Page | 2 Rev: 210301

AFTER INSTALLATION THE END USER SHOULD

KEEP THIS GUIDE FOR FUTURE REFERENCE

DO NOT THROW AWAY

SHOULD YOU ENCOUNTER ANY

PROBLEMS INSTALLING THIS

UNIT, CALL US: 021 4875297

8. Before connecting the product to the power supply or the power outlet, ensure that: - the

data plate (voltage and frequency) correspond to those of the electrical mains - the electrical

power supply/socket is adequate for maximum device power. If not, contact a qualified

technician.

9. Operating temperature: 0°C up to +40°C.

10. The device is designed to extract clean air only, i.e. without grease, soot, chemical or

corrosive agents, or flammable or explosive mixtures.

11. Do not leave the device exposed to the atmosphere (rain, sun, snow, etc.).

12. Do not immerse the device or its parts in water or other liquids.

13. Turn off the main switch whenever a malfunction is detected or in case of

cleaning/maintenance.

14. If the supply cord is damaged, it must be replaced by the manufacturer, its service agent

or similarly qualified persons in order to avoid a hazard.

15. Do not obstruct the fan or exhaust grille and ensure optimum air passage.

16. Ensure adequate air return into the room in compliance with local regulations in order to

ensure proper device operation.

17. If the environment in which the product is installed also houses a fuel-operating device

(fireplaces, stoves etc., that is not a “sealed chamber” type), it is essential to ensure adequate

air intake, to ensure good combustion and proper equipment operation.

18. Make sure there is enough space around the unit for maintenance.

2.0 Introduction

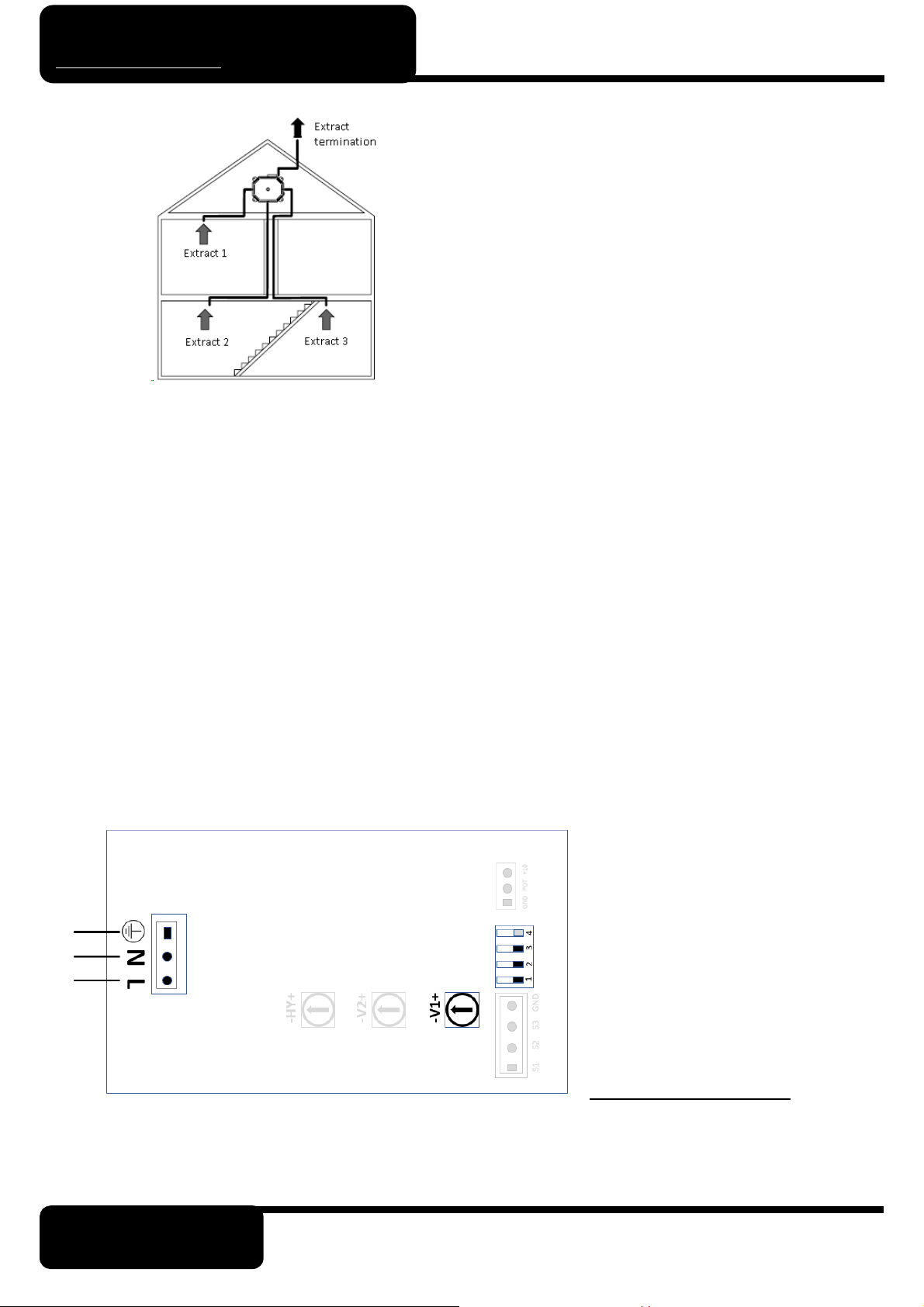

The PHS MEV is a whole house mechanical extract fan designed to be connected to ceiling extracts valves

as per buildings regulations part F. Suitable for above ceiling, false-ceiling or floor installation, horizontally

or vertically. This version is with integral humidistat.

3.0 Technical Specifications

1. Outer fan casing manufactured from powder coated galvanised sheet steel.

2. Top cover made from strong ABS plastic.

3. Internal self-extinguishing acoustic foam lining.

4. EC external rotor motor for energy saving, mounted on ball bearings that guarantee a longer

product life cycle and suitable for cold climates.

5. Forward curved centrifugal impeller to provide a smooth and silent airflow through the unit.

6. Provided with multiple extract points:

a. air exhaust to outside -through 1xØ125mm circular spigot

b. air extract from inside -through 4xØ125mm circular spigots.

7. IPX2 protection.

8. Power supply 230V~ 50/60Hz.

Model Airflow

Static Pressure

Power