PB International UFK Series User manual

Management Concept

With installation- and operating instructions

UFK / UFW series

Suitable for all types UFK/UFW

English

40053

PB International BV

Stikkenweg 50

7021 BN, Zelhem

Netherlands

www.pb-international.nl

1. Introduction

1.1. Guide typical symbols

IMPORTANT!

Failure to follow this instruction may risk in material damage and/or injuries.

PAY ATTENTION!

With non-compliance of the instructions there is a serious risk of damage to the

material, increased risks in equipment malfunctions and risks to the public

health.

1.2. Abbreviations and terms

▪Downstream installation: drinking water system of the building or object following

the UFK/UFW.

1.3. Liability of the manufacturer

Our products are manufactured with the utmost care. We continually look for ways to

improve our quality. Therefor we reserve the right to alter the specifications referred to in

this document.

In the following cases, we as the manufacturer are not liable:

▪Failure to observe the instructions of the device.

▪Faulty or insufficient maintenance on the equipment.

▪Failure to observe the installation instructions of the device

1.4. Responsibility of the installer/contractor

The installer is responsible for the installation and commissioning of the unit. The installer

must observe the following instructions:

▪Read this management concept and these installation and operating instructions

carefully before installing the product.

▪Preserve the installation and operating instructions for future references if needed.

These should be readily available during the lifetime of the product.

We recommend that you keep the installation and operating instruction in the immediate

environment of the product.

▪Install the product in accordance with applicable legislation and standards.

▪After commissioning, carry out all the necessary checks.

▪Explain the product to the end-user.

▪Explain the end-user the importance of maintenance on the product.

▪Hand this management concept to the end-user.

!

!

!

1.5. Disclaimer

To ensure proper functioning of the installation, the given installation- and operating

instructions must be scrupulously observed. Application and/or use of the product in a

way differentiating from its purpose is not allowed. If any damage occurs by misuse of the

installation the supplier and/or manufacturer may not be held liable.

In addition to the legal requirements and guidelines, the guidelines mentioned in the

guide are also to be adhered. For all regulations and guidelines, as mentioned in this

manual, any subsequent regulations and guidelines enabled after the date of installation

are to be adhered to as such.

1.6. Version

Version: V3.2

Year of issue: 2021

1.7. Factory Test

Each product is extensively tested before leaving the factory, including;

▪Electrical operation

▪Product integrity

▪Parameter setting

If you notice any defects please contact your supplier.

1.8. Safety

In the case of leakage occurs outside the equipment:

▪Turn off the water supply

▪Dis-connect the electrical power of the equipment

▪Try to remedy the leak.

In the case of leakage occurs inside the equipment

▪Turn off the water supply

▪Dis-connect the electrical power of the equipment

▪Contact the supplier and follow the instructions

Ensure when work is taking place, that the power supply and water pressure are shut

down to be able to work safe and freely.

!

1.9. Recommendations

The installation of the equipment must be performed by a qualified plumber according to

the assembly instructions in this document.

The equipment must be (highly preferred) installed at room temperature.

▪Check the entire system for leaks after installation.

▪Clamping parts and covers may only be removed for installation. Place these

items back in their proper place after installation.

▪Certification, serial and any other indications stickers may not be removed or

covered and must retain legible during the entire lifetime of the equipment. In

case of a damaged or illegible indication sticker immediately contact the

supplier.

▪All piping after the installation must contain flowing water, at least weekly, to

ensure the quality of water.

▪To ensure water quality through the filter with the supply of hard water a water

softener should be installed. A general guideline to determine the usability of the

water when the water contains hardness above 10 ° DH a water softener should

be placed before the filter.

▪In case a pressure boosting system is placed it should be placed in the feedline to

the ultra-filtration equipment. Exceptions can be made in consultation with the

supplier.

Changes to the equipment should only be performed after written consent by PB

International BV.

2. Preparations

Before the equipment is put into use, the following preparations must be made on the

downstream installation:

▪The downstream installation must be cleaned and disinfected after installation of the

equipment.

▪The drain has to be connected with an air gap

▪There should be a power socket within 2 meters (6 feet) of the device.

▪The construction of a bypass system is not desired. If a bypass will be installed for

well-considered reasons, this should be taken into account prior to installation.

The bypass is closed and sealed, preferably by means of a “block-and-bleed” principle,

and should not be opened under any circumstance without the written consent by PB

International (see illustration below)

!

!

!

Closed sealed

(Block)

Closed Sealed

(Block)

Drainage system

(Bleed)

UF filter module

3. Application Conditions

▪The equipment must be applied to the main water line of an installation or to a supply

line of a part of the installation.

▪The feed water must be of drinking water quality.

▪After assembly the equipment a complete cleaning and disinfection of the equipment

and the whole downstream installation is required to create a hygienic baseline.

Include a copy of the sampling results in the management concept.

▪The cleaning of the equipment should be done in consultation with the manufacturer.

▪Connecting the cleaning system of the drinking water installation should be with a

back flow protector in the feed line.

▪Dead ends must be removed before the baseline cleaning, preferably with concealed

“smooth” piping which is not capped. Changes in the distribution system should be

recorded in the logbook.

Note: Please contact your supplier if there are any questions about the application of

specific resources.

▪The management of the equipment should be properly carried out and recorded in

the log list.

4. Technical Description

4.1. General Description

The device is bearing the product name “UFK” or “UFW”. Both of these sets are based

upon ultrafiltration, intended to keep the downstream drinking water installation bacteria

and/or particle safe. The difference between both systems is in the maximum

temperature of the filter modules. The construction of the products is similar.

The product is designed for application in the main supply pipe or a part of the

installation. The purpose of the equipment is to supply the drinking water network

downstream of bacteria and/or particle safe water.

The intended use of the product entails as described in this manual, making further

contact with the product not necessary. The product should be used only if all parts are

present and assembled and if the maximum supply pressure is lower than 6 bar (~88 PSI),

with a maximum water temperature as indicated in the product specification.

4.2. Product features

Ultrafiltration

Ultrafiltration is a technique used to filter small undissolved particles, such as bacteria out

of the water supply. Ultrafiltration is a membrane based technique. The inside of the

membrane acts as a very fine sieve, with a pore size of 0.015 to 0.03 micrometres (~0.6 to

!

1.2 micro inch). The water has to be pressed through the pores with a pressure of at least

1 bar (~14.5 PSI). The reduction of the bacteria by this technique is 99.99999% (log 6).

Forward flush

This product is equipped with an automatic forward flush function. During this stage all

bacteria that remain trapped in the membranes are rinsed into the sewer.

Filtration

Forward flush

4.3. Main components

1. Digital timer

2. Flush valve spool

3. Connector clearance

4. ½” BSP 3-way coupling

5. Power cord

6. Manometer

7. Pipe clamp

8. 1” BSP 3-way coupling

9. 1” ball valve with drain

10. Filter module UFKM / UFWM

11. Prefilter 200 micron (~7900 microinch)

12. Nonreturn valve

Flushable prefilter

Carbolyxic-, or

cartridgefilter

Manual Flush Valve

4.4. Operating principle

The operating principle of the product is ultrafiltration, where the upstream water supply

is separated by a physical barrier of the downstream water (downstream installation). All

particles in water greater than 0.03 μm (~1.2 µin) remain in the filter. The bacterium safe

water (permeate) is supplied to the drinking water system. The captured particles are

automatically washed away to the drain.

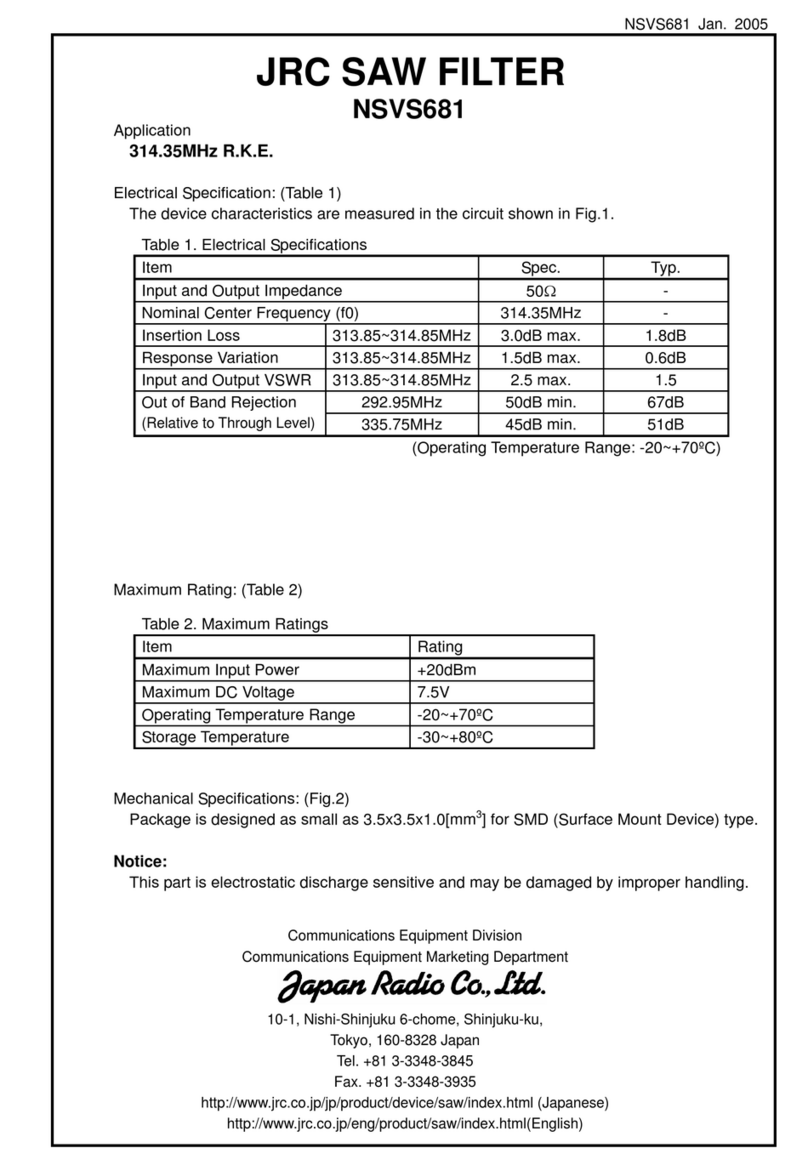

4.5. Technical Specifics

General Specifics

UFK

UFW

Connections

See filter module for specifics

Flush connection

½” BSP female threaded.

Capacity (gal/min)

See filter module for specifics

Pressure loss( bar)

0,8 (~9PSI)

Power supply

See coil for specifics

Electrical power

9W

Pore size

0,015 –0,03 micron (~0.6 to 1.2 microinch)

Max temperature

40°C (104 F)

70°C (156 F)

Material

PVC-U

PVC-C

Supply pressure min

2 bar (~29 PSI)

Medium

Drinking water

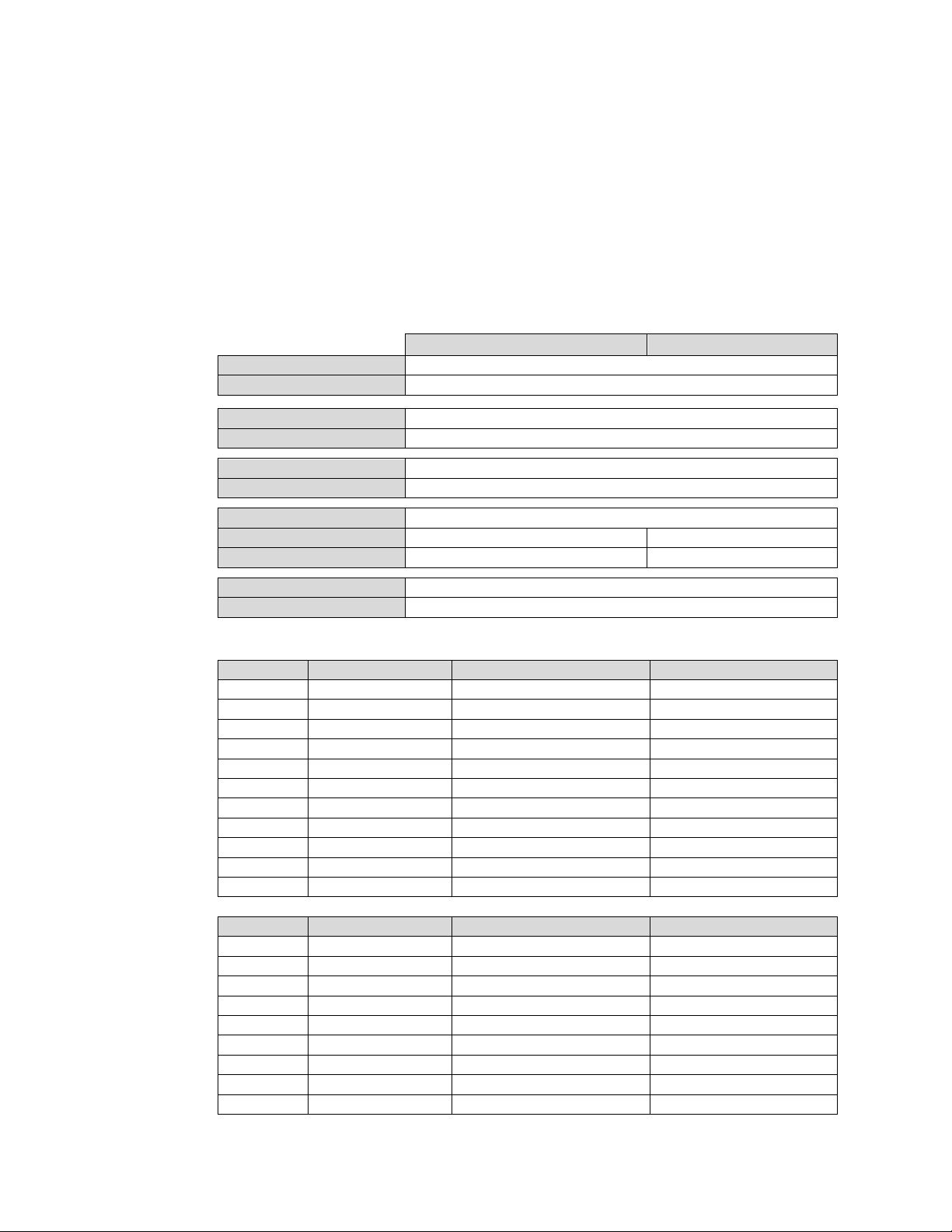

Filter module specifics

Articlenr.

Description

Supply /Permeate

Capacity at 16°C (61 F)

10021

UFK 50-510

½” BSP female threaded.

0.3 m3/h

10022

UFK 63-510

¾” BSP female threaded.

0.5 m3/h

10023

UFK 75-510

¾” BSP female threaded.

0.8 m3/h

10024

UFK 90-510

¾” BSP female threaded.

1.1 m3/h

10025

UFK 90-750

¾” BSP female threaded.

1.7 m3/h

10026

UFK 90-1000

¾” BSP female threaded.

2.2 m3/h

10027

UFK 110-750

1” BSP female threaded.

2.4 m3/h

10028

UFK 125-750

1” BSP female threaded.

3.2 m3/h

10029

UFK 140-750

1” BSP female threaded.

3.7 m3/h

10030

UFK 160-750

1” BSP female threaded.

4.0 m3/h

10031

UFK 160-1000

1” BSP female threaded.

5.0 m3/h

Articlenr.

Description

Supply/ Permeate

Capacity at 30°C (86 F)

10032

UFW 50-510

½” BSP female threaded.

0.4 m3/h

10033

UFW 63-510

¾” BSP female threaded.

0.6 m3/h

10034

UFW 75-510

¾” BSP female threaded.

0.9 m3/h

10035

UFW 90-510

¾” BSP female threaded.

1.3 m3/h

10036

UFW 90-750

¾” BSP female threaded.

2.0 m3/h

10037

UFW 90-1000

¾” BSP female threaded.

2.7 m3/h

10038

UFW 110-750

1” BSP female threaded.

2.9 m3/h

10039

UFW 160-750

1” BSP female threaded.

6.0 m3/h

10040

UFW 160-1000

1” BSP female threaded.

8.4 m3/h

5. Installation instructions

Installation work should be performed by an authorized plumber in accordance with local

and national regulations.

5.1. Package content

Delivery includes:

▪Ultra-filtration module

▪Test report

▪Supply set

▪Permeate set

▪Flush set

5.2. Guidelines

When installing the equipment please take the following guidelines into account;

▪In case of water hammer, a water hammer reducer should be placed in the conduits

to serve as protection for the filter membranes.

▪Noise nuisance created by the filter should be avoided.

▪The installation must be protected from freezing and mechanical damage.

▪Never drop the product, or any parts of it. This may damage it beyond repair.

▪Do not use the product if it is damaged. Always contact your dealer. Never try to

repair the product.

▪The filter is designed with the goal to remove bacteria and/or particles from the

water and may only be used for this purpose.

▪Thoroughly clean the filter regularly, and please contact your supplier for additional

information.

▪Avoid the drying out of the membranes, if the filter module is to be stored for a

longer period of time, the fibres will dry out which can result in permanent damage.

▪Avoid direct exposure to sunlight and UV radiation.

▪Protect against abrasive material. The abrasive material in water can result in

permanent membrane damage. Place a pre-filter with pore size of 60-100 microns

(~2400-3900 micro inch) if visible pollution has been detected.

▪Avoid sudden variation in water temperature: a thermal shock should be avoided.

▪Protect the equipment against concentrated acids and organic solvents: avoid

contact between the membranes and organic solvents, chlorinated solvents, or

concentrated acid.

▪Avoid silicone-based lubricants, chemicals and oily liquids: the silicone materials can

cause permanent blockage of the fine pores of the membrane element.

▪Transport the product carefully: The membrane element can be mechanically

damaged if they fall or collide with hard objects.

!

5.3. Placement

▪The filter should be installed so that all the water is treated in the downstream

installation.

▪The system can be placed immediately after the water meter and/or pump at the

beginning of the pipeline network, or at the beginning of a separate part of the water

line.

▪The installation must be placed in a dry and frost-free area.

▪When placing the equipment please be beware that the equipment remains

accessible for maintenance.

▪The equipment must be securely mounted, preferably on a wall. Follow the

installation instructions that can be found in this document.

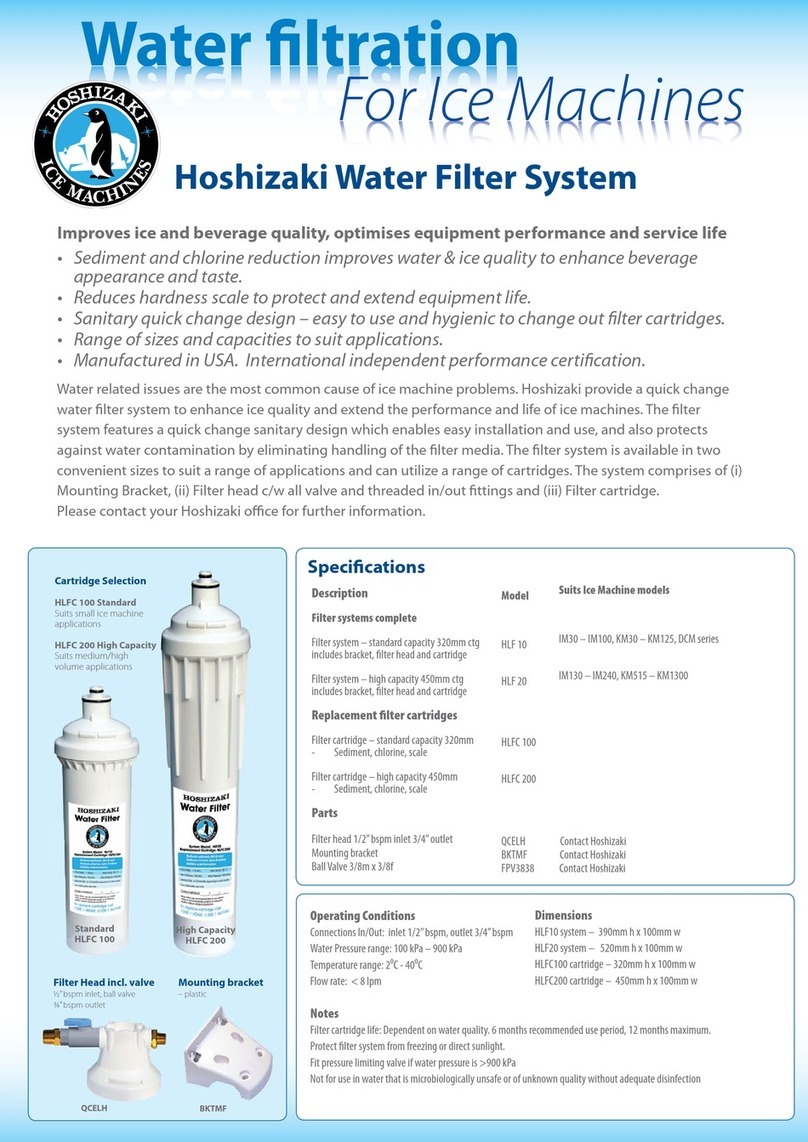

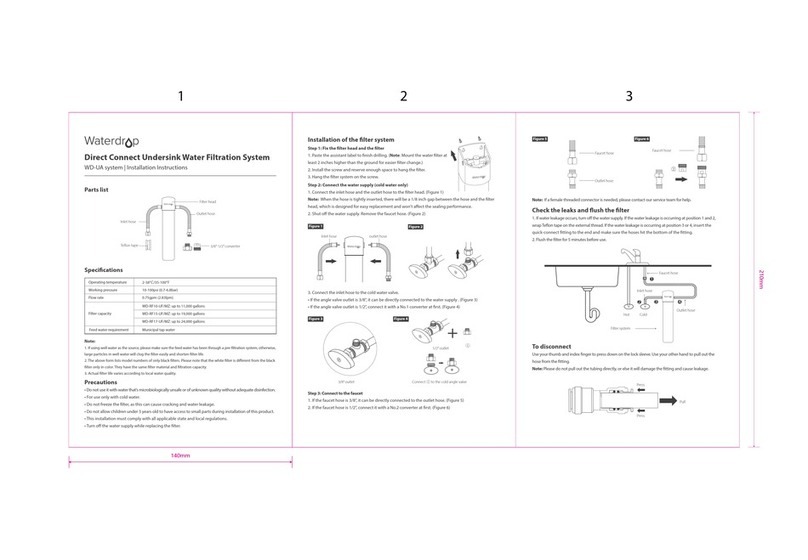

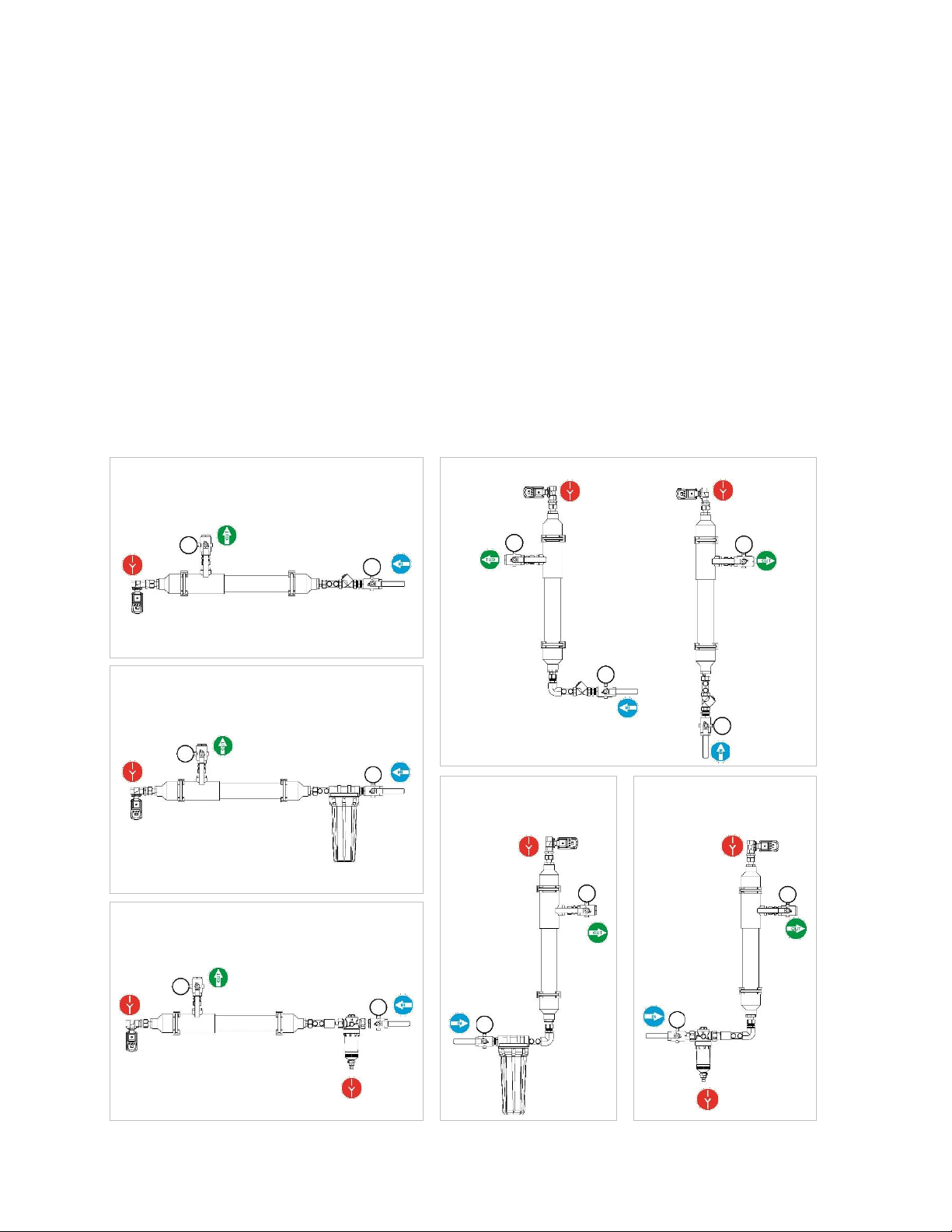

The UFK/UFW can be positioned horizontally, vertically as well as lying down. See the

images below for further reference.

Horizontal

Vertical

With a coarse pre-filter (standard)

With a coarse pre-filter (standard)

With a carbolyxic, or cartridgefilter

With a carbolyxic, or

cartridgefilter

With flushable pre-

filter

With (manual) flushable pre-filter

Note: If the equipment is mounted on a wall, please check whether the wall can support

the weight of the equipment.

5.4. Connections

▪When connecting the device please use FTP or FTPE sealing tape or sealing wire.

▪The use of hemp sealing material is not permitted due to microbial growth and

contamination.

▪The equipment connection ends are fitted with BSP thread. Please use suitable

threaded couplings with BSP threaded connection.

▪Always use the appropriate tools when working with the 6-way and 8-way connection

ends.

▪Turn the part that need tightening until they are completely tightened. Never go

further to avoid damage.

▪All pipes of the UFK/UFW should be tension freely connected to the existing network.

▪Always check whether the downstream installation is connected to the outgoing

permeate side of the equipment.

▪Always make sure the water supply is correctly connected to the inlet side of the

equipment.

Connecting the drain

▪Connect the discharge pipe with an air gap to the sewer drain; use this protection

(atmospheric interruption) according to the local instructions and guidelines.

The drain line (for example, a drain) of a device must be provided with a free range

visibility according to the figure and table below.

The following requirements are placed on the drain:

▪b > G and b > 20 mm (0.8 Inch)

▪e > 4 mm (0.16 Inch)

▪G > E (The capacity from E should fit in without G reaching level 2)

▪S1+ S2+... < 1/3* b * (2 * π* G)

1

Discharge outlet

2

Overflow level

E

Discharge outlet

G

Drain

S1, S2,

etc.

Surface air inlet

b

Distance between

discharge outlet and

overflow level

e

Smallest size for

calculating air inlet

!

5.5. Assembly

1. Install the pipe clamps in the desired location.

2. Place the filter into the tube clips.

Take the items marked feed, permeate and drain.

Assemble these as shown in the examples below. Make the assembly using FTPE sealing

tape or FTPE thread sealant.

3. Install the assembled parts and then in the right place, as indicated on the filter.

4. Mount the BSP -> NPT transition couplings –if applicable –to the feed, permeate and

drain assemblies.

5.6. Installing the plug

1. Loosen the screw and remove it from the connector clearance.

2. Remove the inner part by using a small flat screwdriver.

3. Plug the power cord through the gland parts and all the way through the connector

clearance.

1.

2.

3.

Connect the stripped power cable to the screw terminals. Connect the brown wire to

terminal 1. Connect the blue wire to contact 2. Connect the yellow-green wire to

ground contact 3.

4. Press the inner part and cord back in the connector clearance. The portion may, if

necessary, be rotated in steps of 90 ° tighten the swivel parts firmly.

5.7. Electrical connections

The electrical components are not phase sensitive. The table below lists the main

characteristics of the electrical parts.

Supply voltage

See the coil

Nominal power

5W

Maximum power

9W

Degree of protection

IP65

Power supply unit

Socket outlet

The product is equipped with a plug (2 meters / 6 feet cable length) and suitable for a

power supply with live/neutral/earth connections.

2.

1.

3.

4.

6. Commissioning of the equipment

Please note that after the assembly it is important to carry out the following steps:

6.1. Checklist

▪Ensure that the voltage indicated on the appliance corresponds to the local main

voltage before you connect the appliance.

▪Check that the connections are secure.

▪Check whether the water supply is of drinking quality.

▪Ensure that the supply pressure of the water is at least 2 bar (~29PSI) and up to 6 bar

(~87PSI).

▪Check the wiring of the equipment. The plug must be well connected.

6.2. Commissioning procedure

▪Open the main valve of the drinking water system.

▪Slowly open all manual valves halfway.

▪Allow the filter to slowly fill with water.

▪Turn the manual valve fully open when the filters are completely filled.

▪Ensure that the flush lines and the drain are installed correctly.

▪Visually inspect the equipment for leaks and/or lack of water flow.

▪Plug the equipment in the grounded outlet.

Please note! The product starts immediately with the flushing and venting of the filter.

The PB filter elements contain Glycerine and sodium sulphate for conservation.

Before the appliance is fully operational it should be flushed, for at least 10 minutes, to

remove the above mentioned substances!

Turn the nearest downstream tap (from the installation) open to flush the system for at

least 10 minutes.

Carry out a complete cleaning and/or disinfecting of the equipment and the whole

downstream installation to create a hygienic baseline.

Flushing out the chemicals from the drinking water system must be done with filtered

water.

▪The disinfectant and specified flushing time are recommended by the manufacturer

and should be followed. The flushing shall be done until the presence of disinfectants

is no longer detectable.

7. Settings

7.1. Factory settings

The control of the equipment is set to an average water quality. With these settings the

device in principle will continue to function properly

Rinsing time (forward flush)

5 seconds

Rinsing frequency

4 hours

7.2. Changing settings

When the equipment is becoming clogged by an above-average contamination of the

water supply, the settings can be adjusted in consultation with the supplier. Within the

control unit all settings are interchangeable.

Product use

The changes are to be carried out with the aid of the buttons on the front side of the

control element. The table below shows the functions of the buttons:

Function F1

Function F2

< OFF

Changing flushing interval

Value -

TEST

Manual rinse

Accept change

ON >

Changing flushing time

Value +

The indicator LED’s next to the display indicate the unit’s time value.

1. Press the right button [ON>]. The display will show “ON”

2. Subsequently, the set flush time “5” is displayed on the LED display [sec].

3. With the left button the rinsing time can be shortened up until 1 second, using the

right button the rinsing time can be lengthened up until 99 hours.

4. The set rinsing time is automatically saved after 3 seconds.

1. Press the right button [<OFF]. The display will show “OFF”

2. Subsequently, the set flushing interval “4” is displayed on the LED display [hour].

3. With the left button the flushing interval can be shortened up until 1 second, using

the right button the rinsing time can be lengthened up until 99 hours.

4. The set flushing interval is automatically saved after 3 seconds.By using the [TEST]

button you can interrupt the flushing interval. After the rinsing the filter the flushing

interval will be shown.

8. Problems and Malfunctions

8.1. Detection

The table below shows the possible malfunctions with their possible causes and the

associated action.

We strongly advise you to contact PB International or your local dealer by phone before

you take any actions. Call +31 (0) 314621465. The service department can provide

support for any malfunction. This will prevent unnecessary contamination of the piping

network. Our current helpdesk number is listed in case the PB International office is

unreachable.

Detection

Possible causes

Action

No water pressure at

the taps

▪The supply pressure of

your water provider is too

low.

▪The permeate pressure is

too low (less than 0.5 bar

(~7PSI))

▪Check the supply pressure. Please

contact your water provider.

▪Place a pressure-boosting system.

Less water pressure at

the taps

▪Capacity reduction due to

pollution

▪The supply pressure is too

low (less than 1.5 bar

(~22PSI)

▪Allow a thorough cleaning to

remove all micro contamination.

▪Check the supply pressure. Please

contact your water provider.

▪A pressure-boosting system might

be advisable.

Pump in failure

▪Filter installation is

mounted BEFORE the

pump.

▪The supply pressure of

your water provider is too

low

▪Place the pump in front of the filter

installation.

▪Check the supply pressure. Please

contact your water provider.

8.2. Handling malfunctions

▪Never open the by-pass without consulting the manufacturer or an authorized party.

Opening of the by-pass interrupts the physical barrier.

▪Let the supplier repair the equipment.

If the physical bacteriological barrier fails, even shortly, the owner must assume norm

compliances of bacteria are exceeded within the downstream installation.

Take the number of water samples as prescribed in the management concept to show

possible infection.

▪Immediately after the failure of the barrier.

▪1 month after the failure of the barrier.

▪3 months after the failure of the barrier.

!

In the case of an infection restoring the hygienic baseline situation is a necessary step to

get the physical management operational again. A baseline is a hygienic bacteria

safe piping network. This should be noted by the results of <100 cfu/L (~380 cfu/gal) on

the determined number of sample points.

8.3. Actions in case of power failure

Failure of power supply has no adverse effect on the functioning of the product. There is

still safe water in the distribution system. However, the flushing function does not work

any longer.

It is important to note that the power failure is solved in a timely manner in order to

ensure the correct operation of the filters.

The installation will start flushing immediately after the power is switched on again and

no further actions are deemed necessary. When the system has been offline for more

than a week without power, please contact your supplier first.

9. Maintenance and warranty

To ensure the correct operation of the equipment it should be at least serviced annually

by a service technician authorized by the manufacturer. The following aspects should be

checked every year.

▪Cleaning and disinfection of the filter modules

▪Checking the operation of the equipment

▪Monitoring the operation and integrity of the filter modules

9.1. Warranty

The equipment has a one year manufacturer’s warranty. The warranty applies to

components. The warranty period is 1 year on material and/or workmanship. The

warranty begins on the day of delivery. Incorrect use and/or use of non-original parts will

void any warranty. In case of a defect, the manufacturer will assess the cause of the

defect. The warranty on the equipment is not applicable for contamination and defect of

the membranes by poor water supply and external factors.

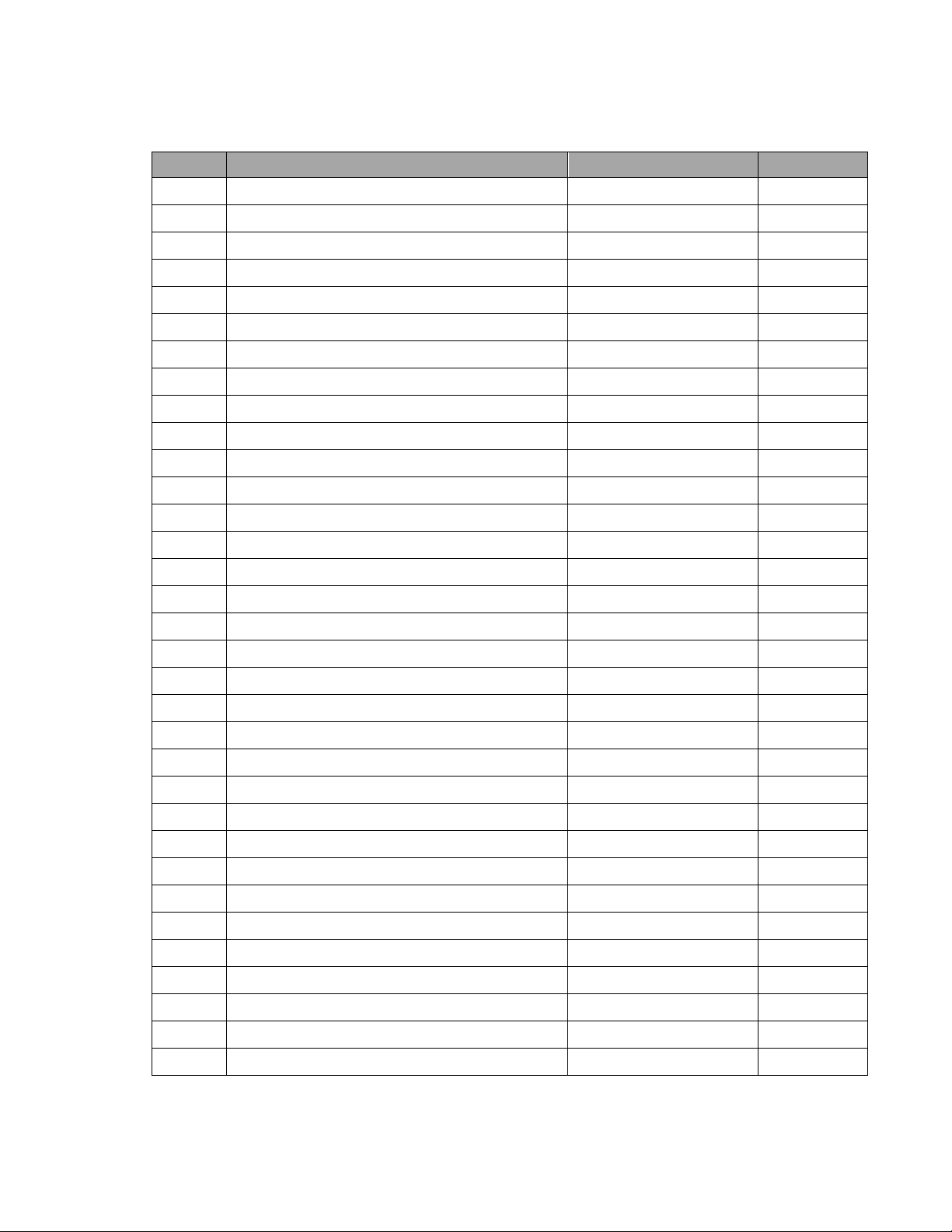

9.2. Maintenance logbook

Please use the maintenance logbook on the next page to write down any malfunctions

and/or defects. The service technician must also keep track of any maintenance

performed earlier in the logbook.

!

Maintenance table

Date

Observation/Maintenance

Action

Signature

This manual suits for next models

41

Table of contents

Other PB International Water Filtration System manuals