Pavone Systems 1006 User manual

Pavone Sistemi

pesatura elettronica industriale

TECHNICAL MANUAL

TESTER 1006 For the simultaneous monitoring of up to 4 load cells

Software version PMT 401 Rel. 1.5

2

THE USE OF THE INSTRUMENT

KEY FUNCTIONS IN OPERATING MODE Page 11

KEY FUNCTIONS WITHIN THE VARIOUS MENUS Page 12

OPERATING MODE : DATA VISUALIZATION Page 14

“WEIGHING PARAMETERS” MENU Page 15

ADDITIONAL FUNCTIONS Page 18

DISPLAY INTENSITY ADJUSTMENT Page 20

THE “CALIBRATOR” FUNCTION Page 21

ACCESSORIES, OPTIONS AND SPARE PARTS Page 23

POWER-ON SEQUENCE Page 13

INSTRUMENT’S FEATURES

TECHNICAL SPECIFICATIONS Page 3

POWER SUPPLY AND BATTERY REPLACEMENT Page 4

CONNECTIONS

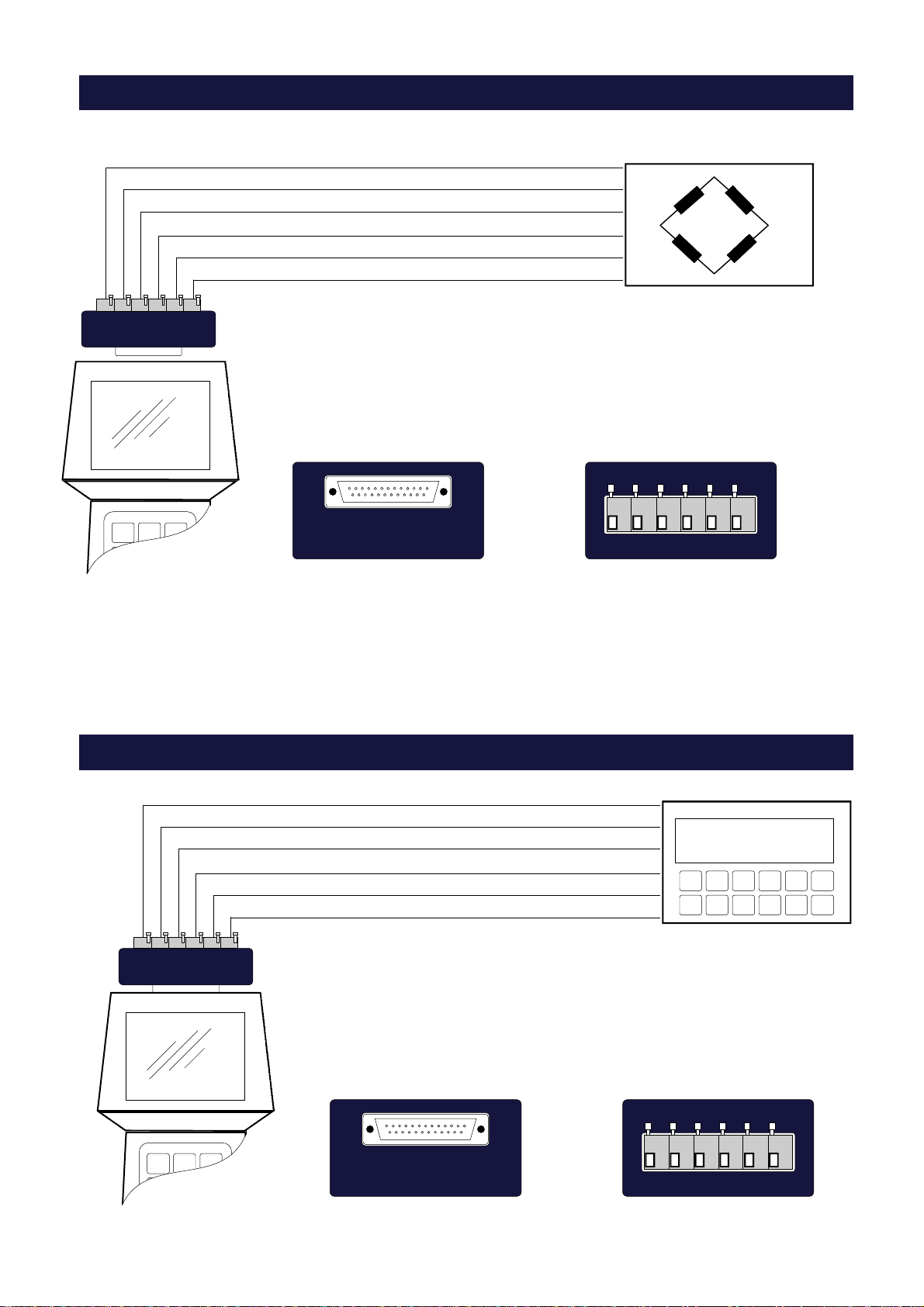

CONNECTION TO THE LOAD CELLS with Cable “A” Page 7

CONNECTION TO THE LOAD CELLS with Cable “B” Page 8

USING THE LOAD CELL TESTER IN “CALIBRATOR” MODE WITH J1/CB BOARD Page 9

MAIN PERFORMANCES Page 5

SWITCHING BETWEEN LOAD CELL TESTER AND CALIBRATOR MODES Page 6

CGS4/C and CEM4/C SUMMING JUNCTION BOXES Page 10

USING THE LOAD CELL TESTER IN “CALIBRATOR” MODE WITH J2/CB BOARD Page 9

CONTENTS

APPENDIX A

CONFIGURATION FILES MANAGEMENT Page 28

ACCESSING THE CONFIGURATION FILES MENU Page 30

SAVING A FILE Page 31

OPENING A FILE Page 34

DELETING ONE FILE / ALL FILES Page 38

TRANSFERRING ONE FILE / ALL FILES Page 39

STORING THE mV/V LOAD CELLS SIGNALS Page 42

STORED mV/V LOAD CELLS SIGNALS VISUALISATION Page 44

GENERATING THE STORED mV/V LOAD CELLS SIGNALS Page 45

UPLOAD/DOWNLOAD SET UP FILE INSTRUMENTS Page 23

RS 232 CONNECTION Page 46

3

TECHNICAL SPECIFICATIONS

Instrument power supply

Current consumption

Operating temperature

Storage temperature

Display

Keyboard

Overall dimensions

Weight

Enclosure

Protection degree (front)

Connection to load cells

With Cable A (std) or Cable B(option)

Load cells excitation voltage

4 individual load cell channels with the

following specs:

Linearity

Internal resolution

Displayed weight resolution

Input signal range

Decimal digits

Battery life

Accuracy of the mV/V signal generated

in Calibrator mode

4 x 1.5 V alkaline disposable batteries -AA size-

or:

4 x 1.2 V Ni-MH rechargeable batteries -AA size-

Min. 125 mA - Max. 190 mA

+ 14°F to + 122°F (-10°C to +50°C)

- 4°F to + 158°F (-20°C to +70°C)

Graphic, 3”

16 keys + On / Off switch

8.66 x 4.60 x 2.00 in. (220 x 117 x 51 mm.) H x W x D

Approximately 1.1 lbs. (500 Grams)

Polyamide (UL94 - V2)

IP 54

“A” type: 6 foot (2 m) cable with 25 pin Sub-D connectors

“B” type: (0,3 m) serial cable

5 Vdc @ 60 mA (4 x 350 Ω load cells) max.

< 0.01% of Full Scale

24 bit

Up to 50.000 counts

-3.9 mV/V to +3.9 mV/V

Up to 3

About 4 hours with disposable batteries

About 8 hours with Ni-MH batteries (2000 mAh)

0.033% of Full Scale (1/3000)

Load cell cnnections

LC Tester side Load cell connections

Standard “B” type cable

Standard “A” type cable with 25 pin Sub-D connectors

LC’s excitation voltage input range

mV signal output range

Min: 3 Vdc Max: 15 Vdc

Min: -3.0 mV Max: +20.3 mV

Load cells impedance 350/700 Ωselection, or min. 300 to max. 4500 Ω setting.

LC Tester side PC or weight instrument

4

POWER SUPPLY AND BATTERIES REPLACEMENT

The Load Cell Tester is powered by “AA” size batteries :

Use four x 1.5 V Alkaline Disposable Batteries or 1.2 V Ni-MH Rechargeable Batteries

The battery life depends on the number of load cells being powered and the intensity level of the LCD display.

Min. consumption is about 125 mA (single 350 Ω load cell with display intensity at intermediate level).

Max. consumption is about 190 mA (four 350 Ω load cells with display intensity at maximum level).

The life of alkaline disposable batteries is about 4 hours in continuous operating mode*, at the max.

consumption.

The life of the Ni-MH rechargeable batteries depends on their capacity (expressed in mA per hour).

For example, with 4 x 2000 mAh batteries, the battery life is over 8 hours in continuous operating mode*, at

the max. consumption (2000 mAh/190 mA = 10,5 h).

Even though the theoretical limit exceeds 10 hours, the auto shut-off takes place sooner in order to assure

the full functionality of the Load Cell Tester and to avoid completely discharging the batteries.

*By “continuous operating mode” we mean that the Load Cell Tester switched-on continuously.

Setting the “auto shut-off” parameter will extend the battery life (see page 16 for additional information).

BATTERY REPLACEMENT

LC TESTER: Rear view

Remove the 3 screws indicated by the arrows

Gently raise side A of the cover and slide it out.

Replace the 4 batteries as required, observing

polarity as marked on the battery holder

(See figure below).

Reposition the cover in its seat

Replace the 3 screws

Side “A”

The manufacturer waives all responsibility for any damage to the Load Cell Tester

caused by the use of batteries other than those listed above.

+

-

+

-

+

-

+

-

5

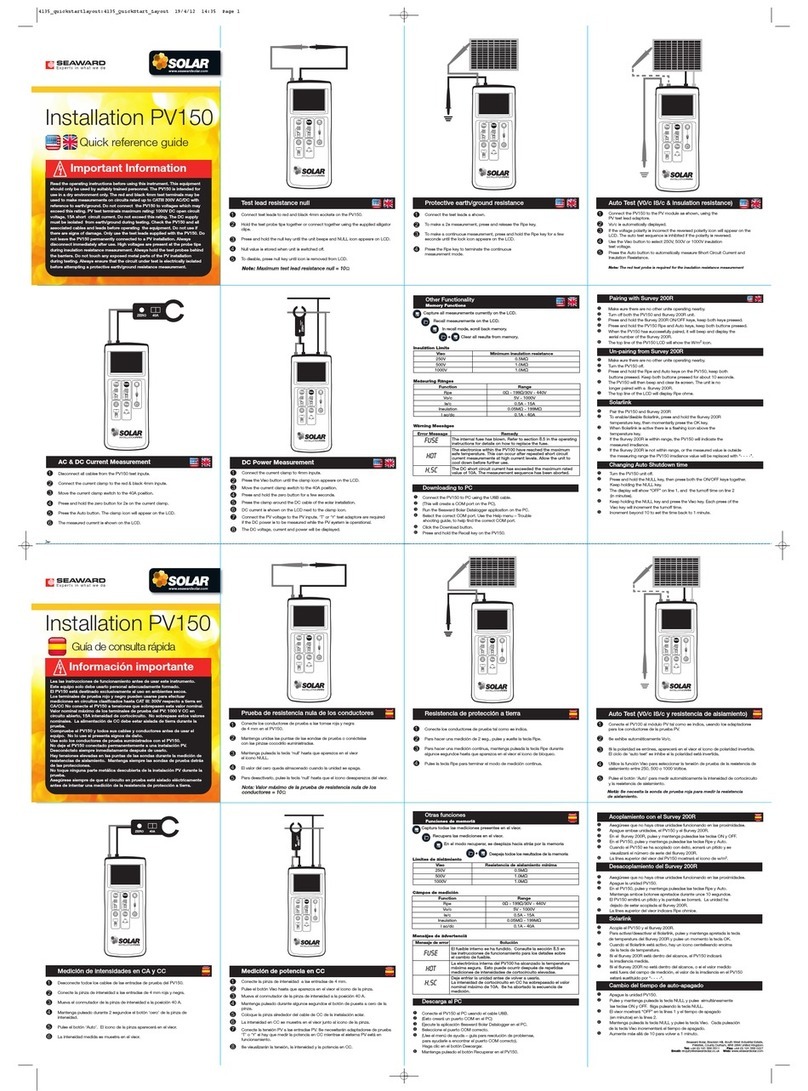

MAIN PERFORMANCES

Even if the 2 main functions performed by the Load Cell Tester are independent, they

allow to carry out the complete analysis of any weighing system composed by load cells (up

to 4) and weight indicator.

Function for testing the load cells

This mode is used to diagnosis the load cells.

The display shows the following group of parameters:

1. The signals coming from the load cells (mV/V values)

2. The distribution of the weight on the load cells (% values)

3. Load on each load cell compared with its nominal capacity (% values)

4. Weight value on each load cell (expressed in the selected measurement unit: g, kg,

Ton, lb, N, kN)

Values 3 and 4 are only displayed if the parameters described on pages 15 to 17 have been

programmed.

Faulty load cells or bad connections*, zero offset drifts or unstable signals can be easily

detected.

* These messages appear on the display in the following conditions:

1. “EXC +” indicates a problem with the + Excitation lead

2. “EXC -” indicates a problem with the - Excitation lead

3. “SIGNAL” indicates a problem with one of the Signal leads

Load Cells Peak Function

The 1006 Tester in this operating mode allows to view the peak values of each load cell.

The peak value cab be enabled or disabled, for all the 4 groups of parameters above

described by pressing long the key 5. To erase peak values detected, press key C.

Transducer Simulator / Calibrator Mode

In this mode the load cell tester is used to calibrate or check out the weight indicator.

A signal of up to 20 mV can be generated and used to check the linearity and to check or

calibrate the Zero and Span of any weighing instrument.

mV/V signal to instrument mV signal to instrument

% of output signal

Excitation from instrument Weight value

mV/V bar-graph (0 - 100%)

Transducer Simulator

Output Signal

+ 1.600mV/V + 7.920mV

V in +4.95

+ 80%

GW 800 kg

6

mV/V Input Signals

1 2

3 4

1.024 1.131

0.978 0.856

Test

Cal

Transducer Simulator

Output Signal

+ 1.600

mV/V + 7.920

mV

V in +4.95

+80%

GW 800 kg

Test

Cal

Test

Cal

Test

Cal

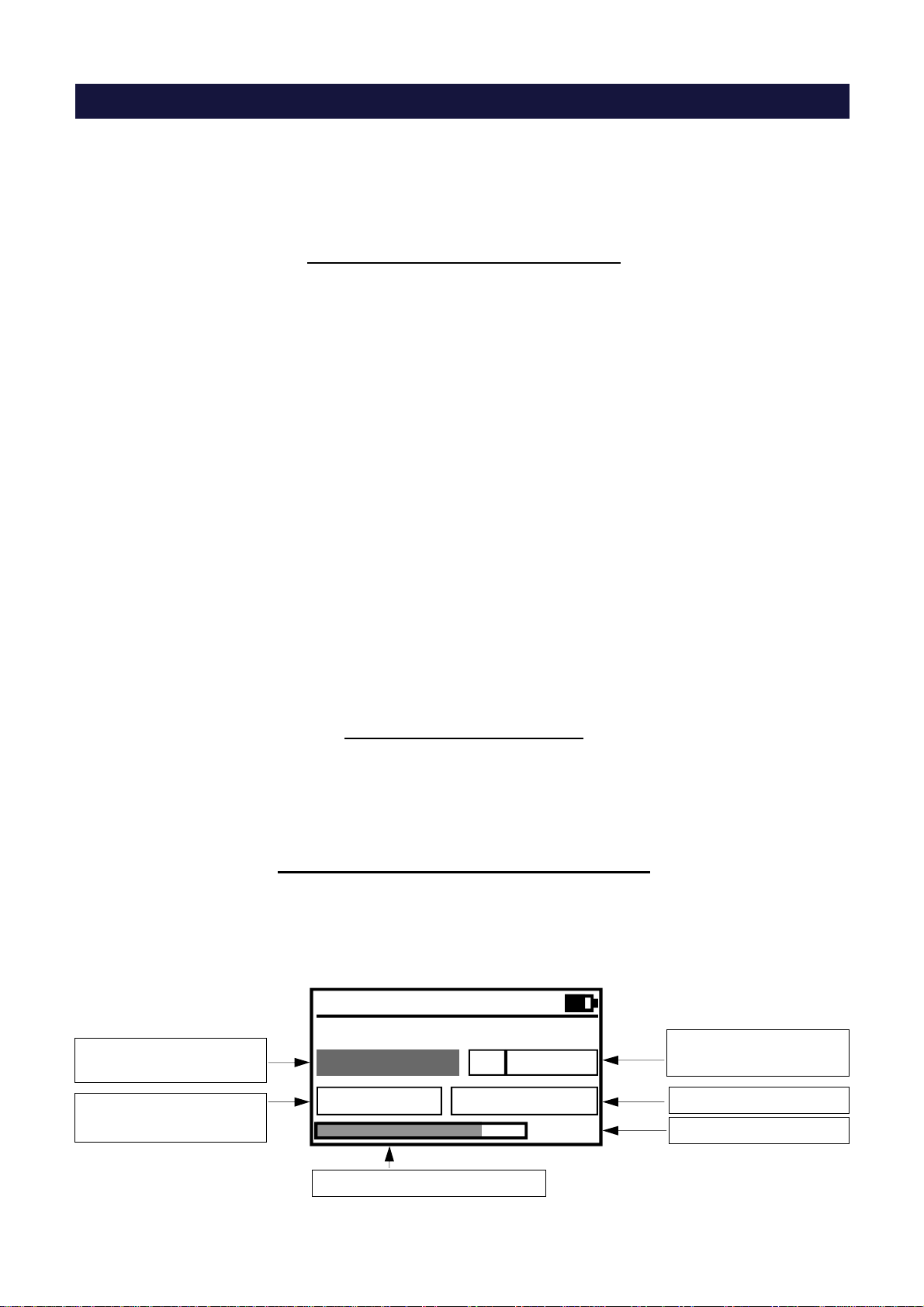

SWITCHING BETWEEN “LOAD CELL TESTER” AND “CALIBRATOR” MODES

Switching between the 2 functions (as described on the previous page) is performed by

pressing the Test/Cal key:

LOAD CELL TESTER

Function

Operating mode described on page 14

CALIBRATOR/SIMULATOR

Function

Oper. mode described on page 21, 22

To be used exclusively for testing

the load cells To be used exclusively for testing

and calibrating the weighing

instrument.

7

Cable “A”, terminates with a 25 pin female Sub-D connector and is supplied with the J1/PT Screw

Terminal Board.

CONNECTION TO THE LOAD CELLS with Cable “A”

L.C. 4

L.C. 1

L.C. 2

L.C. 3

L.C. 1

L.C. 2

L.C. 3

L.C. 4

CGS4/C CEM4/C

Connection using Cable “A” to CGS4/C

Connection using Cable “A” to CEM4/C

Connection using Cable “A” to CGS4/C junction Board

LC’s Tester side

LC’s Tester side

If the existing installation is equipped with model CGS4/C or model CEM4/C summing junction

board, only connect Cable “A” directly to the 25 pin Sub-D connector on the board, without using

the J1/PT Board.

LC’s Tester side

CGs

Cella 1

Cella 2

Cella 3

Cella 4

8

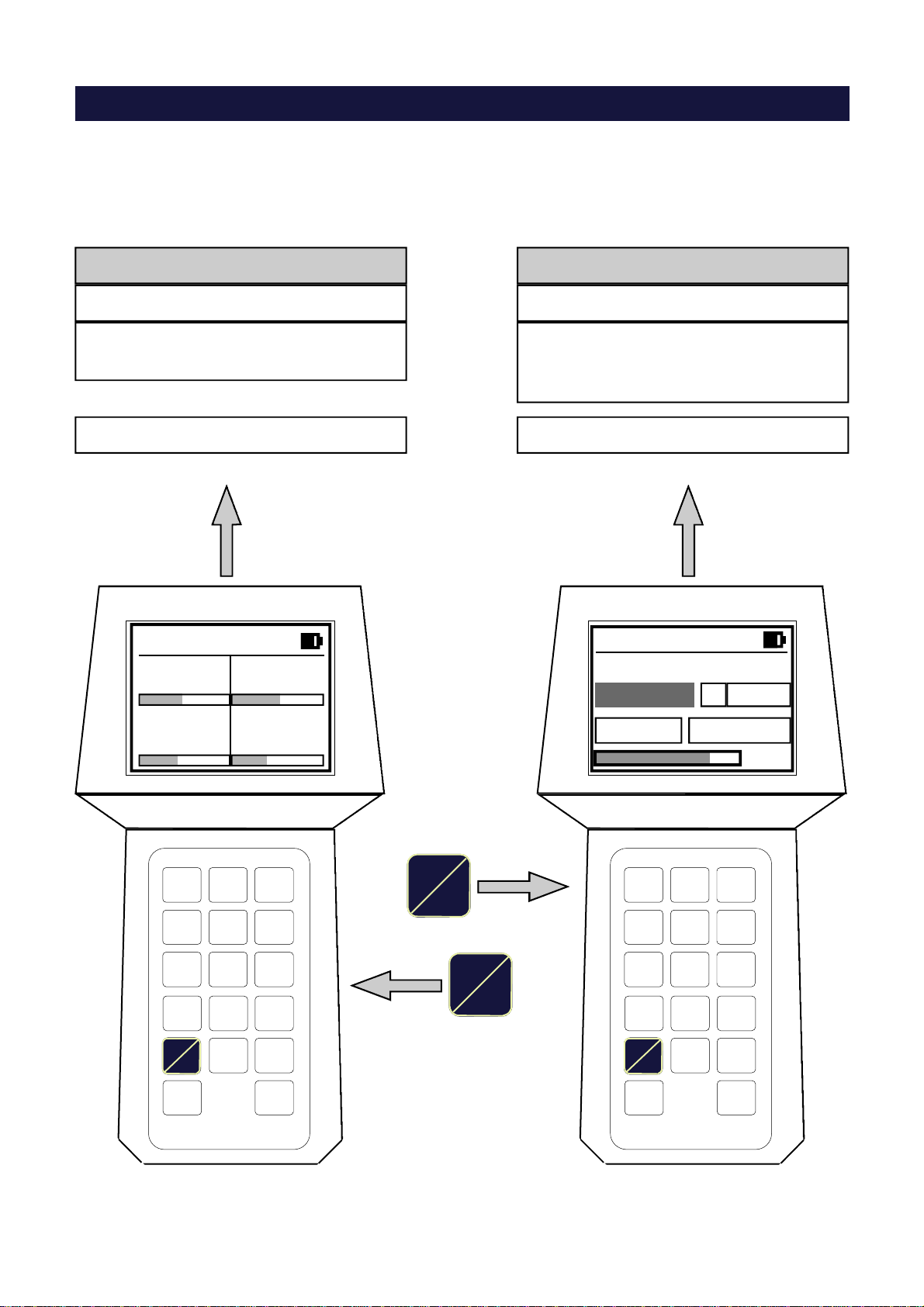

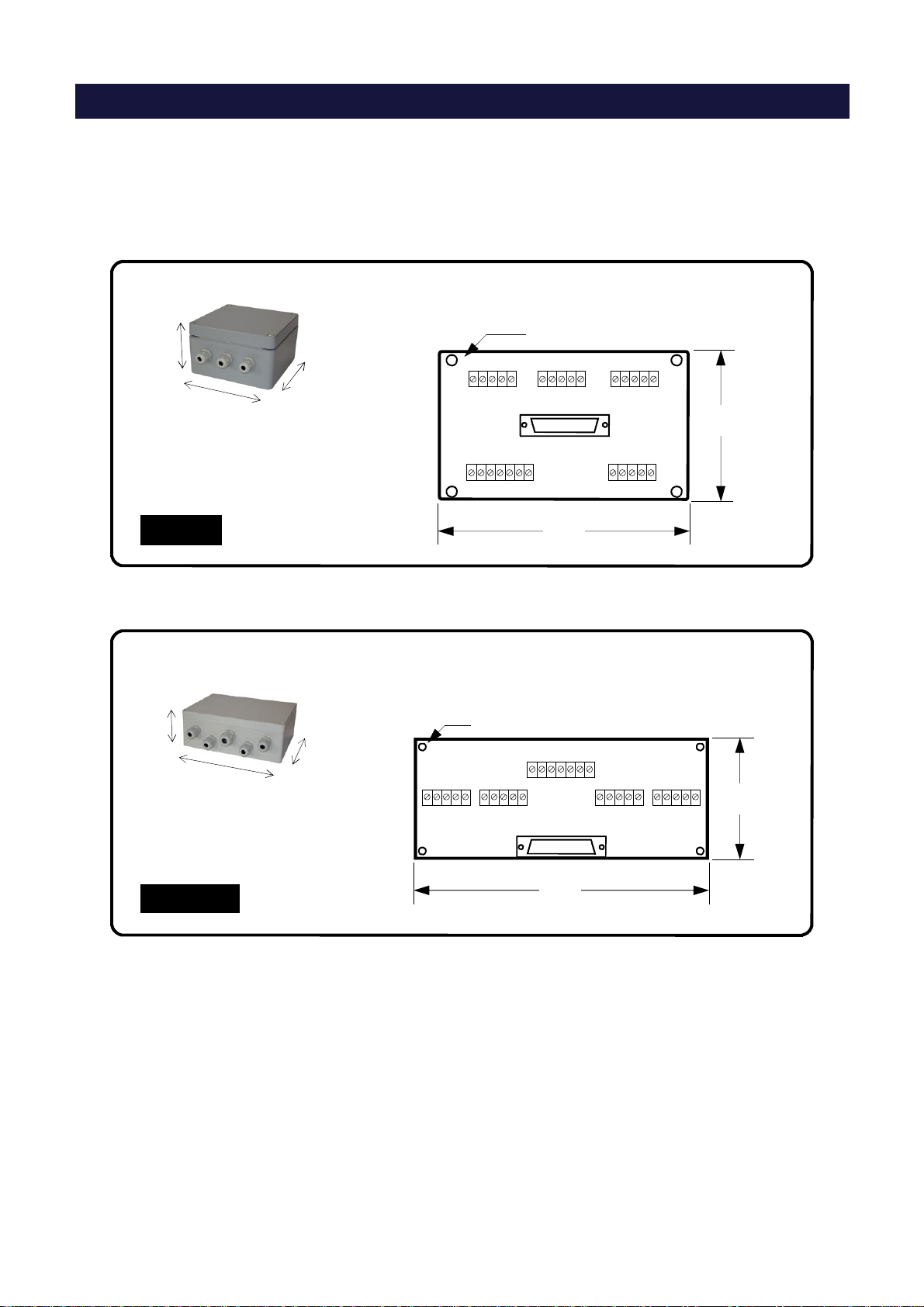

USING THE LOAD CELL TESTER IN “CALIBRATOR” MODE WITH J1/CB

USING THE LOAD CELL TESTER IN “CALIBRATOR” MODE WITH J2/CB BOARD

LC TESTER SIDE

Instrument to be

calibrated

888888

+ Excitation

- Excitation

+ Signal

- Signal

- Sense

+ Sense

INSTRUMENT SIDE

-Exc +Exc +Sns -Sns -Sig +Sig

The J2/CB Calibration Board, supplied with cable “B”,provides another

method of connecting to the weight indicator when using the load cell

tester in “Calibrator” mode. See above illustration for wiring connections.

LC TESTER SIDE

Load cell to be

checked

+ Alimentazione

- Alimentazione

+ Segnale

- Segnale

- Sense

+ Sense

INSTRUMENT SIDE

-Exc +Exc +Sns -Sns -Sig +Sig

The card J1/CB board, supplied with the cable "B", provided allows

the use of the tester for checking the load cell.

See above illustration for wiring connections

9

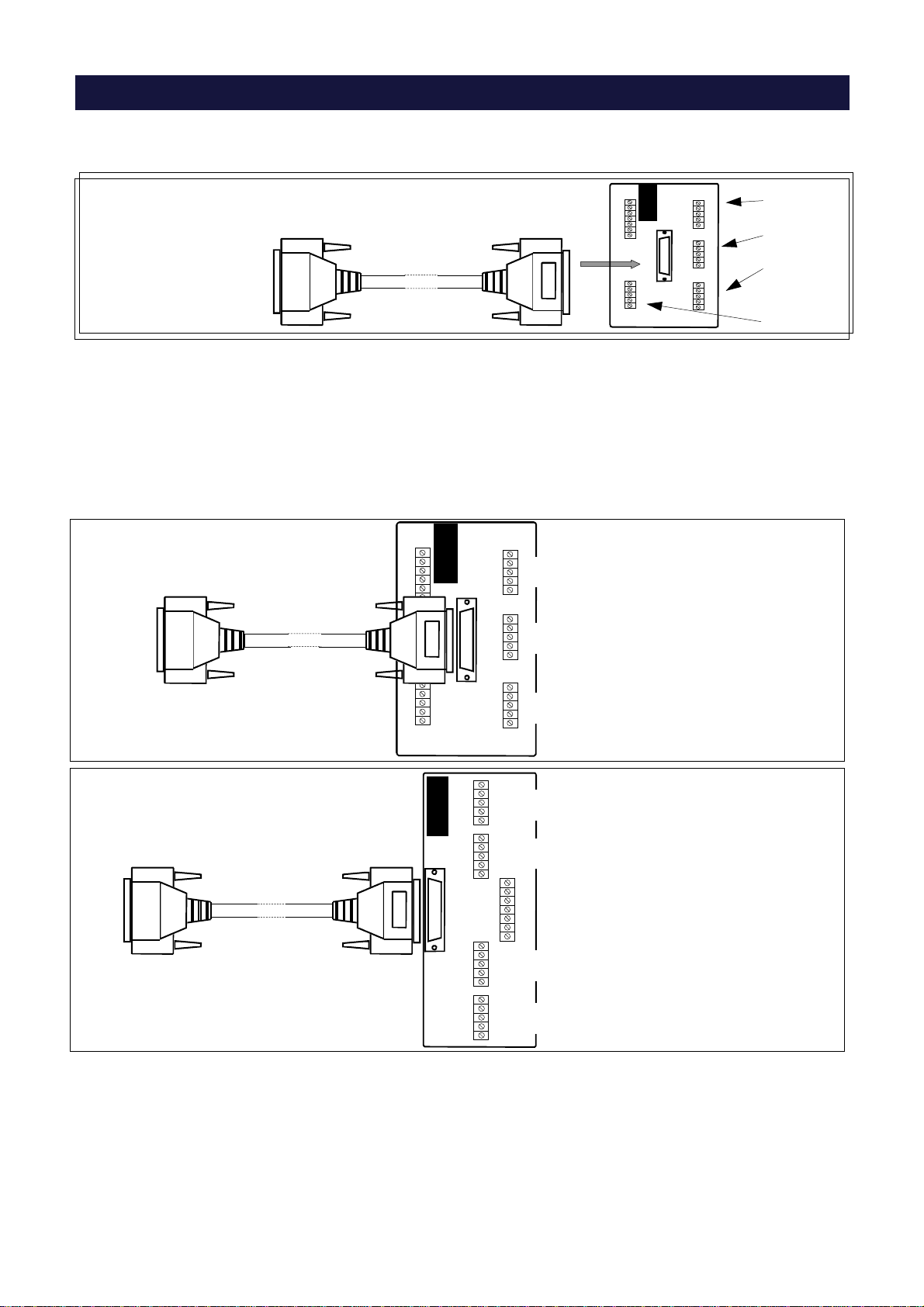

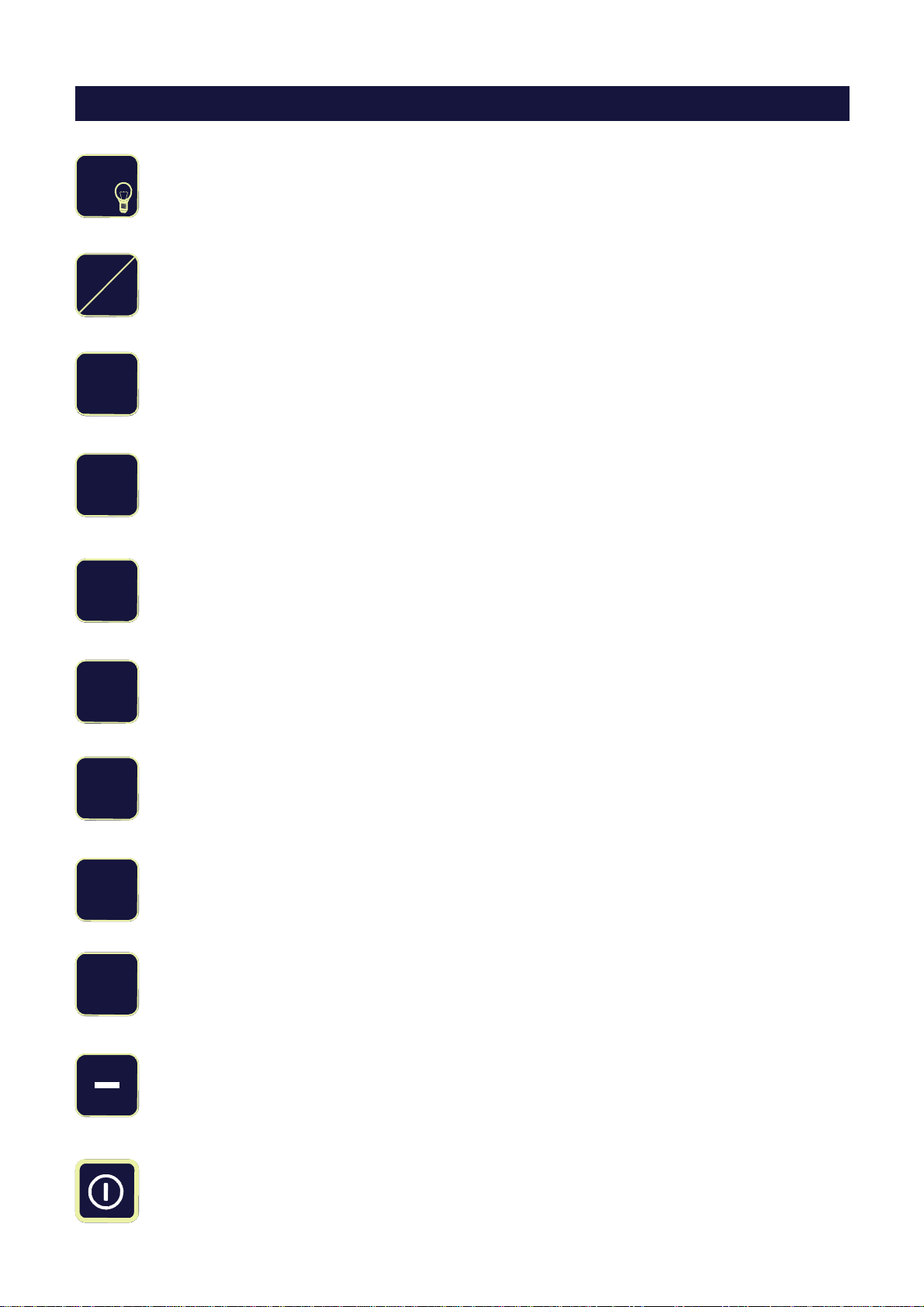

CGS4/C and CEM4/C SUMMING JUNCTION BOXES

The CGS4/C and CEM4/C summing junction boxes, are equipped with a 25 pin

Sub-D connector, which provides a quick reliable connection to the Model 1006

LC System Tester with standard Cable “A”.

In order to use the LC System Tester on weighing systems using summing

J-boxes other than the CGS4/C or CEM4/C, we are offering our customers

a free evaluation for installing a 25 pin Sub-D connector on their own summing

junction boards.

If you would like to take advantage of this offer, we would require detailed

drawings or a sample of the summing J-Boxes that you are currently using.

CGS4/C

CEM4/C

70

170

Ø 5

Box Dimensions

(mm)

87

146

Ø 6,5 Board Dimensions

(mm)

160

160

90

150

200

90

Box Dimensions

(mm)

Board Dimensions

(mm)

10

KEY FUNCTIONS IN OPERATING MODE

3

C .

Enter

0

Switch

view

+

Test

Cal

Display intensity adjustment (see page 20)

Switching between LOAD CELL TESTER and CALIBRATOR modes

Navigating through the various display views in LOAD CELL TESTER mode (see page 14)

Access to configuration menu

Short press: access to “WEIGHING PARAMETERS” (see page 15)

Long press: access to “ SETUP MENU” (see page 17)

Zero the weight value in CALIBRATOR mode (see page 21)

Erase the zero of the weight value in CALIBRATOR mode (see page 21)

Fine increment of the mV/V output signal in CALIBRATOR mode (see page 21)

Fine decrement of the mV/V output signal in CALIBRATOR mode (see page 21)

Switch-off

8

2Coarse increment (in 0.1 mV/V steps) of the output signal in CALIBRATOR mode (see page 21)

Coarse decrement (in 0.1 mV/V steps) of the output signal in CALIBRATOR mode (see page 21)

11

They take meaning of “Arrow up” and “Arrow down”.

They allow to select the previous/next parameter from a list of parameters proposed by

the instrument

8

2

6 Takes meaning of “Arrow right”.

Allows to access the parameter previously selected with Arrow up/down keys.

4

Sometimes the selection of a certain parameter is performed with these keys instead of

with the Arrow up/down keys.

The symbols +and —appear on the display to inform the Operator.

KEY FUNCTIONS WITHIN THE VARIOUS MENUS

Data Selection (from a list)

Takes meaning of “Arrow left”.

Exits the menu without saving the changes

Enter Exits the menu after saving the changes

+

Entering Numerical Data

90 ……

C .

Enter

Keys 0 to 9 are used to program all those parameters requiring numerical

values, such as the load cell capacity, etc.

This key performs 2 functions:

1. Used to insert a decimal point in numerical values.

2. Used to erase the data: Press momentarily to erase the last digit

Press slightly longer to erase all of the data

Confirm and quit the settings.

12

LC System Tester

Firmware: PMT401

Rev. 1.3

Number of Load Cells

1

Enter

Select

Confirm

2

3

4

Selection

Confirm

8

2

Enter

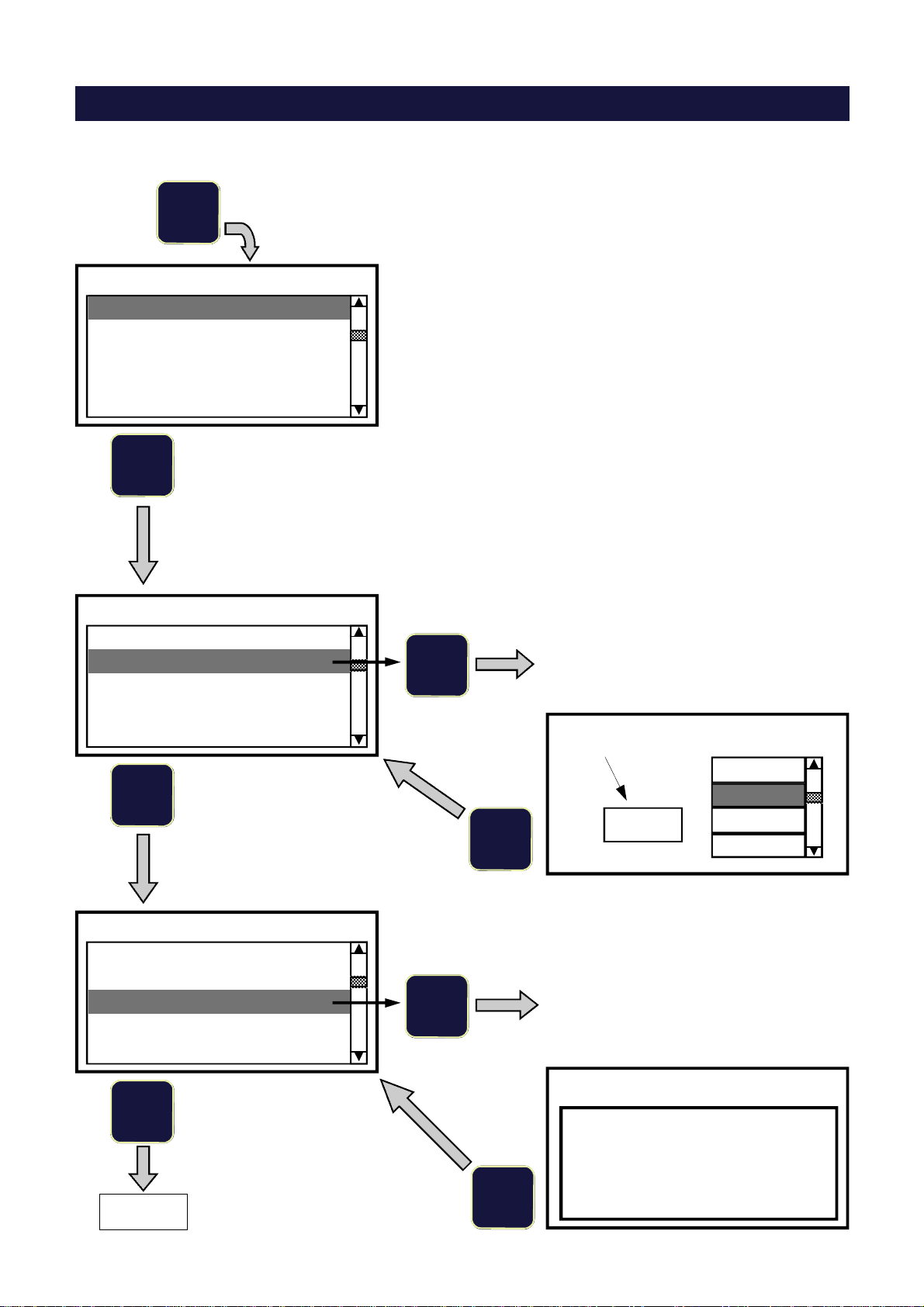

Power-ON:

POWER-ON SEQUENCE

LC’s impedance

Enter

Confirm

350

700

Ω

Ω

Ω

350

700

Enter

mV/V Input signals

1 2

3 4

1.024 1.131

0.978 0.856

Impedance value

1000

3

2

1 Enter

The value can be selected

between 350 and 700Ω, otherwise

it can be programmed by

choosing the empty box in the

lower part of the display.

Once the value has been set, the

LC Tester enters the Operating

Mode automatically.

8

2

Selection

Operating Mode

Enter

Min. programmable value: 300Ω

Max. programmable value: 4500Ω

Decimal values will be automatically rounded

to the lower integer value.

When powering-on the LC Tester the following parameters must be programmed:

Number of load cells - Load cells Impedance.

NOTE:

The firmware code and

the release number

appear on the display

for about 3 seconds:

In case the last switch-off of the LC Tester was caused

by the Auto Shut Off function (see page 18), the LC

Tester immediately resumes the Operating

Mode,without asking for the LC’s Number and

Impedance to be programmed.

The instrument’s memory will keep the stored values.

13

mV/V Input Signals

1 2

3 4

1.024 1.131

0.978 0.856

Weight Distribution

1 2

3 4

25.6 % 28.3 %

24.6 % 21.5 %

% of load on LC’s

1 2

3 4

51.2 % 56.6 %

49.2 % 43.0 %

Weight Values

1 2

3 4

128.0 141.5

123.0 107.5 Distribution of the weight on the load cells

Ideal distribution: 25% each LC

Individual mV/V values coming from the

load cells

Load on each load cell compared to its

nominal capacity

Weight value on each load cell. Expressed

in the selected unit of measurement.

NOTE: Display views 3(% of load on LC’s) and 4(Weight values) give significant values only if the load cell single

capacity and sensitivities have been programmed.

OPERATING MODE : DATA VISUALIZATION

Switch

view

1

2

3

4

During normal operation in Load Cell Tester mode (see page 6), the “SWITCH VIEW” key switches the display

among 4 different views.

Switch

view

Switch

view

Switch

view

14

8

“WEIGHING PARAMETERS” MENU

In Operating Mode:

Enter

Press

Unit of Measurement

Number of Load Cells

Load Cell Capacity

LC Sensitivity Values

Display Division Value

WEIGHING PARAMETERS

8

8

Unit of Measurement

Number of Load Cells

Load Cell Capacity

LC Sensitivity Values

Display Division Value

WEIGHING PARAMETERS

6 Measurement unit selection, with and .

The selected unit of measurement appears

in the box on the left of the screen.

Enter kg

Unit of Measurement

g

kg

Ton

lb

Unit of Measurement

Number of Load Cells

Load Cell Capacity

LC Sensitivity Values

Display Division Value

WEIGHING PARAMETERS

6 Enter the nominal capacity of a single load

cell.

The instrument automatically multiplies

the single load cell capacity by the

“Number of LC’s” being used.

Enter

Enter capacity

of a single LC

250 kg

Load Cell Capacity

Page 16

15

8

Unit of Measurement

Number of LC’s

Load Cell capacity

LC Sensitivity Values

Display Division Value

WEIGHING PARAMETERS

6

Setting the nominal sensitivity (in mV/V)

of each single load cell.

Take the data from the calibration

certificates or from the labels sticked on

the load cells.

Enter

2.0000 mV/V

2.0000 mV/V

2.0000 mV/V

2.0000 mV/V

L.C. 1

L.C. 2

L.C. 3

L.C. 4

LC Sensitivity Values

6

L.C. 1 mV/V

2.0108

LC Sensitivity Values

3

2

1

2.0108 mV/V

2.0000 mV/V

2.0000 mV/V

2.0000 mV/V

L.C. 1

L.C. 2

L.C. 3

L.C. 4

LC Sensitivity Values

8

6

L.C. 2 mV/V

2.0067

LC Sensitivity Values

3

2

1

Setting the nominal sensitivity of

LC 1

Setting the nominal sensitivity of

LC 2

Perform the same procedure for the remaining load cells

4

Page 17

16

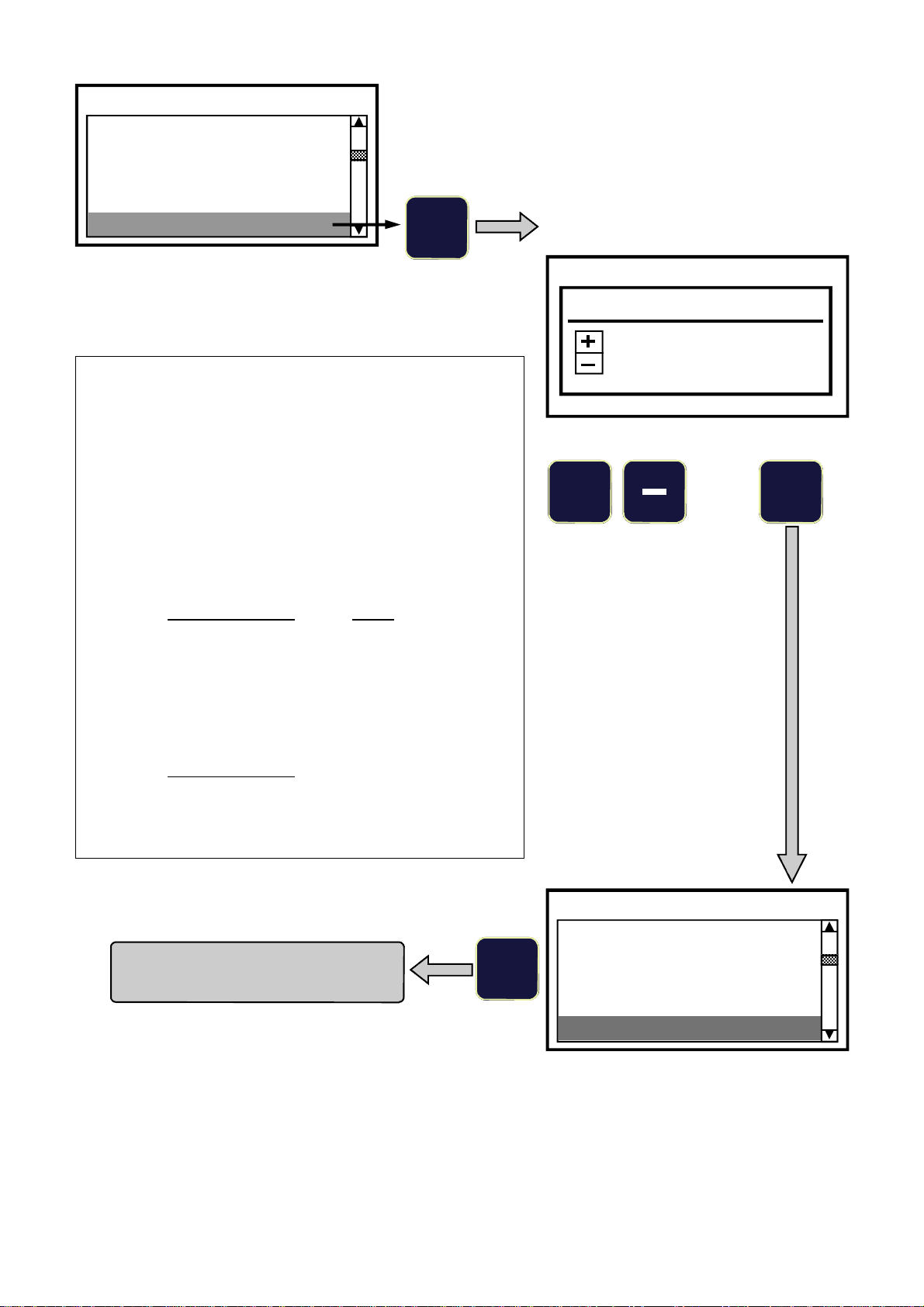

WEIGHING PARAMETERS

6 Selection of the Display division value

Display Division Value

0.1

The Display division value can be selected from a list (0.001 to

100, expressed in the measurement unit previously enabled).

The LC Tester automatically offers a value optimised to 10000

counts, based on the nominal capacity of the load cells (sum

of the load cell’s single capacities).

Example: Single LC capacity = 250

Number of load cells = 4

LC’s Total capacity (250 x 4) = 1000

The Display division value automatically offered by the LC

Tester will be: 0.1 given by the ratio:

LC’s Total capacity _1000_

10000 10000

However the User has the chance to modify this value (+ or -),

bearing in mind that the maximum number of counts can

be 50000.

Considering the example given here above, the ratio:

LC’s Total capacity

50000

equals 0.02.

This will be the minimum usable Display division value.

Enter

+

Selection Confirm

Unit of Measurement

Number of LC’s

Load Cell Capacity

LC Sensitivity Values

Display Division Value

WEIGHING PARAMETERS

4

Exits the menu and returns

to Operating Mode

Unit of Measurement

Number of LC’s

Load Cell Capacity

LC Sensitivity Values

Display Division Value

= 0.1

17

8

8

ADDITIONAL FUNCTIONS

In Operating Mode:

Enter

Press

and hold

Set Date (MM/DD/YYYY)

Auto Shut Off

Set Time

LCD Contrast

Baud Rate

SETUP MENU

5 MIN

Auto Shut Off

OFF

3 MIN

5 MIN

10 MIN

6

Enter

Automatic shut off time delay selection.

The selected value appears in the box on

the left of the screen.

The LC Tester switches off automatically if

no keys are pressed within the selected

time delay.

The countdown is restored if any of the

keys is pressed within the selected time

delay.

“OFF” = function disabled.

Page 19

LCD Contrast

575

SETUP MENU

6

Enter

LCD contrast adjustment.

+Adjustment

Set Date (MM/DD/YYYY)

Auto Shut Off

Set Time

LCD Contrast

Baud Rate

SETUP MENU

18

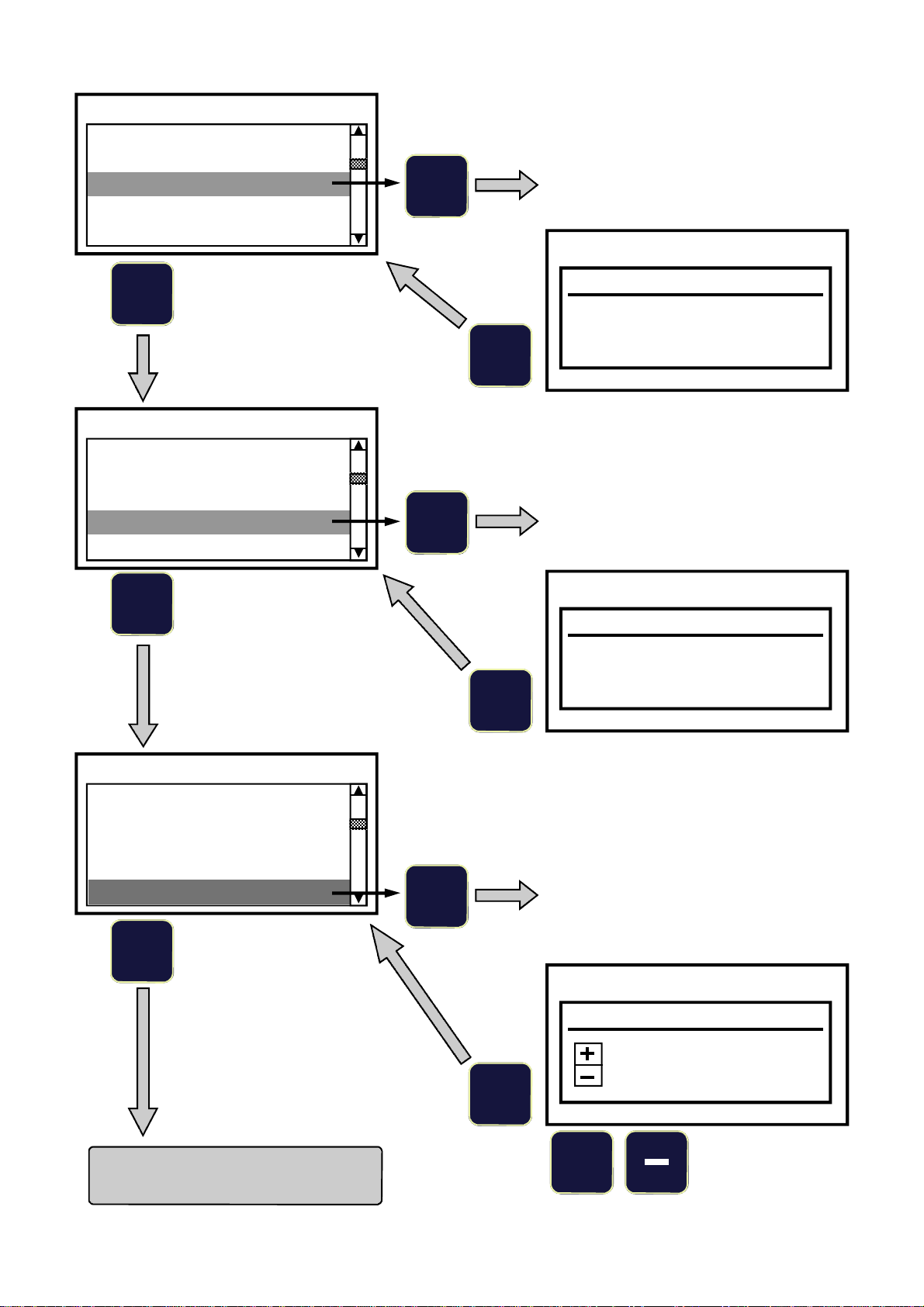

Set Time

16:45

SETUP MENU

6

Enter

Setting the Date

Max. values: 12 (month)

31 (day)

2050 (year)

6

Enter

Setting the Time

Max. values: 23 (hour)

59 (minutes)

8

8

Set Date (MM/DD/YYYY)

Auto Shut Off

Set Time

LCD Contrast

Baud Rate

SETUP MENU

Set Date (MM/DD/YYYY)

Auto Shut Off

Set Time

LCD Contrast

Baud Rate

SETUP MENU

RS-232 Baud Rate

9600

SETUP MENU

Set Date (MM/DD/YYYY)

Auto Shut Off

Set Time

LCD Contrast

Baud Rate

SETUP MENU

6

Enter

RS-232 baud rate selection.

List of values:

1200 - 2400 - 4800 - 9600 - 19200 -

38400 - 57600

+Selection

4

Exits the menu and returns

to Operating Mode

Set Date (MM/DD/YYYY)

09/20/2006

SETUP MENU

19

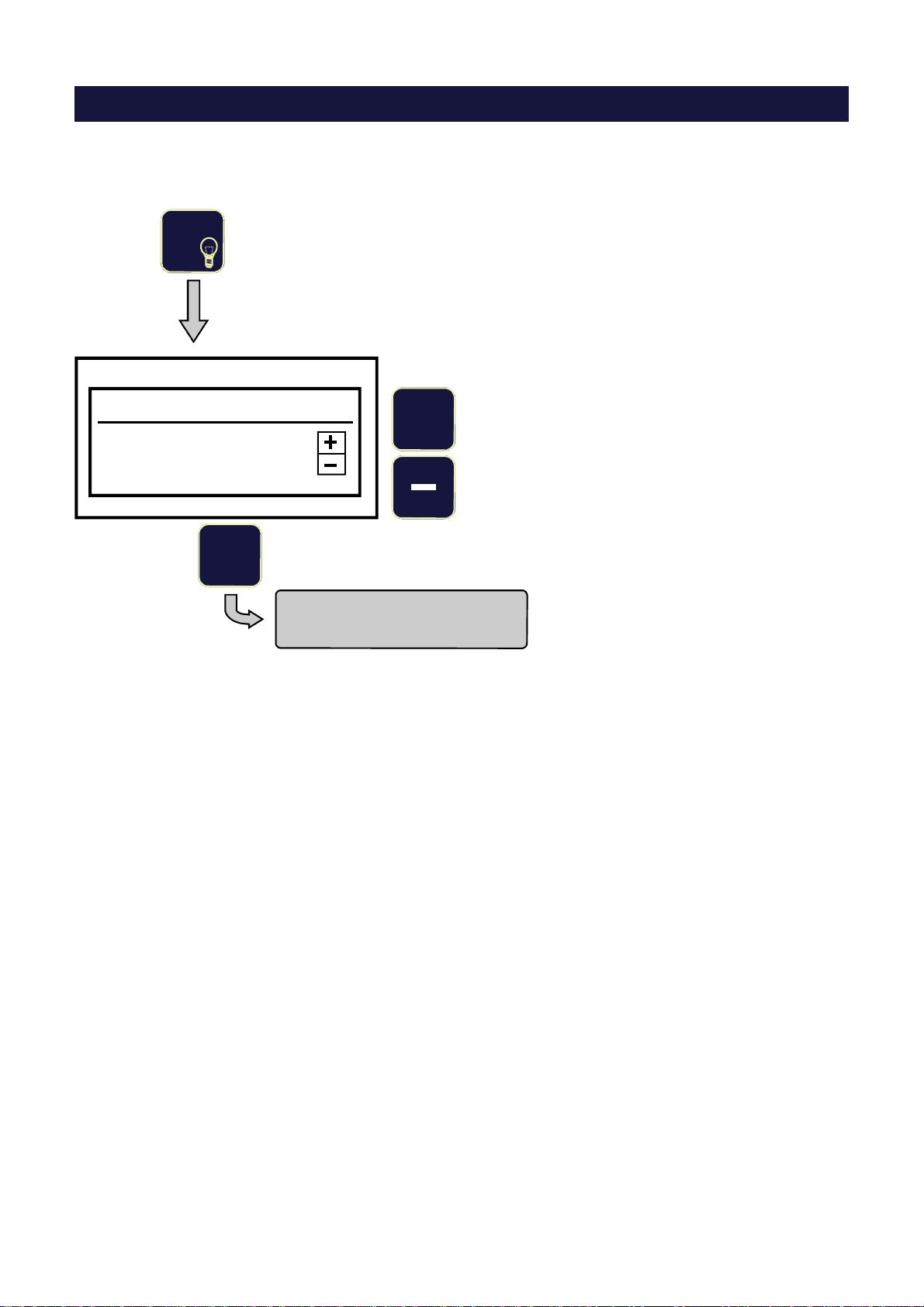

4

DISPLAY INTENSITY ADJUSTMENT

In Operating Mode:

Press 3

Display Intensity

+ / - keys to adjust

key to exit 5

Confirm and return to

Operating Mode

+Increases Intensity

Reduces Intensity

20

THE “CALIBRATOR” FUNCTION

How to enable the function:

Press Test

Cal Transducer Simulator

Output Signal

+ 1.600mV/V + 7.920mV

V in +4.95

+ 80%

GW 800 kg

Displayed data

+ 1.600mV/V

V in +4.95

+ 7.920mV

PL 900 kg

+ 80%

mV/V signal generated by the LC Tester and sent to the instrument.

The and keys allow to generate the signal output (in steps of 0.1 mV/V) over a

range from 0 to FS.

The mV/V Full Scale value corresponds to the average of the individual mV/V load cell

sensitivities programmed in the “WEIGHING PARAMETERS” menu. See page 16.

Load cells excitation voltage coming from the instrumentation.

mV signal generated by the LC Tester and sent to the instrument.

This value is the product of “mV/V” multiplied by “Vin”.

Weight value corresponding to the mV/V signal generated by the LC Tester.

The weight value is expressed in the preselected measurement unit and its Full Scale is

the product of “Single LC capacity” multiplied by “Number of LC’s”, programmed in the

“WEIGHING PARAMETERS” menu.

Percentage of signal output referred to the Full Scale.

Through this function the LC Tester acts as a mV generator, therefore it can be used as a load cell simulator

and/or calibrator for electronic weighing instruments, to check linearity, to check 0 and FS, to perform 0 and FS

calibration.

Refer to page 9 for wiring.

In order for the “CALIBRATOR” function to work correctly, the following parameters

“Number of LC’s”, “LC’s sensitivity” and “Single LC capacity” programmed in the LC Tester

must be the same as those programmed in the instrument to be controlled.

Example:

If the instrument to be controlled is normally connected to 4 load cells 250 kg each, 2 mV/V,

the LC Tester must have been programmed with the same data (see pages 15-17):

Number of LC’s = 4 - LC’s sensitivity = 2.0000 - Single LC capacity = 250.

Table of contents