INSTALLATION

Gas connection

Caution!

The cooker should only be connected to a

gas supply of the particular type that the

appliance is manufactured to function with.

Information about the type of gas that the

cooker has been adapted to by the factory

is shown on the rear panel.

This appliance is suitable for connection with rigid

pipe or flexible hose. The isolating manual shut-off

valve connection point must be accessible when

the appliance is installed.

Natural Gas: the supplied regulator must be fitted

to the appliance inlet connection. Gas pressure must

be adjusted to 1.0 kPa when approximately 50%

of the burnersare on high flame, the appliance test

point is located on the regulator.

LPG: the supplied test point adaptor must be fitted

to the appliance inlet connection. Gas pressure must

be adjusted to 2.75 kPa, the appliance test point

is located on the test point adaptor.

Suitable for connection with a flexible hose assembly.

The flexible hose assembly must be certified to

AS/NZS 1869 class B or D, be of appropriate internal

diameter for the total gasconsumption, be kept as

short as possible (not exceeding 1200mm), must

not be in contact with the floor or any hot or sharp

surfaces. The hose assembly must not be subject

.noitamrofedrogniknik,noisarba,niartsot

Gas leakage and operation of the appliance must

be tested by the installer before leaving. Check all

For minor adjustment and fault finding refer to

page 25 If this appliance cannot be adjusted to

perform correctly. Refer to the warranty card for

service & parts contact information. Where the

●Install the cooktop

Remove the crown caps and burner

crowns from the oven, and arrange

them on the cooktop as per the earlier

diagram entitled. Description of the

Caution!

The crown cap and burner cap must be tightly

installed to ensure that the gas flame burns

as intended. if the flame fails to ignite, it may

be because these components have been

To fit the rear panel/splashback,slide the

10

appliance! These components will fit

together neatly when correctly installed.

lugs on the bottom of the panel into the

with screws provided.

matching slots on rear of stove and fix

burner flames are blue in colour, stable and

with no appreciable yellow tipping, carbon

deposition, lifting, floating, lighting back or

completely ignite at both high low flame settings

objectionable odour. Test burners individually and

in combination.

data plate is obscured by cabinetry when the cooker

is in the installed position, place the supplied

duplicate data plate to a suitable adjacent surface

or within the instruction manual for future reference.

incorrectly installed.

11

INSTALLATION

On completion of the cooker installation,

the tightness of all connections should be

.paoshtiwretawgniylppa.g.e,dekcehc

Do not use fire to check tightness.

Anti tilt chains are located at the rear of the

llawehtotderucesebtsumdnaecnailppa

behind the appliance to prevent accidental

tipping/tilting. The chain length must be as

short as practicable to avoid appliance tilting

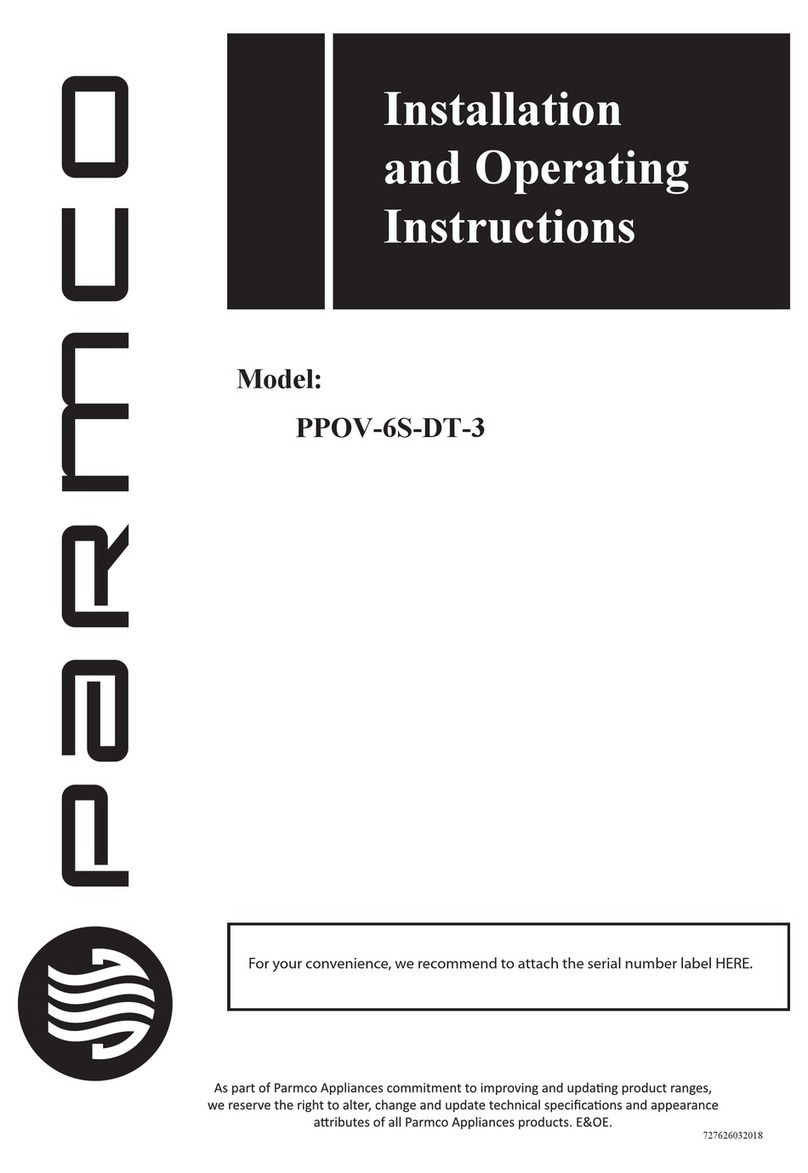

Flexible hose connection

Beginning of operation

In case the appliance is connected by

means of a flexible hose, the position A of

the hose is not permissible.

In case the connection hose is made of

metal, position A is permissible.

Start using the appliance in accordance

with the instructions for use.

i

Caution!

forward and also diagonal to avoid appliance

moving sideways.

Fix the cooker to the back wallwith

2 chains

Lit up all burners and check the stability of

the flame with high and low setting. Adjust

air intake if necessary. After that, take time

and explain the operation and control of

the appliance to the user and read with him

the instructions for use.

Liquefied gas connection

Adapting the cooker to

another type of gas

This operation may only be carried out by

an appropriately authorised fitter.

The cooker is supplied with natural gas

(NG 1.0kpa).If the cooker is to be supplied

with differs from the gas provided

for the

cooker by the manufacturer, burner nozzles

must be exchanged and the flame needs to

be adjusted.

In order to adapt the cooker to burn a

different type of gas, you should:

●Exchange nozzles (see tables below),

●

●

Adjust the “economical” flame.

If you need to replace the natural gas

(NG 1.0kpa) , please contact

the service center.

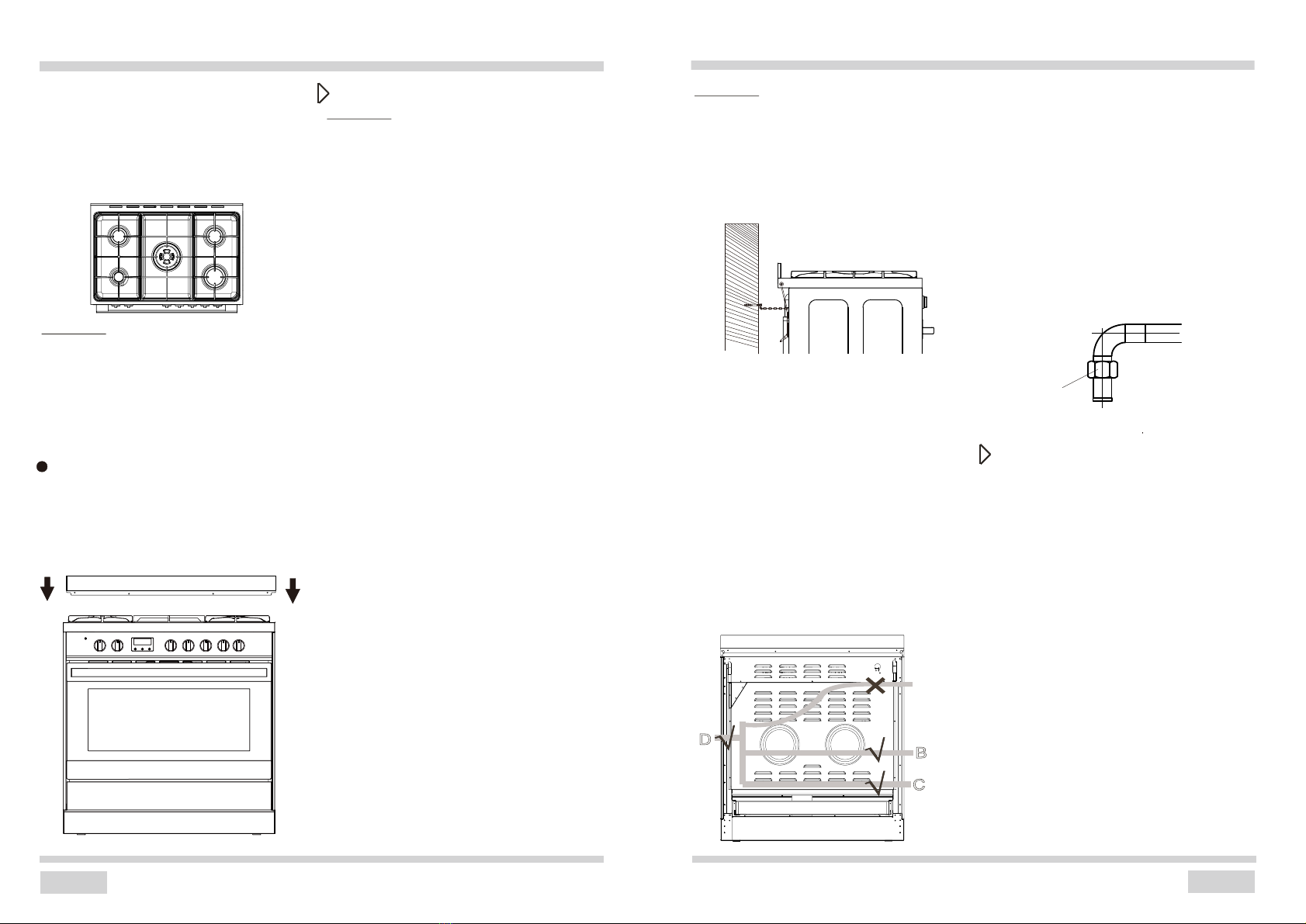

ccording to NG install instruction:

se M7sleeve to replace LPG nozzle to be NG nozzle

djust NG pressure,ignite to check burner minimum

ame status,adjusting damping hole till flame is stable.

A

B

C

D

9 Connection R 1/2

9