GENERALLY

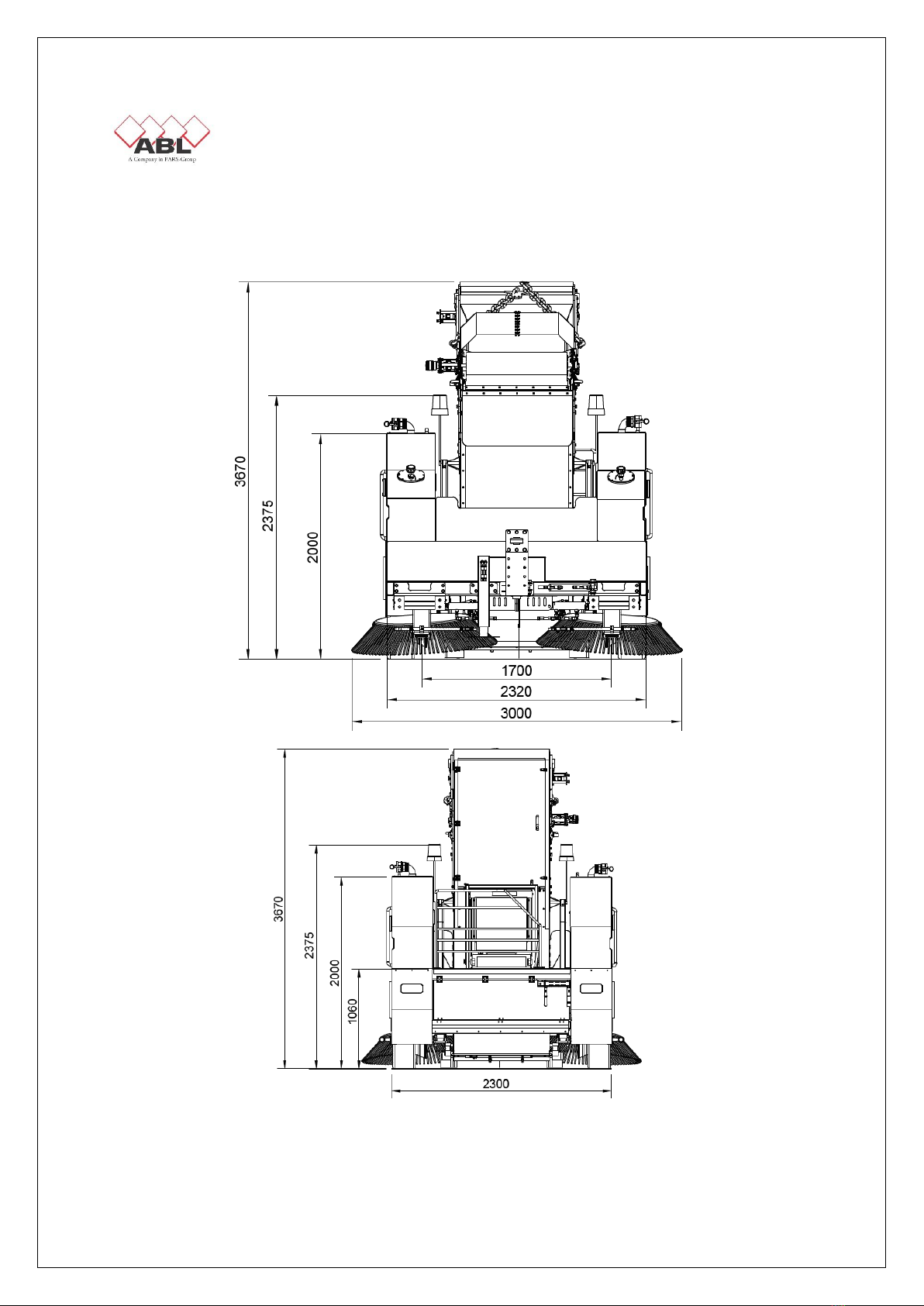

ABL GIANT 3.0 is a truck towed mechanical elevator sweeper with its own diesel engine for

hydraulic operation. This machine has a wheel axle with spring leaf suspension which is

specially adapted for this machine, it allows to transport the machine at 80 km/h on the

roads.

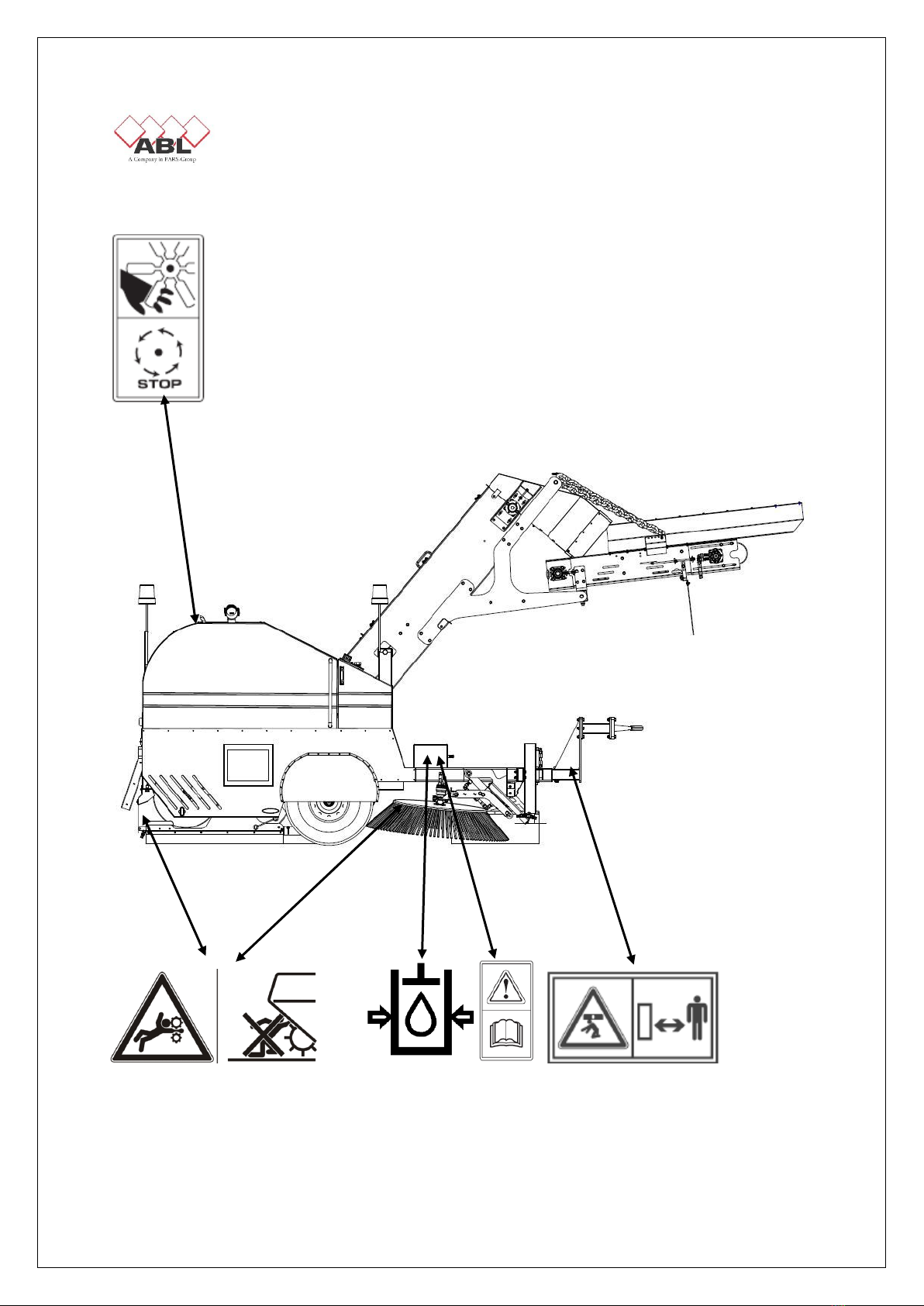

To maintain vehicle operation and road safety, maintenance work shall be

performed at the specified intervals, that are specified in this book

The towing vehicle should be a tipping truck, with an approved trailer coupling and electrical

socket for lighting and right and left turn indicators. All sweepers functions are controlled

with one touch easy control display in drivers’ cabin.

Sweeping principle

The side brushes sweep the material into the centre of the machine, back brushes throw the

debris further up into the elevator. The conveyor belt moves the thrash up on the truck

platform, the water spray bar prevent the dust binding.

The ABL GIANT 3.0 sweeper is suitable for sweeping sand, gravel, paper on streets and

squares roads and industrial areas. Avoid sweeping up packaging strips, large stones and

pieces of wood that can damage elevator rakes in the elevator.

4