Tube assembly

E24 Catalogue 4100-5/UK

8

576

12 3 4

910 11 12

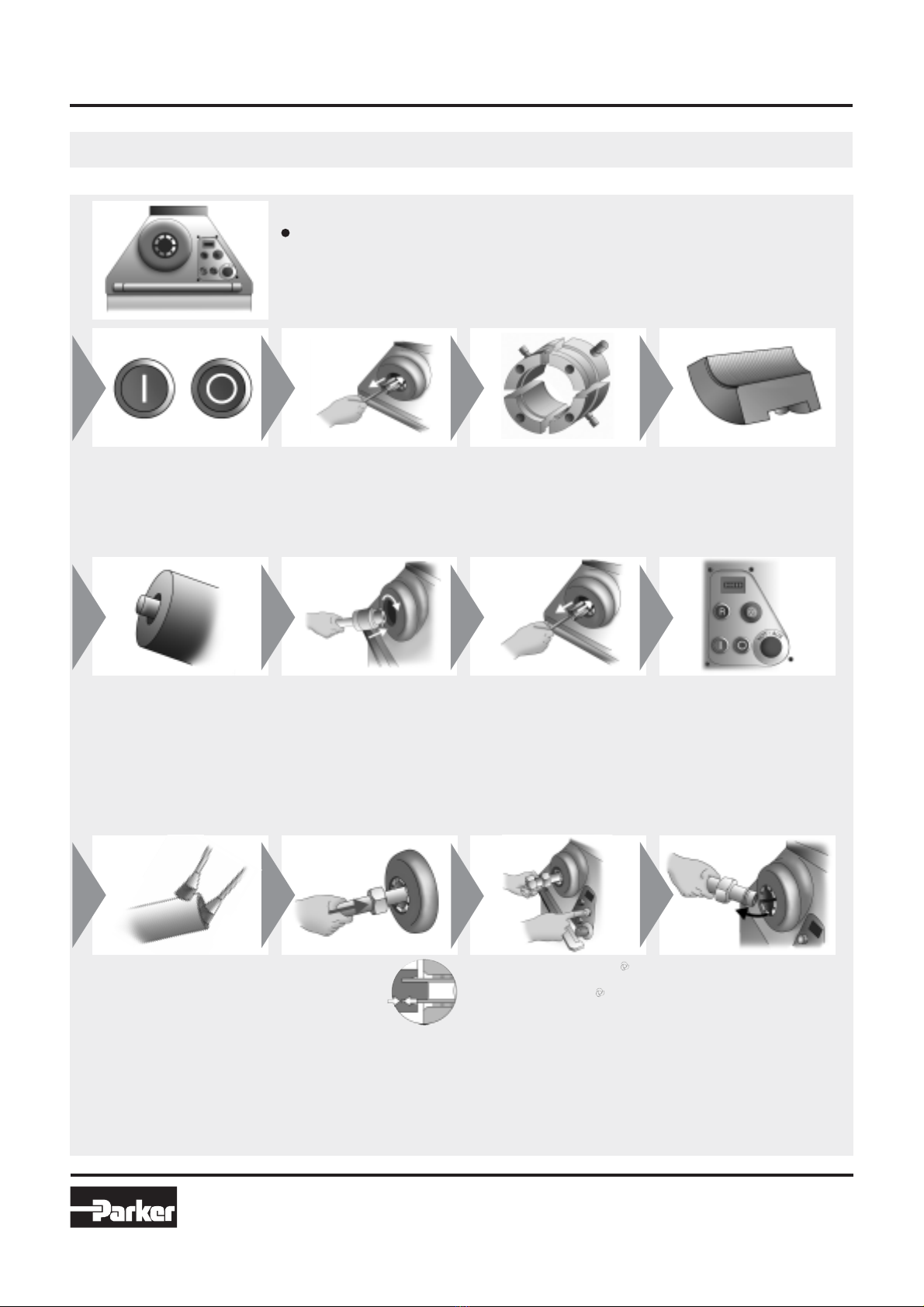

EO2-FORM assembly instructions

Tube forming with EO2-FORM F2

Reliable forming method

Change tool only when drive

switched off (button 0)

Obey safety instructions

●Select suitable forming die

according to tube material, outer

diameter and wall thickness

●Select suitable clamping dies

according to tube outer diameter

Keep stainless tube clamping

dies seperate from other tube

materials to prevent contact

corrosion

●Use magnetic holder to insert

forming die

●Turn clockwise to lock bayonet

fixture

●Tube can be taken out after the

clamping dies are open

●Reset button (R) lights up and

the machine is ready for the next

operation

●Check tools regularly (approx.

50 assemblies) for dirt and wear

●Remove tools for cleaning

●Clean clamping dies with wire

brush

●Clean forming die using

compressed air

●Replace worn-out tooling

●Press and hold start button

until tube is clamped

●Instead of start-button foot-

switch can be used

Hold tube firmly until clamping

dies are closed

●Use support for long tubes

Do not reach into tool area while

machine is working

●Check clamping dies for dirt,

wear and damage

●Check forming die for dirt,

wear and damage

●Insert clamping dies in holder

●Pins must lock in drill holes

●Use handling pin for easy die

insertion

●Switch on drive (button I)

●Each time the drive is switched

on, the reset button (R) must be

pressed first

●The automatic tool recognition is

initiated

Clamping dies will close

Reset button (R) must be held

until it lights up

●Lighten of reset button (R)

indicates “ready to start“

Make sure tube-end is free

of burrs, chips and dirt

Lubricate inside and outside

of tube-end

●Use EO-NIROMONT for best

performance

●Insert tube-end with

nut into open tool

until it firmly

touches the stop

at the end

Press tube-end firmly

into the tube stop

●Do not turn tube-end

anti-clockwise