PB iMPB User manual

iMPB

Installation Manual

www.powerbarsystems.com

Page 01

Introduction

Powerbar Ltd supply all busbar sections

tested in accordance with type test

requirements as detailed in IEC61439-6

or UL857 and are subject to a full Quality

Check before packaging.

In order to ensure that the Busbar remains

in this condition during transport,

unpacking and installation on site, it is

important to study this document.

If the guidelines outlined within this

document are not adhered to, this could

give rise to the damage of the product,

electrical failure of the Busbar, personal

injury, or even death.

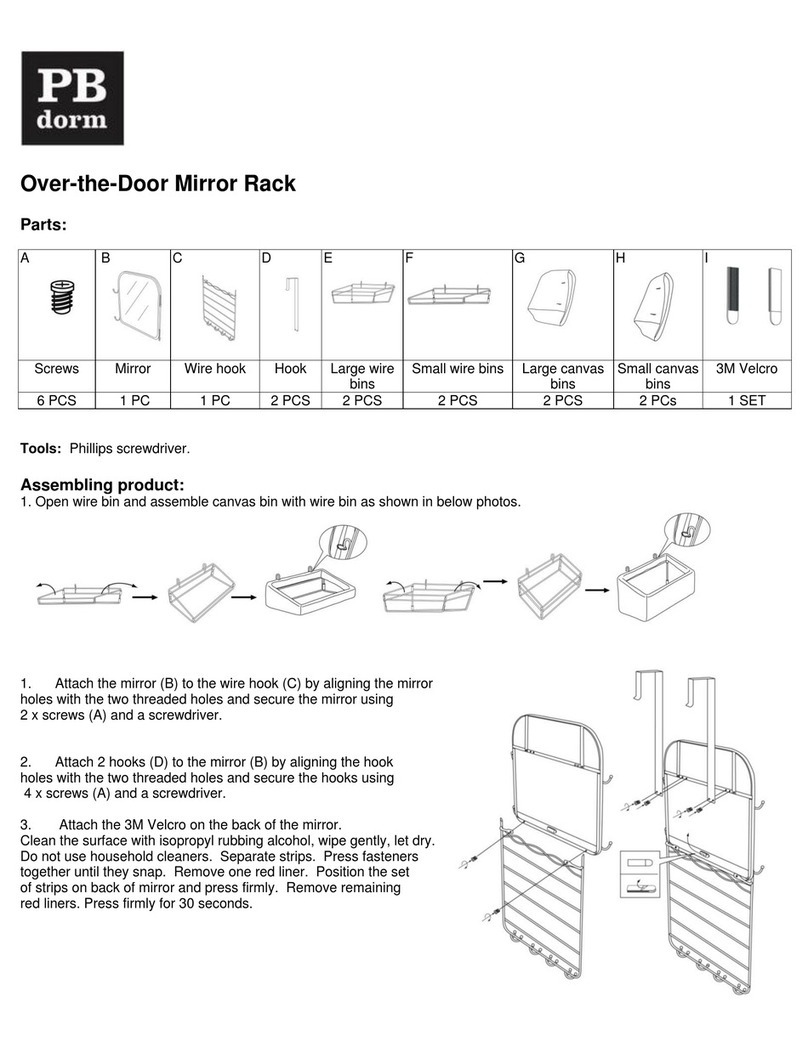

Manual Lifting

In accordance with Manual Lifting

Regulations the guidelines below are

provided to reduce risk of injury to

personnel and damage to equipment

during transport and installation of

busbar section.

PPE (Personal Protection Equipment)

should be worn at all times in accordance

with Health and Safety Regulations and

specic site requirements. When lifting

Busbar sections, care must be taken to lift

each section along its center and not by

the end sections or conductors.

Mechanical Lifting

Some sections of Busbar may require

mechanical lifting due to their weight.

Options for mechanical lifting includes

Genie® Lift™, forklift, scissor lift, platform

lift and block and tackle. A full assessment

of the risks should be carried out by the

installer before commencing work.

The Busbar must be safely secured to the

lifting apparatus before lifting.

Always check that the load does not

exceed the safe working load of the lifting

apparatus. Ensure that equipment is used

as per manufacturer’s guidelines.

Storage

The Busbar will be delivered to the

customer neatly stacked on a wooden

pallet for ease of removal. The maximum

weight of the pallet will not exceed

2500kg / 5500lbs.

The Busbar is protected from minor water

ingress by means of an overall outer

polythene wrap which should be left in

position until the bar is mounted.

If the Busbar is not to be installed

immediately upon delivery it should be

stored in a heated, clean, dry area. Busbar

should never be stored outdoors.

This Installation Manual is designed to assist in the Safe Handling and Installation of

the iMPB system. These instructions are in addition to normal safe working practices

as required by the local health and safety regulations. These instructions do not in

any way advocate a departure from these requirements. THIS EQUIPMENT

OPERATES AT

MAX 600V PHASE

Ensure COMPLETE electrical

isolation, verication and lock o

of supply device in accordance

with isolation procedures for

the particular installation prior

to carrying out installation

of the busbar , inspection, or

maintenance.

Only Powerbar approved

installation personnel may carry

out installation of this product.

If training is required contact

Powerbar using the details at

the back of the brochure and

specify the nature of the training

requirements. Training can

be provided on site or at our

manufacturing facility.

Handling

Powerbar iMPB

Page 02

Installation

Busbar

The Busbar Sections are secured to a framing system,

such as Unistrut®, using the Hanging Brackets as shown

below. The bar can be secured both on its at or on its

edge.

Before lifting a Busbar Section, ensure that a detailed

risk assessment is carried out for the lifting procedure

being performed in that specic area.

Powerbar recommend that the hanging brackets must be

mounted no more than 750mm / 30”from the center of the

joints. Care is to be taken not to damage ends of the busbar

during installation.

Powerbar recommends the hanging brackets be mounted

no more than 1.5 metres / 5’apart.

Ensure that each section

of busbar has at least one set of xing brackets tted and that

the Busbar is level and plumb before nal tightening of all

joints. Either drop rod or unistrut style hanging brackets are

supplied depending on the client’s request.

* Please note: Powerbar hanging bracket’s must be used.

186mm

Max 750mm to rst hanger

Max 750mm to rst hanger

It is the responsibility of the support system supplier to ensure their

system can safely support the weight of our product.

MAX DISTANCE 1.5 MTRS

Page 03

Joint Pack

Step 2.

Line up the joint pack with the rst length and push on until the

seperator plate ns are touching the end piece of the busbar.

Insert the rst joint pack locking bracket by rotating into place

and loosly tighteng the nuts.

Never force the joint or strike it with any object, as this may

damage the joint or the busbar section. The joint should be

inserted by means of constant force i.e. pushing by hand.

Ensure the joint pack assembly is:

free from contaminates

unblemished

not damaged

correctly aligned

The steps below outline best practice, the Busbar orientation and site conditions may restrict installers from adhering to this

methodology. In these cases installers must be cautious and ensure the joint pack is installed correctly. Ensure all parts are meggered

and visually inspected prior to installation.

www.powerbarsystems.com

Step 1.

The joint pack bottom cover and hanging brackets should be

removed. The top cover comes xed to the internal joint pack

parts. Busbar’s have to be at least 142mm / 5.6”apart for the joint

to be inserted.

Min 50mm / 1.96”

50mm / 1.96”

100mm / 3.94”

Step 3.

Line up and insert the second length until the seperator plate ns

are touching the end piece of both busbars. Insert the second

joint pack xing bracket into place. Tighten both joint pack xing

brackets to 10Nm.

Joint Pack

Locking Bracket

Powerbar iMPB

Step 5.

Tighten the joint pack center bolt to 25Nm using a calibrated torque

wrench. If installed correctly the joint will appear level.

*The joint pack center bolt should be torqued to 25Nm (221 in/lbs)

Step 4.

Attach the Bottom Joint pack cover using the M6 socket cap screws

provided. Tighten to 10Nm.

Bottom Joint pack cover

Page 04

Cable End Box

This is generally the rst component to be mounted on a run.

The entire route should initially be inspected for any obstructions before installation.

The box should be installed at the correct height in accordance with the approved drawings.

A plumb line should be applied at this point from the start of the run to the end of the run, as a guide for the installation of the Busbar Run.

Joint Pack

Gland/Conduit plate

*A Joint Pack is pre-tted to each cable

end box which determines the neutral

side of the busbar run. The approved

drawings will show this detail.

Joint pack Center Bolt

Table of contents

Other PB Indoor Furnishing manuals

Popular Indoor Furnishing manuals by other brands

Regency

Regency LWMS3015 Assembly instructions

Furniture of America

Furniture of America CM7751C Assembly instructions

Safavieh Furniture

Safavieh Furniture Estella CNS5731 manual

PLACES OF STYLE

PLACES OF STYLE Ovalfuss Assembly instruction

Trasman

Trasman 1138 Bo1 Assembly manual

Costway

Costway JV10856 manual