PBM HAV Series Owner's manual

PBM SUPPLY & MFG., INC

SINCE 1969

OWNER’S / OPERATOR’S MANUAL

P/N: HAV-OM

Eective: March 16, 2020

Read the Operator’s Manual entirely. When you see

this symbol, the subsequent instructions and

warnings are serious - follow without exception.

Your life and the lives of others depend on it!

California Proposition 65 Warning

WARNING: This product contains chemicals known to

the state of California to cause cancer, and birth defects

or other reproductive harm.

www.p65warnings.com

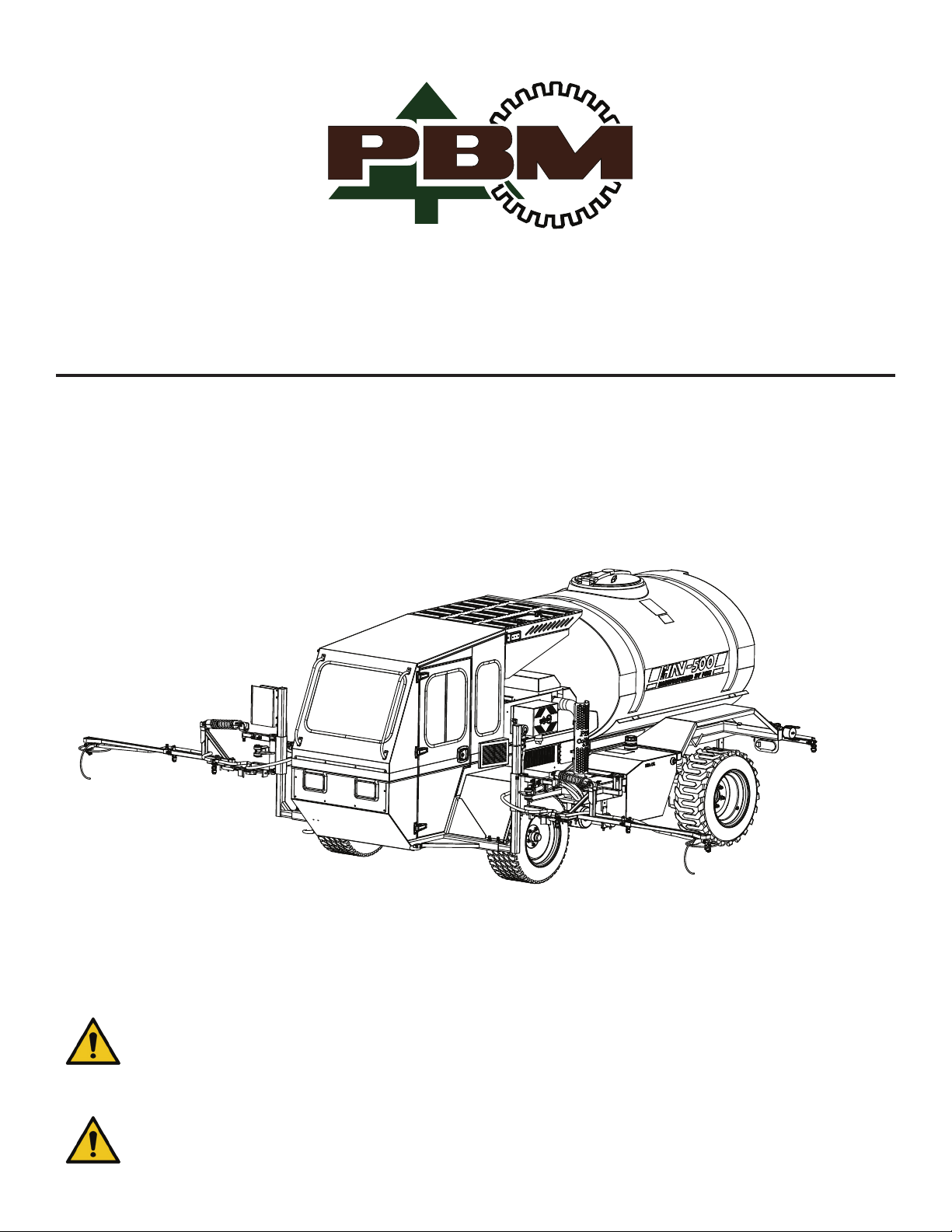

Tier 4 HAV Self-Propelled Sprayer

PBM SUPPLY & MFG., INC

SINCE 1969

2

Table Of Contents

PBM Supply & MFG., Inc. www.pbmsprayers.com

324 Meyers St. Chico CA 95928 1-800-688-1334

Table Of Contents

Introduction.................................................... 3

Application..................................................... 3

Identication .................................................. 3

Booms & Accessory Identication:......................... 3

Equipment Record: ................................................... 3

Important Safety Information ....................... 4

Safety Alert Symbol .................................................. 4

Signal Words ............................................................. 4

Safety Precautions.................................................... 4

Operational Safety Precautions............................ 4

Safety Precautions for Children ........................... 5

Sprayer Shutdown & Storage Safety ................... 5

Tire Safety............................................................... 5

Transport Safety..................................................... 6

Maintenance Safety ............................................... 6

Be Prepared For An Emergency ........................... 6

Proper Personal Protective Equipment (PPE)..... 7

Use Seat belts ........................................................ 7

Keep Riders o of Machinery ............................... 7

Read Chemical Labels Before Use....................... 7

Safe Working Capacity .......................................... 7

Safety Labels ................................................. 8

Applying Safety Labels............................................. 8

Safety Label Locations.......................................... 8

Operating Instructions................................ 13

Dashboard Controls ............................................... 13

Control Lever Controls ........................................... 14

Engine Display ........................................................ 14

Gauge Post .............................................................. 14

Preparing To Operate The HAV Sprayer ............... 15

Setting The Boom Height .................................... 15

Setting The Boom Width ..................................... 16

Testing the Spray System ...................................... 18

Self Test & Visual Inspection .............................. 18

Flushing the Pump ................................................. 19

Emergency Stopping .............................................. 19

Transportation ......................................................... 20

Trailer Transportation.......................................... 20

Roadway Transportation..................................... 20

Jump Starting The HAV .......................................... 21

Maintenance ................................................ 22

Break-in Period........................................................ 22

Service Schedule .................................................... 23

Service Procedures................................................. 24

Re-torquing The Rear End Suspension Bolts ... 24

Changing Hydraulic Oil ....................................... 24

Checking The Spray System............................... 25

Checking The Engine Oil Level .......................... 25

Checking The Coolant Level............................... 25

Changing Radiator Coolant ................................ 26

Checking Radiator Hoses ................................... 26

Checking The Air Filter........................................ 27

Draining The Fuel-Water Separator.................... 28

Inspecting The Crank Case Breather Tube........ 28

Flushing The Spray System................................ 28

Inspecting Fuel Lines ......................................... 28

Checking The Hydraulic Oil Level ...................... 28

Changing Engine Oil............................................ 29

Changing Engine Oil Filters................................ 29

Inspecting Wheel Bearings ................................. 29

Removing Sediment From The Fuel Tank ......... 29

Replacing The Fuel-Water Separator ................. 30

Replacing The Fuel Filter .................................... 30

Replacing Fuel Pipes And Clamps ..................... 31

Inspecting The Battery And Cables.................... 31

Replacing The Battery ......................................... 31

Draining The Air Tank.......................................... 31

Replacing The Air Tank ....................................... 32

Greasing Front End Components ...................... 32

Inspecting The Air Conditioning Unit................. 32

Preparing The HAV For Storage ......................... 33

Troubleshooting ...................................................... 33

Common Replacement Parts ................................. 34

Front End Replacement Parts ............................... 35

Warranty ....................................................... 36

Vehicle Specications................................. 37

Vehicle................................................................... 37

Hydraulic Drive System....................................... 37

Auxiliary Hydraulic System................................. 37

Spray System ....................................................... 37

Service Records .......................................... 38

PBM SUPPLY & MFG., INC

SINCE 1969

3

Introduction

PBM Supply & MFG., Inc. www.pbmsprayers.com

324 Meyers St. Chico CA 95928 1-800-688-1334

Introduction

Congratulations on the purchase of your new PBM sprayer. We are condent that you will be satised with

the build quality and performance of your sprayer. e purpose of this manual is to instruct operators how to

safely operate and maintain the sprayer so that it will last for years to come.

Application

PBM sprayers are designed to meet the requirements needed for many dierent types of spraying. Sprayers

can be paired with approved PBM accessories such as spray booms for spraying crop care chemicals, spray

wands or spray guns for spot treatments and tree spraying, or set up with water nozzles for dust suppression or

ground coverage.

Identication

HAV sprayers are identied by a serial number label attached to the inside the drivers side of the cab near the

operators seat. Refer to this number when calling for service or technical support.

Booms & Accessory Identication:

HAV sprayers are congured with dierent boom and accessory options for certain applications. Because these

dierences may eect how the machine is operated, it is important to understand their dierences and limita-

tions. A copy of the original work order is supplied with the documentation of each HAV sprayer. is docu-

ment will list the options and accessories supplied with your sprayer.

Equipment Record:

Record your machine details in the log below. If you replace this manual, be sure to transfer the information to

the new manual.

Model Number

Serial Number

Purchase Date

Dealer Name

Dealer Contact

Accessory 1

Accessory 2

Accessory 3

Accessory 4

PBM SUPPLY & MFG., INC

SINCE 1969

4

Important Safety Information

PBM Supply & MFG., Inc. www.pbmsprayers.com

324 Meyers St. Chico CA 95928 1-800-688-1334

Important Safety Information

It is important to carefully read and understand this manual and any included manuals prior to operating PBM

equipment.

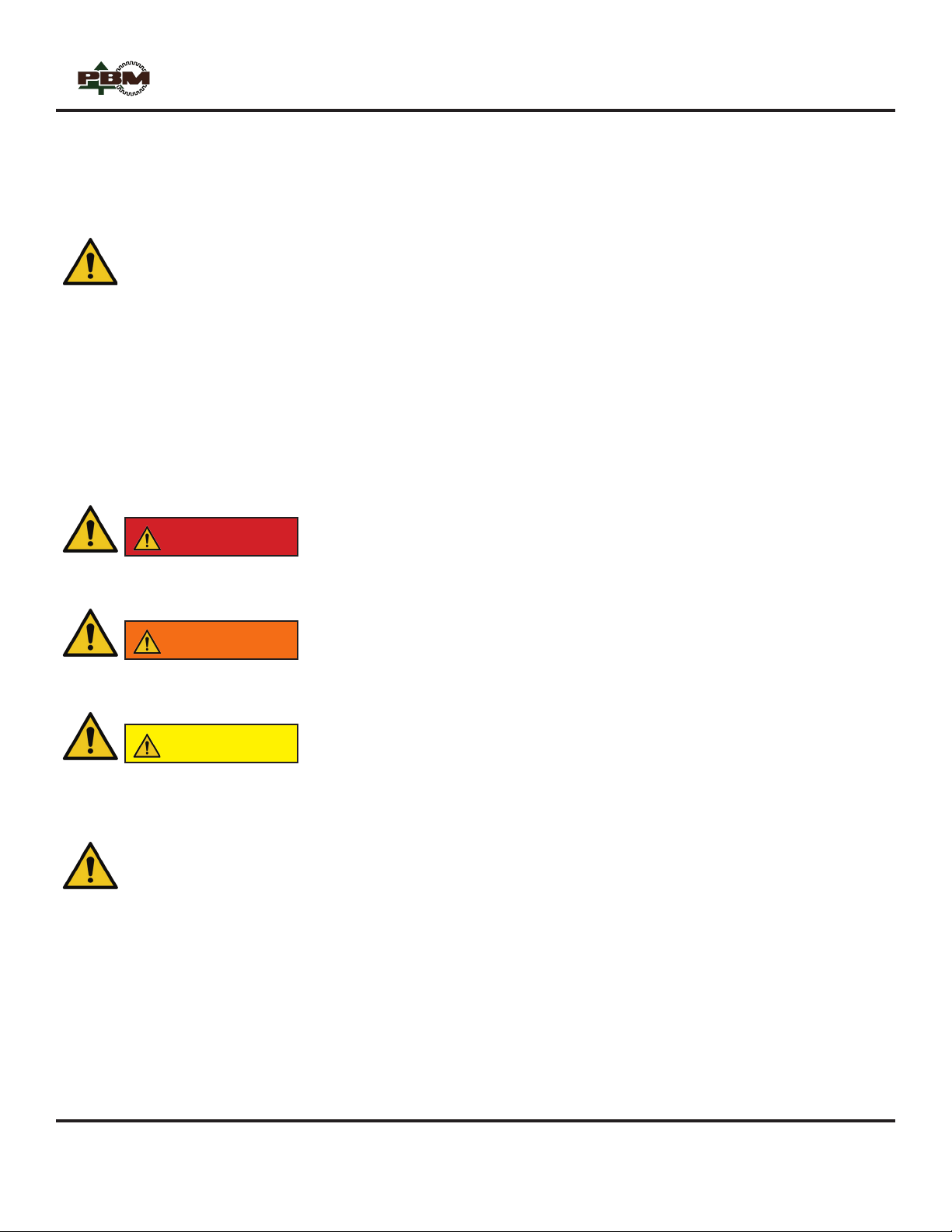

Safety Alert Symbol

e safety alert symbol indicates there is a potential hazard to personal safety involved and extra safety

precaution must be taken. When you see this symbol, be alert and carefully read the message that follows it. In

addition to design and conguration of equipment, hazard control, and accidental prevention are dependent

upon the awareness, concern, prudence, and proper training of personnel involved in the operation, transport,

maintenance, and storage of equipment.

Signal Words

Be aware of signal words.

Signal words are used to designate the level of seriousness that a hazard may produce.

DANGER - Indicates a hazardous situation that if not avoided, will result in death or

serious injury.

WARNING - Indicates a hazardous situation that if not avoided, could result in death or

serious injury.

CAUTION - Indicates a hazardous situation that if not avoided, may result in minor or

moderate injury

Safety Precautions

Operational Safety Precautions

Careful operation is the best preventative measure against accidents. All operators should read this manual and

any associated manuals before operating this machine.

• oroughly read and understand the “Safety Label” section of this manual. Read all instructions noted on

Safety Labels.

• Do not operate the equipment while under the inuence of drugs or alcohol as they impair the ability to

safely and properly operate equipment.

• e operator should be familiar with all functions of the vehicle and implement, and be able to handle

emergencies quickly.

• Make sure all guards and shields appropriate for the operation are in place and secured before operating

PBM SUPPLY & MFG., INC

SINCE 1969

5

Important Safety Information

PBM Supply & MFG., Inc. www.pbmsprayers.com

324 Meyers St. Chico CA 95928 1-800-688-1334

equipment.

• Never run the sprayer in high range with chemical in the tank.

• Keep all bystanders away from equipment and work area.

• Start sprayer from drivers seat with hydraulic controls in neutral.

• Operate sprayer controls from the driver’s seat only.

• Never dismount from a moving vehicle or leave engine running.

• Do not allow anyone to stand between sprayer and spray booms.

• Keep hands, feet, and clothing away from power-driven parts.

• While transporting or operating equipment, watch out for objects overhead or along side such as fences,

trees, buildings, wires, etc.

• Do not turn vehicle so tight as to cause hitched equipment to contact the vehicle.

• Store sprayer in an area where children normally do not play. Secure equipment with blocks.

Safety Precautions for Children

Tragedy can occur if the operator is not alert to the presence of children. Children generally are attracted to

implements and their work.

• Never assume children will remain where you last saw them.

• Keep children out of the work area and under the watchful eye of a responsible adult.

• Be alert and shutdown the sprayer if children enter the work area.

• Never carry children on the sprayer. ere is not a safe place for them to ride. ey may fall of and be sub-

ject to injury, or impede the control of the implement/vehicle.

• Never allow children to operate the machine, even under adult supervision.

• Never allow children to play on the equipment.

• Use extra caution while backing up. Before the vehicle starts to move, make sure the area is clear.

Sprayer Shutdown & Storage Safety

• Park on solid, level ground and close spray booms. Secure spray booms with the supplied pins or chains.

• Put the vehicle in park or set the brake, turn o engine, and remove the switch key to prevent unautho-

rized starting.

• Relieve all pressure to hydraulic auxiliary lines.

• Wait for all components to stop before leaving the operators seat.

• Use steps, grab handles, and anti-slip surfaces when stepping on and o of the vehicle.

• Detach and store implements in areas where children normally do not play. Secure implements using

blocks and supports.

Tire Safety

• Changing tires can be dangerous and must be performed by trained personnel using the appropriate tools

and equipment.

• Always maintain correct tire pressure. Do not inate tires above the recommended pressure.

Table of contents

Other PBM Paint Sprayer manuals