WARNING

*

This

product

should

be

serviced

only

by

trained,

qualified

personnel.

As

for

the

oven

lamp,

it

is

replaceable

by

the

users.

*

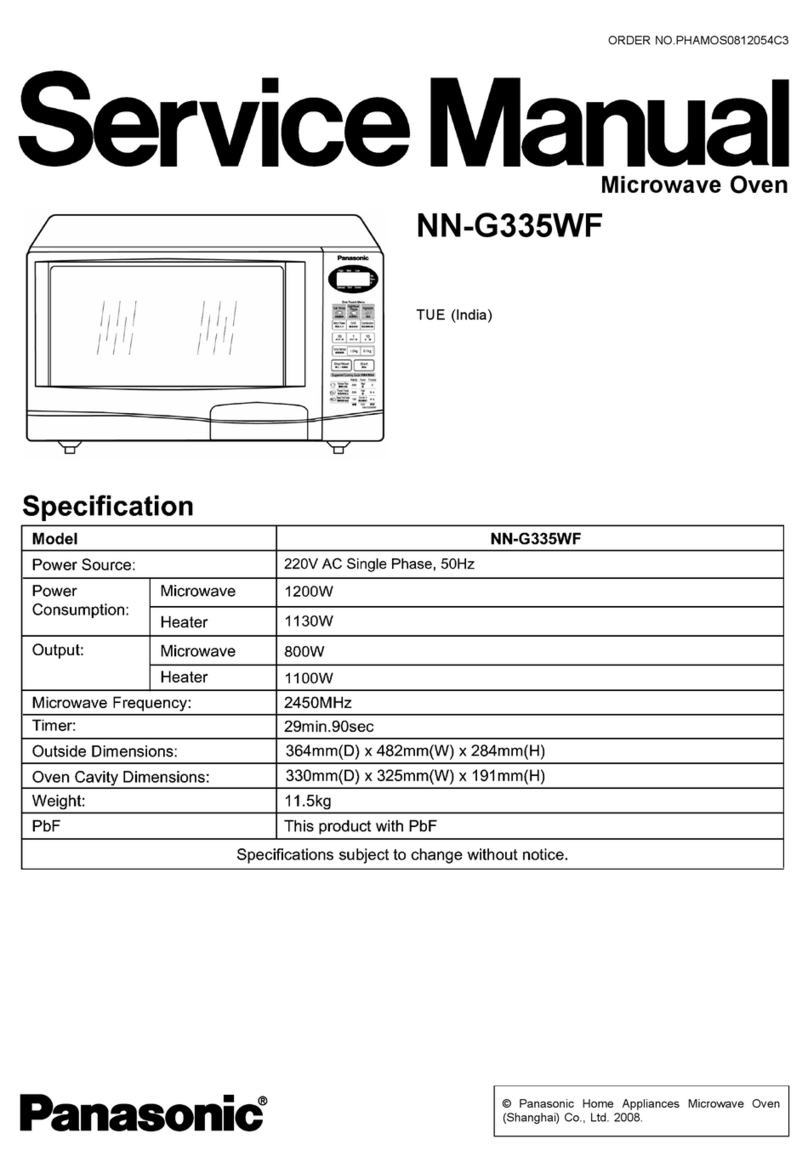

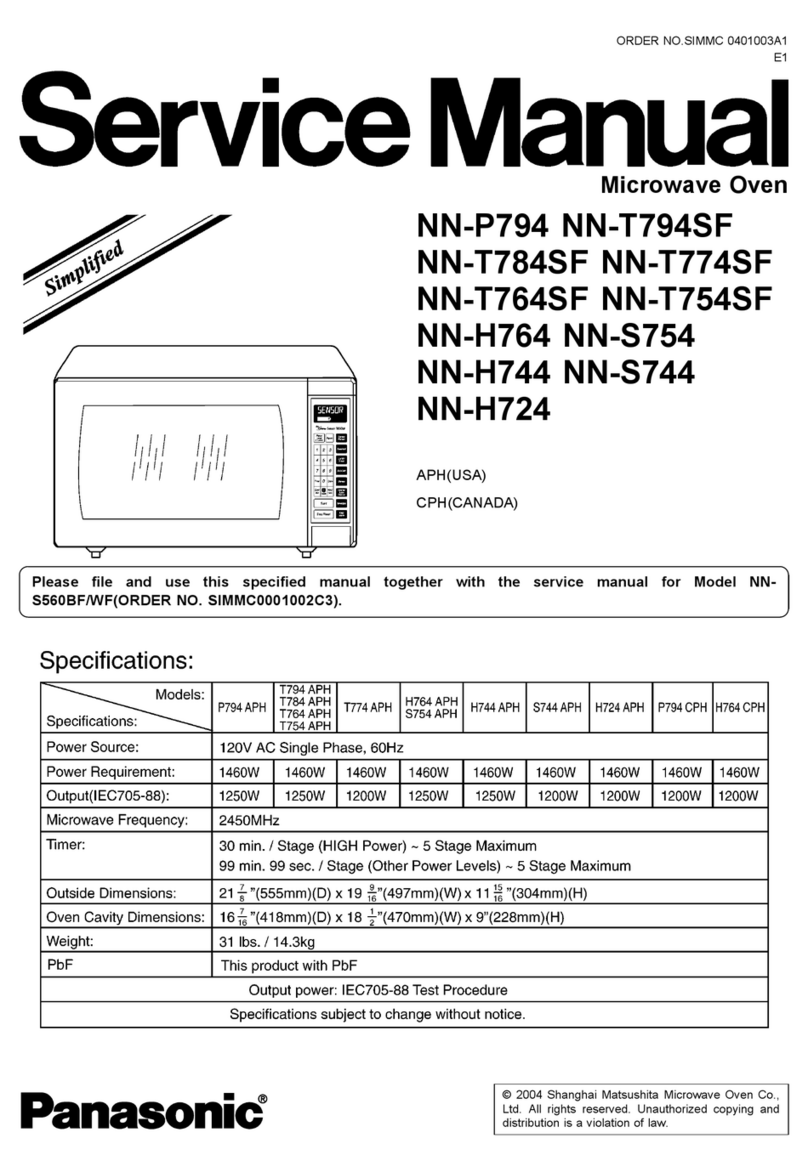

This

service

manual

covers

products

for

following

markets.

When

troubleshooting

or

replacing

parts,

please

refer

to

the

country

identifications

shown

below

for

your

applic-

able

product

specification.

For

United

Kingdom

For

NAAFI

CONTENTS

OUTLINE DIAGRAM

&

CONTROL

PANEL

NE-992/NE-993

FX

oy

0)

350)

5)

|

ERE

EEEEE

ESSE

ORES

SSSSSSEEOOOSOOOOOOOOOOOOCOOOOEOOOORSOOOOOOOOCOOOSOOOOOOOOOOOOOOOCOO

SSCS

SSOSEOOSSEOOOOOOOOOOOOOOOOOOOOOOOOOOOSSEOOSOOSOS

7

SCHEMATIC

DIAGRAM

IN

=o

9]

ko

EERE

OSES

SSS

OOSSSSOOCOSSEOEOSOOOOOO

OOOO

OOSEOOOSECOOOSOOOOOSOOSSOCOOOSOOOOOOOOOOOOOOOOOSOOOOOOLOOOOOOOOOOOOOOOOOOOOOOOOOOS

8

INT

=n)

fe

OEEES

EEE

EECES

ESOS

OOOO

OSOSOOSEOOSOOOOOOOOOOOOOOOOOOOOOOOOCOOSOOOOOOSOOOEOOOOOSOOOOOOSOOOSOCOOOOOOOOCOOOOOOOOOOOSSSOOOOOOOOOCOOOOOOOOOOSOOOCOOOOOOSS

9

DESCRIPTION

OF

OPERATING

SEQUENCE

sssssesreerserretesteseeseseeeeeeenteeneeeteeceeteeteeneesseeneesnreseseneesneeeeseseneeseccseaaeecnseenseseneenn

stieeee

10

AUTO

SENSOR

EXPLANATION,

K

FACTORS

AND

POWER

LEVELS:

er

rrceccrecrecetcret

ess

nee eet

eeetee

eee

te

cect

ee

cease

eens

ene ane

nena

naeeenraeceeen

ernie

seen

ets

17

CAUTIONS

TO

BE

OBSERVED

WHEN

TROUBLESHOOTING:

:::-----

Jagdine

Seahees

WgdesvaaUaduetcdea

wed

decease

dovae

det

asses

vatea

sedans

coedeue

evensersgseeer

vane

Seobesgs

18

DISASSEMBLY

AND

PARTS

REPLACEMENT

PROCEDURE:

::11rr:cstseeertseerereetetteeeeenteeeectnseeeereeeertseeeeen

nines

esennenegaaeeesrnnneeerenernens

sannnnes

19

COMPONENT

TEST

PROCEDURE

<vrreeeesrececrteeseeeseesereeeceeeeeeeaeeeeeeneeeseneneeeerseeeesnseeeenisaeessseeteesesceseseeanerecereneeeeeeesenenreeeeesnn

ceeees

23

MEASUREMENTS

AND

ADJUSTMENTS

‘crccerescccteersseesesteteseeeeeeeenessseeennneesenseeeesssseeserseeeeenseesensasasesensteeeersaneeecaeeeensneeecererteis

cenernes

25

TROUBLESHOOTING

GUIDEs

+s

ceesccestresteereeerseeeseetseeseeeneeneeeneens

teen

senna

ee

teens

eeneeen

eee

eeeeenee

sete

ee

ene

ee

eee

teeeeeeeneecneaeeeeeeeneesneeeteeeie

oeetse

26

DIGITAL

PROGRAMMER

CIRCUIT

TEST

PROCEDURE

NE-992/NE-QO3-+coecccceereeeeseeteseeesseceesseecsseeeseeeeessenseseneeeeessseessseeeneeeenieeestecenseeeseeensseeeneeeeessaeeesaeesaeeessaeeeeecaesesennegenseneese

#aeeeees

33

Nn

dE

EEEEESEELEESOOEESSOEESOSORSOOOSOSOOSOOOOSEOOSSOOOIOOOOOOOESOOOOOOOOCOOOSOOOOICOSOOOOOOOOOOOOOOOOOSCOOSOOOOOOSOOOOSO

SOOT

SS

CCCOCOOOOOOOCOOOCOOOOESOOOOS

44

EXPLODED

VIEW

AND

PARTS

LIST

<coccccesceerseceeesesseseeeeseeense

senses

eenneesenee

settee

enneeeteeenteeeneeetieetnsaeerseeseeeerineernaeeee

sees

sensneeesennenniy

earns

50