Panasonic TH-42PW5 User manual

Other Panasonic Monitor manuals

Panasonic

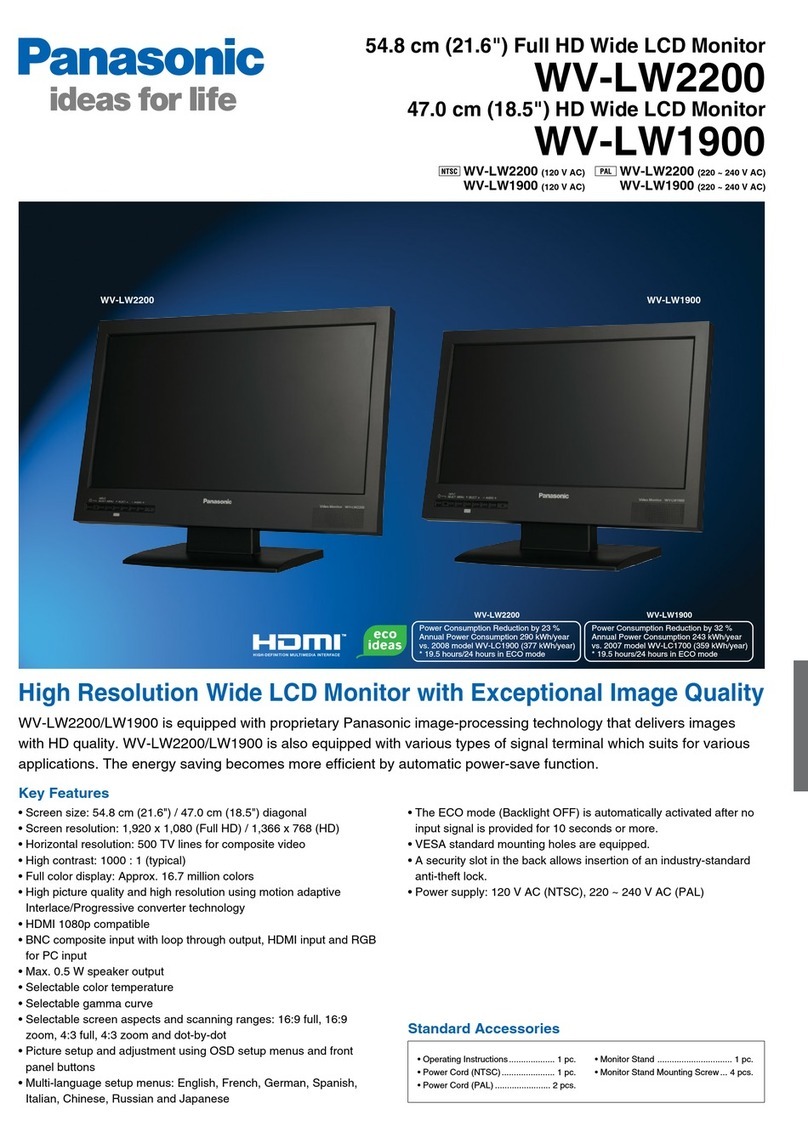

Panasonic WV-LW2200 User manual

Panasonic

Panasonic TH58PH10UK - 58" Plasma Panel User manual

Panasonic

Panasonic TH-37PW7BX User manual

Panasonic

Panasonic WVCM146 - COLOR MONITOR User manual

Panasonic

Panasonic Viera TH-42PW3 User manual

Panasonic

Panasonic BT-LH1710W User manual

Panasonic

Panasonic CQ-VD5005U User manual

Panasonic

Panasonic TX-1703MA Series User manual

Panasonic

Panasonic TX-15TA1C User manual

Panasonic

Panasonic TH-L37U20R User manual

Panasonic

Panasonic Viera TH-42PHW5 User manual

Panasonic

Panasonic TH-37PR11UH User manual

Panasonic

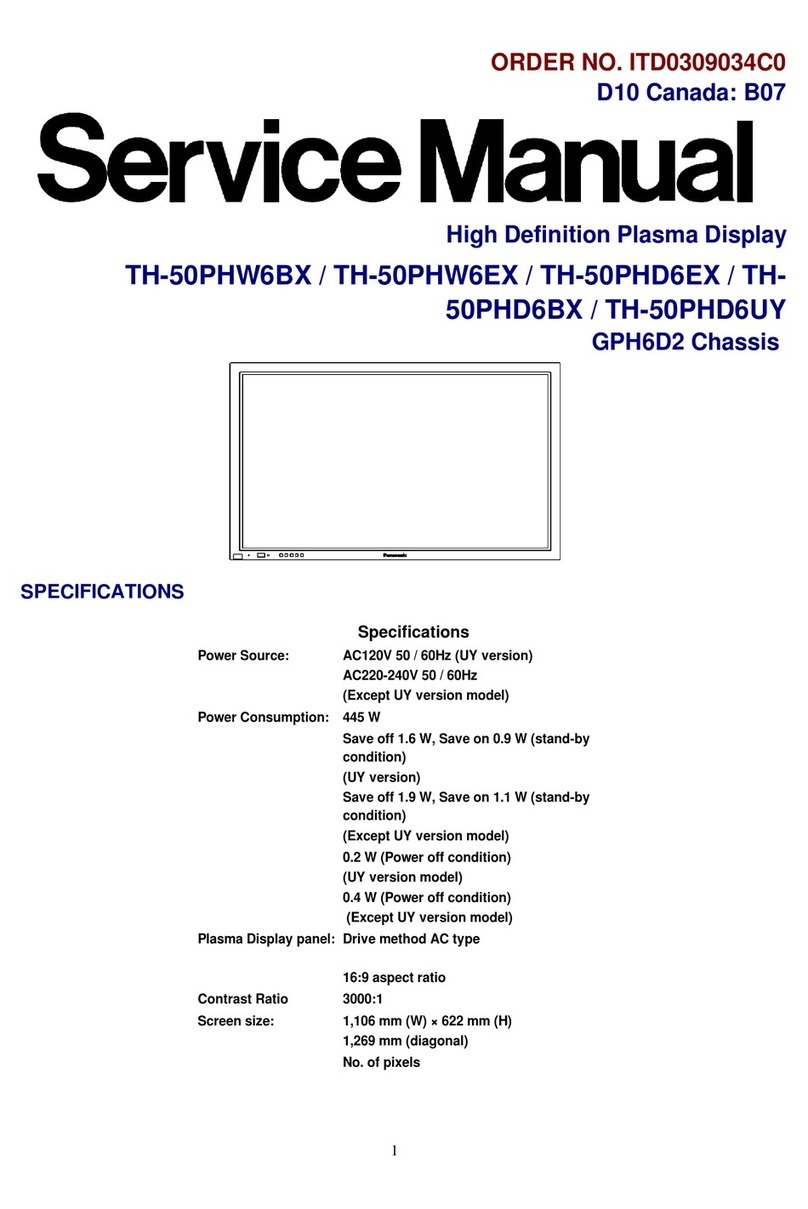

Panasonic TH-50PHW6BX User manual

Panasonic

Panasonic PANAFLAT LC-50 User manual

Panasonic

Panasonic WVBM1790 - B/W VIDEO MONITOR User manual

Panasonic

Panasonic CT-36HL44 User manual

Panasonic

Panasonic WVCK1420A - COLOR MONITOR User manual

Panasonic

Panasonic TH-42PW6BX User manual

Panasonic

Panasonic TH-50PHD3VTH-50PH30V User manual

Panasonic

Panasonic TH-65PB1E User manual