INSTRUCTIONS CM441

For Instructions in Local Languages

and Technical Support:

www.panduit.com/resources/install_maintain.asp

E-mail:

Fax:

(708)444-6448

www.panduit.com

Page 4 of 4

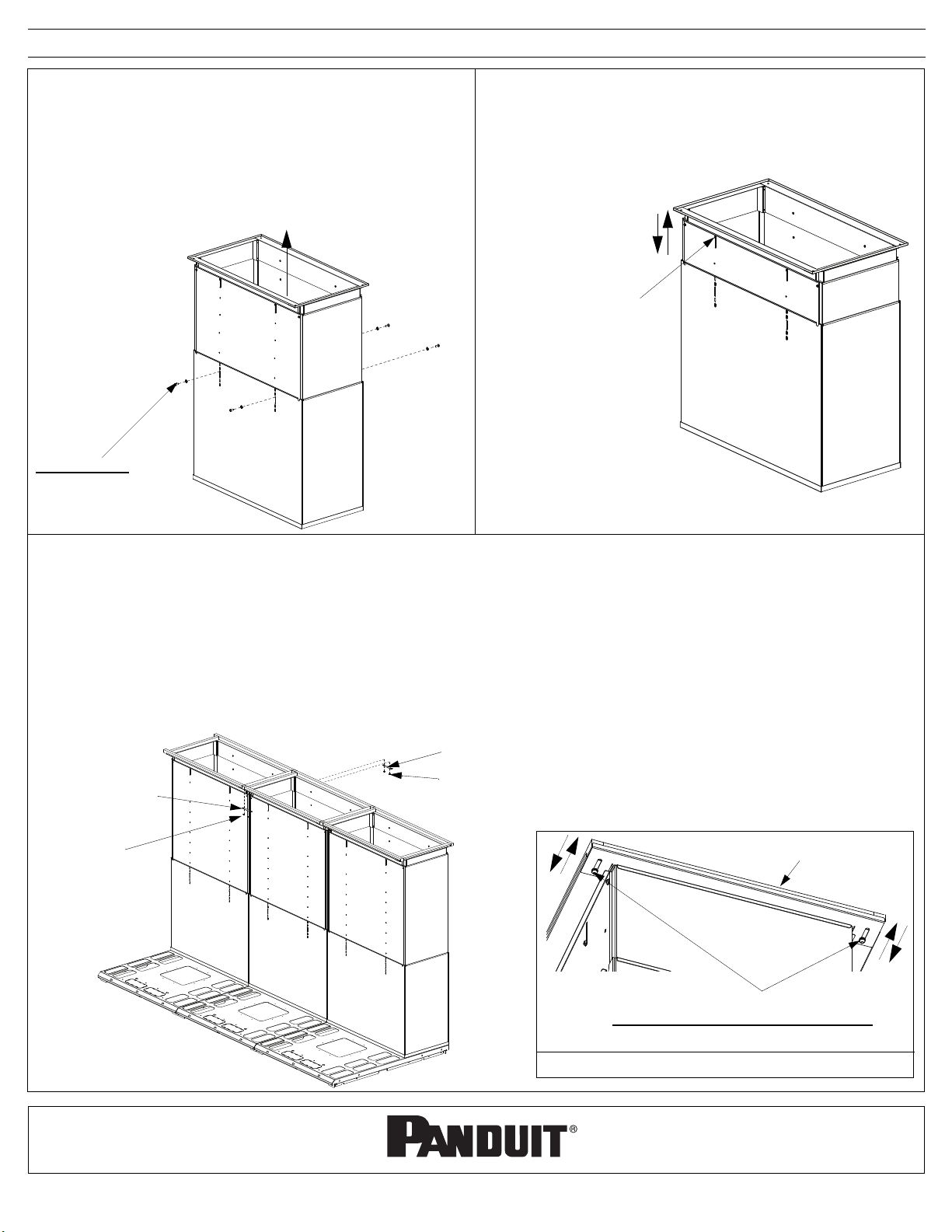

Extend Telescoping Duct Assembly

Extend upper tier of duct assembly to desired height and install (4)

#10-32 Phillips screws and lockwashers to support upper tier.

Tighten all #10-32 Phillips screws to 26 in-lbs. 3.5” spacing of

threaded holes in upper tier of exhaust duct allows for variable

height adjustment of exhaust duct. Various slots in lower tier allow

for additional fine adjustment of upper tier height.

Extend Top Collar

Loosen #10-32 Phillips screws to make fine adjustments of top

collar and tighten screws to secure top collar in postion.

Install Screws

(Upper Tier)

(4) #10-32 Phillips Screws

and Lockwashers

Tighten ALL #10-32 Phillips Screws to 26 in-lbs

Tighten ALL #10-32 Phillips Screws to 26 in-lbs

(4) #10-32 Phillips Screws

and Lockwashers

Ganging of CVED40VE**

NOTE: Some adjustment to the leveling of the base of cabinet may be required for exhaust duct to align with exhaust ducts of adjacent

cabinets. (See CM443* for leveling instructions)

Remove #10-32 hex nuts securing End Seal Bracket to underside of top collar. Install ganging bracket to top collar and re-install #10-32

hex nuts as shown below.

End seal brackets are adjustable to accomodate conditions between cabinets or at the end of a row. Adjust the end seal bracket as

needed by loosening (2) #10-32 nuts using a 7/16” socket wrench or end wrench. Reposition the end seal bracket and retighten (2) #10-

32 nuts. Trim excess material from adhesive foam seals installed on top collar if necessary. (See Sealing Foam section on page 2.)

End Seal Bracket

Loosen and retighten #10-32 nuts to adjust end seal

bracket - Remove nuts to install ganging bracket

(use 7/16” socket wrench or end wrench)

VIEW SHOWS UNDERSIDE OF END SEAL BRACKET

Ganging Bracket

Ganging Bracket

Re-install [2]

#10-32 hex nuts

(use 7/16” socket

wrench or end wrench)

Re-install [2] #10-32 hex nuts

(use 7/16” socket wrench or end wrench)