1PRODUCT VIEW ILLUSTRATION:...................................................................................... 4

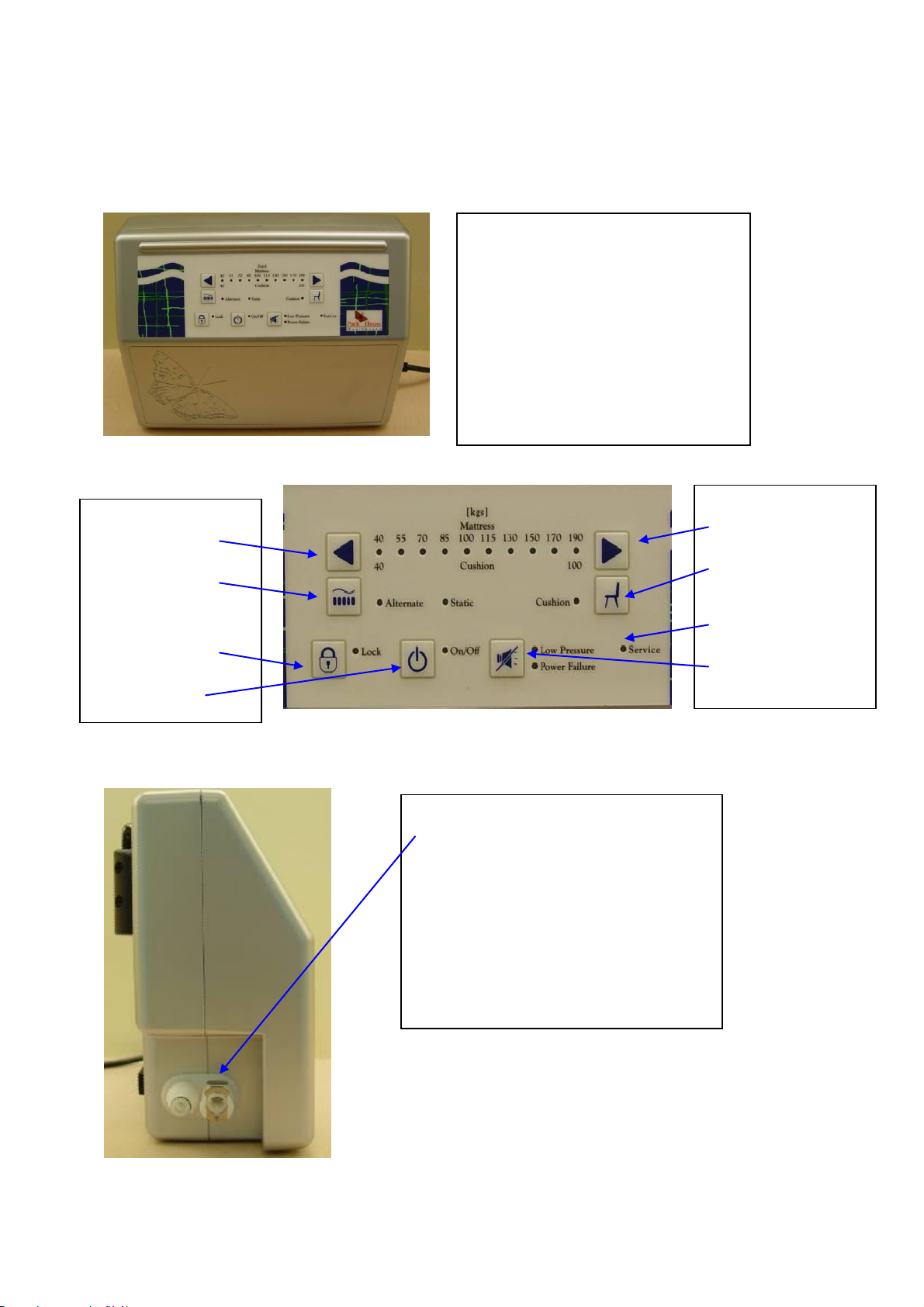

1.1 FRONT VIEW ..................................................................................................................4

1.2 PANEL VIEW ...................................................................................................................4

1.3 SIDE VIEW 1 ..................................................................................................................4

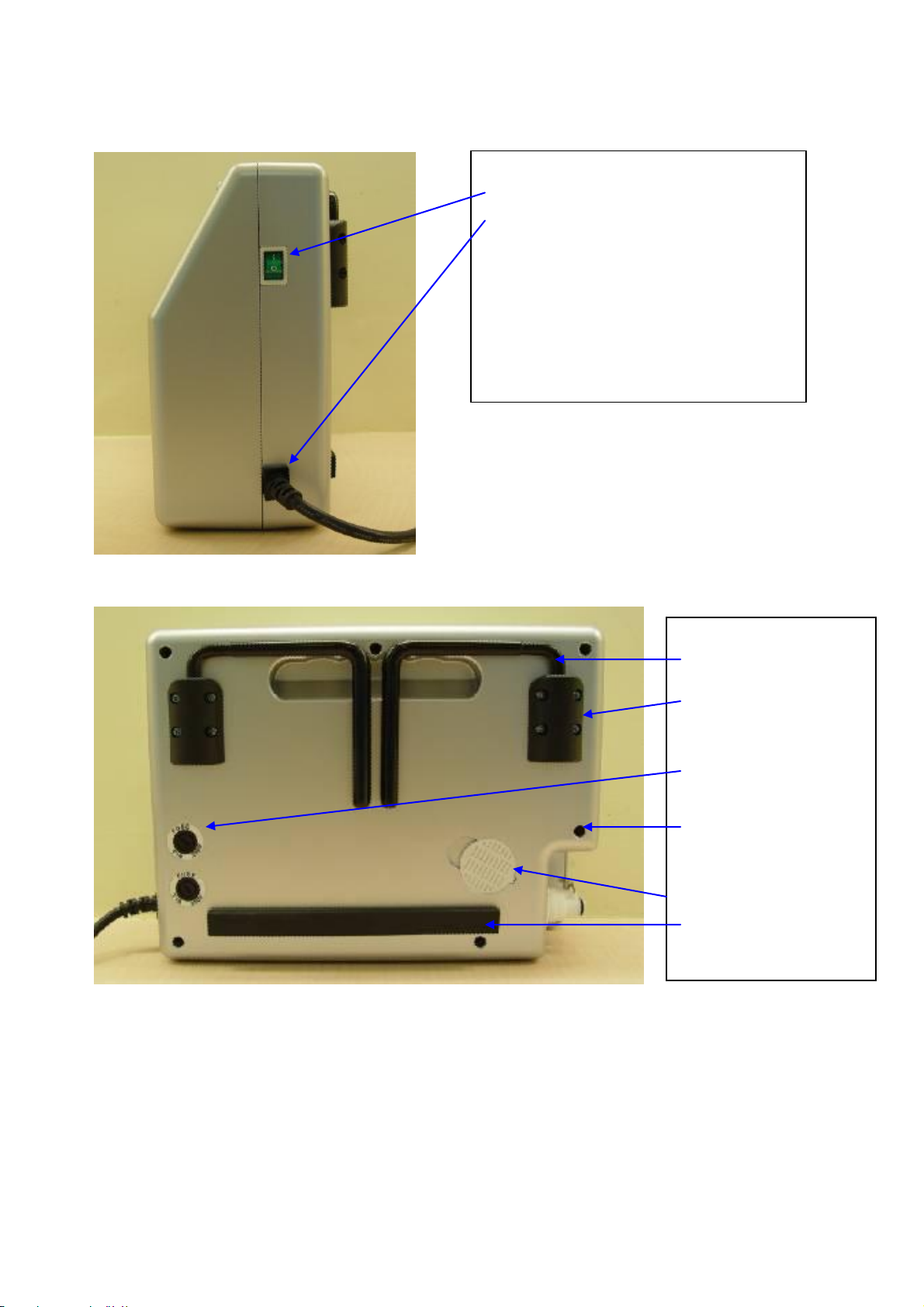

1.4 SIDE VIEW 2 ..................................................................................................................5

1.5 REAR VIEW ....................................................................................................................5

2SERVICE INSTRUCTION: .................................................................................................. 6

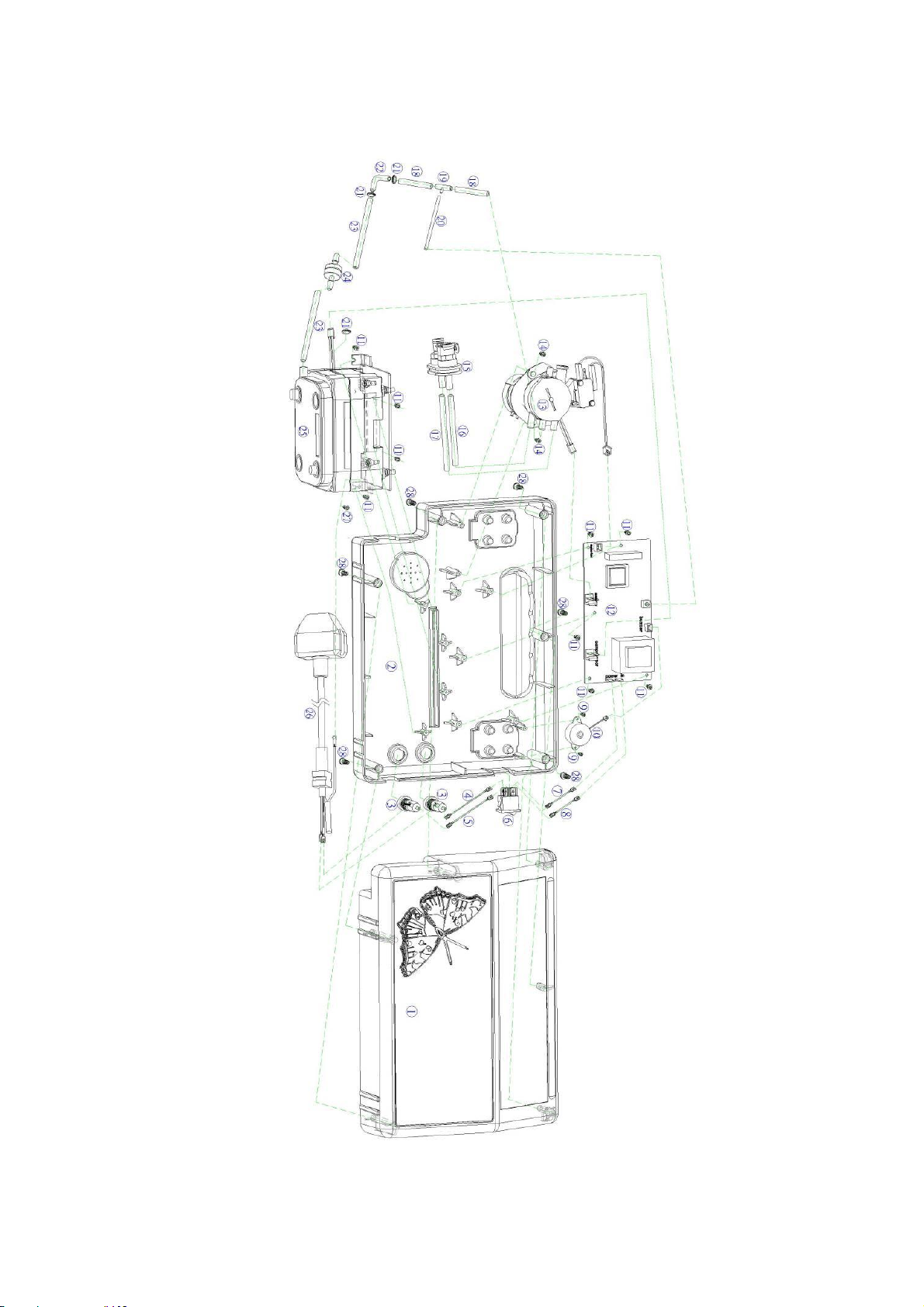

2.1 ALL PART ILLUSTRATION .................................................................................................... 7

2.1.1 PHP1000 Pump ..................................................................................................... 7

2.1.2 PUMP Exploded View Diagram………………………………………………………………………………………………9

2.1.3 PUMP ASSEMBLY BOM……………………………………………………………………………………………………………10

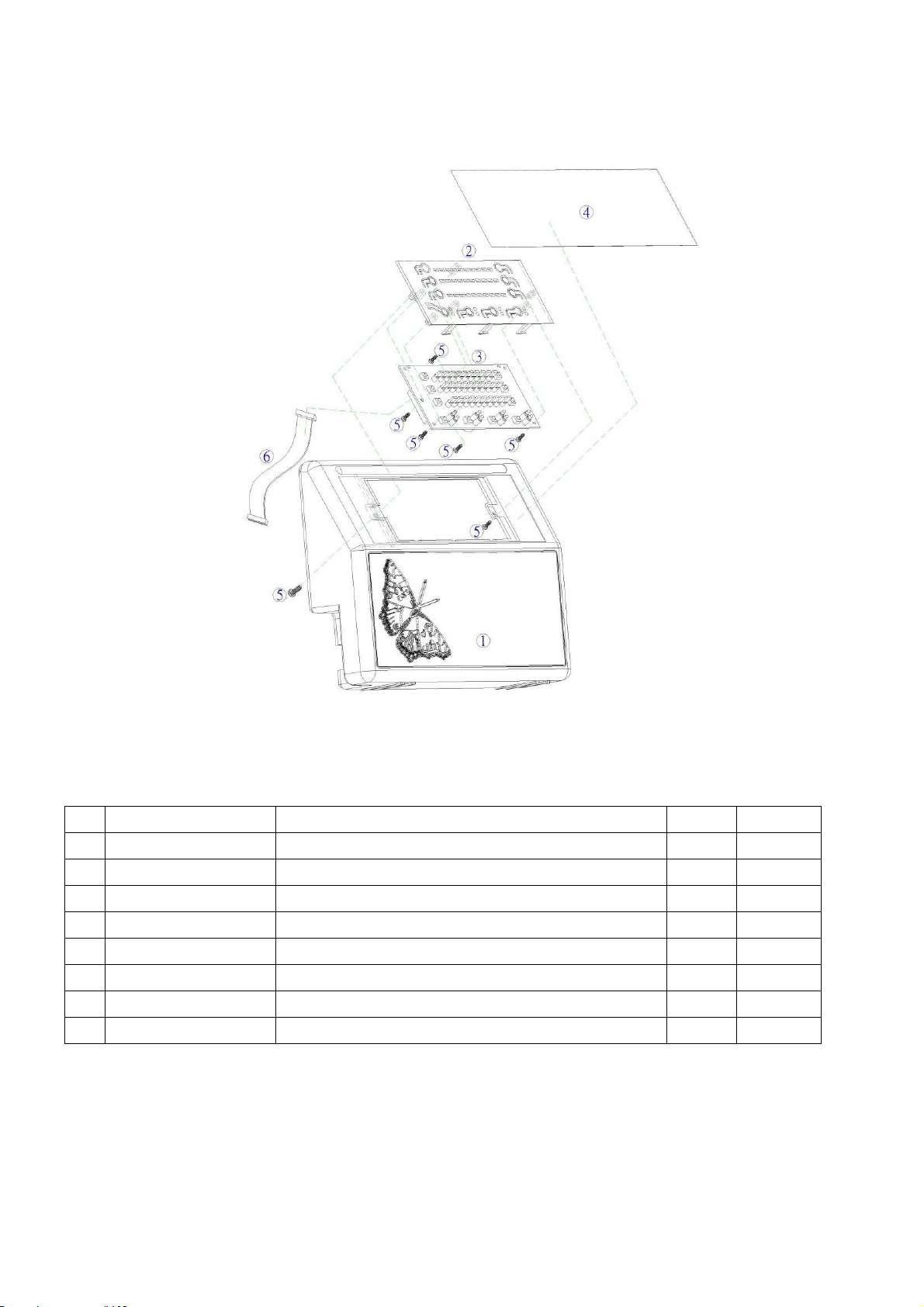

2.1.4 TOP CASE EXPLODED VIEW DIAGRAM…………………………………………………………………………………11

2.1.5 TOP CASE ASSEMBLY BOM……………………………………………………………………………………………………11

2.1.6 BASE CASE EXPLODED VIEW DIAGRAM………………………………………………………………………………12

2.1.7 BASE CASE ASSEMBLY BOM…………………………………………………………………………………………………12

3 SERVICE CHECKLIST:…………………………………………………………………………………………13

3.1 SERVICE REPAIR SOP …………………………………………………………………………………………………………………14

3.1.1 T1 CHECK PRESSURE RANGE.................................................................................. 14

3.1.2 T2 PRESSURE CALIBRATION…………………………………………………………………………………………………16

3.1.3 T3 NO POWER………………………………………………………………………………………………………………………..21

3.1.4 T4 LEAD WIRES DISCONNECTED…………………………………………………………………………………………22

3.1.5 T5 PUMP IS NOT FUNCTIONING……………………………………………………………………………………………23

3.1.6 T6 PANEL PCB LED LIGHT MALFUNCTION……………………………………………………………………………24

3.1.7 T7 BUZZER MALFUNCTION……………………………………………………………………………………………………25

4RECOMMENDED TOOLS: ................................................................................................. 26

5 Replacing the Cell System: .....................................................................27