Panasonic NV-FJ623EC User manual

Other Panasonic VCR System manuals

Panasonic

Panasonic NV-HS1000 User manual

Panasonic

Panasonic Omnivision PV-V4621 User manual

Panasonic

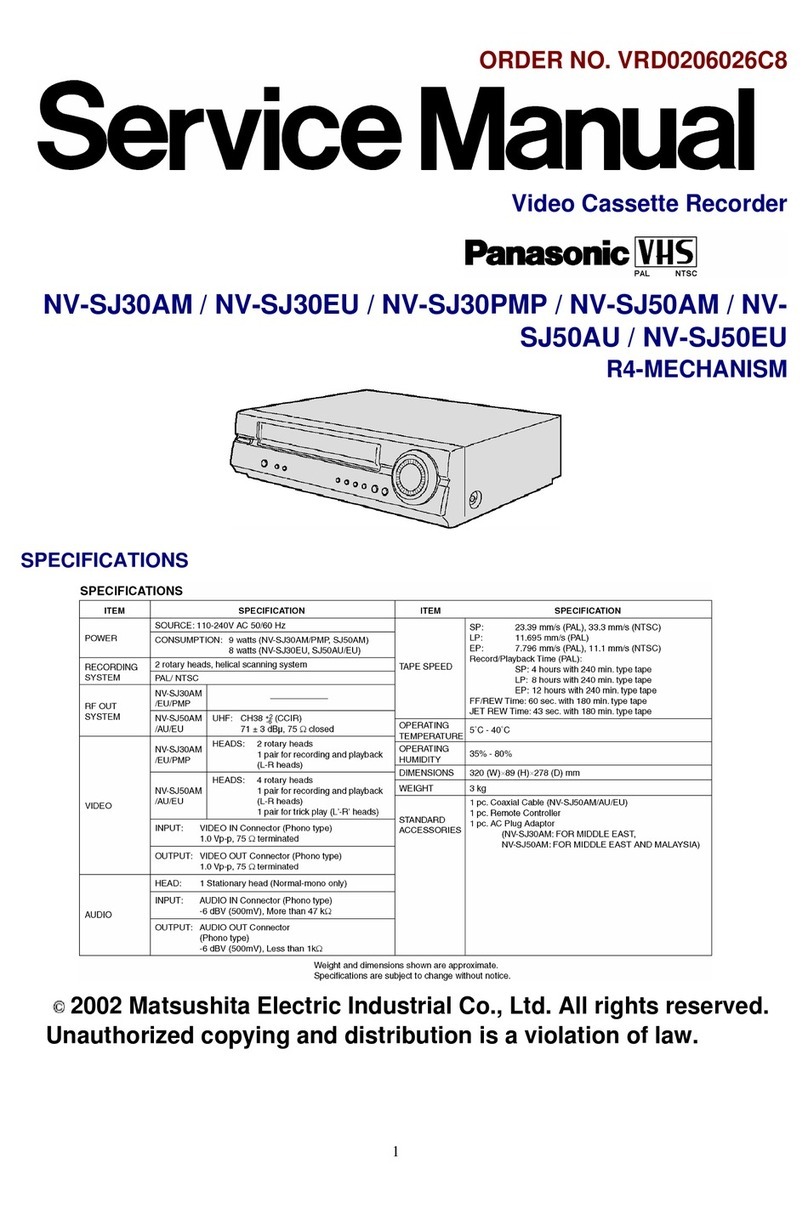

Panasonic NV-SJ30AM User manual

Panasonic

Panasonic AJ-HD3700H User manual

Panasonic

Panasonic Omnivision PV-V4611 User manual

Panasonic

Panasonic AG5210 - VIDEO CASSETTE RECORDER User manual

Panasonic

Panasonic Omnivision VHS PV-C2061 User manual

Panasonic

Panasonic OmniVision PV-QV200 User manual

Panasonic

Panasonic NV-SD10 Series User manual

Panasonic

Panasonic Omnivision PV-8405S User manual

Panasonic

Panasonic Omnivision PV-V4611 User manual

Panasonic

Panasonic Omnivision PV-V4611 User manual

Panasonic

Panasonic NV-DV10000B User manual

Panasonic

Panasonic AG-DV1000P User manual

Panasonic

Panasonic AJ-YA120AG User manual

Panasonic

Panasonic OmniVision PV-C2060 User manual

Panasonic

Panasonic AJ-D455P User manual

Panasonic

Panasonic PV-V4612 User manual

Panasonic

Panasonic Omnivision PV-V4020 User manual

Panasonic

Panasonic NV-SV120EF User manual