Table

of

Contents

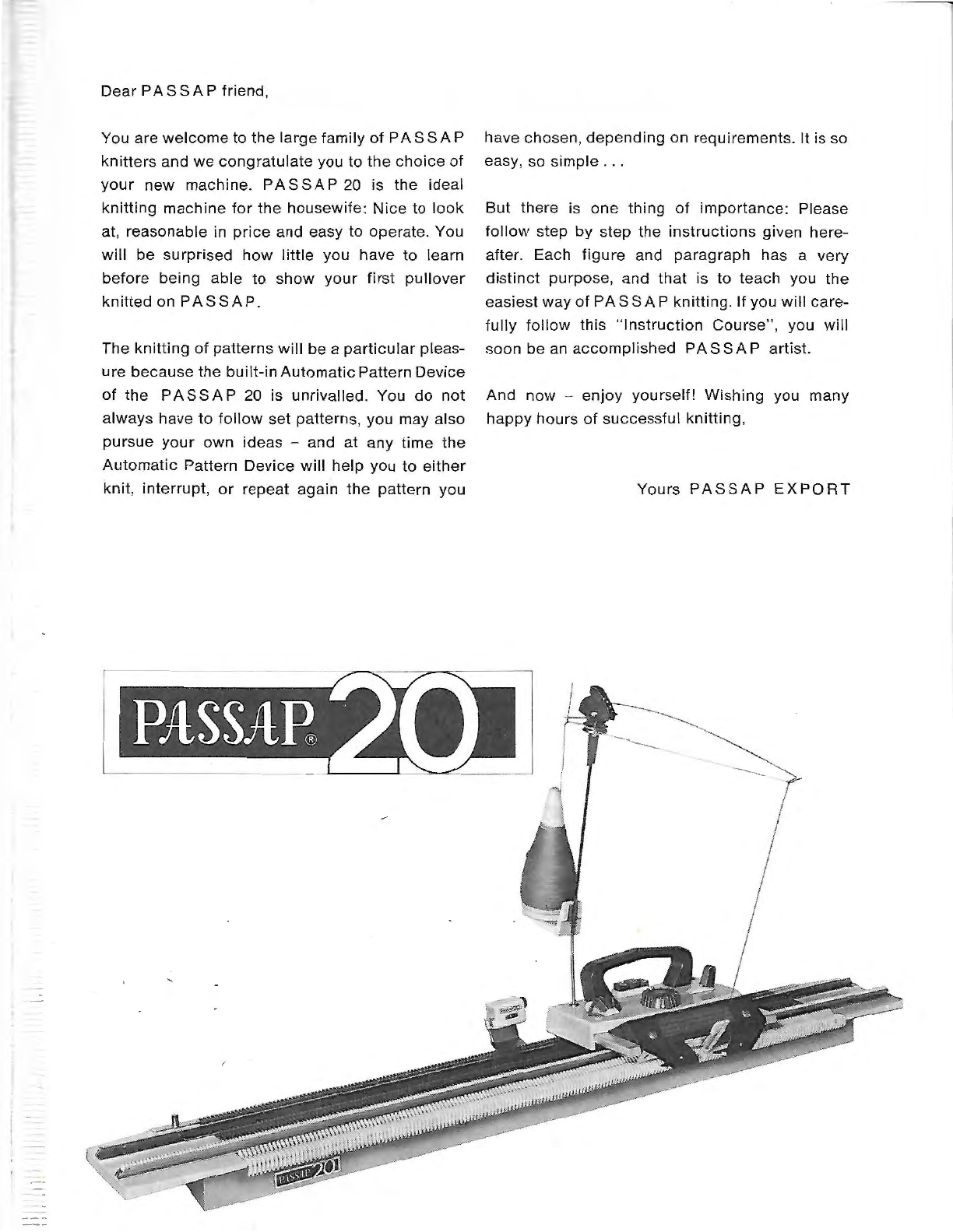

I

nt

roduct

ion -Ill

us

tration

of

the P

ASS

A P 20 .

Alphabetical Inde

x.

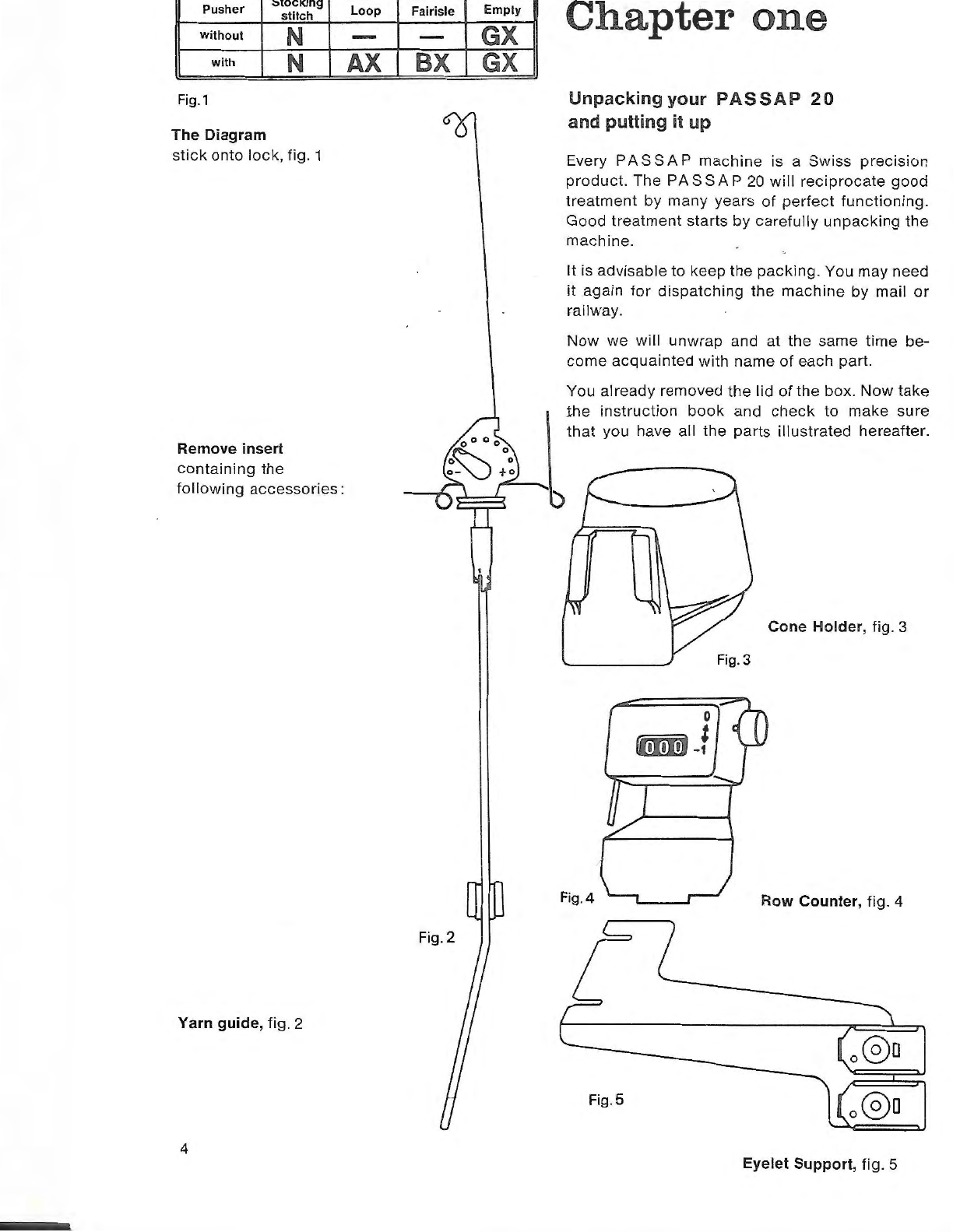

Chapter One

Un

packing

the

PASS

A P

20

and

putting

it

up

-Movement

of

lo

ck

with

latch

needles

Chapter

Two

Preparation

fo

r knitting -Yarn winding - Th

reading-

Ad

justing yarn tension

First

test

square: Casting on -

Knitting-

Turning

up

hem (all needles) - Increasing -

Decreasmg -

Unr

avelltng rows -Casting o

ff

First aid: Edge stitch and

stitch

.

Chapter Three

Pa

ge

1

2

4

. . .

15

Some theory: Pushers -Dial selector -Keys -Some

pra

ctical examples . . . . . . . .

33

Chapter Four

S

econd

test square: 1 : 1 hem -

two

AX

patterns-

a

BX

pattern -cable pattern and

crocheting

st

itches - V-ne

ck-

Pattern diagram

F1

rst a

1d:

casttng on 1 : 1 . . . . . . . . . . . . . . . . . . . . . . . . .

42

Chapter Five

Chi

ld's

Sweater-

Explanation basic pattern . . . . . . . . . . . . . . . . . . .

58

Chapt

er

Six

Th

ird

te

st

square: Hem with

picot

edge ·- Buttonholes - Heel

_,

Graduati

ons-

B

aby

sock

First aid: Empty

co

n

e,

part

of

s

titches

dropped . . . . . . . . . . . . . . . . .

60

Chapter

SE!ven

Shapin

g:

Basic patterns - T

est

square -

PASS

A P-C

hart

-

Ca

lculating - H

ow

to

make up . .

69

Chapt

er

Eight

St

it

ch patterns . . . . . . . . . . . . . . . . . . 79

Chapt

er

Nine

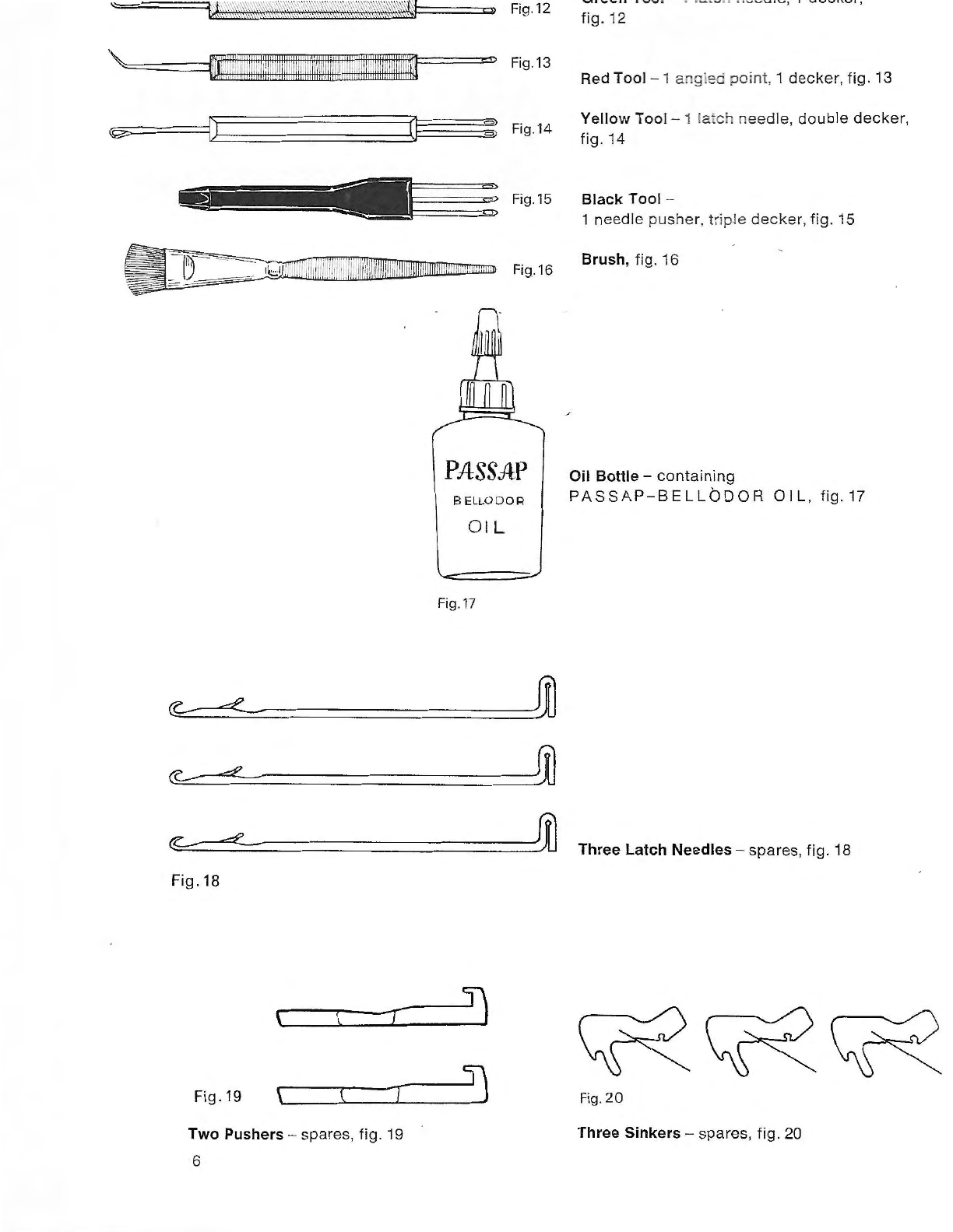

Tec

hnic

al

hint

s: Changing latch needle - Chang

ing

sinker - Bending and changing

pusher

-

Cl

ea

ntng

an

d oiling . . . . . . . . . . . . . . . . . . . . . . . . . . . 91