definition

6. Product and accessories packing list

2-pins plug for unit power

(24VDC)

4-pins plug for output

( 4-20mA )

6-pins plug for output

( Modbus-TCP RS485)

7

1 2 4 5

Instrucation manual

Main unit 3Two-pins plug

mating cable

Four-pins plug

mating cable

Six-pins plug

mating cable

6O-Ring 6Clamp band 6Pass certificatation

7. Installation Precautions

1. The installation form of this product is a hoop quick-installation type;

2. When installing, please pay special attention not to scratch the prism and probe;

3. When installing, please pay special attention to avoid strong impact on the instrument;

4. When installing, please pay special attention not to miss the sealing ring;

5. Ensure that the cable is correctly connected to the port;

6. The power can be turned on only after the product is installed;

7. Installation method, installation method of cleaning device.

In-line Refractometer Instruction Manual

Pass

Ethernet Tx- ,

Yellow

Ethernet Tx- ,

Green Ethernet Rx- ,

Black

Ethernet Rx+ ,

Red

Normal curve pipe

Small curve pipe Neck to increase flow rate pipe

>1.5m/s

Mounting type 2: Large pipeline and container installation

Big pipeDigester with scraper and steam Container

8

Mounting type 1: Compact small pipe installation

Cleaning device installation

In-line Refractometer Instruction Manual

3”Clamp band1.5" Clamp mounting

1.5" Clamp mounting

3”Clamp Intelligent cleaning device

O-Ring

In-line Brix

O-Ring

Reciprocating mobile cleaning wipe head

Set

Intercalation

time

Running

time

min

sec

Start Stop

Button definition

Menu (Menu) Return (ESC) Up (∧) Down (∨). Menu is equivalent to the confirmation key, and the ESC

exit key can be single-pressed or long-pressed to move up (∧) down (∨)

8. Operation instructions

menu type First level menu Second level menu

No.

Measurement interval 4,6,8,101

Calibrate 0 Calibration 0 returns to the main page

successfully, EE0 is displayed if it fails

2

Brix corresponding to the upper limit of

20mA in the current 4~20mA Default value depend on the measurement range

3

Decimal places 0,1,2

4

Display temperature, refractive index or

polling display

1=temperature, 2=refractive index,

3=polling display

5

Mode-S measurement stability 1, 2, 3, 4, 5 total 5 gears

6

Temperature correction in units of 0.1 Increase or decrease by 0.1

7

Brix corresponding to the lower limit 4mA

in the current 4-20mA Default 0%

8

Temperature 4-20mA upper limit 1 as the unit

Increase or decrease the upper limit of the solution 4-20mA output

by 1. When the temperature value is greater than or equal to the

upper limit, the output is 20mA, and the value range is -10-130

9

Temperature 4-20mA lower limit 1 as the unit Increment or decrement the lower limit of the 4-20mA output of the

solution by 1, when the temperature value ≥the upper limit, the

output 4mA, the value range is -10-130

10

Menu structure

step1 step2 step3 step4 step5

Menu

Menu

ESC

Return

(∧)

Up

(∨)

Down

9

>>> >>> >>> >>>

In-line Refractometer Instruction Manual

Connect the

power to RM ,

the measure-

ment starts

Calibrate 0 with

distilled water (

The factory

Settings of the

product have

been validated )

Install well our

RM on the

location that

needs to be

measure .

When the

sample flows

into the prism

surface

Measurement

starts , brix (%)

value and current

temperature T will

be displayed .

In the measurement interface, press Menu to enter the first level menu, and ESC to return to the measurement

interface. Under the first level menu, you can use the up and down keys to select the corresponding options. When

you press Menu, you will enter the second level menu. The up and down keys will adjust the corresponding options.

After adjustment, press Menu to save the settings and return to the first level menu. After adjustment, press ESC

to not save and Return to the first level menu.

10

menu type

No.

The alarm high limit is 1 as the unit When the measured concentration exceeds the high limit, the

display flashes quickly, and the value range is 0-100 When the

setting value is greater than 95, it is equivalent to turning off

thealarm output

11

Alarm low limit 1 as unit

Increase or decrease by 1 when the measured concentration is

lower than the low limit, display Slow flashing, when the set

value is less than 0, it is equivalent to turning off the alarm

output

12

Device ID address Default is 1

The default is 1.0

13

Reset

Display concentration magnification

* only display the concentration magnification , output no

Return to the main page after successful reset,

display EE1 on failure

14

15

In-line Refractometer Instruction Manual

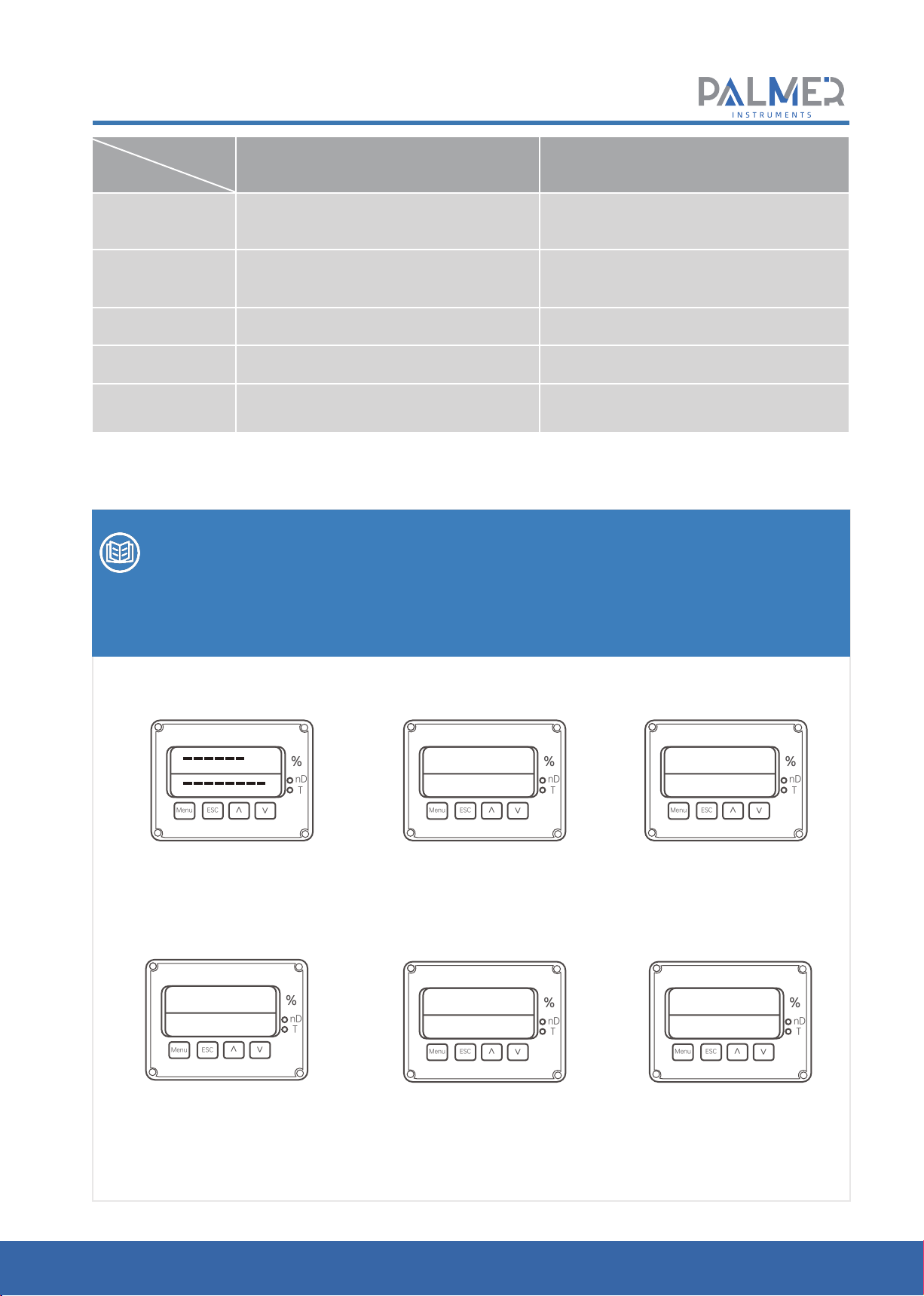

Menu ^

^

ESC

%

nD

T

Menu ^

^

ESC

%

nD

T

nD & T polling display

You can choose to display only T

or nD or both through the menu.

Normal measurement display

***(Current Brix)

T(Current Temperature)

***

T

LLLL

T

Menu ^

^

ESC

%

nD

T

Calibration 0 failure display EE0

EE0

T

Boot display

Menu ^

^

ESC

%

nD

T

Menu ^

^

ESC

%

nD

T

Menu ^

^

ESC

%

nD

T

Brix exceeds the measuring rangeNo solution display

T (Current Temperaure) T (Current Temperaure)

LLLL

T

HHHH

T

First level menu Second level menu

This manual suits for next models

1

Table of contents

Other Palmer Measuring Instrument manuals