Determination of Valve Torque

By properly sizing an actuator to a valve for a specific

application, performance is guaranteed and economies are

gained. Before an actuator can be sized for an application,

the amount of torque required must be determined. The

operating torque of a ball valve is influenced by the design,

seat material, and application (service) conditions.

Stem torque is primarily dependent upon the tightness of the

stem nut. The design of the SB Series Ball Valve is such

that the stem torque is constant. Ball/seat torque is created

by the friction between the ball and seat and is also very

sensitive to service conditions. The “floating ball”design

concept allows the system pressure to force the ball into the

downstream seat. The higher the system pressure, the

harder the ball is forced into the downstream seat, and,

therefore, the higher the torque. Also, since different seat

materials have different coefficients of friction, the ball/seat

torque also becomes a function of the seat material being

used.

Valve torque is also a function of the media flowing through

the valve. Abrasive medias have a tendency to increase the

amount of friction between the ball and seats, whereas some

light oils, which provide additional lubricity, may reduce the

amount of torque required.

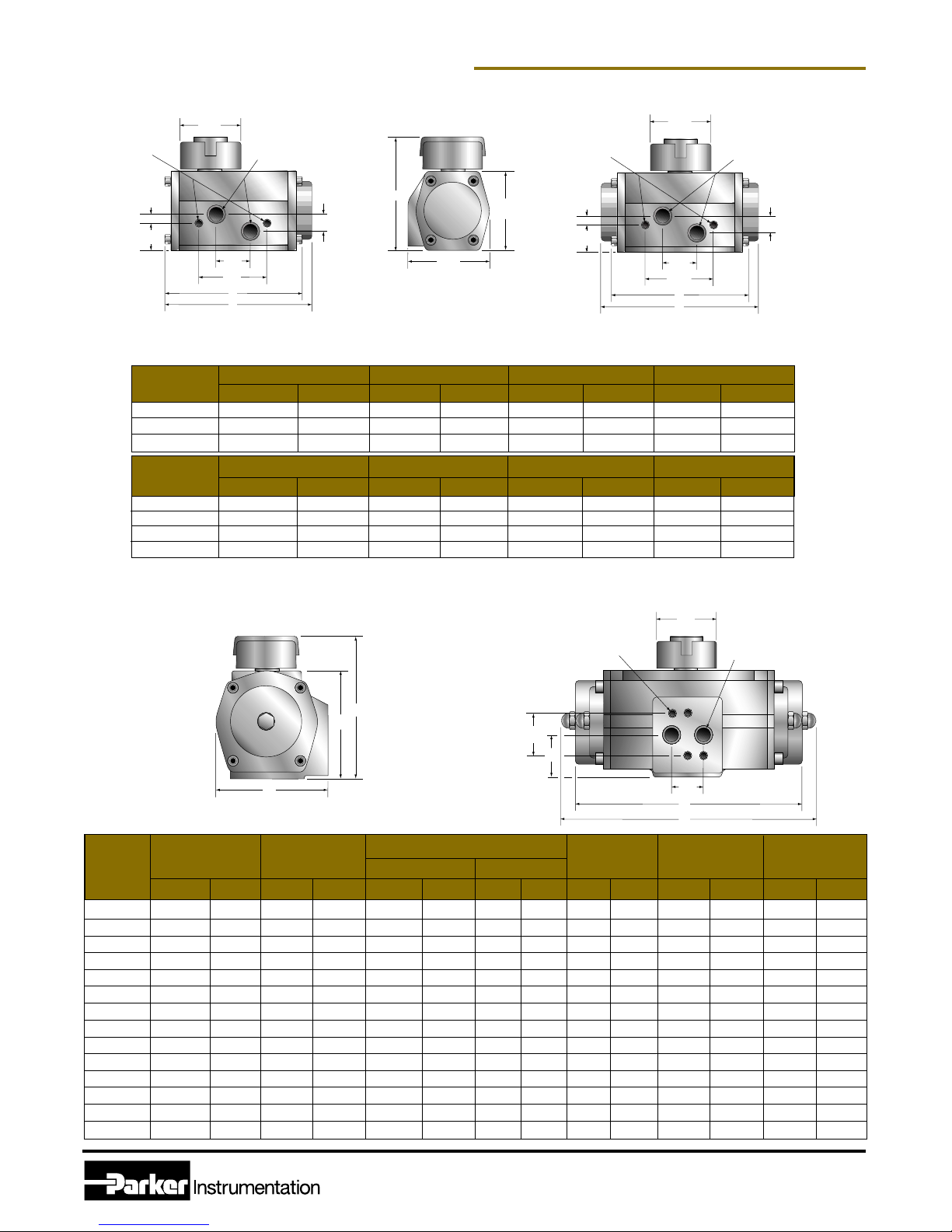

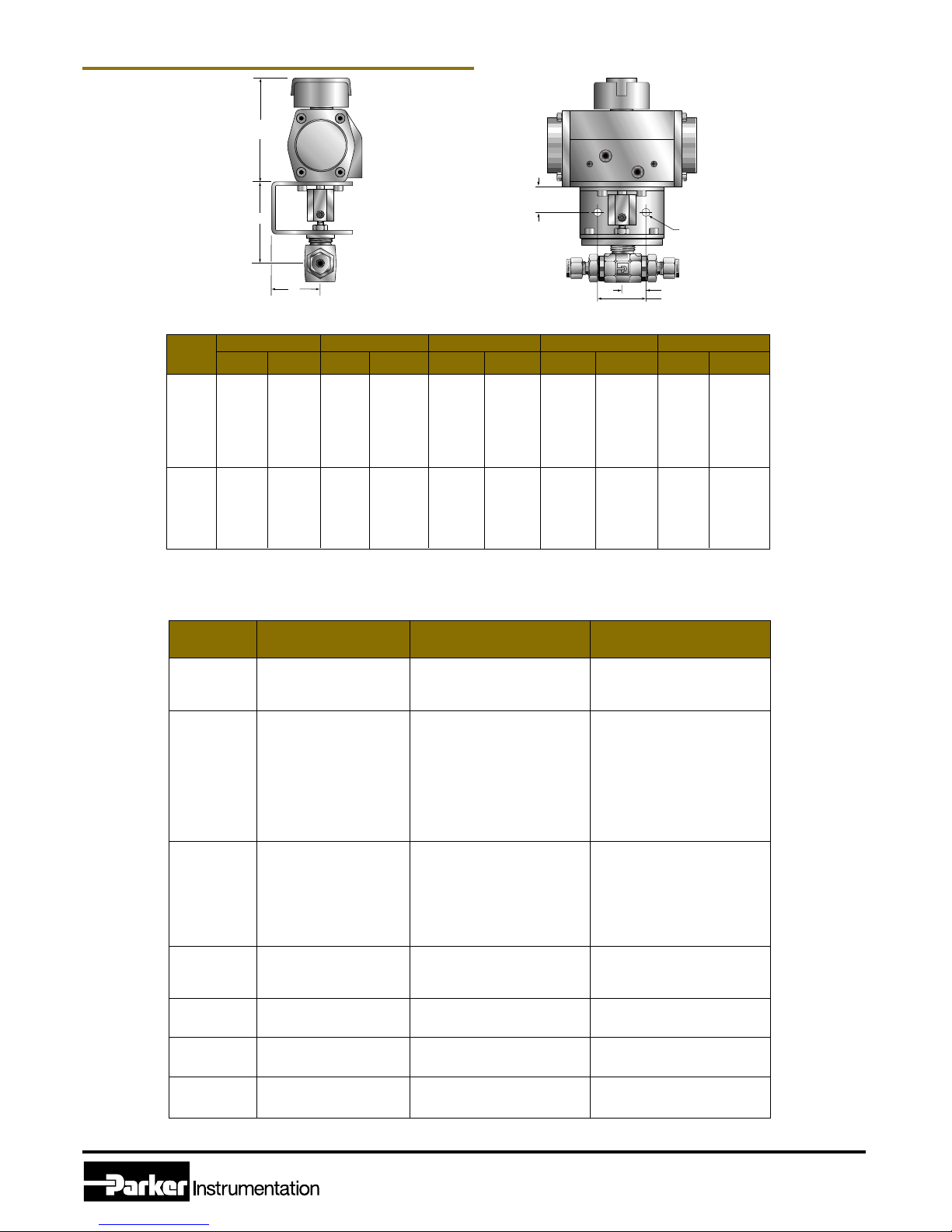

The pressure torque curves on page 7 are the result of

laboratory testing using water at ambient temperature as the

medium. Torque values derived from these curves, when

the appropriate service condition correction factors are

applied, will be adequate for the vast majority of applications.

Based upon the valve size, seat material, and differential

pressure across the valve (in the closed position), the

amount of torque required may be determined using the

following procedure:

1. Find the valve torque from the appropriate curve by

using the differential pressure. Locate the differential

pressure on the horizontal axis of the chart and move up

until you arrive at the appropriate valve size. Transfer

the intersecting point across to the vertical axis of the

graph and read the required torque.

2. Multiply this torque by the service and media application

factor multipliers. The maximum combined multiplier

should never be greater than 2.

When the torque requirements have been determined,

the actuator may be properly sized.

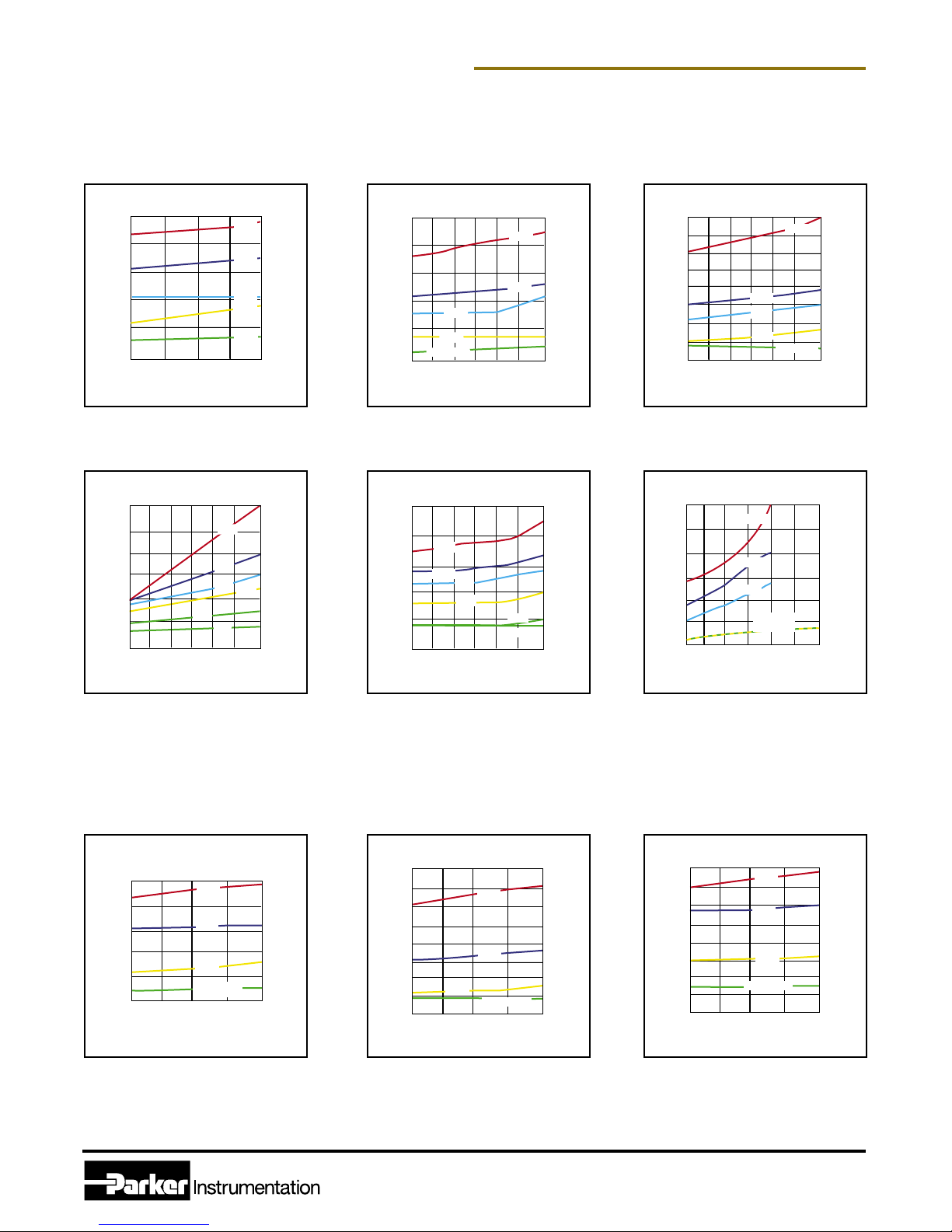

1. Double Acting Operation (AD)

Select the actuator whose torque output, at the

minimum air supply pressure, exceeds the calcu-

lated torque. Actuator torque output charts are

shown on pages 8 and 9.

2. Spring Return Operation, Fail Closed (AC)

Select the actuator whose spring torque output

exceeds the calculated torque. Actuator torque

output charts are shown on pages 8 and 9. In

addition, check the selected actuator to insure the

air torque output at the minimum air supply pressure

also exceeds the calculated torque.

3. Spring Return Operation, Fail Open (AO)

Select the actuator whose spring torque output

exceeds the calculated torque. Actuator torque

output charts are shown on pages 8 and 9. In

addition, check the selected actuator to insure the

air torque output at the minimum air supply pressure

also exceeds the calculated torque.

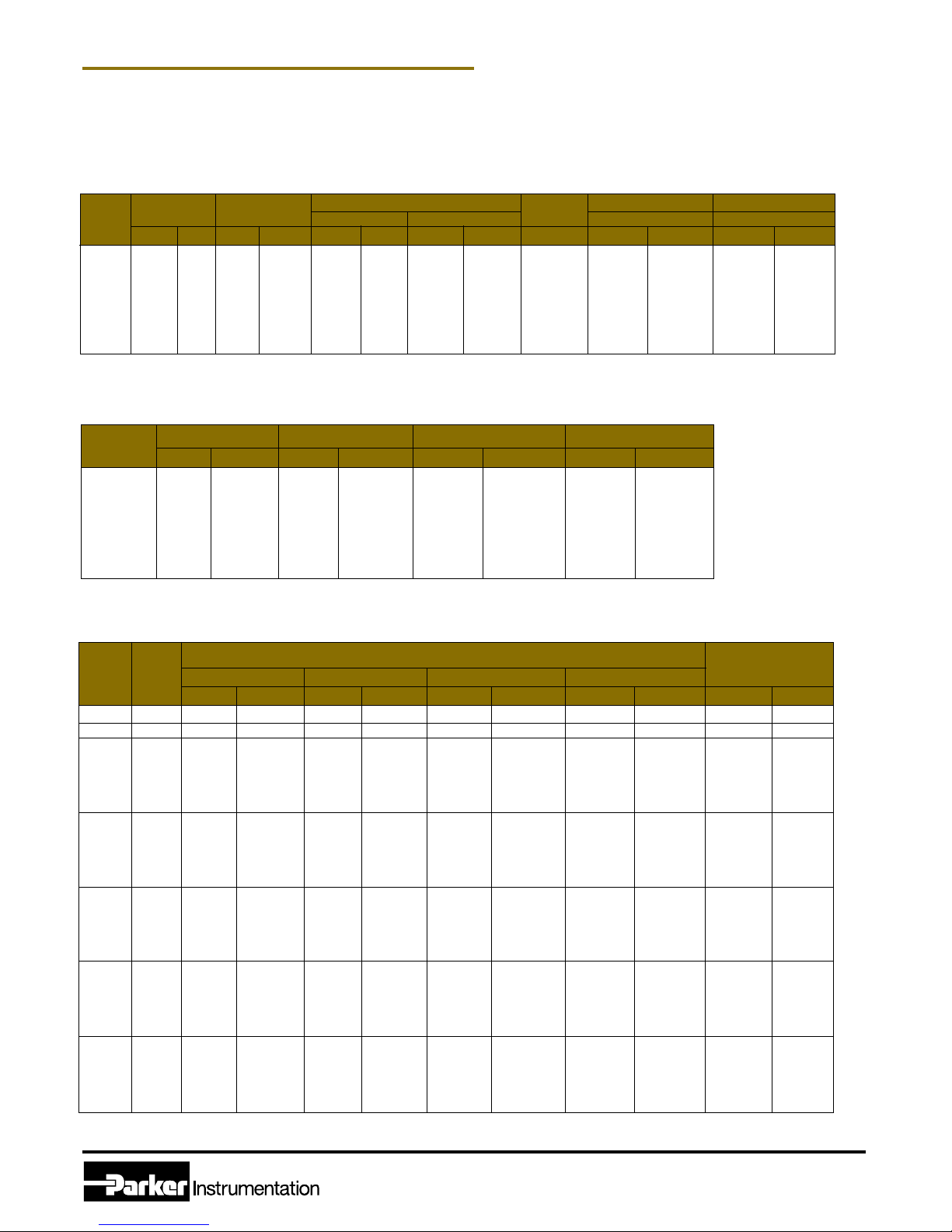

A. Service

On-Off 1.00

Emergency shutdown (cycled

less than once per month) 2.00

Applications with less than two

cycles per day 1.20

Applications below –20 ˚F (-29 ˚C) 1.25

B. Media

Saturated steam 1.20

Clean saturated steam 1.00

Liquid, clean (particle free) 1.00

Liquid, dirty (slurry), raw water 1.80

Gas, clean and wet 1.20

Gas, clean and dry (superheated stm.) 1.00

Gas, dirty (natural gas) 1.50

Chlorine 1.50

Application Factor Multiplier

Actuator Selection

Parker Hannifin Corporation

Instrumentation Valve Division

Jacksonville, Alabama

Pneumatic Actuators

6