I

I Introduction

• This service manual is for the following product.

Paper Folder PF-P3100

• Prior consent

This service manual is intended for use when repairing and maintaining this

machine to keep it in top working condition. In order for you to safely perform

repair and maintenance work on this machine, please make sure that you fully

read and understand all of the notes related to safety that are written through-

out this service manual.

- Horizon International, INC. cannot accept responsibility for any loss, damage, or

injury as a result of unauthorized modification, misuse, or use outside the

machine’s specifications, or any unsuitable or inadequate maintenance performed

by you or by authorized service personnel.

- Horizon International, INC. is continuously working to improve the design and

performance of all of its products. Consequently, the contents of this service

manual may be changed at any time in the future without prior notice.

Furthermore, Horizon International, INC. bears no additional liability for any added

contents.

- All rights with regards to copyrights are reserved. The copying or distribution of

any part or whole of this manual is strictly prohibited unless prior written

permission is obtained directly from Horizon International, INC.

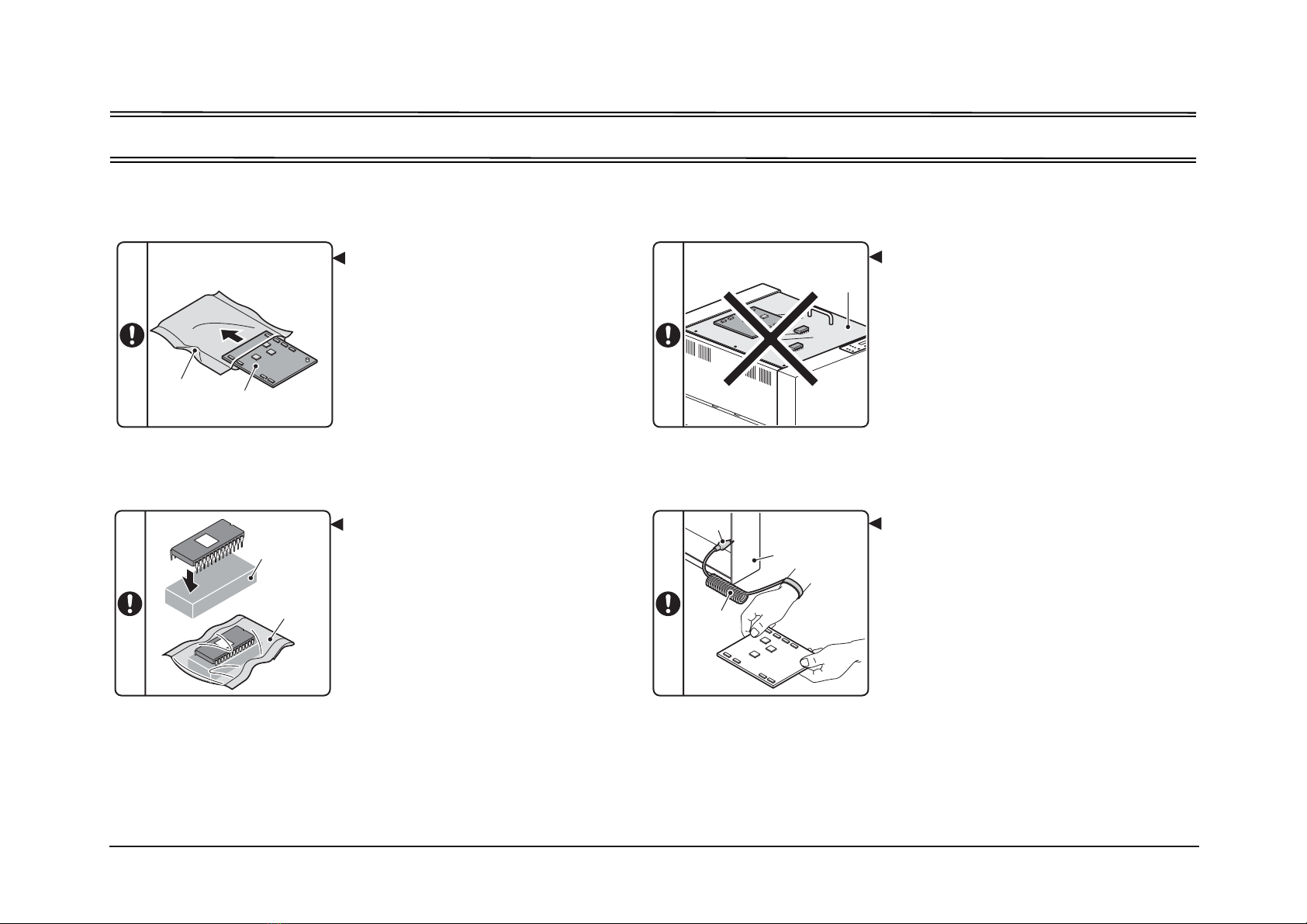

• Caution when undertaking service operations

- When replacing parts or performing other such maintenance operations, switch

the power supply Off before starting unless it is necessary to keep the power on.

Also, remove the power cable from the socket before starting for additional safety.

- When removing covers, be extremely cautious of rotating objects such as belts

and pulleys, and of electrical wiring etc.

- Always perform operations alone. This manual is written on the assumption that

operations will be performed by one person.

- Make sure that other people do not touch the machine during operation.

- When turning the power back on, wait for approximately 10 seconds after turning

the power Off before switching it On again.

- When replacing parts, use the parts shown in the parts book unless commercially

available parts with exactly the same functions and performance can be obtained.

• Safety precautions

- In order to perform repair or maintenance work safely on this machine, thoroughly

read all of the warnings and cautions related to safety that are written in this

service manual BEFORE commencing any operation. Failing to heed the safety

precautions in this manual may lead to accidents resulting in injury or death.

- The maintenance procedures and safety precautions described in this service

manual are only effective if the repair/maintenance procedures specified for this

machine are followed.

- Precautions that if not followed correctly may lead to accidents resulting in injury

or death are indicated by this heading.

- Precautions that if not followed correctly may lead to accidents resulting in

machine damage or malfunctions are indicated by this heading.

- It is impossible for Horizon International, INC. to prevent all possible dangers

related to this product and its use. Therefore, the precautions shown in this service

manual and warning labels displayed on the product do not completely warn

against all possible dangers.

- Some of the diagrams in this service manual are drawn with covers removed to

describe the details or internal sections of the machine.

WARNING

CAUTION

Edited and Published by Horizon International, INC.

070608/PFP3100/00E/TM/HI,MT US503013-00