4 5

WORK AREA

• ALWAYS use in a well ventilated area.

• ALWAYS use the appropriate safety equipment.

• NEVER use in the vicinity of other people, children or animals.

• READ these safety instructions before using the equipment.

• DO NOT operate the sprayer while persons

(especially children) or animals are in close vicinity.

The operator is responsible for any damage or harm

to third parties.

• When using plant protection equipment and while

working with plant protection chemicals of any kind,

always observe the safety precautions prescribed

by the chemical manufacturer. The operator is to

observe personal safety regulations (Safety

Clothing).

• Heavily dilute (approx. 1:10) surplus spray fluid left

over after treatment of field or garden, and spray the

solution over the area you have already treated.

• After every use and especially after the end of the

spraying season, clean and flush the sprayer, tank

as well as all parts which come in contact with

chemicals.

• Residues of plant protection chemicals may lead to

corrosion and damage of the sprayer.

• Clean and service wear parts such as nozzles,

filters, gaskets and seals.

• NEVER clean nozzles with hard objects.

• ALWAYS use original parts. Damaged parts should be

replaced without delay.

• ALWAYS release all pressure in the tank or spray line

before commencing service or maintenance work

on the machine.

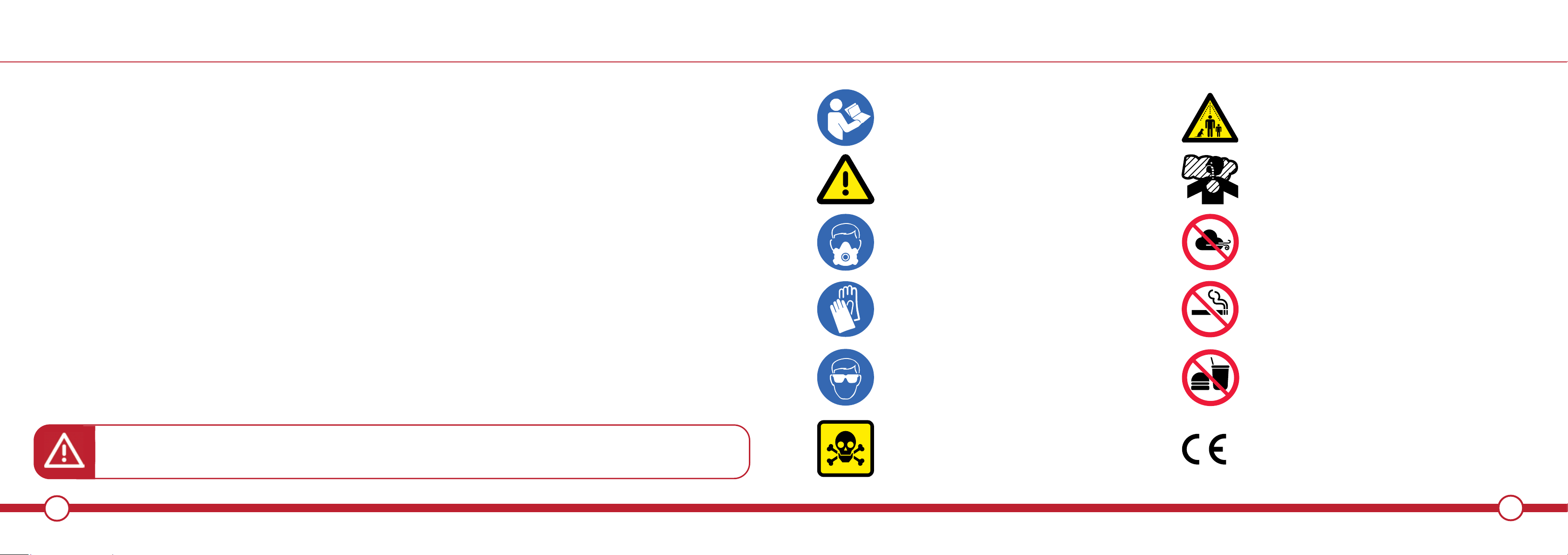

HEALTH & SAFETY INFORMATION

HEALTH & SAFETY INFORMATION

WARNING - To reduce the risk of injury,

user must read instruction manual.

This symbol, before a safety comment, indicates a

PRECAUTION, a WARNING or a DANGER. Ignoring

this warning can lead to an accident for yourself or for

others. To limit the risk of injury, fire, or electrocution

always apply the recommendations indicated.

WARNING! Chemicals contain toxic substances.

Do not use the sprayer in closed or poorly ventilated areas.

CONFORMS TO CURRENT SAFETY STANDARDS

WARNING! Do not use in windy conditions.

EYE PROTECTION Approved eye protection

should be worn at all times during operation.

GLOVES Gloves should be worn where appropriate.

RESPIRATOR A Breathing respirator should be worn

at all time whilst in use.

WARNING! Do not smoke whilst in use.

WARNING! Do not eat or drink whilst in use.

POISONOUS FUMES Do not use the sprayer in an

enclosed space.

KEEP BY STANDERS AWAY Including children and animals.

WARNING! To reduce the risk of injury, user must read instruction manual thoroughly.

WARNING! Always use the appropriate safety equipment in a well ventilated area.

WARNING! Never use in the vicinity of other people, children or animals.