ED&D LT-952HC User manual

PRODUCT SAFETY SOLUTIONS

USER’S MANUAL

LEAKAGE CURRENT TESTER

MODEL

LT-952HC

PRODUCT SAFETY SOLUTIONS

© 2017 Educated Design & Development, Inc. All rights reserved. Rev C

Page 1 of 19

Model LT-952HC MANUAL INDEX

Table of Contents

INTRODUCTION:..........................................................................................................................................2

Warnings: ..................................................................................................................................................2

Product purpose: .......................................................................................................................................2

Understanding Leakage Current................................................................................................................3

Before using: .............................................................................................................................................5

PRODUCT COMPONENTS:.........................................................................................................................6

PRODUCT SPECIFICATIONS:...................................................................................................................10

OPERATING INSTRUCTIONS: ..................................................................................................................11

THEORY OF OPERATION: ........................................................................................................................14

REFERENCE STANDARDS: ......................................................................................................................17

MAINTENANCE/STORAGE:.......................................................................................................................17

PARTS/SERVICE: ......................................................................................................................................17

Fuse locations: ........................................................................................................................................17

CALIBRATION: ...........................................................................................................................................18

LIMITED WARRANTY:................................................................................................................................19

CONTACT INFORMATION:........................................................................................................................19

IMPORTANT!

PLEASE READ THE ENTIRE MANUAL BEFORE USING THE

LT-952HC

PRODUCT SAFETY SOLUTIONS

© 2017 Educated Design & Development, Inc. All rights reserved. Rev C

Page 2 of 19

LEAKAGE CURRENT TESTER MODEL LT-952HC

IMPORTANT INSTRUCTIONS - RETAIN THESE INSTRUCTIONS FOR FUTURE REFERENCE

INTRODUCTION:

Thank you for choosing the ED&D LT-952HC. With proper use and care it will give many years of accurate

and reliable service. Upon receiving the unit please check for obvious physical damage to the packaging

material and the instrument itself. If any damage is evident, please immediately notify your ED&D

representative. We strongly recommend you keep all ED&D packaging for future shipping requirements.

Warnings:

CAUTION

CAUTION! LEAKAGE CURRENT TESTING IS INHERENTLY HAZARDOUS

RISK OF ELECTRIC SHOCK – KEEP HANDS AND FINGERS AWAY FROM ENERGIZED

COMPONENTS AT ALL TIMES

NO USER SERICEABLE PARTS INSIDE – SERVICING BY QUALIFIED SERVICE

PERSONNEL ONLY

Product purpose:

The LT-952HC leakage current tester is a state-of-the-art test instrument designed to measure leakage

current in accordance with national and international standards such as 60950, 60335, 6500, 61010, and

others based on IEC 60990.

LT-952HC is designed to make leakage current testing easy. Gone is the jumble of wires necessary to

simulate the prescribed test conditions. No more searching for an adequate meter to use. No more worries

about calibration or correlation with the testing agencies. The LT-952HC transforms what was once a one-

hour procedure into a quick and simple test.

Features that make the LT-952HC easy to use include:

PRODUCT SAFETY SOLUTIONS

© 2017 Educated Design & Development, Inc. All rights reserved. Rev C

Page 3 of 19

Built-in 3 1/2-digit LCD meter that measures the true RMS value of leakage current. True RMS is

especially important in products where the leakage current is non-sinusoidal as is possible with switch-

mode power supplies and products that use them.

The LT-952HC is designed to test any single-phase product rated 100-120 or 200-240 Volts that

requires 30 Amps or less current.

True 30 Amp open neutral, open ground, and line polarity (forward/reverse) test conditions.

120V front panel receptacle provides quick access for testing 120V products at up to 20 Amps. The 30

Amp rear panel receptacle allows easy connection to any product rated 100-120V or 200-240V at up to

30 Amps, with any plug configuration, using the appropriate adapter cord set.

Front panel access to the internal meter circuit to measure leakage from surface-to-surface or surface-

to-ground as required by many Safety Standards.

Rear panel jacks provide access to the Body Circuit Impedance to observe the wave shape of the

leakage current or to connect a second meter.

The ability to measure the leakage current of a product through the ground wire of the product's power

cord.

Reference to the meter circuit can be easily switched between Line, Neutral, and Ground as required

by the applicable Standard(s).

Understanding Leakage Current

A. What Is Leakage Current?

Leakage Current is the amount of current "filtered" to the grounding conductor by filtering components as well

as current that leaks through insulating materials. When a product is properly bonded to ground, the leakage

current will ideally follow this path to ground. However, if the product is not grounded or is improperly

grounded, a person contacting the product may become the path of least resistance. If this occurs, the human

body becomes the path for the leakage current with the result being dependent upon the level of the current

and the person in question.

PRODUCT SAFETY SOLUTIONS

© 2017 Educated Design & Development, Inc. All rights reserved. Rev C

Page 4 of 19

B. How Is Leakage Current Measured?

To measure leakage current, the scenario described above must be simulated. The worst case exists when

the human body is the sole path for the leakage current. Therefore, when conducting this test the product is

energized with the grounding conductor disconnected, and all other possible ground paths isolated.

A meter representing the human body (Body Impedance Model) is then connected between the grounding

conductor of the product (or the enclosure) and the grounded conductor of the power system (neutral). The

grounded conductor is used rather than earth ground for several reasons including reliability/repeatability of

the test. (Distance from the ground point and other ground currents could affect the test). Some Standards

also require referencing both hot and neutral to simulate polarity reversal.

NOTE: In some field testing situations, where the product is reliably connected to ground through the

building structure (i.e. mounted to a grounded pad, or connected to grounded water pipes, etc.), it may be

appropriate to measure the leakage current in the grounding conductor or from any exposed surfaces to

ground. (Refer to “Field Testing Grounded Products”, Chapter 2, for additional details.)

During this test, the unit is energized and any switches within the product controlling primary power (and likely

to be operated in normal use) are opened and closed in all possible combinations. Since the amount of

leakage current is proportional to the supply voltage, this test is typically done at the product's maximum rated

input voltage.

C. The Human Body Model

As previously indicated, a meter with precision impedance correlating to the impedance of the human body

is used to represent the human body. Extensive tests have been done to approximate the impedance of the

human body. These tests have shown that in different environments, with the user subjected to different

physical situations, the body impedance differs. On average, the human body impedance is equivalent to

1500 ohms shunted by a 0.15 µF capacitor.

It should be noted that most of the body impedance is a result of skin resistance. Therefore, in cases where

a person’s skin is likely to be cut (such as in a hospital), the human body resistance model may be different.

Similarly, moisture lowers the skin resistance. Most Standards deal with these issues by lowering the leakage

current limit for hand held products and products that may be exposed to moisture. Furthermore, it has been

proven that the perception to shock (threshold of perception) is directly related to frequency and therefore,

different body impedance models may be used when testing products whose leakage current contains

significant high frequency leakage.

D. Leakage Current Limits

The limits for leakage current vary among Standards. Depending upon the environment the product is being

used in and assumptions concerning the user, different limits may be imposed. These limits are not only

imposed to reduce the risk of shock, but also to minimize the possibility of reaction by the intended user. This

is important to emphasize because many assume the limits are only imposed to minimize injury from electric

shock. Although currents in the low milliampere range can cause injury or death in children and some adults,

they can also cause involuntary reactions that cause injury. In other words, a person may touch a product

and receive an unexpected shock which, in itself, does not cause injury, but instead causes the individual to

react in a manner that results in injury.

PRODUCT SAFETY SOLUTIONS

© 2017 Educated Design & Development, Inc. All rights reserved. Rev C

Page 5 of 19

Before using:

•Read the entire manual before attempting to use the Leakage Tester.

•Operation and use of the LT-952HC is to be performed by Qualified Personnel ONLY.

•WARNING: Person(s) using this device should have proper education/training in its use.

•CAUTION: Be aware that there are no user serviceable parts. Do not open any product enclosure.

Return unit to ED&D for servicing.

PRODUCT SAFETY SOLUTIONS

© 2017 Educated Design & Development, Inc. All rights reserved. Rev C

Page 6 of 19

PRODUCT COMPONENTS:

I. Figure 1 - Front Panel

A. Neutral Open / Closed Switch

B. Line Forward / Reverse Switch

C. Ground Open / Closed Switch

D. LCD Display

E. Power On / Off Switch

F. D.U.T. (Device Under Test) Receptacle

G. Open / Closed Ground Indicator Lights

H. Meter Connection Jacks

I. Range Selector Switch

J. Meter Reference Switch

K. Meter Connection Switch

A

B

C

D

E

F

G

H

J

K

I

PRODUCT SAFETY SOLUTIONS

© 2017 Educated Design & Development, Inc. All rights reserved. Rev C

Page 7 of 19

PRODUCT COMPONENTS: (Continued)

A. NEUTRAL SWITCH: Controls the connection of the incoming neutral line to the product under test.

This switch allows the neutral to be disconnected as called for in some Standards. With 240 Volt

operations, this switch disconnects one side of the 240 Volt line (Line 2).

B. LINE SWITCH: Controls the connection of the incoming line and neutral conductors to the product

under test. This switch allows the line and neutral polarity to be reversed as called for in some

Standards. With 240 Volt operations, this switch swaps both sides of the 240 Volt line.

C. GROUND SWITCH: Controls the connection of the incoming ground line to the product under test.

This switch allows the grounding conductor of the product under test to be disconnected as called

for in most Standards. The red Ground Open light illuminates signaling the potential for danger that

exists when the product ground is disconnected. The momentary Ground Switch must be toggled to

“OPEN” in order to isolate the ground at the D.U.T. output receptacles.

D. METER DISPLAY: 3 1/2-digit LCD display that measures the true RMS value of leakage current.

E. POWER SWITCH: This switch controls power to the internal circuitry of the LT-952HC only. When

the switch is ON, the meter display should be visible and the green Ground Closed lamp should be

lit. For safety, the LT-952HC is designed to disable both the front and rear panel outlets when the

power switch is OFF.

F. D.U.T. OUTLET: Provides a convenient way to connect 120 Volt, 15 Amp products to the LT-952HC.

There is no need for a rear panel cord-set adapter. For safety, this outlet is disabled when the LT-

952HC is set for 240 Volt operation.

G. GROUND INDICATORS: The Open Ground and Closed Ground indicators continuously display the

state of the grounding conductor to the product under test. The Open Ground indicator is colored

red to signal possible danger in that the product's safety ground has been defeated. The green

Closed Ground indicator signals that the grounding conductor to the product under test is intact.

H. METER CONNECTION BANANA JACKS: Allows external connection to the meter measurement

circuit as described under “Meter Connection Switch”

I. METER RANGE SELECTOR SWITCH: This Switch controls the sensitivity of the internal meter

circuit. The meter can be set to either 0-2 or 0-20 mA full-scale range.

J. METER SELECTOR SWITCH: Controls the connection of the meter measurement circuit to the

product under test in the following manner:

Surface-To-Surface - This selection connects both sides of the meter measurement circuit to the front panel

banana jacks. Leads connected to these jacks are used for measuring the leakage between any two

surfaces on the product under test.

Device Under Test Ground - This selection connects the device under test ground to one side of the meter

measurement circuit. The other side of the meter measurement circuit is connected to the meter reference.

PRODUCT SAFETY SOLUTIONS

© 2017 Educated Design & Development, Inc. All rights reserved. Rev C

Page 8 of 19

The momentary Ground Switch must be toggled to “OPEN” while making measurements to complete the

connection. This setting is used to measure leakage via the product's supply cord grounding lead.

Surface To Reference - This selection connects one side of the meter measurement circuit to one of the

front panel banana jacks for connection to the measurement surface. The other side of the meter

measurement circuit is connected to the meter reference. This connection is used to measure the leakage

between an exposed metal surface and the meter reference point.

PRODUCT COMPONENTS: Rear Panel

WARNING!

– Hazardous Voltage exists at the banana jacks when the Meter Reference Switch is set to

Line and the LT-952HC is set for 115 Volt operation. Hazardous Voltage also exits at the banana jacks

when the Meter Reference Switch is set to Line or Neutral and the LT-952HC is set for 230 Volt operation.

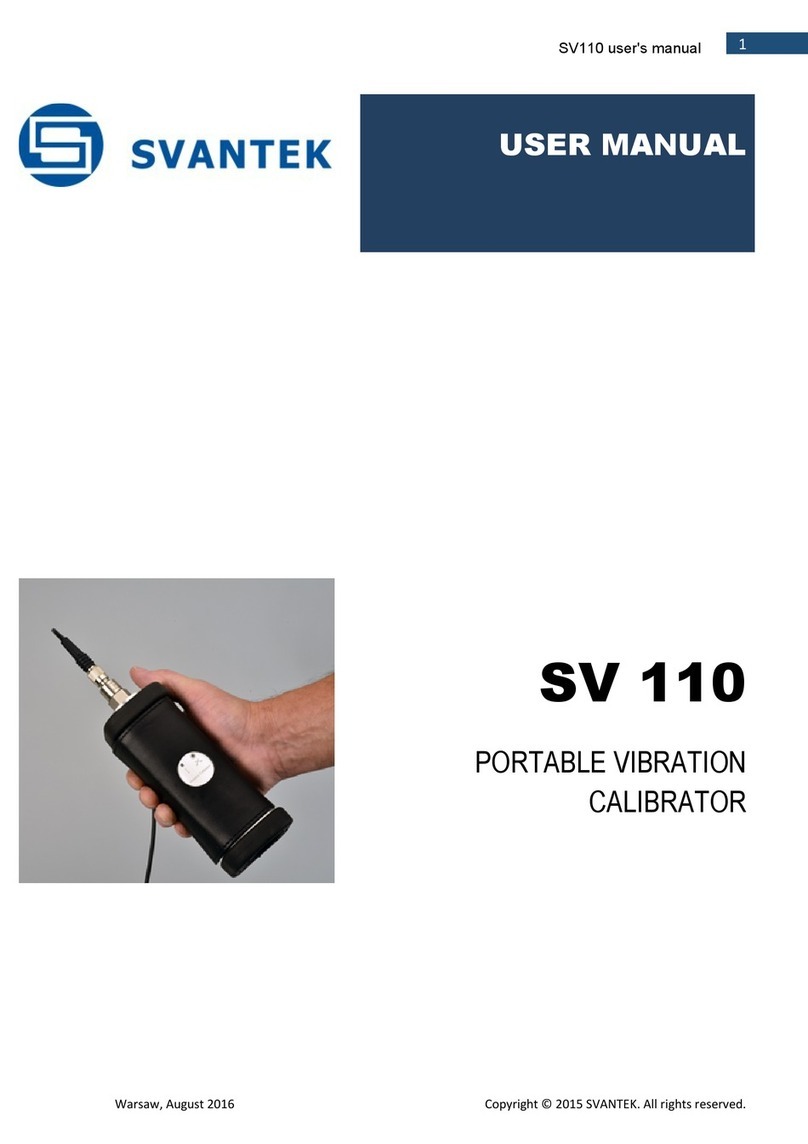

II. Figure 2 – Rear Panel

A. External Meter Jacks

B. D.U.T. (Device Under Test) Output

C. 115 / 240 VAC Selector Switch

D. Input Power Connection

E. Meter Fuse Holder

F. Line Fuse Holder

E

A

B

C

D

F

PRODUCT SAFETY SOLUTIONS

© 2017 Educated Design & Development, Inc. All rights reserved. Rev C

Page 9 of 19

PRODUCT COMPONENTS: (Continued)

A. EXTERNAL METER JACKS – These banana jacks allow direct access to the Body Impedance Network.

This is used for connecting an external meter or for observing the wave shape of the leakage current

with a scope.

WARNING! –

Because these terminals are connected to the Body Impedance Network, hazardous

voltages may exist on one or both jacks.

WARNING! –

Any external equipment connected to these jacks must be electrically isolated from the

AC line. Failure to do so can result in damage to the LT-601HC or the connected equipment.

CAUTION!

- The line 1 (Hot) conductor of the rear panel D.U.T. output connector is energized at all

times when the LT-952HC is connected to a power source!

B. VOLTAGE SELECT SWITCH – This switch configures the LT-952HC to run off either

100-120 or 200-240 VAC. The switch must be set to the proper position before

power is applied to the LT-952HC.

C. D.U.T. INPUT CONNECTOR - This standard NEMA L6-30 twist-lock connector is

designed to connect the LT-952HC to the product under test. This is normally used

for products requiring 200-240 Volts or more than 20 Amps at 100-120 Volts.

Connection can be made to any plug configuration by using the appropriate cord-set.

D. METER FUSE – The meter fuse is designed to protect the LT-952HC’s sensitive

meter measurement circuit from damage in cases of overload.

E. LINE FUSE – The line fuse protects the LT-952HC from power surges and from

inadvertent connection to a 240 Volt source when the Voltage Selector Switch is set

to 115 Volts.

F. LINE FUSE – The line fuse protects the LT-952HC from power surges and from

inadvertent connection to a 240 Volt source when the Voltage Selector Switch is set

to 115 Volts.

PRODUCT SAFETY SOLUTIONS

© 2017 Educated Design & Development, Inc. All rights reserved. Rev C

Page 10 of 19

PRODUCT SPECIFICATIONS:

Operating Ranges:

Range Resolution Accuracy

0 – 2 mA 1 µA 1%

0 – 20 mA 0.01 mA 1%

Input Ratings: Voltage Amperes Frequency

100 – 120 VAC 30 A 50 / 60 Hz

200 – 240 VAC 30 A 50 / 60 Hz

Body Circuit Impedance:

2000 Ω±20 Ω

Output Ratings: Same as Input ratings

Testing Tolerance: 90-132 / 180-264 VAC

Display: 3-1/2 Digit LCD display

Power Connection: Certified power supply cord with integral plug

Environmental Ratings: Operating Temperature: 0°C to 50°C.

Storage Temperature: –40°C to 70°C.

Humidity: 80% R.H., 0°C to 35°C

Overall Dimensions: 11-1/2 in. W x 13-1/2 in. D x 5-1/4 H in. (29.2 cm W

x 34.3 cm D x 13.33 cm H) Overall Weight: 9.0 lb

(4.0 Kg)

Body Circuit: Precision network in accordance with UL 2950 /

CSA 950 (Bi-National Standard), IEC60950 2

nd

edition w/ amendments 1&2, and EN60950 2

nd

edition w/ amendments 1&2.

Measurement Method: True RMS Responding Meter

Meter Measurement Reference:

Neutral @ 115 VAC

Ground @ 230 VAC

Meter Connection Selector Switch: Allows the meter measurement point to be selected

as either:

Through product’s power cord grounding

conductor

From an exposed surface to the meter

reference point

Between two exposed surfaces

Frequency Response of the Meter: The LT-952HC measures cumulative leakage

current from all frequencies up to and including

1MHz.

PRODUCT SAFETY SOLUTIONS

© 2017 Educated Design & Development, Inc. All rights reserved. Rev C

Page 11 of 19

OPERATING INSTRUCTIONS:

This chapter explains the proper use of the LT-952HC. This includes instructions on how to perform

leakage measurements through the product under test’s power cord grounding conductor and measuring

leakage current from surface to ground or neutral and between surfaces. All of these tests generally need

to be run to test compliance with IEC60950. As such, they assume the product is completely isolated from

ground. Finally, this chapter will show how to measure leakage current in field-testing situations where the

product cannot be isolated from ground.

For these examples, assume that the product under test is a 120 Volt cord-connected piece of equipment

that is being tested for compliance. Please refer to

IEC60950

for complete testing specifics.

Measuring Through the D.U.T. Power Cord Ground

1. Isolate the product under test from ground. This can be accomplished by placing the product on a rubber

pad or other suitable insulator. This may also include disconnecting any accessory cables connected to the

product under test (i.e. a shielded monitor or printer cable).

2. To verify that there are no other grounds to the equipment under test, connect an ohmmeter between the

ground pin on the product under test and the power system ground. Readings of close to 0 Ohms indicate

the presence of an extraneous ground that needs to be removed. This step can probably be omitted for

simple test setups. The only penalty for an extraneous ground may be a blown meter fuse in the LT-

952HC.

3. Secure the work area so that you or another person cannot accidentally come into contact with the

product during the test. Since the product ground is disconnected while the Ground switch is toggled

OPEN, the product under test poses a potential shock hazard.

4. Set the controls on the LT-952HC as follows:

Voltage selector 115

Power OFF

Neutral CLOSED

Line FORWARD

Meter Connection D.U.T. GROUND

Range 20mA

5. Connect the product under test to the front panel receptacle. Make sure that the product under test’s

power switch is ON.

6. Turn the Power switch of the LT-952HC to ON. Observe that the leakage indicated on the LT-952HC is

ZERO. This is normal as the leakage current is flowing through the still connected product ground.

7. To measure leakage, depress and hold the Ground switch to the OPEN position. Within a few seconds,

the display on the LT-952HC should settle to the final leakage current value. If the displayed result is less

than 20mA, change the Range switch to the 2mA position.

PRODUCT SAFETY SOLUTIONS

© 2017 Educated Design & Development, Inc. All rights reserved. Rev C

Page 12 of 19

OPERATING INSTRUCTIONS: (Continued)

8. IEC60950 specifies that the measurement taken in step 7 be repeated for each position of the product’s

power switch and with all combinations of the “Neutral” and “Line” switches on the LT-952HC. Be sure to

release the Ground switch before changing any of the test conditions (Line or Neutral switches) or before

contacting the device under test. Failure to do this will result in blown meter fuses on the LT-952HC.

Surface to Reference Leakage Measurement Procedure

1. Isolate the product under test from ground. This can be accomplished by placing the product on a rubber

pad or other suitable insulator. This may also include disconnecting any accessory cables connected to the

product under test (i.e. a shielded monitor or printer cable).

2. To verify that there are no other grounds to the equipment under test, connect an ohmmeter between the

ground pin on the product under test and the power system ground. Readings of close to 0 Ohms indicate

the presence of an extraneous ground that needs to be removed. This step can probably be omitted for

simple test setups. The only penalty for an extraneous ground may be a blown meter fuse in the LT-

952HC.

3. Secure the work area so that you or another person cannot accidentally come into contact with the

product during the test. Since the product ground is disconnected while the Ground switch is toggled

OPEN, the product under test poses a potential shock hazard.

4. Set the controls on the LT-952HC as follows:

Voltage selector 115

Power OFF

Neutral CLOSED

Line FORWARD

Meter Connection SURFACE TO REFERENCE

Range 20mA

5. Connect the product under test to the front panel receptacle. Make sure that the product under test’s

power switch is ON.

6. Set the Power switch of the LT-952HC to ON. Observe that the leakage indicated on the LT-952HC is

ZERO. This is normal as the leakage current is flowing through the still connected product ground.

7. Connect a test lead from the right front panel banana jack on the LT-952HC to the surface to be tested on

the product.

8. To measure the true leakage, depress and hold the Ground switch to the OPEN position. Within a few

seconds, the display on the LT-952HC should settle to the final leakage current value. If the displayed

result is less than 20mA operate the Range switch to the 2mA position.

9. IEC60950 specifies that the measurement taken in step 8 be repeated for each position of the products

power switch and with all combinations of the Neutral and Line switches on the LT-952HC. Be sure to

release the Ground switch before changing any of the test conditions (Line or Neutral switches) or before

contacting the device under test. Failure to do this will result in blown meter fuses on the LT-952HC.

PRODUCT SAFETY SOLUTIONS

© 2017 Educated Design & Development, Inc. All rights reserved. Rev C

Page 13 of 19

OPERATING INSTRUCTIONS: (Continued)

Surface to Surface Leakage Measurement Procedure

1. Isolate the product under test from ground. This can be accomplished by placing the product on a rubber

pad or other suitable insulator. This may also include disconnecting any accessory cables connected to the

product under test

2 Secure the work area so that you or another person cannot accidentally come into contact with the

product during the test. Since the product ground is disconnected while the Ground switch is toggled

OPEN, the product under test poses a potential shock hazard.

3. Set the controls on the LT-952HC as follows:

Voltage selector 115

Power OFF

Neutral CLOSED

Line FORWARD

Meter Connection SURFACE TO SURFACE

Range 200mA

4. Set the Power switch of the LT-952HC to ON.

5. Connect the product under test to the front panel receptacle. Make sure that the product under test’s

power switch is ON.

6. Connect the test leads from the front panel banana jacks on the LT-952HC to the two surfaces to be

tested on the product.

7. Within a few seconds, the display on the LT-952HC should settle to the final leakage current value. If the

displayed result is less than 20mA operate the Range switch to the 2mA position.

8. IEC60950 specifies that the measurement taken in step 7 be repeated for each position of the products

power switch and with all combinations of the Neutral and Line switches on the LT-952HC. Be sure to

release the Ground switch before changing any of the test conditions (Line or Neutral switches) or before

contacting the device under test. Failure to do this will result in blown meter fuses on the LT-952HC.

Field Testing Grounded Products

(Products that cannot be isolated from earth ground)

These instructions will indicate how to measure leakage current when the device under test (D.U.T.) cannot

be isolated from ground. This may be the case when conducting tests in the field since the D.U.T. may be

reliably connected to ground through the building structure (i.e. mounted to a grounded pad, or connected to

grounded water pipes, etc.).

Please read the section “Understanding Leakage Current” before proceeding. You will note that in order to

measure the entire leakage current of a product, the product must be completely isolated from ground.

However, in a field-testing situation, you may only be concerned with the leakage current through the

PRODUCT SAFETY SOLUTIONS

© 2017 Educated Design & Development, Inc. All rights reserved. Rev C

Page 14 of 19

OPERATING INSTRUCTIONS: (Continued)

grounding lead. Remember, the reason to isolate the product is to simulate the worst-case scenario of the

product not being reliably grounded and the human body being subjected to the entire leakage current.

If you are at the installation site and you can verify that the product is reliably grounded, you may not be

concerned with the overall leakage current with the product completely isolated. Rather, you may only want

to know if there is extraneous leakage current from an operator surface, which could present a shock

hazard. Similarly, you may want to measure the current in the main grounding conductor after servicing the

product. In order to make such measurement, refer to the previous instructions for Surface-to-Surface,

Surface to Reference, and D.U.T. grounding conductor.

WARNING: WHEN TESTING A PRODUCT THAT CANNOT BE ISOLATED, ALWAYS SET THE METER

REFERENCE SWITCH TO GROUND. SETTINGS OTHER THAN GROUND, WHEN THE DEVICE

UNDER TEST IS NOT ISOLATED, CAN RESULT IN LINE VOLTAGE BEING APPLIED ACROSS THE

METER MEASUREMENT CIRCUIT. THE RESULT IS EXCESSIVE CURRENT THROUGH THE METER

THAT CAN CAUSE THE METER FUSE TO BLOW.

THEORY OF OPERATION:

This section of the manual contains a description of the circuitry used in the LT-952HC. During this

discussion, please refer to the Block Diagram located following this section.

The LT-952HC is composed of 3 major sections. The first is the high current handling switching section.

The second is the meter measurement section, and the third is the low Voltage power supply.

AC Current Switching Circuit

The AC Current Switch section consists of the rear panel incoming power connector, and both front and

rear panel D.U.T. outlets. This section also contains the Test Condition, Ground Switching, and 120 Volt

Disconnect blocks.

Test Condition Simulator

This section is composed of two switches. The first, a SPST type, is used to simulate an open neutral

condition. The second relay, a DPDT type, is used to physically reverse the hot and neutral wires

connected to the product under test.

Ground Switching

A momentary SPDT switch is used to perform the ground switching function. In the normally closed

position, the ground from the incoming power line is connected to the front and rear panel output

receptacles. When the switch is toggled OPEN, the ground lead of the product under test is routed to the

meter connection selector.

PRODUCT SAFETY SOLUTIONS

© 2017 Educated Design & Development, Inc. All rights reserved. Rev C

Page 15 of 19

THEORY OF OPERATION: (continued)

120-Volt Automatic Disconnect

A power relay, a DPST type, is used to disconnect the front panel 120 Volt outlet when the rear panel

Voltage selector is set to 230 Volt operation. If 230 Volts is inadvertently applied to the LT-952HC while the

Voltage selector is set to 115, the line fuse is designed to open which will cause the relay contacts to open.

Meter Measurement Circuit

The Meter Measurement Circuit contains the electronics to convert low-level leakage currents in the

microamp range into numbers that can be displayed on the front panel display. The Meter Measurement

Circuit contains the Meter Reference, Meter Connection, Body Circuit, Meter Range & Scaling, RMS to DC

Converter, and Analog to Digital Converter Blocks.

Meter Reference

The meter reference circuit consists of the SP3T front panel Meter Reference switch. This switch selects

between line, neutral, and ground references and sends the selected reference to the Meter Connection

Circuit.

Meter Connection

The Meter Connection Circuit receives inputs from the front panel banana jacks, meter reference switch,

and ground switching circuit. The front panel Meter Connection switch, a DP3T type, is used to select

between the various inputs. The three possible meter connections are D.U.T. ground to reference, surface

to reference, and surface-to-surface. The selected connection is then sent to the Body Circuit.

Body Circuit

The Body Circuit used is that shown in IEC 60990, Figure 4.

Meter Range & Scaling

The Voltage across the Body Circuit, which is proportional to the leakage current, is sent to the Meter

Range & Scaling block. This output is then sent to a X1 or X10 attenuator, which is controlled by the front

panel Range switch. The output of the Range switch is connected to the RMS – DC converter.

RMS to DC Converter

This section is composed of a single monolithic integrated circuit that computes the true RMS value of the

input waveform. The output of this circuit is a DC Voltage that is directly proportional to the RMS value of

the input.

Analog to Digital Converter

This section converts the output of the RMS to DC converter to a visible display on the LCD panel. This

circuit also drives the LCD display directly.

TROUBLESHOOTING:

This chapter contains answers to the most frequent questions or problems that may be encountered during

the use of the LT-952HC. Please read this section in its entirety before contacting E.D.&D. for assistance.

PRODUCT SAFETY SOLUTIONS

© 2017 Educated Design & Development, Inc. All rights reserved. Rev C

Page 16 of 19

Problem: The meter fuse blows.

Solution: Confirm that the fuse being used is the correct type and rating as indicated in the Maintenance

Section of this Manual.

Solution: The device under test is inadvertently grounded through another connecting cable. This happens

frequently when testing computers. The extra ground can come from a monitor or other cord connected

peripheral. To avoid another blown fuse, verify that there are no extra grounds by measuring with an

ohmmeter before trying to measure leakage.

Solution: The device under test is connected to earth ground through the mounting means or from connection

to a grounded water pipe. This can be the case when testing stationary cord connected equipment. If this is

the case, please refer to “Field Testing Grounded Products”, chapter 2.

Solution: Do not change test conditions while holding the Ground switch in the OPEN position. This causes

momentary transients that will blow the fuse. Depress the Ground switch only long enough to take a

measurement.

Problem: The front panel AC receptacle is dead.

Solution: The front panel receptacle is designed to be disabled whenever the LT-952HC is connected to a

240 Volt source. Check the position of the rear panel Voltage Selector switch.

Solution: The rear panel circuit breaker has tripped due to an overload. Reset the circuit breaker. Verify that

the input current to the device under test does not exceed 20 Amps when using the front panel receptacle.

Solution: The Neutral Switch is set to OPEN

Problem The meter on the LT-952HC indicates a single "1" with the remaining 3 digits blanked.

Solution: This indicates an over range condition. Switch to the higher 20mA range. If already on the 20mA

range, the product under test has excessively high leakage or there is a ground path from the device under

test (possibly via an accessory cable).

Problem The meter display is blank and the Ground Closed indicator does not light when the LT-

952HC is turned on.

Solution: Check to make sure that the LT-952HC is receiving power and that the Voltage Selector switch is in

the proper position. Check the Line Fuse on the LT-952HC.

Problem The Line fuse on the LT-952HC blows.

Solution: Check to make sure it is the correct type and rating as indicated in the Maintenance Section of the

Manual.

Solution: Verify that the rear panel Voltage Selector switch is in the proper position. The Line fuse is

PRODUCT SAFETY SOLUTIONS

© 2017 Educated Design & Development, Inc. All rights reserved. Rev C

Page 17 of 19

TROUBLESHOOTING: (continued)

designed to blow if the LT-952HC is connected to 230 Volts and the Voltage Selector switch is set to 115. If

the Voltage Selector switch is set to the proper position and the fuse still blows, then the LT-952HC has been

damaged and should be returned to E.D.&D. for repair.

Problem The LT-952HC always seems to measure near zero leakage when measuring leakage surface

to reference.

Solution: The momentary Ground switch on the LT-952HC must be toggled to OPEN. Otherwise, the leakage

current is effectively shunted around the meter circuit to the ground.

REFERENCE STANDARDS:

60950, 60335, and IEC 1010 based Standards.

MAINTENANCE/STORAGE:

See the instructions in the Calibration section of this manual. No other periodic maintenance is required.

Always keep your tester clean by wiping the surface with a clean towel. Commercially available cleaning

products can be used, provided that they are mild, non-corrosive, and non-abrasive. Blue liquid window

cleaner works well.

This instrument contains no user serviceable parts. A special calibration sticker is provided. Removal of

the calibration sticker will void the required calibration as well as the warranty.

PARTS/SERVICE:

No user serviceable parts inside. Return the LT-952HC to ED&D for service. Contact ED&D for an RMA

number before returning.

Fuse locations:

See Product Components Figure 2- Rear Panel on page 8 for fuse locations.

PRODUCT SAFETY SOLUTIONS

© 2017 Educated Design & Development, Inc. All rights reserved. Rev C

Page 18 of 19

CALIBRATION:

The LT-952HC should be re-calibrated annually under normal circumstances and usage. It should also be

re-calibrated if it exhibits inconsistent, unexpected, or ambiguous behavior. There are no user-available

adjustment means; it must be returned to a competent and qualified calibration lab for service.

The international standard ISO/IEC 17025 lists requirements that testing and calibration laboratories must

meet if they wish to demonstrate that they operate a management system, are technically competent, and

are able to generate technically valid results. The exclusive use of calibration service providers which have

been recognized by an independent accreditation body as conforming to the requirements of ISO/IEC

17025, and whose scope of accreditation encompasses leakage current testers, is the most reliable way to

ensure that your test device continues to meet the requirements of the standard and is strongly

recommended. ED&D offers calibration services that meet these requirements. Please contact us to

arrange for service.

The recommended calibration intervals are as follows:

6 Months - If the LT-952HC is being used in an environment where it is subject to vibration and frequent

changes in temperature (i.e. Field Testing).

12 Months - If the LT-952HC is being used in a laboratory or production setting with a controlled environment.

PRODUCT SAFETY SOLUTIONS

© 2017 Educated Design & Development, Inc. All rights reserved. Rev C

Page 19 of 19

LIMITED WARRANTY:

Educated Design & Development, Inc. (“ED&D”) hereby warrants to the original purchaser of any new

ED&D Model LT-952HC Leakage Current Tester that the device shall be free from defect in material and/or

workmanship. This warranty shall extend for a period of 1 year (365 days) from the date of purchase.

Should any defect arise within the warranty period, ED&D may repair the unit, send replacement parts, or

replace the defective unit with a new unit at ED&D’s sole discretion. Under no circumstances, however,

shall ED&D be required to refund the purchase price of any product.

This warranty does not cover any failure or damage to the product resulting from accident, alteration or

misuse of the product or failure to follow manufacturer’s operating instructions. This warranty also does not

cover damage to the unit caused by excessive overload. Furthermore, this warranty does not cover damage

caused by use of any attachment not original equipment of the product. In addition, ED&D shall not be liable

for any damage done to the device under test as a result of the surge application. ED&D shall not be liable

for any damage caused by use of the product other than indicated in the manufacturer’s instructions.

ED&D DISCLAIMS ANY LIABILITY FOR ANY DAMAGES RESULTING FROM DELAY OR LOSS OF USE

AND SERVICE, OR REPAIR, OR FOR LOSS OR DAMAGED DEVICES, OR FOR ANY INCIDENTAL OR

CONSEQUENTIAL NEGLIGENCE OR OTHER FAULT ON THE PART OF THE MANUFACTURER OR

OTHERS. THE IMPLIED WARRANTIES ON THIS PRODUCT SHALL BE IN EFFECT ONLY FOR THE

DURATION OF THE EXPRESSED WARRANTY PERIOD AS SET FORTH ABOVE, AND THEREAFTER,

THERE SHALL BE NO WARRANTIES, EITHER EXPRESSED OR IMPLIED, INCLUDING WARRANTIES

OF MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSE.

CONTACT INFORMATION:

For Assistance With This Product, Please Contact:

ED&D

901 SHELDON DRIVE

CARY, NC 27513 USA

800-806-6236

919-469-9434

919-469-5743 (fax)

www.ProductSafeT.com

Table of contents

Other ED&D Test Equipment manuals