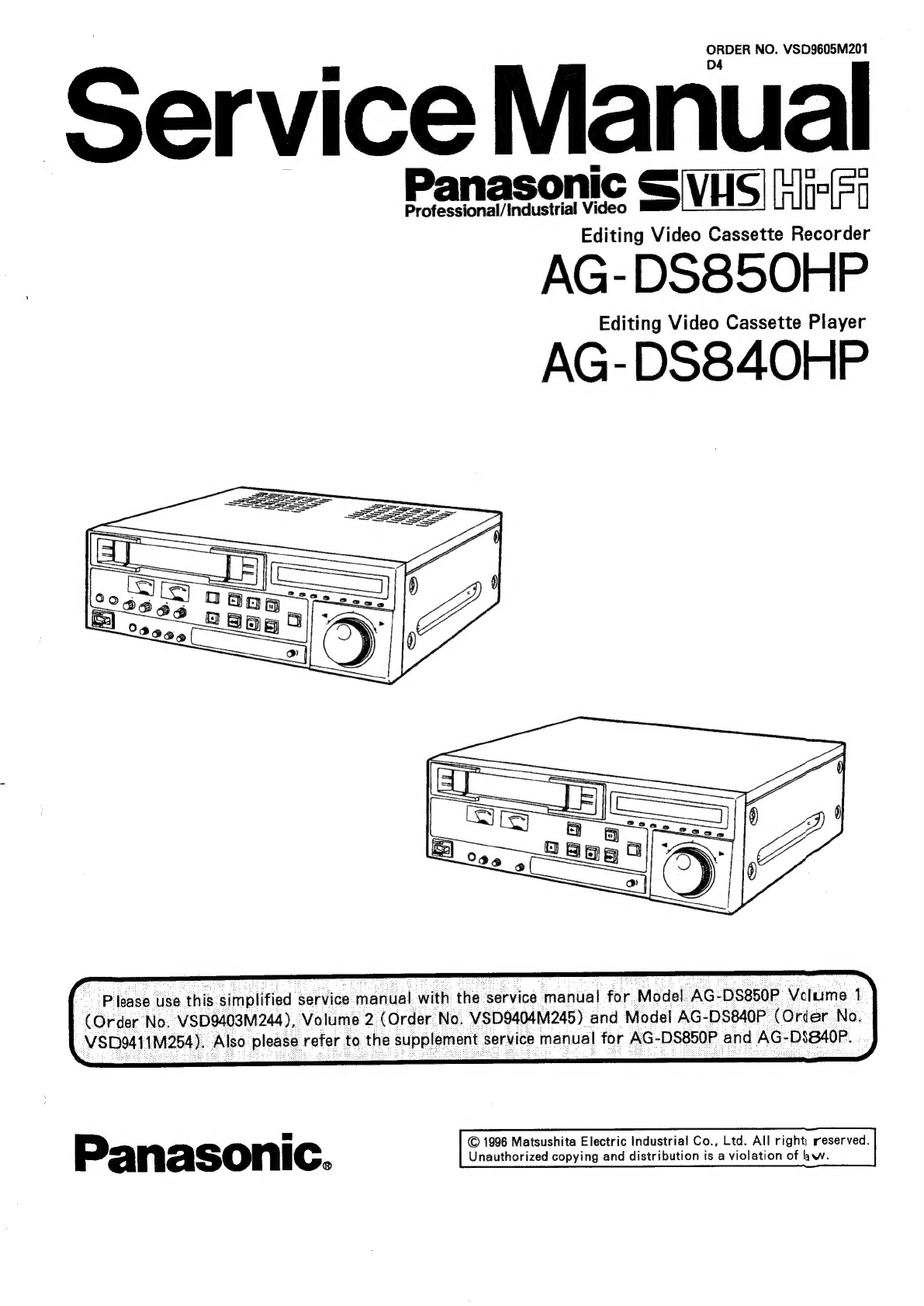

Panasonic AG-DS850HP User manual

Other Panasonic VCR System manuals

Panasonic

Panasonic NV-SJ400A User manual

Panasonic

Panasonic OmniVision PV-M1339 User manual

Panasonic

Panasonic PV-V4624S-K User manual

Panasonic

Panasonic NV-SD1 Series User manual

Panasonic

Panasonic Omnivision PV-7665S User manual

Panasonic

Panasonic NV-FJ617EE User manual

Panasonic

Panasonic NV-HD100 User manual

Panasonic

Panasonic NV-FJ600 Series User manual

Panasonic

Panasonic PV-V4535S-K User manual

Panasonic

Panasonic Omnivision PV-S4680 User manual

Panasonic

Panasonic PV-V4623S-K User manual

Panasonic

Panasonic AG-DTL1E User manual

Panasonic

Panasonic NV-HV62PX User manual

Panasonic

Panasonic NV-SD420 Series User manual

Panasonic

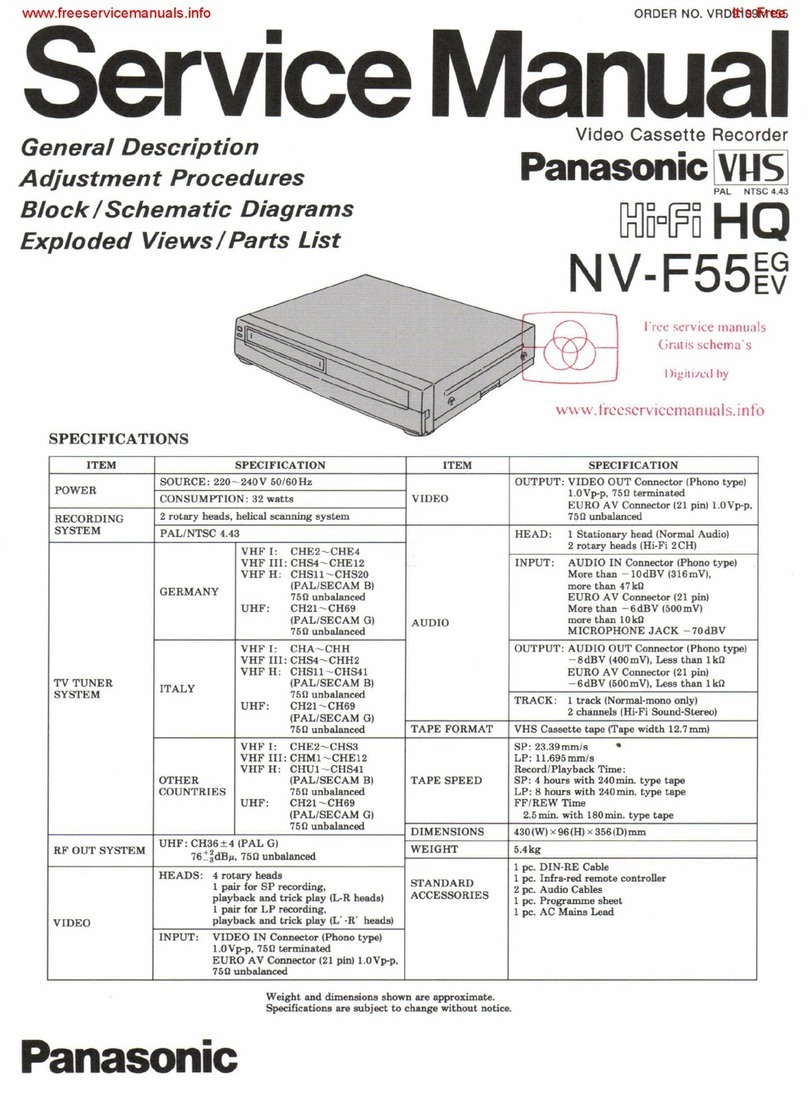

Panasonic NV-F55EG User manual

Panasonic

Panasonic NV-HD600 Series User manual

Panasonic

Panasonic Omnivision PV-8455S User manual

Panasonic

Panasonic AJD220 - DVC PRO DESCKTOP PLA User manual

Panasonic

Panasonic NV-SV121 Series User manual

Panasonic

Panasonic NV-SD450B User manual