-

3

-

GENERAL GUIDELINES

1. When servicing, observe the original lead dress. If a short

circuit is found, replace all parts which have been over-

heated or damaged by the short circuit.

2. After servicing, see to it that all the protective devices

such as insulation barriers, insulation papers shields are

properly installed.

3. After servicing, make the following leakage current

checks to prevent the customer from being exposed to

shock hazards.

LEAKAGE CURRENT COLD CHECK

1. Unplug the AC cord and connect a jumper between the

two prongs on the plug.

2. Measure the resistance value, with an ohm meter,

between the jumpered AC plug and each exposed

metallic cabinet part on the equipment such as

screwheads, connectors, control shafts, etc. The

resistance value must be more than 5MΩ.

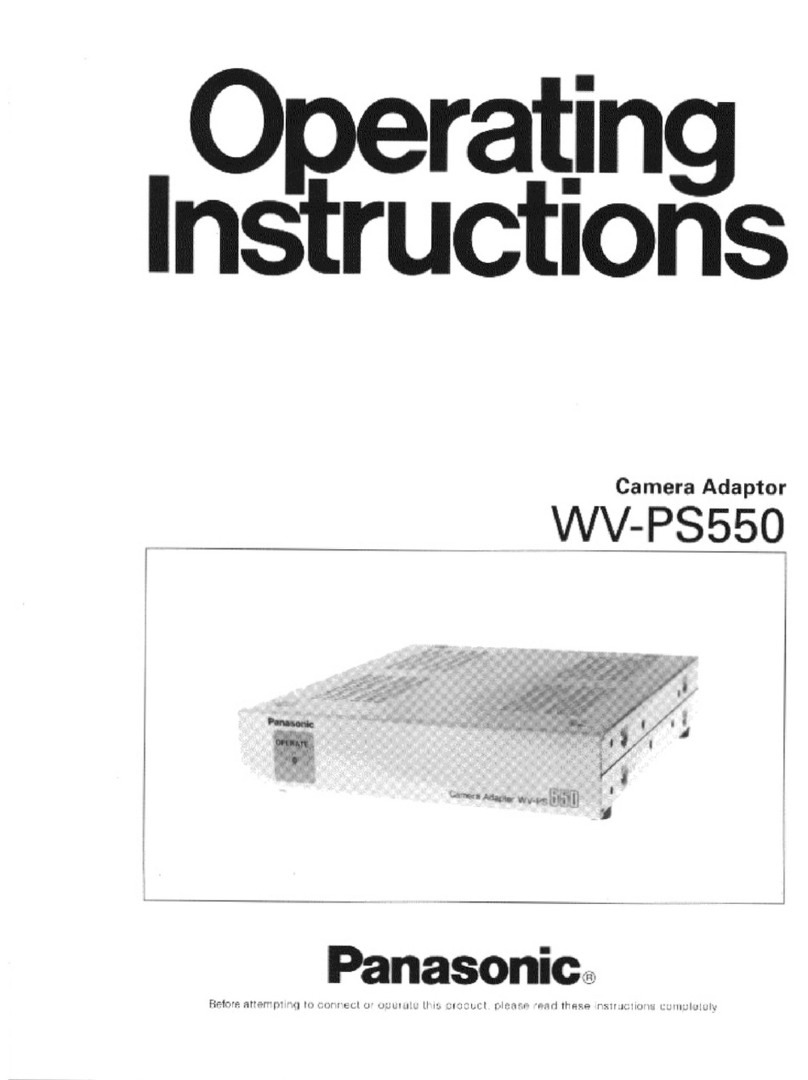

Figure1

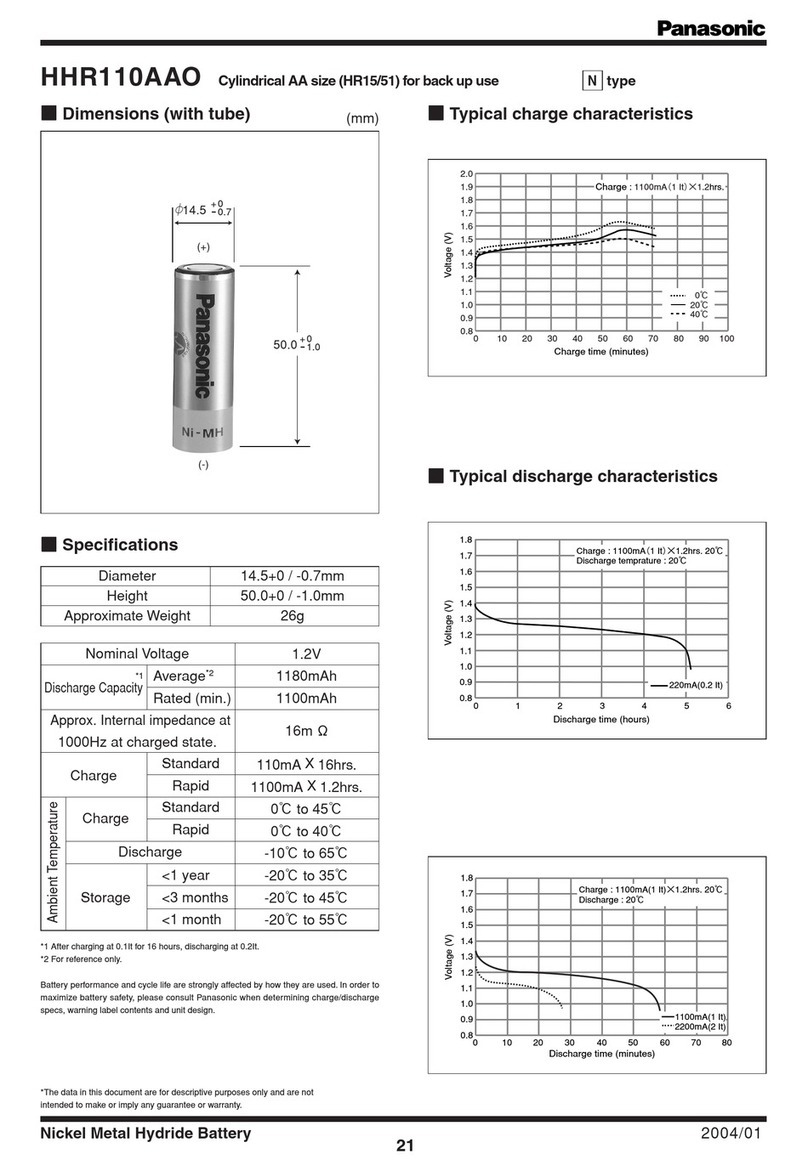

LEAKAGE CURRENT HOT CHECK (See Figure 1)

1. Plug the AC cord directly into the AC outlet.

Do not use an isolation transformer for this check.

2. Connect a 1.5kΩ, 10W resistor, in parallel with a 0.15µ

F capacitor, between each exposed metallic part on the

set an a good earth ground such as a water pipe, as

shown in Figure1.

3. Use an AC voltmeter, with 1000 ohms/volt or more

sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the

voltage at each point.

5. Reverses the AC plug in the AC outlet repeat each of the

above measurements.

6. The potential at any point should not exceed 0.15 volts

RMS. A leakage current tester (Simpson Model 229

equivalent) may be used to make the hot checks, leakage

current must not exceed 0.1 milliamp. In case a

measurement is outside of the limits specified, there is a

possibility of a shock hazard, and the equipment should

be repaired and rechecked before it is returned to the

customer.

ELECTROSTATICALLY SENSITIVE (ES) DEVICES

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically sensitive (ED) Devices. Examples of

typical ES devices are integrated circuits and some field-

effect transistors and semiconductor “chip” components. The

following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor

component or semiconductor-equipped assembly, drain

off any electrostatic charge on your body by touching a

known earth ground.

Alternatively, obtain and wear a commercially available

discharging wrist trap device, which should be removed

for potential shock reasons prior to applying power to the

unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface

such as aluminum foil, to prevent electrostatic charge

buildup or exposure of the assembly.

3. Use only a grounded tip soldering iron to solder or

unsolder ES devices.

4. Use only an anti-static solder removaldevice classified as

“anti-static” can generate electrical charges sufficient to

damage ES devices.

5. Do not use freon-propelled chemicals. These can

generate electrical charges sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its

protective package until immediately before you are

ready to install it.

(most replacement ES devices are package with leads

electrically shorted together by conductive foam,

aluminum foil or comparable conductive material).

7. Immediately before removing the protective material from

the leads of a replacement ES device, touch the

protective material to the chassis or circuit assembly into

which the device will be installed.

CAUTION : Be sure no power is applied to the chassis or

circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpacked

replacement ES devices. (Otherwise harmless motion

such as the brushing together of your clothes fabric or the

lifting of your foot from a carpeted floor can generate

static electricity sufficient to damage an ES device).

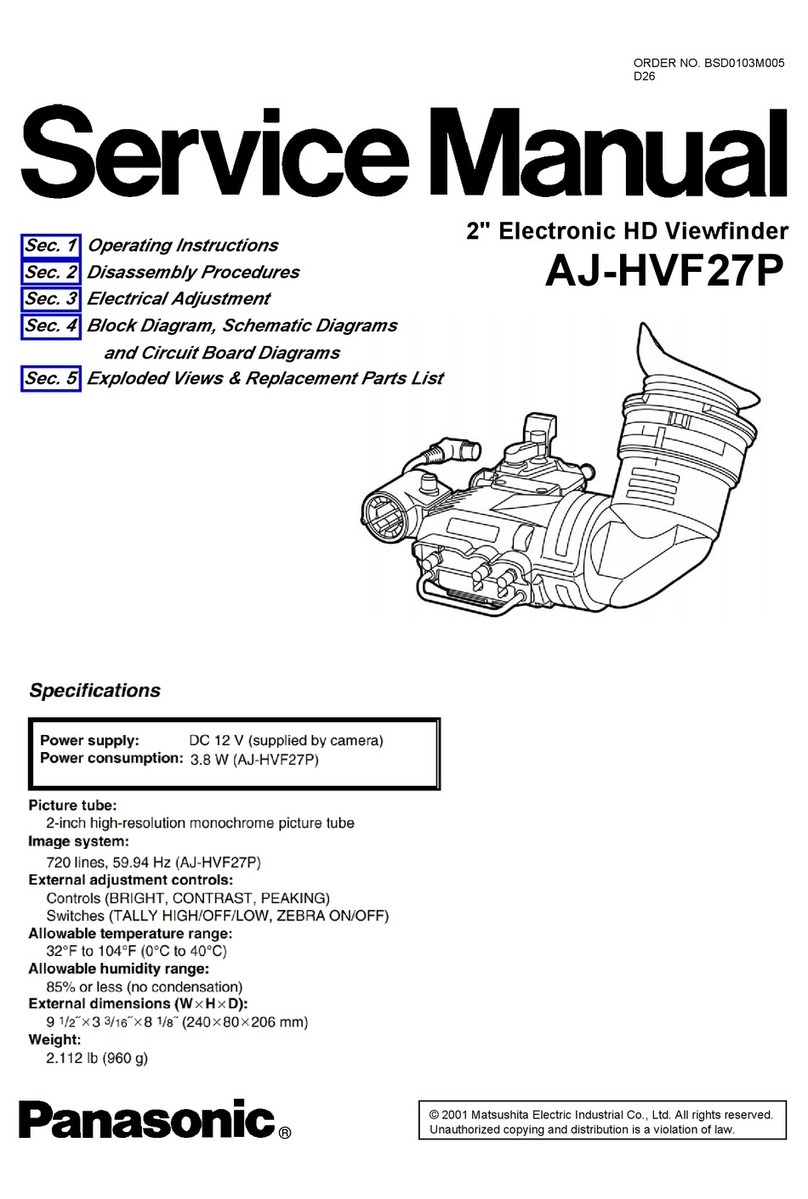

X-RADIATION

WARNING

1. The potential source of X-radiation in EVF sets is the

High Voltage section and the picture tube.

2. When using a picture tube test jig for service, ensure that

jig is capable of handling 10kV without causing x-

radiation.

Note : It is important to use an accurate periodically

calibrated high voltage meter.

3. Measure the High Voltage. The meter (electric type)

reading should indicate 2.5kV, 0.15kV. If the meter

indication is out of tolerance, immediate service and

correction is required to prevent the possibility of

premature component failure. To prevent an x-radiation

possibility, it is essential to use the specified picture tube.

SAFETY PRECAUTIONS

±

AC VOLTMETER

Hot-Check Circuit

TO

APPLIANCES

EXPOSED

METAL PARTS

COLD

WATER PIPE

(EARTH GROUND)

1500Ω

0.15µF

10W