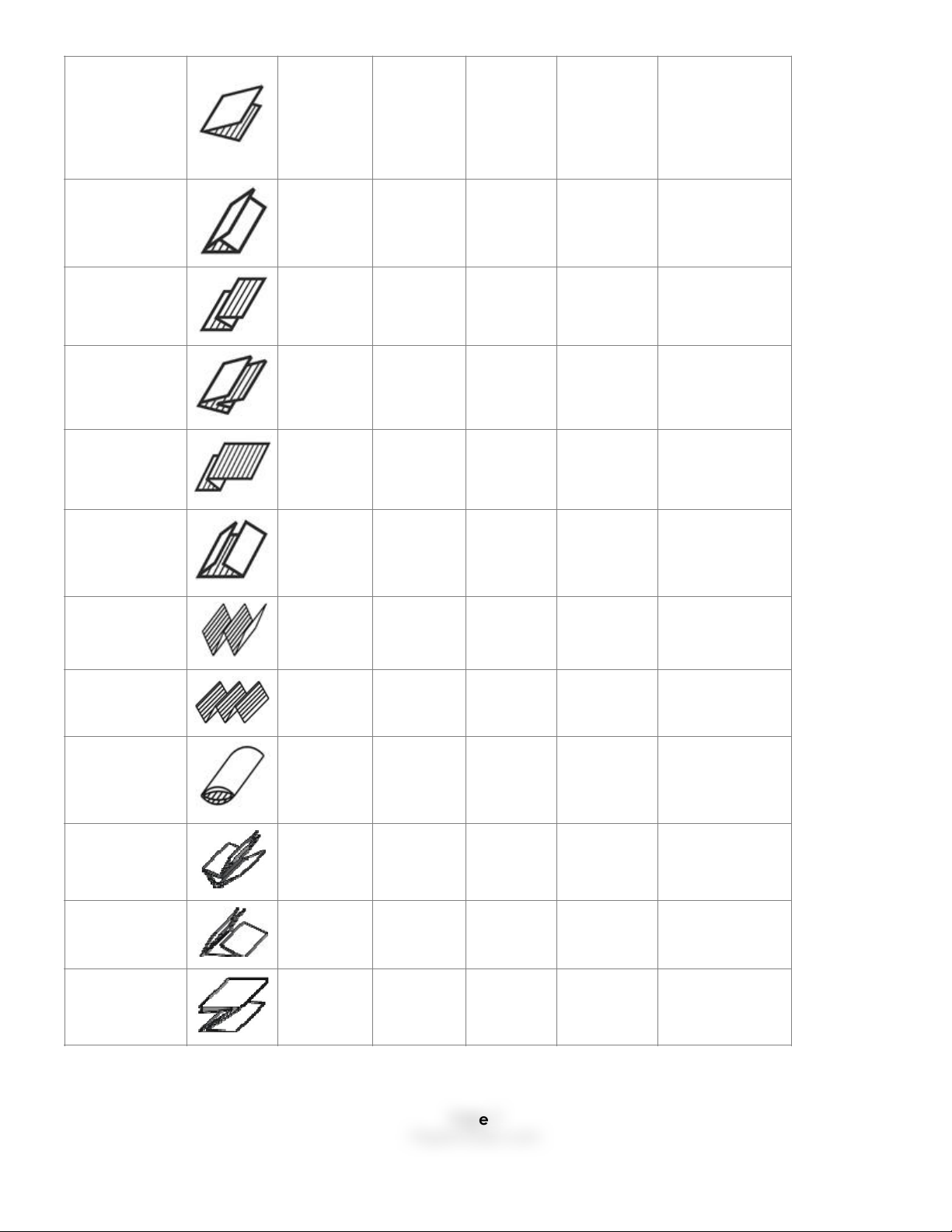

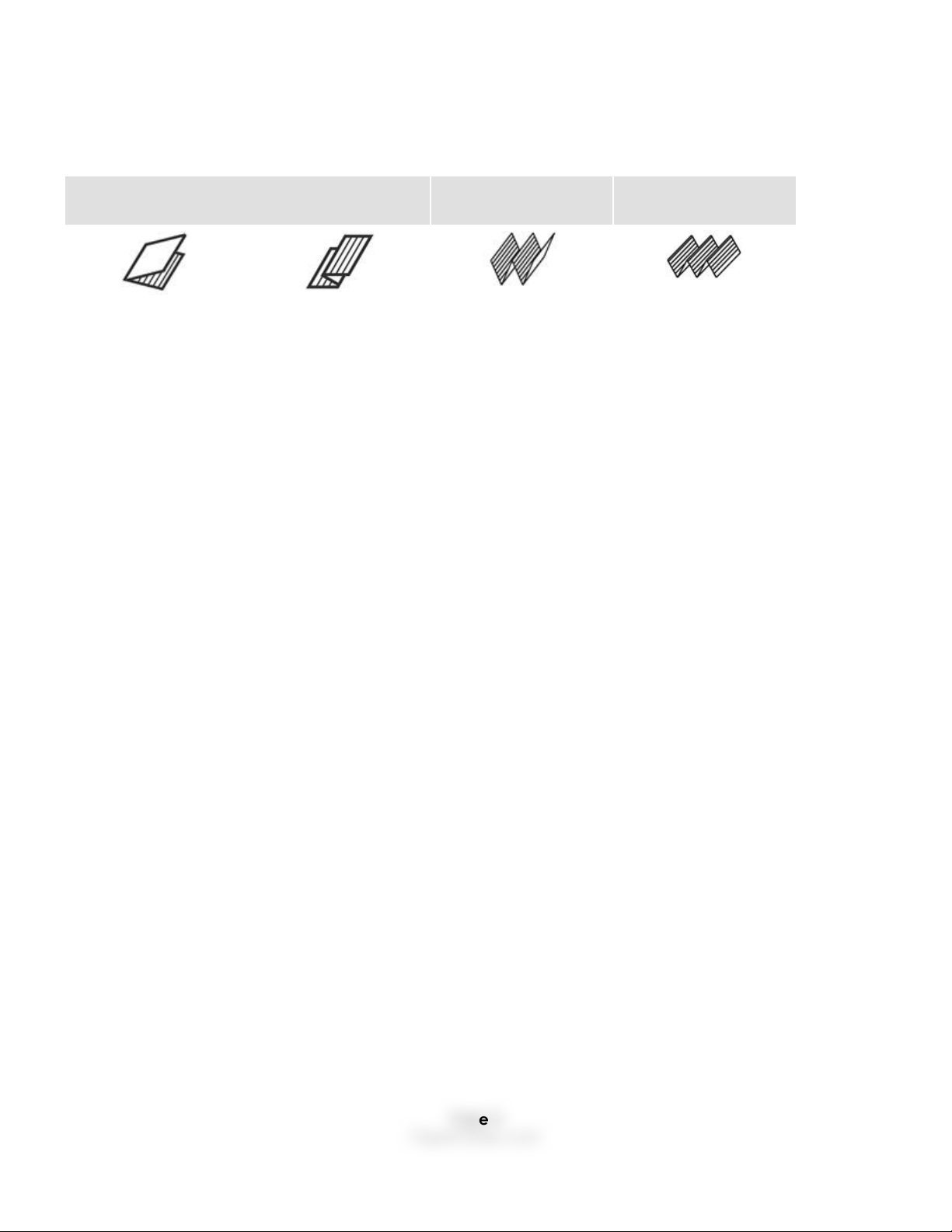

IF YOU ARE PERFORMING CROSS FOLDS

The only folds we recommend for cross folding are Fan-Folds, so called because they look like a fan

from the side. Here the folds you can perform on the PH-17 for cross folds:

IF A FOLD PLATE IS NOT NEEDED, IT MUST BE CLOSED. To do this, you remove the fold plates that are

not needed for that fold and replace them with the Close Plates that come with the machine.

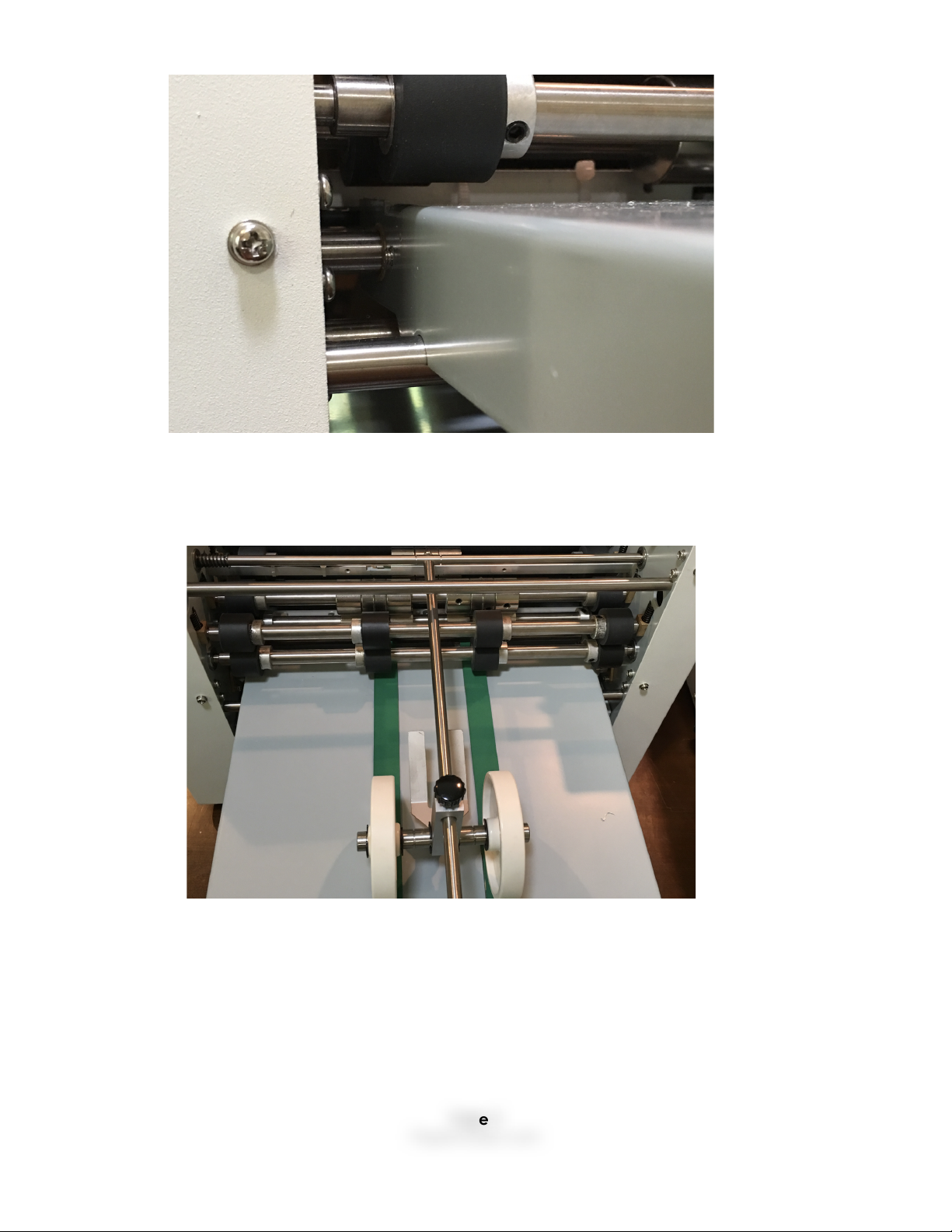

HOW TO SET EACH FOLD

To set the size for the fold you want to perform, consult the chart. It will require that you measure the

paper you are folding and calculate where the stop(s) should be placed. Each fold plate has 2

knobs (this closeup just shows one). You loosen them and put them at the proper position for the

fold. Start with an approximate position for your fold. This one is set at 2.75" to perform a 4-panel fan-

fold on letter paper. Run a sample. Then adjust the fold as needed. It may take a few times to get

the fold precisely as you want. ONCE YOU GET IT THERE, PUT A MARK ON THE FOLD PLATE AND NAME

THE FOLD ON EACH SIDE. t will make it easier next time. IF YOU ARE PERFORMING A CROSS FOLD, YOU

CAN ONLY USE A HALF FOLD, Z FOLD, 4 PANEL FOLD OR 5 PANEL FOLD. SEE THE CHART.

SKEW

IF THE FOLD STOPS ARE NOT PRECISELY EVEN, THEY WILL SKEW. If the sides of the paper are not even

(SKEW), you must raise or lower one side or the other. If it is just one panel, adjust the fold plate for

that fold. In a fan-fold, the top fold on the paper is done by the first fold plate, the second fold on

the second plate and so on.

If the bottom of the fold sticks out to the bottom left, move the left side a bit higher. If the right side

sticks out to the bottom left, move the right side a bit higher. Then run a sample and compare it.

OUTPUT WHEELS

Adjust the output wheels for the type of fold. In for shorter; out for longer. Start longer and shorten if

needed. You do not want the paper to back up into the machine.