2

TABLE OF CONTENTS

PAGE

1 Safety Precautions -----------------------------------------------3

1.1. General Guidelines ----------------------------------------3

1.2. Touch-Current Check--------------------------------------3

2Warning--------------------------------------------------------------4

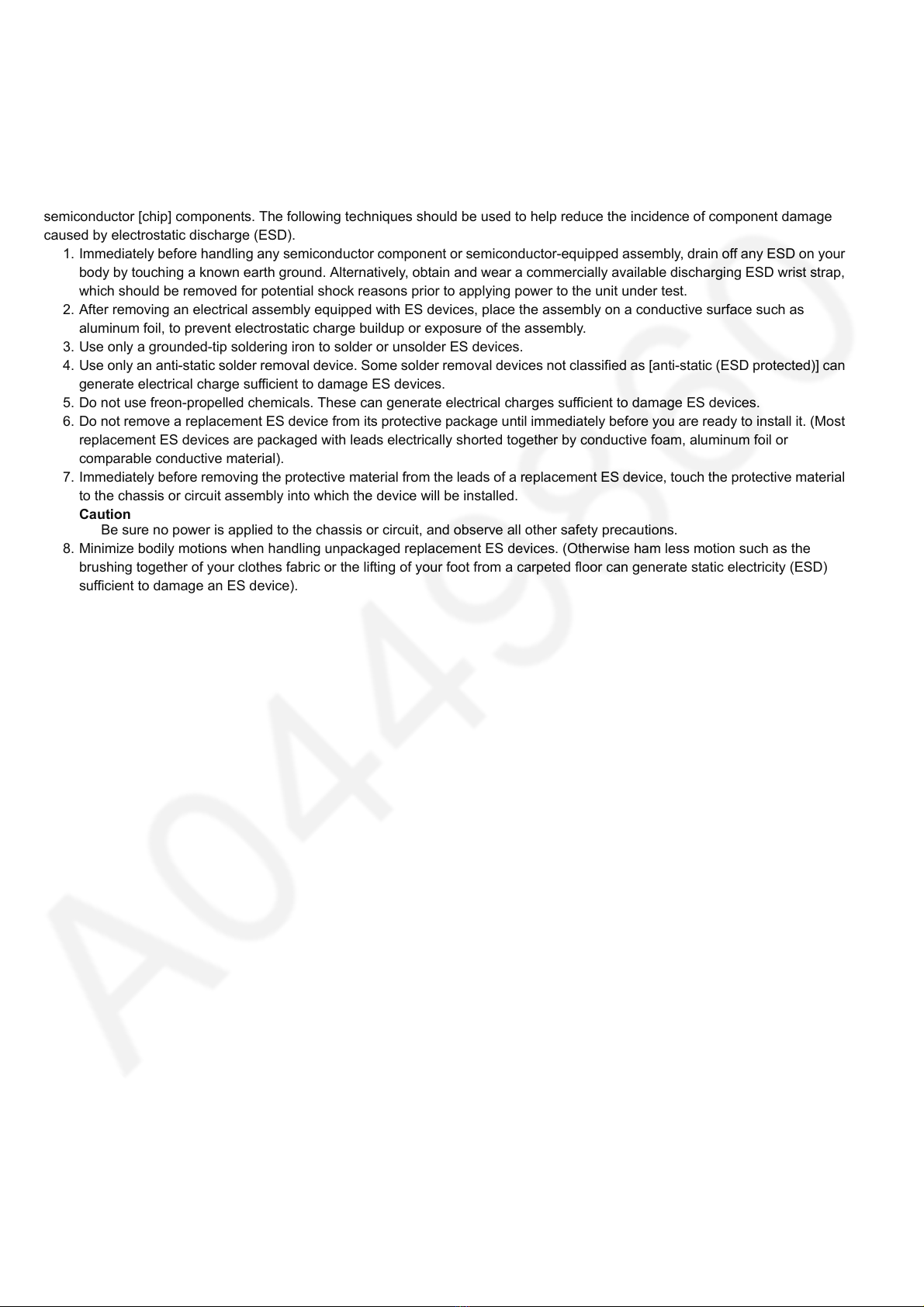

2.1. Prevention of Electrostatic Discharge (ESD)

to Electrostatically Sensitive (ES) Devices ----------4

2.2. About lead free solder (PbF) ----------------------------5

3 Service Navigation------------------------------------------------6

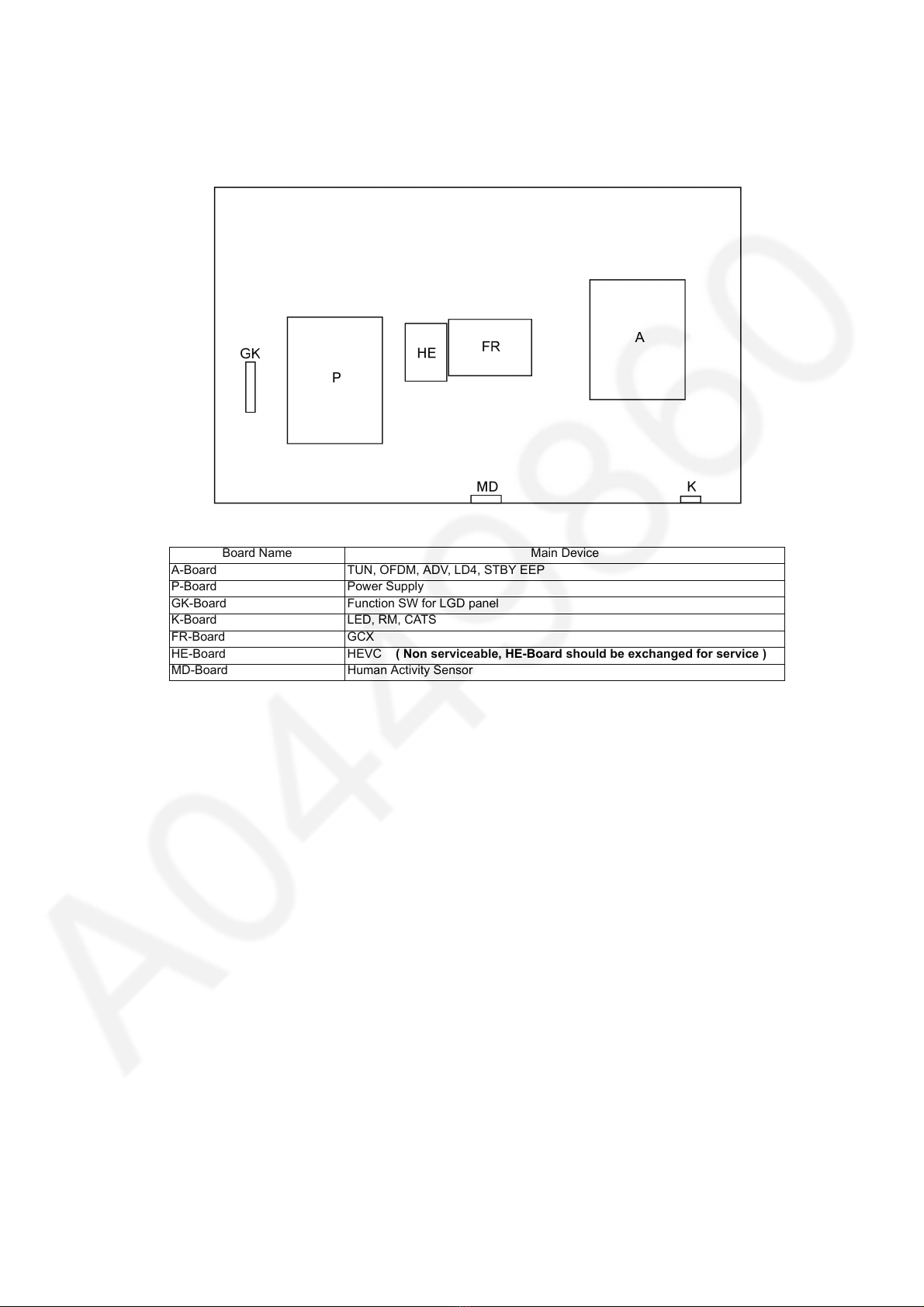

3.1. PCB Layout --------------------------------------------------6

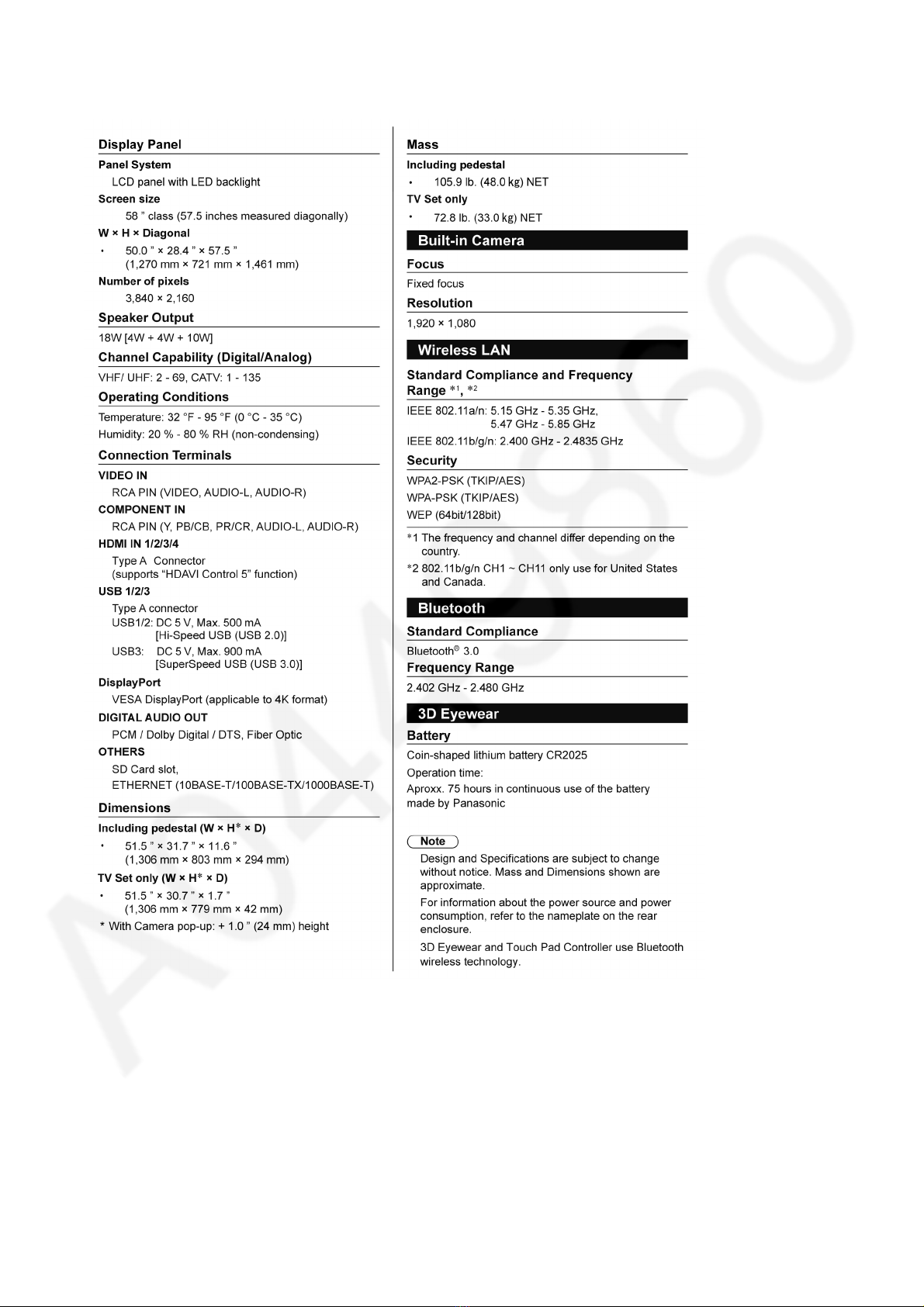

4 Specifications ------------------------------------------------------7

5 Technical Descriptions------------------------------------------8

5.1. Specification of KEY for DTCP-IP, WMDRM

and Widevine------------------------------------------------8

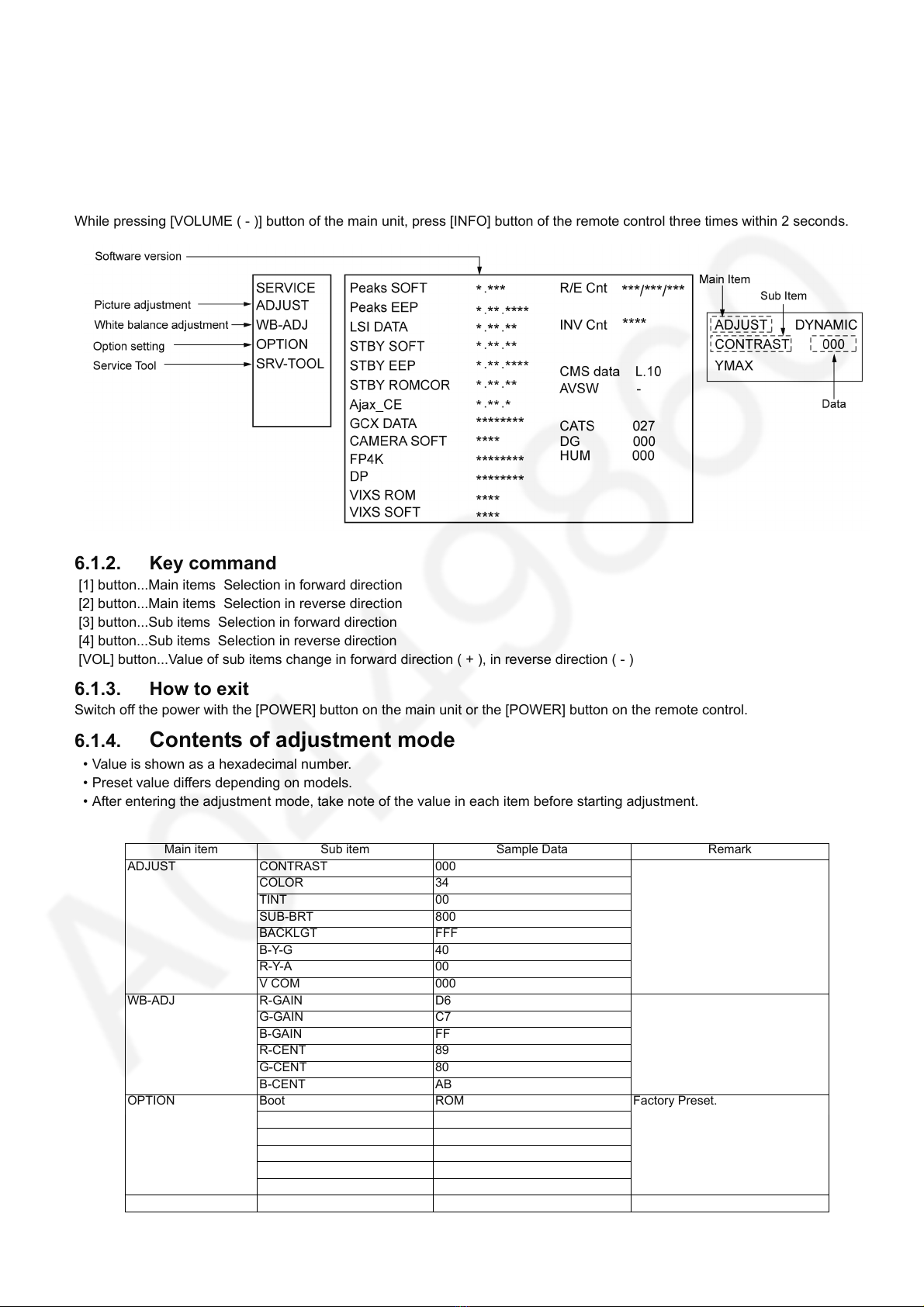

6 Service Mode -------------------------------------------------------9

6.1. How to enter into Service Mode ------------------------9

6.2. SRV-TOOL------------------------------------------------- 10

6.3. Hotel mode------------------------------------------------- 11

6.4. Data Copy by USB Memory --------------------------- 12

7 Troubleshooting Guide---------------------------------------- 15

7.1. Check of the IIC bus lines------------------------------ 15

7.2. Power LED Blinking timing chart --------------------- 16

7.3. LCD Panel test mode / FR test mode--------------- 16

8 Disassembly and Assembly Instructions --------------- 17

8.1. Disassembly Flow Chart for the Unit ---------------- 17

8.2. Disassembly Procedure for the Unit----------------- 17

9 Measurements and Adjustments -------------------------- 36

9.1. Voltage chart of A-Board ------------------------------ 36

9.2. Voltage chart of P-Board ------------------------------- 36

9.3. Voltage chart of HE-Board ----------------------------- 36

9.4. Voltage chart of FR-Board ----------------------------- 36

10 Block Diagram --------------------------------------------------- 37

10.1. Main Block Diagram ------------------------------------- 37

10.2. Block (1/3) Diagram ------------------------------------- 38

10.3. Block (2/3) Diagram ------------------------------------- 39

10.4. Block (3/3) Diagram ------------------------------------- 40

11 Wiring Connection Diagram --------------------------------- 41

11.1. Caution statement.--------------------------------------- 41

11.2. Wiring (1) --------------------------------------------------- 41

11.3. Wiring (2) --------------------------------------------------- 42

11.4. Wiring (3) --------------------------------------------------- 43

11.5. Wiring (4) --------------------------------------------------- 44

11.6. Wiring (5) --------------------------------------------------- 44

12 Schematic Diagram--------------------------------------------- 45

13 Printed Circuit Board ------------------------------------------ 45

14 Exploded View and Replacement Parts List ----------- 45

14.1. Exploded View -------------------------------------------- 45

14.2. Electrical Replacement Parts List-------------------- 45