Patz Corporation 400 Material Mover Instruction manual

Technical Data and Layout Planner

Patz Corporation

P.O. Box 7

Due to continual updating, design and specifications are Pound, WI 54161

subject to change without notice. Tel: (920) 897-2251

Fax: (920) 897-2142

PA-15589 Rev. 2/18 Copyright ©2001-2018 Patz Corporation PRINTED IN U.S.A. www.patzcorp.com

400 Material Mover

Chain Direction

2

Standard Equipment Specifications

Overall Lengths: 20’ (6.096 m) to 200’ (60.96 m). (Max. 400’ (152.4 m) chain length depending on load and configuration.)

Construction: All steel; slide is High-Strength, Corrosion Resistant steel.

Chain: 400 hook-and-eye, all steel link, progression forged; heat treated.

Flites: 467: 4” (102 mm) high at tip, 1/4” (6.4 mm) thick, all steel, 1/2” (12.7 mm) wear shoe welded to bottom.

447: 2” (51 mm) high, 1/4” (6.4 mm) thick, all steel, 2 x 3 x 1/2” wear shoe welded to bottom.

Steel Trough and Concrete Gutter width: 18” (457 mm).

Planetary Gear Drive: Planetary speed reducer with 12, 18, 24, 30 and 36 ft/min (3.7, 5.5, 7.3, 9.1 and 11 m/min) chain speed; 2, 3, 5 or

7-1/2 H.P. motor.

Heavy Roller Chain Drive: V-belt and single-strand final drive roller chain reducer with 18 or 30 ft/min (5.5 or 9.1 m/min) chain speed;

maximum 5 H.P. motor.

203SMTP Gearbox reducer drive: 24 or 36 ft/min (7.1 or 11 m/min) chain speed; 2 or 3 H.P. motor.

Load Capacity: Up to 45 ft3/min (1.274 m3/min), at 36 ft/min (11 m/min) depending on gutter width and depth, elevation and type of material

moved. (Through trapdoor, 25 ft3/min (0.708 m3/min))

Span: Up to 20’ (6.096 m) between supports.

Color: Blue baked-on-polyester powder coat and epoxy polyester finish.

Electrical Controls: Customer supplied.

Assembly: Conveyor supplied unassembled.

Options: Flite wiper brushes material off flites; stands for support; trapdoor to drop material out bottom of trough; covers for troughs; corner

sections; stainless steel slide; double corner wheels for smoother operation under heavier loads; steel liner for concrete trough provides

a smooth surface.

Drive Motors: 2, 3, 5 or 7-1/2 H.P., 1 ph. or 3 ph.

Optional Equipment Specifications

Calculating Capacity

Capacity and HP requirements can vary depending on the material moved, inclines involved and many other factors. Consideration must

be given to the machine layout, incline, elbows, chain length and speed, as well as material density, moisture content, and frictional

characteristics of the material to be moved. Use caution when material unit weights exceed 40 lbs. per cu. ft. (640.7 kg/m3) as material depth

in troughs should not exceed 2-4 inches (50.8-101.6 mm). Slanted side walls may reduce capacity, but should be used with rigid materials

such as wood blocks or bark to avoid bending flites.

U.S. UNITS

M-400 Material Mover, moves 15 ton/hour, wood chips at

30 lbs/cu. ft.

1) 15 T x 2000 #x hr. = 500 #/min.

hr. T 60 min.

2) 500 #/ min. = 16.7 ft3/ min.

30

#/ cu.ft.

3) 6” material depth at 24 FPM gives 18 ft3/min.

delivery (from table).

EXAMPLE

1) Convert to lbs./min.

2) Divide by material unit weight to determine volume.

3) Refer to Volume Capacity Table for material delivery rate at an estimated depth in trough.

METRIC UNITS

M-400 Material Mover, moves 13.61 t/hr, wood chips at

480.5 kg/m3.

1) 13.61 t/hr x 1000 kg x hr. = 226.8 kg//min.

t 60 min.

2) 226.8 kg/ min. = 0.47 m3/ min.

480.5 kg/m3

3) 152.4 mm material depth at 7.3 m/min gives

0.510 m3/min. delivery (from table).

MATERIAL DELIVERED PER MINUTE ( 18” (457 mm) WIDE TROUGHS)

2 (50.8) .25 (0.007) 3.0 (0.085) 4.5 (0.127) 6.0 (0.170) 7.5 (0.212) 9.0 (0.255)

4 (101.6) .50 (0.014) 6.0 (0.170) 9.0 (0.255) 12.0 (0.340) 15.0 (0.425) 18.0 (0.510)

6 (152.4) .75 (0.021) 9.0 (0.255) 13.5 (0.382) 18.0 (0.510) 22.5 (0.637) 27.0 (0.765)

8 (203.2) 1.0 (0.028) 12.0 (0.340) 18.0 (0.510) 24.0 (0.680) 30.0 (0.850) 36.0 (1.020)

10 (254.0) 1.25 (0.035) 15.0 (0.425) 22.5 (0.637) 30.0 (0.850) 37.5 (1.062)

Material Depth

(Inches)

Volume of Matl.

per Running ft

ft3/min (m3/min.)

VOL. @ 12 ft/min

(3.7 m/min)

ft3/min (m3/min.)

VOL. @ 18 ft/min

(5.5 m/min)

ft3/min (m3/min.)

VOL. @ 24 ft/min

(7.3 m/min)

ft3/min (m3/min.)

VOL. @ 30 ft/min

(9.1 m/min)

ft3/min (m3/min.)

VOL. @ 36 ft/min

(11.0 m/min)

ft3/min (m3/min.)

VOLUME CAPACITY TABLE

45.0 (1.274)

It is the user’s responsibility to cover all walkways and return troughs with a steel floor plate to prevent possi-

ble personal injury. Cover should extend from hold down post at bottom end of the elevating slide to and includ-

ing return corner. If no elevating slide is used, trough covers should extend from the drive unit to and including

the return corner. Right Hand (R.H.) = Counter-clockwise chain movement.

Left Hand (L.H.) = Clockwise chain movement.

Shaded Portion = Loaded trough.

3

Typical Installations

A

O

N

Q

A

O

U

C

T

ST

R

N

O

N

B

S

T

V

C

O

K

B

J

N

#1 R.H. WITH STEEL DOUBLE

TROUGH SECTIONS (ELIMINATES

RETURN CORNER)

NOTE: If using layout #3 or #4 with dry

material and a horizontal center

slide (N) between hold down

post section (O) and return

corner section (P or R), keep

horizontal portion to a minimum

(25’ (7.62 m) or less). This

reduces wear on return guide.

#3 R.H. WITH STEEL DOUBLE

TROUGH SECTIONS AND 90°

RETURN CORNER SECTION.

#2 R.H. WITH STEEL SINGLE TROUGH

SECTIONS AND SPLIT CHUTE (ELIMINATES

RETURN CORNER).

#4 R.H. WITH COMBINATION DOUBLE AND

SINGLE TROUGH SECTIONS AND 90°

RETURN CORNER SECTION.

Q

P

N - Center Slide

O - Hold Down Post Section

P - 90° Return Corner

Section

Q - 10’180°EndSection

R - Single Trough 90°

Return Corner Assy.

S - Single Trough 90°

Corner Wheel Assy.

T - Single Trough Section

U - 8’HoldInAngle

V - Split Chute Transition

Section

N

4

TypicalInstallations(Con’t)

A - Slide

B - Front Slide

C - Rear Slide

D - Hold Down Post

E - 180°CornerLiner

F - Single Trough Liner

G - 90° Corner Liner

H - 90° Corner Wheel Assy.

I - 90° Return Corner

J - Split Chute Front

Section

K - Split Chute Return

Trough

L - Split Chute Wear Plate

M - 180°CornerWheelAssy.

A

D

F

E

M

A

D

IFM

E

F

A

D

I

H

F

G

L

H

G

D

C

K

B

J

NOTE: The shaded portions indicate where the troughs can be loaded.

#1 L.H. CONCRETE TROUGHS WITH

STEEL LINERS (ELIMINATES

RETURN CORNER).

#3 L.H. CONCRETE TROUGHS WITH

STEEL LINERS AND 90° RETURN

CORNER.

FOR DRY MATERIAL

- USE RETURN

CORNER WITH

UHMW SHOE.

#2 L.H. CONCRETE TROUGHS WITH

STEEL LINERS AND SPLIT CHUTE

(ELIMINATES RETURN CORNER).

#4 L.H. CONCRETE TROUGHS WITH

STEEL LINERS AND 90° RETURN

CORNER.

NOTE: If using layout #3 or #4 with dry

material and a horizontal section

between hold down post (D) and

90° return corner section (I), keep

horizontal portion to a minimum

(25’ (7.62 m) or less). This

reduces wear on return shoe.

RETURN

TROUGH

FIELD CUT

RETURN

WEAR

PLATE

HOLD

DOWN

POST

3’6”

4’4”

5’2”

(1.067m)

(1.321 m)

(1.575m)

5’11”

(1.803m)

6’9”

(2.057m)

7’7”

(2.311 m)

8’

(2.438m)

10’

(3.048m)

12’

(3.658m)

14’

(4.267m)

16’

(4.877m)

18’

(5.486m)

20’

(6.096m)

22’

(6.706m)

24’

(7.315m)

26’

(7.925m)

28’

(8.534m)

30’

(9.144 m)

32’

(9.754m)

34’

(10.363m)

36’

(10.973m)

38’

(11.582m)

40’

(12.192 m)

8’5”

(2.565m)

9’3”

(2.819m)

10’1”

(3.073m)

10’10”

(3.302 m)

11’8”

(3.556m)

12’6”

(3.81m)

13’4”

(4.064m)

14’2”

(4.318m)

15’0”

(4.572m)

15’10”

(4.826m)

16’8”

(5.08m)

IMPORTANT: Maximum split chute angle

22° to allow sufficient chain

wrap for proper operation,

dimensions given reflect

that maximum angle.

MAXIMUM WALKWAY WIDTH

5

Typical Trough Cross Sections

LOADED

SIDE

OR EMPTY

RETURN

LOADED

SIDE

OR EMPTY

RETURN

SIDE

LOADED

SIDE

OR EMPTY

RETURN

SIDE

LOADED

SIDE

OR EMPTY

RETURN

SIDE

In Floor

Above Floor

NOTE: Unlined concrete troughs can produce added friction, resulting in increased horsepower requirements, increased wear of the flites, as

well as wearing away of the concrete.

Typical Split Chute Straight Pull, Right Hand Installation

LOADED

SIDE

OR EMPTY

RETURN

SIDE

6

Dimensions

Single Trough,

Straight Pull

(Right Hand)

Single Trough, Side Pull

(Right Hand)

Single Trough

Slanted60°

Sidewall

(End View)

Available in

1’,2’,4’,10’

Lengths.

SINGLETROUGH,STEEL,SLANTED60°AND90°STRAIGHTSIDEWALL

BOLT-TOGETHER SECTIONS

120

(3048mm)

24

(610mm)

28-1/2

(724mm)

26-7/8

(683mm)

18

(457mm)

12-7/8

(327mm) 11-1/2

(292 mm)

24-7/8

(632mm)

Single Trough

90° Straight

Sidewall

(End View)

Available in

1’,2’,4’,10’

Lengths.

24

(610mm)

130-7/1660°

(3313 mm)

119-3/4 90°

(3042 mm)

77-1/460°

(1962mm)

71-7/890°

(1826mm)

70-1/2

(1791mm)

52-1/2

(1334 mm)

53-3/860°

(1356mm)

4890°

(1219 mm)

46-1/2

(1181mm)

46-1/2

(1181mm)

52-1/2

(1334 mm)

117

(2972mm)

81(2057mm)

Minimum

46-1/2

(1181mm)

53-3/860°

(1356mm)

4890°

(1219 mm)

46-1/2

(1181mm) 28-1/2

(724mm)

93

(2362mm)

106-7/1660°

(2704mm)

95-3/4 90°

(2432 mm)

120

(3048mm)

24

(610mm)

52-1/2

(1334 mm)

52-1/2

(1334 mm)

70-1/2

(1791mm)

77-1/460°

(1962mm)

71-7/890°

(1826mm)

24

(610mm)

57(1448mm)

Minimum

A

B

C

C

AB

A - Single Trough Section

B - Single Trough 90° Return

Corner Assy.

C - Single Trough 90° Corner

Wheel Assy.

12-7/8

(327mm)

24

(610mm)

18

(457mm)

7

Dimensions

DOUBLETROUGH,STEEL,SLANTED60°SIDEWALL

BOLT-TOGETHER SECTIONS

ALLCOMPONENTS:18”(457)TROUGHWIDTH

DIMENSIONS: INCHES (MM)

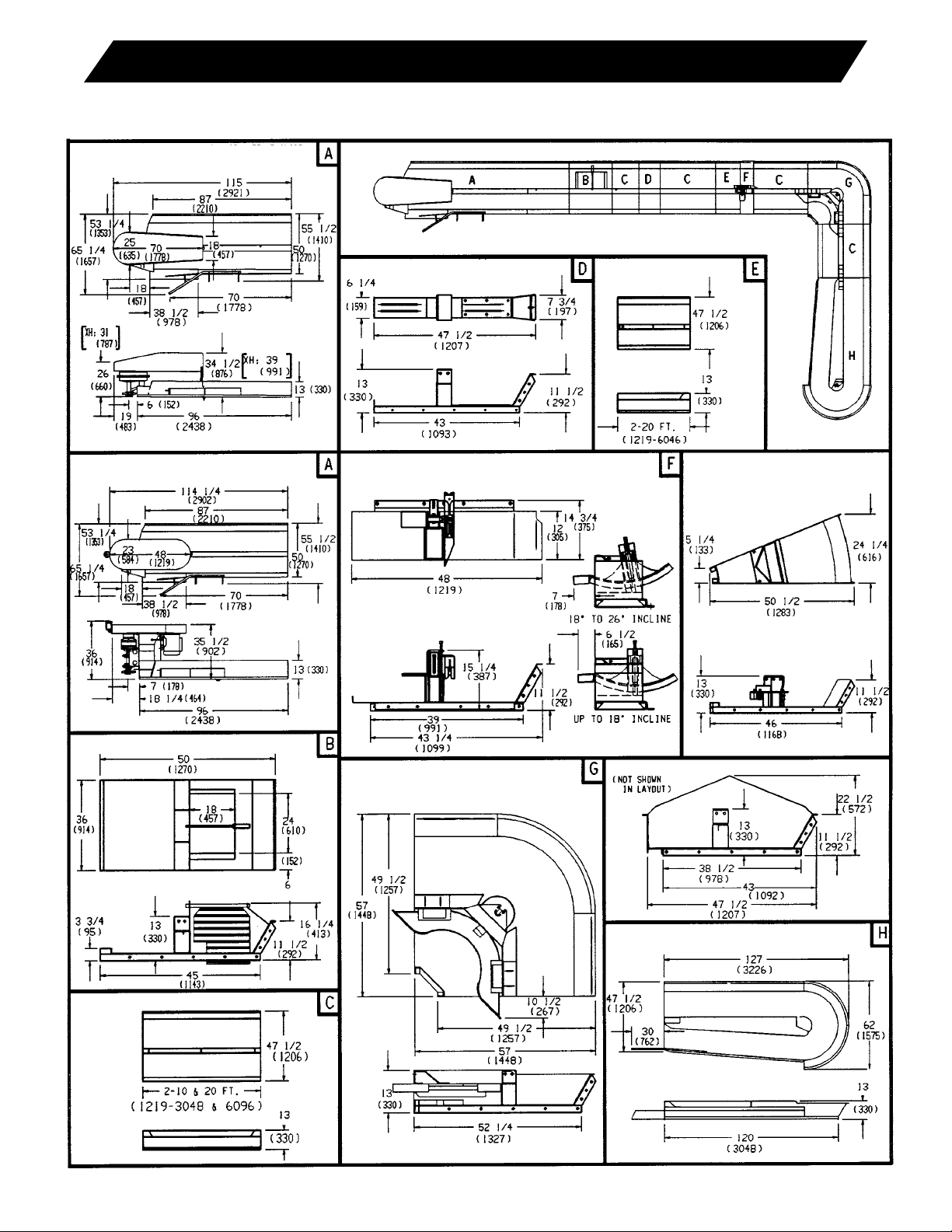

203, HVY. & XH REDUCER DRIVE UNIT

&FRONTSLIDE(8FT.SHOWN)

7°ELBOWSECTION

TRAPDOOR SECTION

90° CORNER SECTION COVER ASSEMBLY

10’180°ENDSECTION

CENTER SLIDE

REAR SLIDE

22.5° SL. CORNER SECTION

(NOT SHOWN IN LAYOUT)

PLANETARY DRIVE UNIT & FRONT

SLIDE(8FT.SHOWN)

HOLD DOWN POST SECTION WITH SHOE

AND RETURN GUIDE

8

Dimensions

DOUBLE TROUGH, STEEL, 90° STRAIGHT SIDEWALL

BOLT-TOGETHER SECTIONS

ALLCOMPONENTS:18”(457)TROUGH

DIMENSIONS: INCHES (MM)

203, HVY. & XH REDUCER DRIVE UNIT

&FRONTSLIDE(8FT.SHOWN)

7°ELBOWSECTION

TRAPDOOR SECTION

90° CORNER SECTION COVER ASSEMBLY

10’180°ENDSECTION

CENTER SLIDE

REAR SLIDE

22.5° SL. CORNER SECTION

(NOT SHOWN IN LAYOUT)

PLANETARY DRIVE UNIT & FRONT

SLIDE(8FT.SHOWN) HOLD DOWN POST SECTION WITH SHOE

AND RETURN GUIDE

Proposed Layout: 1/4” = _____ft.

Dealer/Distributor: _____________________________

Address: ____________________________________

____________________________________

Phone: ______________________________________

Fax: ________________________________________

E-mail: ______________________________________

Customer: ___________________________________

Address: ____________________________________

____________________________________

Phone: ______________________________________

Fax: ________________________________________

E-mail: ______________________________________

Date: ______________________________________

By: ________________________________________

Patz Corporation, P.O. Box 7, Pound, WI 54161-0007 Phone: 920-897-2251 Fax: 920-897-2142 [email protected] www.patzcorp.com

Copyright ©2001-2017 Patz Corporation

Table of contents

Popular Accessories manuals by other brands

Panasonic

Panasonic ECONAVI CZ-CENSC1 operating instructions

B&PLUS

B&PLUS RS12T-TF423A-TP01 instructions

Vericon Systems

Vericon Systems MultiDOT quick start guide

Movisens

Movisens EdaMove 3 user manual

iOptron

iOptron SmartStar Cube E Series instruction manual

Monacor

Monacor JTS MA-HPF operating instructions